27 minute read

3Maintenance

3.1General information care and servicing

WARNING!

•Instruction is necessary before operating or servicing the machine. Read and understand this entire manual. Follow warnings and instructions for operation and maintenance. Check for correct function after adjustments or maintenance. Failure to follow instructions can result in serious injury.

•Be sure you are familiar with all safety devices and controls before operating or servicing the machine. Know how to stop before starting. This machine is designed for use only with Mustang approved accessories or attachments. The Mustang cannot be responsible for safety if the unit is used with non-approved attachments.

•Hydraulic reservoir is under pressure. Avoid contact with leaking hydraulic fluid under pressure. It can penetrate the skin and eyes.

Care and servicing

Care and servicing have a significant influence on the readiness for operation and service life of the machine.

Before performing service and maintenance, always read, understand and follow the instructions provided in:

• The “Safety instructions” section in the operator’s manual.

• All associated attachment operator’s manuals.

For additional service information about the engine, see the engine manual provided with the machine.

Use of lubricants that do not correspond to the manufacturer’s recommendations may invalidate warranty claims.

More frequent servicing, other than the recommended intervals, may be required under extreme operational conditions (extremely dusty or hot conditions).

Always dispose of waste lubrication oils and hydraulic fluids according to local regulations or take to a recycling center for proper disposal. DO NOT pour fluids onto the ground or down a drain.

DO NOT power wash the main hydraulic pumps and controls, throttle solenoids and sealed bearings. High-pressure water can be forced through seals and trapped within these components, causing premature failure.

The operating pressure settings of the hydraulic system should only be adjusted by trained, qualified personnel. If malfunctions are caused by unauthorized alteration of operating pressure settings, all warranty responsibilities of the manufacturer are invalidated.

Maintenance safety

• Never service the machine without reading the applicable instructions.

• Always lower bucket and dozer blade to the ground before performing any maintenance.

• Use correct procedures to lift and support the machine. Always lift the blade fully before installing jackstands.

• Keep engine cover and hydraulic valve cover closed except for service. Close and latch covers before operating the machine.

• Be sure to have the work area properly ventilated when grinding or welding parts. Wear a dust mask.

• Exhaust fumes can kill. Exhaust system must be tightly sealed. If working in an enclosed area, vent exhaust to outside when engine must be run for service.

• Never modify equipment or add attachments not approved by Mustang.

• Stop the engine and let it cool, then clean engine of any flammable materials before checking fluid levels.

• Never service or adjust machine with the engine running unless the service procedure requires it.

WARNING!

•Avoid contact with leaking hydraulic fluid or diesel fuel under pressure, which can penetrate the skin and eyes. NEVER use your hands to search for hydraulic fluid leaks; use a piece of paper or cardboard. Escaping fluid under pressure can be invisible and can penetrate the skin and cause serious injury. If any fluid is injected into your skin, see a doctor immediately. Injected fluid MUST be surgically removed by a doctor familiar with this procedure, or gangrene may result.

• Never fill fuel tank with engine running, while smoking or when near open flame.

• Keep body, jewelry and clothing away from moving parts, electrical contacts, hot parts and exhaust.

• Wear eye protection when servicing the machine.

• Lead acid batteries produce flammable and explosive gas. Keep arcs, sparks, flames and lighted tobacco away from batteries.

• Batteries contain acid, which burns eyes and skin on contact. Wear protective clothing. If acid contacts body, flush well with water. For eye contact, flush well with water and get immediate medical attention.

3.2Fluids and lubricants

Diesel engineEngine oil

SAE grade 10W30 or 15W40 and API classification CD (or higher, e.g., CI-4), such as BP Vanellus MG 15W40, BP Vanellus C-Extra 10W30 or Chevron Delo 400

Hydraulic oil tankHydraulic oil

Hydraulic oil with anti-wear, antifoam and anti-oxidation additives that conforms to ISO viscosity grade 46, such as Mobile DTE 15M, Amoco Rykon 46 or BP Energol HLP-HD 46

Swing ringGrease

Final drive unitGear oil gear

Heavy-duty lithium complex grease with 3% molybdenum disulfide, such as Chevron RPM heavy duty grease No. 2,

Moly 52 or BP

Moly EP2

EP grade gear oil that conforms to API GL5, such as Chevron Delo Gear 80W90 or BP

EP grade gear oil that conforms to API GL5, such as Chevron Delo Gear 80W90 or BP

Heavy-duty lithium complex grease with 3% molybdenum disulfide, such as Chevron RPM

1.The capacities indicated are approximated values; the oil level check alone is relevant for the correct oil level

Oil grades for the diesel engine, depending on temperature.

3.3Maintenance decal symbols

Symbol Assembly Explanation

GeneralVisual check

GeneralGrease instructions

Fuel systemDrain condensation water

Fuel systemReplace the fuel filter, clean the fuel prefilter

RadiatorCheck the coolant level

RadiatorDrain and fill with new coolant

EngineCheck valve tip clearance; adjust if necessary

EngineCheck the engine oil level

EngineChange engine oil

EngineReplace the oil filter

EngineCheck V-belt tension

Traveling driveChange oil

Traveling driveCheck oil

UndercarriageCheck track tension

Hydraulic systemCheck oil level

Hydraulic systemChange hydraulic oil

Hydraulic systemReplace the hydraulic oil filter, replace the breather filter

Radiator finsClean

Heating, air conditioning Replace the cab air filter

3.4Maintenance decal

3.5Maintenance schedule

1.Check the gearbox oil every second time 50 s/h servicing is performed.

