2 minute read

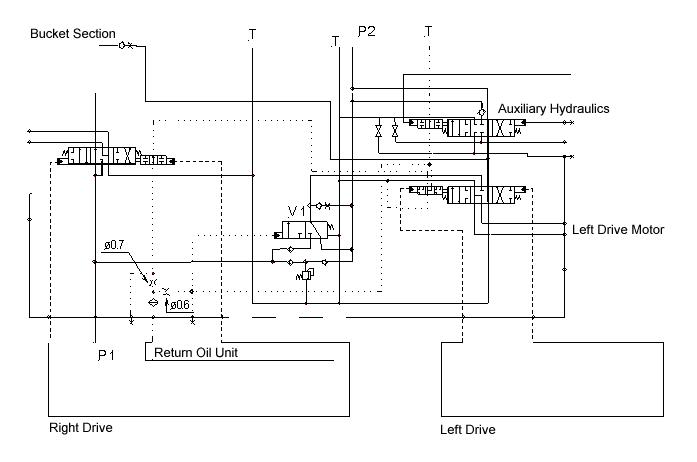

Pict.: Function Drive counte- balancing system

Id.No.: 918173

Edition: Sept. 05

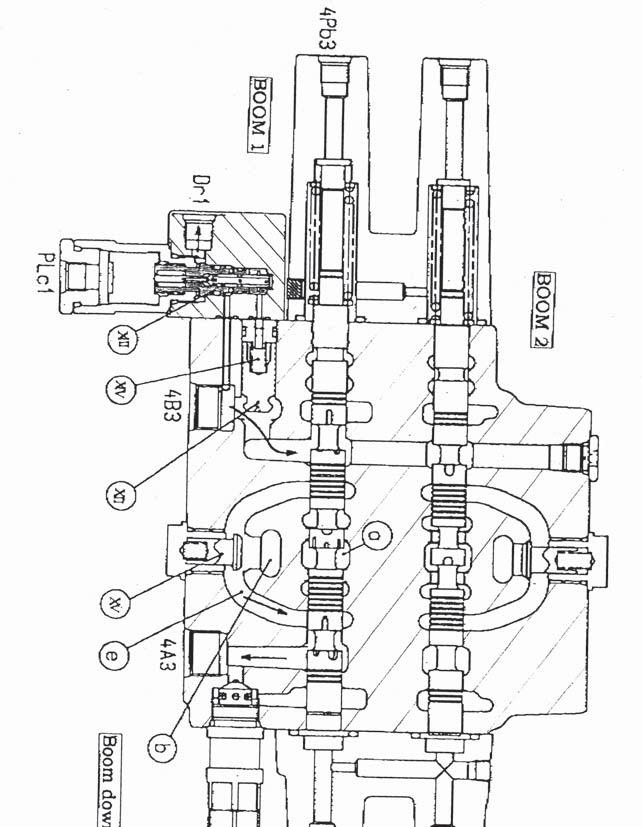

Function Summation Boom / Dipper arm cylinder

Feature: Both pumps (P1 and P2) are used for the function to achieve a faster motion. For the boom lifting and dipper stick out (cylinder rodside) motion.

Boom UP (cyl. bottom side) :

-If function boom lifting up is active - both sections (1+ 2) in the main valve blcok are piloted parallel.

-The oil from pump P2 is transfered internal to the main pipe of the boom section and passes the leakage free valve spool boom.

-The timing of summation is controlled by the spring tension of the summation spool. (Fine metering - only realized by the spool boom 1)

-A fixed quantiy of oil can always pass the combination spool - which gives a fixed maximum summation pressure. (see pressure setting)

Boom DOWN (cyl. rod side):

-The leakage free valve for the spool boom is piloted parallel by the joystick hose and opened.

Due to this, the oil from the bottom side of the cylinder can pass the leakage free valve - to tank.

-The summation function for boom down (5Pa3) is not active.

Dipper arm OUT (cyl. rod side):

-If function dipper arm out is active - both sections (1+2) in the main valve block are piloted parallel.

-A part of the oil from pump P1 is transfered internal (passing a check valve) to the main section dipper arm.

-The timing of summation is controlled by the spring tension of the summation spool. (Fine metering - only realized by the main spool)

-A fixed quantity of oil can always pass the summation spool - which gives a fixed maximum summation pressure.

Dipper arm IN (cyl. bottom side):

-The leakage free valve for the spool dipper stick is piloted and opened parallel by the joystick hose Due to this, the oil from the rod side of the cylinder can pass the leakage free valve - to tank.

-The summation function for dipper arm in (4Pa4) is not active.

Id.No.: 918173

Edition: Sept. 05

Id.No.: 918173

Edition: Sept. 05

Function Leakage free valve - section spools

- Boom down - cylinder bottom side

- Dipper am out - cylinder rod side

Features:

-Pilot controlled load holding valves to block any spool leakage and movement of a cylinder.

Boom Up: (boom cylinder bottom side)

- Leakage free valve is floated and passed by the high pressure oil to the bottom side of the boom cylinder.

Boom Down:

- The leakage free valve is opened to tank by the joystick hose - boom down.

- Due to this, the oil from the bottom side of the cylinder can pass the leakage free valve. Dipper arm In (dipper arm cylinder bottom side):

- Leakage free valve is opened to tank by the joystick hose - dipper arm cyl. bottom side

- Due to this, the oil from the rod side of the cylinder can pass the leakage free valve. Dipper arm Out :

- Leakage free valve is floated and passed by high pressure oil to the rod side of the dipper stick cylinder.

Id.No.: 918173

Edition: Sept. 05

Hydraulics

5. MAIN VALVE BLOCK Option: Shock valves AH

Features:

-Pressure shock limiting of auxiliary hydraulic system components (Section AH) - e.g.: Hydraulic breaker

-The components, the pump and the valve block is protected by the primary pressure limiting valve if the spool auxiliary hydraulics is “open” . If the spool is not piloted - the system between the valve and the consumer is not protected in case of shocks.

-For information about setting without secondary pressure limiting valves (shock valves) see the Technical Data chapter.

Assembling:

-The pressure setting and assembling has to be done by authorized trained persons only. Always replace both plugs at the same time.

Plugs

Id.No.: 918173

Edition: Sept. 05