1 minute read

Removal and Installation of Alternator

from Sumitomo SH250-5 SH250-5LR Hydraulic Excavator Service Repair Manual WLSM2105-00W - PDF DOWNLOAD

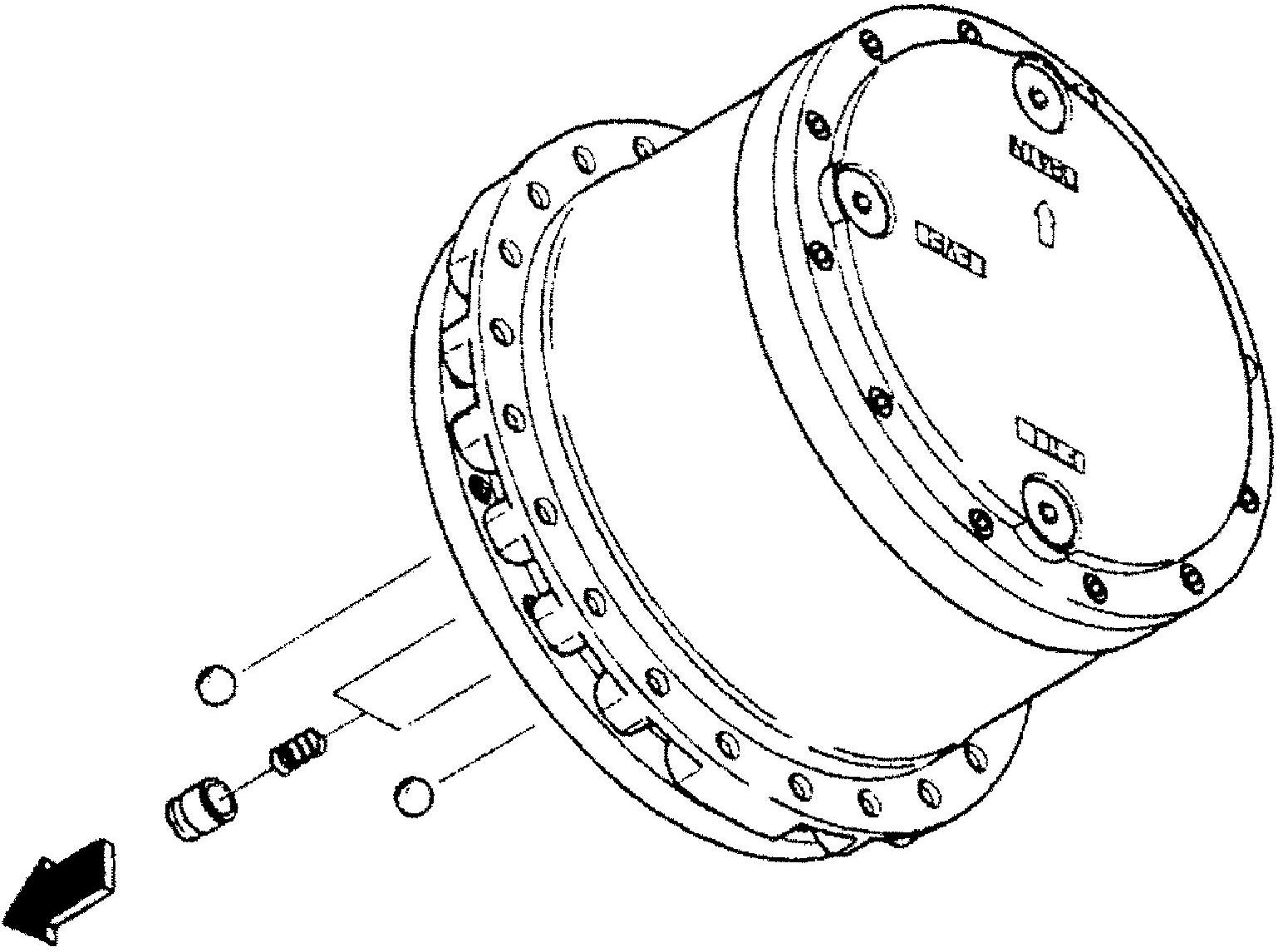

3) Remove the retainer holder (1-4-4) from the cylinder block (1-4-1) and remove the pins (1-4-9) from the cylinder block.

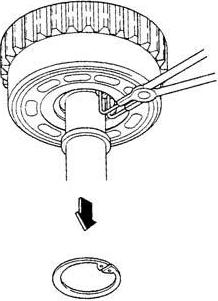

4) Secure the cylinder block (1-4-1) on the manual press platform with the sliding surface facing up, remove the snap ring (1-4-5), press the collar (1-4-8) with the removal jig to make the spring (1-4-7) bend, and use snap ring pliers to remove the snap ring.

Caution: When removing the snap ring, observe the following precaution. a.The snap ring is stiff and may come off from the snap ring pliers when the snap ring is being removed, which could cause injury. When removing the snap ring, make sure to use a disassembly jig and check that the nails of the snap ring pliers are in the snap ring hole before removal. 5) Remove the collar (1-4-8), spring (1-47), and spring seat (1-4-6) from the cylinder block (1-4-1).

[13]Removal of swash plate

Remove the swash plate (1-5) from the flange (1-1).

Cautions: When removing the swash plate, observe the following precautions. a.Be careful not to scratch the swash plate sliding surface. If this surface is scratched, the machine will no longer display prescribed capabilities. b.Piston assemblies (1-7) and steel balls (1-6) may be attached to the swash plate. When these are attached, be careful not to let them fall. [14]Removal of piston assembly and steel ball

Remove the piston assemblies (1-7) from the flange (1-1) and remove the springs (1-20).

Remove the steel balls (1-6) from the flange.

Caution: The steel balls are difficult to remove, so use the following procedure to do this. a.With the steel balls mounted on the flange, use white kerosene or thinner to degrease. b.Use a magnet to remove the steel balls from the flange. [15]Removal of shaft

Remove the shaft (1-3) and ball bearing (1-8) from the flange (1-1).

Cautions: When removing the shaft, observe the following precautions. a.Be careful not to scratch the spines on the shaft. b.Be careful not to scratch the sliding section of the shaft oil seal (1-12). Scratching this surface may cause oil leaking.