2.Clean the water ducts every second time 1000 s/h servicing is performed.

3.First check at 50 s/h, then every 500 s/h.

Check,cleanorinspect,continued

Check tracks for cracks or cuts.xx

Check track tension. Adjust if necessary.xx

Check bearing play on tread rollers, track carrier rollers and front idlers. xx

Check piston rods for damage.xx

Check screws for tightness.xxx

Check pin lock (dipper arm and attachment). xx

Check hydraulic line clamps.xx

Check indicator lights for correct function. xxx

Check cab tilt lock components.xxx

Inspect couplings. Check for dirt buildup on the hydraulic system dust caps. xx

Check insulating mats in the engine compartment. xxx

Inspect grease supply of the central lubrication system.

Verify that warning decals and Operator’s Manual are in place. xxx

Check engine cover gas strut.xx

Fluid and filter changes

Engine oil filterx*xx Fuel filterx*xx

Air filter element when indicator light comes on x

Engine coolantxx

Hydraulic oil filter insertx*xx

Hydraulic oilxx

Breather-hydraulic oil tankxx

Gearbox oilx*xx

Air conditioning

Functional check

Leakage check

3.6General maintenance

Cleaning

Cleaning the machine is divided into three separate areas:

• Cab interior

• Machine exterior

• Engine compartment

For safety and health reasons, follow these cleaning instructions:

Washing solvents

• Ensure adequate room ventilation.

• Wear suitable protective clothing.

• Do not use flammable liquids, such as gasoline or diesel fuel.

Compressed air

• Work carefully.

• Wear goggles and protective clothing.

• Do not aim the compressed air at the skin or at other people.

• Do not use compressed air for cleaning your clothing.

When using a high-pressure cleaner or steam jet

• Electrical components and damping material must be covered and not directly exposed to the jet.

• Before use, cover the vent filter on the hydraulic oil tank and the filler caps for fuel, hydraulic oil, etc.

• Additionally, protect the following components from moisture:

• Engine.

• Electric components such as the alternator, etc.

• Control devices and seals.

• Air intake filters, etc.

When using volatile and easily flammable, anti-corrosion agents and sprays

• Ensure adequate room ventilation.

• Do not use unprotected lights or open flames.

• Do not smoke.

CAUTION!

Never use high-pressure cleaners, steam jets or high-pressure water to clean inside the cab. Water under high pressure may penetrate into the electrical systems, cause short circuit, damage seals, and disable controls.

The following items are recommended for cleaning the cab interior:

• Broom

• Vacuum cleaner

• Damp cloth

• Bristle brush

• Water and mild soap solution

Cleaning the seat belt:

• Clean the seat belt with only a mild soap solution; do not use chemical agents because they may destroy the seat belt fabric.

The following items are suitable for cleaning the cab exterior:

• High-pressure cleaner

• Steam jet

IMPORTANT!

Turn off the engine and allow it to cool before spraying the machine with a high-pressure cleaner or steam jet.

IMPORTANT!

When cleaning the engine with a water or steam jet, do not point the jet directly at electric sensors such as the oil pressure switch. Humidity penetrating electric sensors will cause them to fail and lead to engine damage.

Maintenance

Threaded connections, attachments, pivots and hinges

Threaded connections and attachments

All threaded connections must be checked regularly for tightness, even those not listed in the maintenance schedules. Tighten loose connections immediately.

Pivots

And Hinges

3.7Lubrication

All mechanical pivot points on the machine (e.g., door hinges, joints) and fittings (e.g., door arresters) must be lubricated regularly.

3.8Fuel system

Specific safety instructions

• Extreme caution is essential when handling fuel — high risk of fire.

• Never work on the fuel system in the vicinity of open flames or sparks.

• Do not smoke when working on the fuel system or when refueling.

• Before refueling, turn off the engine and remove the ignition key.

• Do not refuel in an enclosed space without proper ventilation.

• Wipe up fuel spills immediately.

• Keep the machine clean to reduce the risk of fire.

Filling the fuel tank

WARNING!

Stop and cool the engine before adding fuel. NO SMOKING. Failure to follow this instruction can cause an explosion or fire.

The fuel level in the tank is indicated by the fuel gauge (1) on the console. See Fig. 3.

To fill the tank, remove the fuel filler cap (2) located on the left rear of the unit behind the cab, by rotating the lock cover (3) and inserting the ignition key into the lock and unlocking the cap. Fill using clean diesel fuel with a cetane rating over 45. Re-install fuel cap.

IMPORTANT!

Never operate machine until fuel tank is completely empty. If this occurs, the fuel system will have to be bled of air. Always fill tank after use.

When using the machine in cold weather, make sure to use the proper fuel blend to prevent the fuel filters from “jelling” up. If this happens, the fuel filter and water separator elements will have to be replaced, and the fuel will have to be replaced with the proper fuel.

WARNING!

Always clean up spilled fuel and oil. Keep heat, flames, sparks and lighted tobacco away from fuel and oil. Failure to use care around combustibles can cause explosion or fire, which can result in injury or death.

Fuel filter

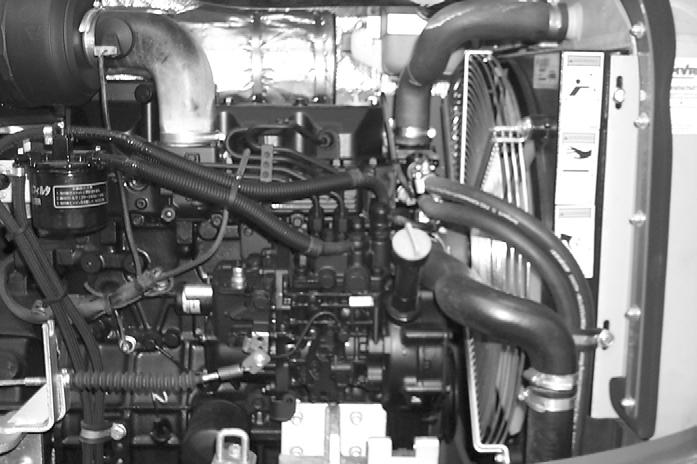

The fuel filter is located behind and below the engine cover.

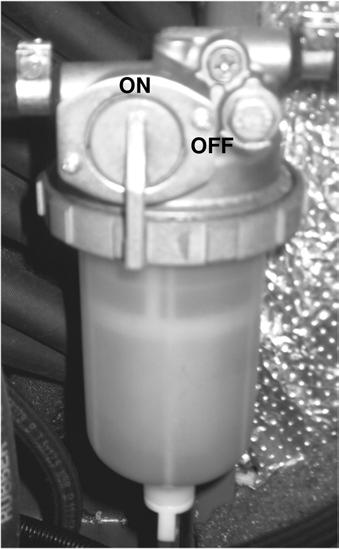

1.Shut off fuel using the shut-off valve (2) on the water separator. See Fig 5.

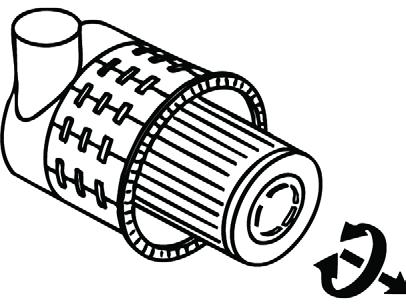

2.Clean dirt from the housing and unscrew the fuel filter element. See Fig 4.

3.Remove and discard old filter element properly.

4.Clean around the filter housing.

5.Put oil on the seal of the new filter element.

6.Install the fuel filter and hand tighten.

7.Open fuel valve.

The fuel system must be purged of air after changing the fuel filter, or if the fuel tank has been run dry. See Purging air from the fuel system on page3-15.

Fuel shut-off valve, fuel prefilter and water separator

If water is seen in the plastic water separator bowl or the indicator ring rises to position (3), the bowl will need to be drained. See Fig. 5.

Note: The water separator is located behind the engine, underneath the engine cover.

1.Shut off fuel using the fuel valve (2). See Fig. 5.

2.Unscrew plug (4) and collect the water that drains out of the hose. Allow water to drain until the indicator ring returns to the bottom of the water separator.

3.Tighten plug (4) and discard fuel/water according to local regulations. DO NOT pour it onto the ground or down a drain.

4.Open fuel valve.

Purging air from the fuel system

WARNING!

DO NOT air bleed a hot engine. Spilled fuel can cause a fire.

The fuel system runs from the fuel tank, through the water separator, fuel filter, fuel injection pump and high pressure piping to the fuel injection nozzles. If the fuel tank has been run dry, or if the fuel filter, water separator or fuel lines have been replaced, trapped air will have to be removed, or bled, from the fuel system.

Bleed air from the fuel system according to the following steps:

1.Fill the fuel tank.

2.Make sure that the valve on the water separator (2) is in the ON position.

3.Turn the ignition key to the first position.

4.Wait about five minutes while the fuel system bleeds itself automatically.

5.Start the engine.

If the engine runs smoothly and then stops, or if it does not run smoothly, turn off the engine and bleed the system again as described above.

3.9Engine lubrication system

IMPORTANT!

If the engine oil level is too low or if an oil change is overdue, this may cause Engine damage or loss of output.

Checking engine oil level

IMPORTANT!

See the lubricant list for engine oil grade. Use only the engine oil specified, or equivalent quality and grade, or damage to the engine could occur.

To check the engine oil, the machine must be on a level surface and the engine turned off.

1.Run the engine until it is at operating temperature, then turn off the engine.

2.Pull the engine cover latch lever (located beneath the operator’s seat) and raise the engine cover.

Note: The marks on the dipstick indicate the minimum and maximum oil levels.

3.Check the engine oil level using the dipstick (1) located at the front of the engine. SeeFig.6

4.If required, add oil through the oil filler neck (3). See Fig. 6.

3.10Changing engine oil and filter

1.Place the machine on a level surface. Run the engine until it is at operating temperature, then turn off the engine.

2.Pull the engine cover latch handle (located beneath the operator’s seat) and raise the engine cover.

3.Position waste oil collection container under engine oil pan.

4.Remove the drain plug from the oil pan and allow oil to drain into waste oil collection container.

5.Remove the oil filter, using a filter spanner wrench as necessary. See (2) Fig. 6.

6.Clean the filter housing surface. Put a film of clean oil on the filter gasket. Install the new filter with gasket and hand tighten.

7.Reinstall the drain plug.

8.Remove the oil fill cap from the engine. Pour in new oil. Crankcase capacity (including the oil filter) is 10.8 qts. (10.2 L). DO NOT fill crankcase above the MAX mark on the dipstick.

9.Reinstall oil filler cap.

10.Start the engine and let it run for several minutes. Watch the engine oil light on the control panel. The light should turn off after several seconds. If it does not, shut off the engine and determine the cause.

11.Stop the engine and check for leaks at the oil filter and oil drain plug.

12.Check the oil level again and add oil if necessary.

3.11Coolant system

Checking coolant level

IMPORTANT!

Insufficient coolant level reduces heat dissipation capacity, which can lead to engine damage.

Note: Engine must be cold.

1.Pull the engine cover latch handle (located beneath the operator’s seat) and raise the engine cover.

2.Check the coolant level in the expansion reservoir. See Fig. 7.

3.If low, remove cap and overflow tube.

4.Fill reservoir to FULL line (1). See Coolant compound table on page2-7 for correct coolant mixture for the engine.

3.12Air cleaner service

Note: The air filter indicator lamp illuminates when the air cleaner element needs to be replaced. See Instrument panel overview on page 1-8

IMPORTANT!

Filter cartridges degrade prematurely when used in acidic air. Acidic air is present in acid production facilities, steel and aluminium mills, chemical plants and other non-ferrous metal plants.

Do not clean air filter cartridges, replace them instead. Never reuse a damaged air filter.

General air filter maintenance:

• Store filters in original packaging in a dry place.

• Do not strike the filter against other objects during installation.

• Check air cleaner attachments, air intake hoses and air filters for damage. Repair or replace as necessary.

• Frequently check clamps and screws at the induction manifold for tightness. Tighten as necessary.

• Check the function of the dust valve weekly. Replace if necessary. See Dust valve functional check on page 3-20.

1.The air cleaner is located under the engine cover. Press the engine cover release button and raise the engine cover.

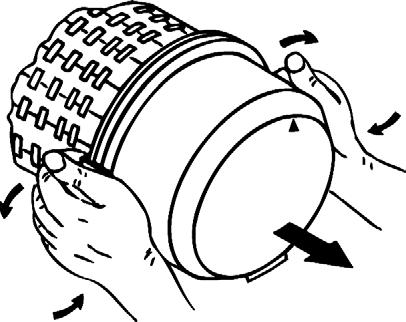

2.Release the bow clips (1) to remove the air cleaner cover and gasket (2). See Fig. 8.

3.Carefully remove outer air cleaner element (3). Carefully remove inner air cleaner element (3). Clean air cleaner elements with 30 psi (207kPa) compressed air from the inside. Clean all contamination (dust) from inside the upper and lower air cleaner housing and cover.

4.Replace both the inner and outer air cleaner elements when the indicator light comes on or according to the maintenance schedule.

5.Reinstall air cleaner elements (3 and 4), gasket and air cleaner cover (2). Fasten bow clips (1).

6.Close and secure engine cover.

IMPORTANT!

Do not knock the air filter element against a solid object to remove dust. The element may become distorted and damaged.

Do not operate engine without the air cleaner element installed or damage to the engine could occur.

Dust valve functional check

Perform this check weekly.

1.Turn off the engine and allow it to cool.

2.Set the parking brake.

3.Squeeze the discharge slot of dust valve. See (B) Fig. 9.

3.13Checking and adju sting V-belt tension

WARNING!

Check or tighten/replace the V-belt when the engine is turned off — Risk of personal injury.

Turn off the engine before performing inspection work in the engine compartment.

Disconnect the battery or battery master switch. Let the engine cool down.

IMPORTANT!

Replace damaged V-belts immediately. Cracked and stretched V-belts cause engine damage.

Check the V-belt daily or every 10 service hours, and tighten as needed.

Note: Tighten new V-belts after 15 minutes of running time.

1.Turn off engine and fold up the control lever base.

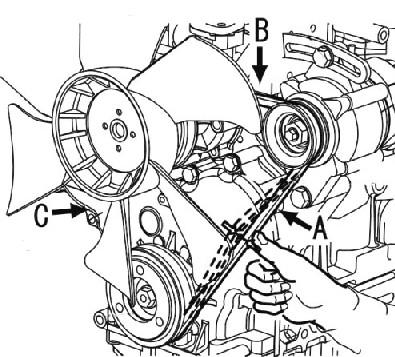

2.Open the engine cover and carefully inspect the V-belt (1) for damage. See Fig. 10. If it is damaged, replace it.

3.Press on the V-belt with approximately 22 lbs. (100 N) of force between the crankshaft pulley and fan pulley (C) to check deflection. See Fig. 10. A new belt should deflect 0.24–0.32 in. (6–8 mm); a used V-belt (after approximately five minutes running time) should deflect 0.27–0.32 in. (7–8mm). If deflection is more than specified, proceed to step 4.

4.Remove cover (2). See Fig. 11.

5.Loosen adjustment bolt (3) and rotate the alternator (4) in the direction of the arrow until correct V-belt tension is established.

6.Tighten adjustment bolt (3) and re-check V-belt tension.

7.Install cover (2).

Checking and adjusting air conditioning V-belt tension

1.Turn off engine and fold up the control lever base.

2.Open the engine cover and carefully inspect the V-belt (1) for damage. See Fig. 12. If the V-belt (1) is damaged, replace it.

3.Press on the V-belt to check deflection. The belt deflection should be no more than 11/32 in. (9 mm). If deflection is more than 11/32 in. (9 mm), proceed to step 4.

4.Loosen jam nut (2) and rotate the adjustment nut (3) until the correct V-belt tension is established.

5.Tighten jam nut (2) and re-check V-belt tension.

3.14Pressure check General

• Run the machine until it reaches normal operating temperature before checking hydraulic pressure.

Note: Hydraulic oil normal operating temperature: 122°F (50°C) minimum.

• Check pressure drop under a constant load.

• Set the primary pressure limiting valves (PPLV) at maximum engine RPM. See Hydraulic system on page 2-3 for the pressure settings.

Pressure check of variable di splacement pumps P1 and P2

Hydraulic supply for boom, bucket, right- and left-hand side drive functions, auxiliary hydraulics, boom 2, dipper arm and dipper arm 2.

Checking primary pressure limiting valve 1 (PPLV 1) for pumps P1 and P2

1.Connect a pressure gauge to measuring port MP 1 (1) for P1 or MP 2 (2) for P2. SeeFig. 13.

2.At maximum engine RPM, retract the dipper arm cylinder (or extend the boom cylinder) as far as it will go.

3.Check and record the pressure value.

Checking pressure prop

1.At maximum engine RPM, retract the dipper arm cylinder (or extend the boom cylinder) as far as it will go.

2.Quickly reduce engine RPM from maximum to minimum. Observe the pressure drop.

3.Check and record the pressure value.

Pressure drop should not exceed the specified value by more than 10%. See Hydraulic system on page 2-3 for pressure values.

Adjusting primary pressure limiting valve 1 (PPLV 1) for pumps P1 and P2 a.Loosen the pressure limiting valve locknut. b.Loosen the pressure limiting valve until you observe a pressure drop on the pressure gauge. c.Adjust the pressure limiting valve and tighten the locknut.

1.Adjust the pressure at the primary pressure limiting valve (PPLV 1) (A) on the main valve block. See Fig. 14.

The valve seat may be stuck and must be loosened first.

2.After completing the adjustment, check the primary pressure limiting valve (A) and the pressure drop.

3.For P1 check rod side boom, forward/reverse driving to the left functions.

4.For P2 check base side dipper arm, base/rod side bucket, forward/reverse, driving to the right functions.

Pressure check of gear pumps P3 and P4

Checking the auxiliary hydraulics pressure

IMPORTANT!

Factory settings for auxiliary hydraulics secondary valves may be incorrect because the valves must be adjusted to the attachment.

Hydraulic supply for the dozer blade, rotation, 3rd control circuit, triple articulation boom option.

Checking primary pressure limiting valve 2 (PPLV 2) for pump P3

1.Connect a pressure gauge to measuring port MP 3 (3). See Fig. 15.

2.At maximum engine RPM, extend the dozer blade cylinder as far as it will go.

3.Check and record the pressure value.

Checking pressure drop

1.At maximum engine RPM, extend the dozer blade cylinder as far as it will go.

2.Quickly reduce engine RPM from maximum to minimum. Observe the pressure drop.

3.Check and record the pressure value.

Pressure drop should not exceed the specified value by more than 10%. See Hydraulic system on page 2-3 for pressure values.

Adjusting primary pressure limiting valve 2 (PPLV 2) for pump P3 a.Loosen the pressure limiting valve locknut. b.Loosen the pressure limiting valve until you observe a pressure drop on the pressure gauge. c.Adjust the pressure limiting valve and tighten the locknut.

1.Adjust the pressure at the primary pressure limiting valve (PPLV 2) (B) on the main valve block. See Fig. 16.

The valve seat may be stuck and must be loosened first.

2.After the adjustment is complete, check the primary pressure limiting valve (B) and the pressure drop.

Checking pilot control pressure

Checking the primary pressure limiting valve 2 (PPLV 2) for pump 4

1.Connect a pressure gauge to measuring port MP 4 (4). See Fig. 15.

2.At maximum engine RPM, extend the dozer blade cylinder as far as it will go.

3.Check and record the pressure value.

Pressure is limited to 2393 psi (165 bar) by pressure cut-off valve. See Pressure cut-off valve on page5-27.

4.Check with the retract dozer blade, boom swivel and rotate functions.

Checking pilot control pressure

1.Connect a pressure gauge to measuring port MP (5), Fig. 17.

2.Move the control lever base (safety switch) to the work position.

3.Activate the joystick.

4.Check and record the pressure value.

Adjusting pressure reducing valve (PREV. 4)

1.Adjust the pressure at the pressure reducing valve (PREV 4) on the control oil unit (C), Fig. 18. See Hydraulic system on page 2-3 for pressure values.

2.Check the pilot control pressure again after adjustment is complete.

Gear motor secondary pr essure limiting valve

Check (idling speed)

1.Connect a pressure gauge to measuring port MP 3.

2.Place the bucket, the boom, or the dozer blade firmly against the ground to prevent the machine from moving when the travel drive is engaged. Engage the travel drive, which pushes against the bucket/boom/dozer blade resistance and builds up pressure in the system.

3.Check and record the pressure value.

Adjusting the gear motor secondary pressure limiting valve a.Loosen the locknut of the pressure limiting valve (1). See Fig. 19. b.Loosen the pressure limiting valve until you observe a pressure drop on the pressure gauge. c.Adjust the pressure limiting valve and tighten the locknut.

1.Adjust the pressure at the secondary pressure limiting valve on the gear motor.

The valve seat may be stuck and must be loosened first.

2.After the adjustment is complete, check the secondary pressure limiting valve again.

Measuring ports overview

Primary pressure limiting valves

Ref. Description

1Primary pressure limiting valve, pumps 1 and 2PPLV 1

2Primary pressure limiting valve, pumps 3 and 4PPLV 2

3Pressure reducing valvePREV 4

Rated

Drop

Rated

Rated value 4351 ±44 psi (300 ±3 bar)

EXTEND

RETRACT

FORWARD

Left-hand side drive

REVERSE

Drop 363 psi (25 bar)

Drop 363 psi (25 bar) Bucket

Rated value 4351 ±44 psi (300 ±3 bar)

Drop 363 psi (25 bar)

Rated value 4351 ±44 psi (300 ±3 bar)

Drop 363 psi (25 bar)

Rated value 4351 ±44 psi (300 ±3 bar)

Drop 363 psi (25 bar)

Drop

Drop

Drop

Drop

Drop 363 psi (25 bar)

Drop

3.16Hydraulic system

General hydraulic system service information

WARNING!

The hydraulic reservoir is under pressure. Never use your hands to search for hydraulic fluid leaks; use a piece of paper or cardboard to find leaks. Escaping fluid under pressure can be invisible and can penetrate the skin, causing serious injury. If any fluid is injected into your skin, see a doctor immediately. Injected fluid MUST be surgically removed by a doctor familiar with this procedure, or gangrene may result.

Hydraulic fluid flowing out of a high pressure line may cause fire, malfunction, property damage and/or personal injury. If a hydraulic leak is detected, immediately shut down the machine and repair the leak before restarting the machine.

WARNING!

Insufficient, incorrect or contaminated hydraulic oil can damage the hydraulic system. Use a strainer/return line filter when filling the system. Check the hydraulic oil level frequently and fill as necessary. See Checking hydraulic oil level on page3-31. Use only authorized oils of the same type. See Fluids and lubricants on page3-3.

Replace hydraulic hoses if any of the following are detected:

• Damaged or leaking seals.

• Worn/torn shells or uncovered reinforcement branches.

• Expanded shells in several positions.

• Entangled or crushed movable parts.

• Debris jammed or stuck in hose casings.

Checking hydraulic oil level

1.Position the machine on a level surface.

2.Fully extend the bucket and boom, retract arm and position as shown in Fig. 22.

3.Lower bucket and dozer blade to the ground. See Fig. 22. Turn off the machine.

Fig. 22:Checking and changing hydraulic oil

4.Check the hydraulic oil level sight gauge (1). Oil level should be visible in the sight gauge. See Fig. 23. If hydraulic oil is required, proceed to step 5.

5.Remove the rear cover and slowly open the breather filter (2) with a cloth to relieve pressure. Slowly open hydraulic oil filler cap (3) and then remove cap.

Note: A short hex shaft is included in the tool kit. This tool is designed to be used with a standard ratchet wrench to open the filler cap.

6.With the filter insert (4) in place, add hydraulic oil until oil level is between the marks on the indicator.

Machine condition

Before taking into service

TemperatureOil level

Between 50° and 86°F (10° and 30°C)

Normal operation Between 122° and 194°F (50° and 90°C)

LOW mark

FULL mark

7.Re-install hydraulic oil filter insert and filler cap and tighten securely.

8.Start engine and let idle for a few minutes.

9.Check hydraulic functions. Recheck hydraulic oil level.

Adding hydraulic oil

IMPORTANT!

Do not add hydraulic oil unless the engine is turned off; otherwise pressure in the system will push oil out of the filler opening on the hydraulic tank.

Add oil as follows:

• Park the machine on level ground.

• Retract all hydraulic cylinders.

• Switch engine off.

• Fold the control lever base up.

• Clean the area around the filler opening (C). See Fig. 24.

• Open filler opening (C).

• Add hydraulic oil as required.

• Check the hydraulic oil level at the indicator.

• If needed, add oil and recheck level.

• Close the filler opening (C).

Monitoring the hydraulic return oil filter

The red indicator (1) on the instrument panel monitors the return filter. See Fig. 25.

The filter element must be replaced:

• If the indicator (1) comes on when the hydraulic oil is at operating temperature.

• After no more than 1500 service hours (yearly).

In cold weather, the indicator (1) may come on immediately when the engine is started. This is caused by increased viscosity. In this case: Increase the engine speed so that the indicator (1) turns off.

Changing hydraulic oil

IMPORTANT!

Run the machine until the hydraulic oil is warm (122°F [50°C]) before changing oil. Retract all hydraulic cylinders before changing oil.

1.Position the machine on a level surface.

2.Fully extend the bucket and boom, and retract arm as shown in Fig. 22. Lower bucket and dozer blade to the ground. Turn off the machine.

3.Slowly open the filler cap to relieve pressure (2) Fig. 23.

4.Remove the hydraulic oil filler cap (3) Fig. 23, and remove filter insert (4) as shown in Fig. 23.

IMPORTANT!

The filler cap and filter assembly will be removed over the rear cover. Protect rear cover from spilled or dripping hydraulic fluid.

5.Open the reservoir drain plug and drain oil into a suitable container. Re-install drain plug and tighten securely.

Environment!

Always dispose of hydraulic fluids according to local regulations or take to a recycling center for proper disposal. DO NOT pour onto the ground or down a drain.

6.Reinstall filter insert (5).

7.Fill reservoir with hydraulic oil until oil level is between marks on sight gauge.

8.Re-install the hydraulic breather filter (2) and tighten securely.

9.Start engine and let it idle for a few minutes. Cycle all front attachment hydraulic functions and recheck hydraulic oil level.

Hydraulic cooling system

The hydraulic system uses a hydraulic cooler to keep the hydraulic fluid at the proper temperature. The cooler is located inside the engine compartment near the engine radiator. Inspect the cooler for leaks or damage.

Checking hydraulic pressure lines

Specific safety instructions

WARNING!

Hydraulic reservoir is under pressure. Never use your hands to search for hydraulic fluid leaks; use a piece of paper or cardboard to find leaks. Escaping fluid under pressure can be invisible and can penetrate the skin, causing serious injury. If any fluid is injected into your skin, see a doctor immediately. Injected fluid MUST be surgically removed by a doctor familiar with this procedure, or gangrene may result.

Release hydraulic system pressure before re-tightening leaking threaded fittings and hose connections.

Never weld or solder faulty or leaking pressure lines and connections. Replace damaged parts with new ones.

• Leaks and damaged pressure lines must be immediately repaired or replaced. This not only increases the operating safety of the machine but also helps to protect the environment.

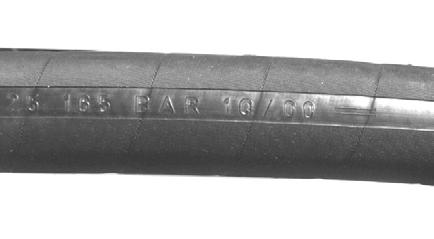

• Replace hydraulic hoses every six years from the date of manufacture, even if they do not appear to be damaged.

In this respect, we recommend that you follow all the relevant safety regulations for hydraulic lines, as well as the safety regulations regarding accident prevention and occupational health and safety in your country.

The date of manufacture (month or quarter and year) is indicated on the hose.

Example:

The indication “1 Q/05” means manufactured in the 1st quarter of 2005.

3.17Track system

WARNING!

Immediately after turning off the engine, the engine’s components and oil are very hot. This may cause burns. If the inside of the travel drive is under pressure, the oil or plug may be forced out.

Risk of injury and scalding.

Wait until the engine has cooled down before beginning work. Slowly open the plug to reduce the pressure inside.

Changing final drive oil

1.Position the machine on a level surface with final drive plugs positioned as shown in “drain position,” Fig. 27. Turn off the engine.

2.Open both plugs and drain oil into a suitable container. Re-install plugs.

3.Start the engine and move the machine slightly until plugs are positioned as shown in “fill position,” Fig. 27. Turn off the engine.

4.Remove both screw plugs. Pour fresh oil (Chevron Delo Gear 80W90 or BP Transgear 80W90) into the top hole until oil starts to run out of the bottom hole.

5.Re-install both plugs securely.

Environment!

Always dispose of oil according to local regulations or take to a recycling center for proper disposal. DO NOT pour fluids onto the ground or down a drain.

Checking and adjusting track tension

WARNING!

Do not work under the machine with the tracks off the ground if the machine is only supported by the attachment.

Risk of personal injury.

Firmly support the machine with chocks or suitable jack stands.

1.Position the machine on a level surface.

2.Use the bucket and dozer blade to lift the unit up until tracks are just clear of the ground as shown in Fig. 28. Turn off the engine.

3.Measure the clearance at the second track roller from the drive gear. Deflection should be between 3/4–1 in. (20–25 mm). See Fig. 29.

4.Using a grease gun, pump grease into the fitting (A) until the track is properly tensioned. See Fig. 30.

Note: A grease gun is supplied with machine tool kit.

IMPORTANT!

Do not over-tension the track. If track is too tight, loosen the grease fitting to relieve pressure.

WARNING!

Do not loosen grease fitting more than two turns, or grease fitting could be ejected under pressure and cause injury.

5.Repeat steps 3 and 4 for right side track.

6.Start the engine. Lower the unit to the ground.

Maintenance

Lubrication block

Apply grease to the lubrication block as follows: Lubrication point (A) for the offset cylinder. See Fig. 31. Lubrication point (B) for the live ring.

IMPORTANT!

Apply grease to lubrication points (A) and (B) daily.

Note: A portable light can be connected to the lubrication block’s 12-V connection (C).

IMPORTANT!

Follow the lubrication and maintenance instructions in the attachments’ operator’s manual. Correct maintenance and service is absolutely necessary for smooth and continuous operation, and for an increased service life.

3.18Electrical system

Service and maintenance work at regular intervals

Before driving the machine

Check every time before driving the machine:

• Is the light system OK?

• Is the signaling and warning system OK?

Weekly

Check weekly:

• Electric fuses. See Fuse box in instrument panel on page2-5.

• Cable and ground connections.

• Battery charge condition. See Battery on page3-40.

• Condition of battery terminals.

Instructions concerning specific components

Cables, bulbs and fuses

Always follow the following instructions:

• Defective electrical system components (with the exception of bulbs and fuses) must be replaced by a trained technician.

• When performing maintenance work on the electrical system, pay particular attention to ensuring good electrical contacts in leads and fuses.

• Blown fuses indicate overloading or short circuits. Correct the problem in the electrical system before installing the new fuse.

• Only use fuses with the specified load capacity (amperage). See Fuse box in instrument panel on page2-5.

Alternator

Always follow the following instructions:

• Never run the engine without the battery connected.

• When connecting the battery, make sure the poles (+/–) are not reversed.

• Always disconnect the battery before welding near the battery or connecting a quick battery charger.

• Replace defective charge indicators immediately. See Instrument panel overview on page1-8.

Battery

WARNING!

•Batteries contain acid, which burns eyes and skin on contact. Wear safety goggles and protective clothing to keep acid off body.

•If battery acid is spilled, thoroughly rinse the affected surfaces immediately with plenty of water.

•Keep open flames and sparks away from the battery. Battery charging produces flammable/explosive gas.

•Do not interrupt the battery jump charging circuit at the battery terminals. Sparking may result.

•Do not jump start the machine if the battery is frozen or battery electrolyte level is low. An explosion or ruptured battery may result.

•Make sure the poles (+/-) are not reversed when jumping the battery.

•Never place tools/conductive items on the battery. A short circuit may result.

In case of acid contact, wash immediately with water for several minutes. In case of eye contact, get medical attention immediately.

The battery is located under the cab near the rear of the undercarriage. See (1) Fig. 32.

To gain access to the battery (1), see Tilting the cab on page1-12 to tilt and secure the cab.

Battery cables must be clean and tightly secured. Remove any acid or corrosion from the battery and cables using a sodium bicarbonate and water solution. Cover the battery terminals and cable ends with battery-saver grease.

Note: The battery is maintenance-free and requires no other service.

Using a booster batt ery (jump-starting)

WARNING!

Keep arcs, sparks, and open flames away from batteries. When jump-starting from a booster battery, make the final connection (negative) to the machine frame away from the battery. A battery can create flammable gases. Sparks or open flames can cause this gas, and the battery, to explode.

DO NOT jump-start or charge a frozen battery. Warm battery to 61°F (16°C) before connecting to a charger. Unplug charger before connecting or disconnecting cables to battery.

IMPORTANT!

Do not jump start using a running machine. High voltage spikes from a running machine can burn out glow plugs.

IMPORTANT!

Damage to the alternator can occur if:

•Engine is operated with battery cables disconnected.

•Battery cables are connected when using a fast charger or when welding on the machine. When welding on the machine, remove both cables from the battery and ground the welder to machine frame near repair area.

•Incorrectly connected booster cables.

1.Be very careful when jump-starting the machine. Booster battery must be 12-V.

2.Turn ignition key to the OFF position.

3.Open the engine cover.

4.First, connect one end of the cable to the positive (+) terminal on the booster battery. Connect the other end of the same cable to the positive (+) terminal on the battery disconnect switch, on the machine you are trying to start.

5.Connect one end of the second cable to the negative (–) terminal on the booster battery. Connect the other end of that same cable to the frame of the machine you are trying to start.

6.Start the engine. After the engine is running, remove the cable connected to the frame first. Disconnect the other cable from the battery disconnect turn on the positive (+) terminal.

IMPORTANT!

DO NOT allow the cable ends to touch when removing them from the batteries. Arcs and direct short circuits can cause severe damage to the electrical system of a running machine.

IMPORTANT!

Do not test run the engine with a disconnected battery.

Replace a defective alternator immediately. An illuminated battery charge Indicator can indicate a malfunctioning alternator. See Instrument panel overview on page1-8.

3.19Cab heater filter

Replacing the inside heater filter

Tilt the cab to replace the filter. See Tilting the cab on page1-12.

The heater is located at the rear half of the cab.

Replacing the filter:

1.Open the heater cover.

2.Replace the heater filter. See Fig. 33.

3.Replace and secure the heater cover.