1 minute read

Hy-tec Hydraulics

f.Raise the pressure to 125-140 kg/cm2. Do not raise the pressure sufficiently to blow the relief valve. Wait for 2-3 minutes and observe plugs and ports for leakage. If any of these plugs are leaky tighten it or replace if required.

g.IF oil is coming out from coupling pressure pipe, or port (9-3) ‘check valve’ is leaky, remove check valve and observe sear for any damage, observe ‘O’ ring for any cut and deformation etc. Before reassembling, change ‘O’ ring on seat.

h.After reassembling, observe the pressure guage, if the pressure is coming down, and if oil is leaking from clearance between main spool and sleeve is more than (0.0100.012) mm. Replace the spool with the spool of bigger diameter and do necessary lapping.

Hy-tec Hydraulics

Dismantling procedure of the hydraulics.-

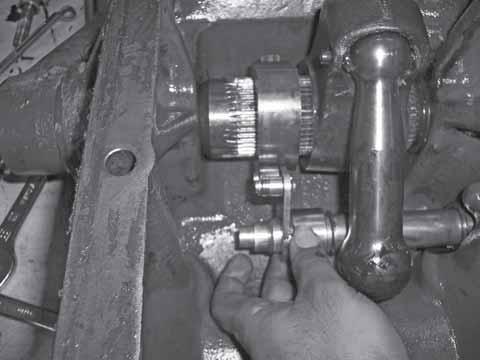

A) Dismantling procedure of the bell crank Assembly-

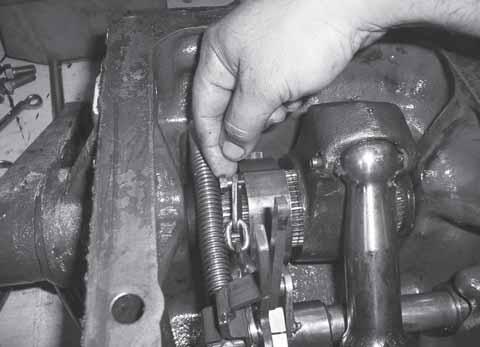

1Remove the M14 lock nut of the crank toplink assembly.

4Remove the M8 bolt of pin crank top link.

5Remove the pin crank top link.

2Remove M14 Flange nut on the crank toplink.

6Remove crank top link.

7Remove ‘2’ bolts (M12 x 1.75) of draft sensing mounting assembly.

3Remove the step bolt DC outer block of DC Connecting link.

8Remove sleeve draft sensing

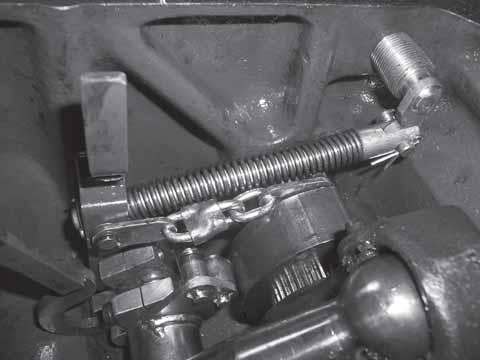

9Remove outer DC sensing spring.

10Remove inner DC sensing spring.

11Remove Spindle Draft Sensing..

Hy-tec Hydraulic

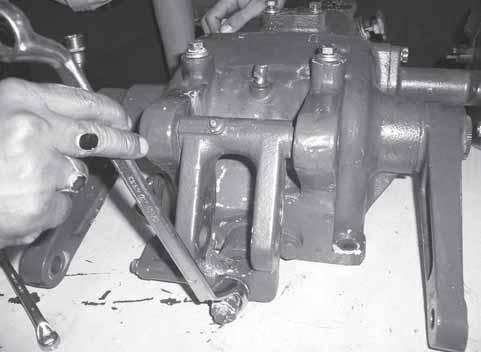

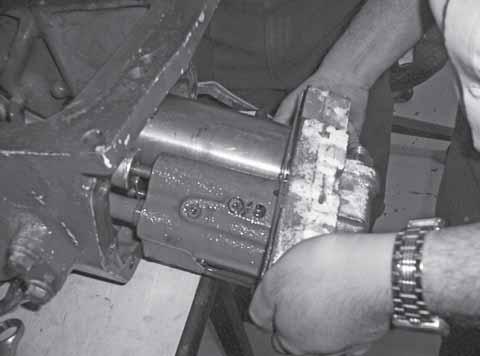

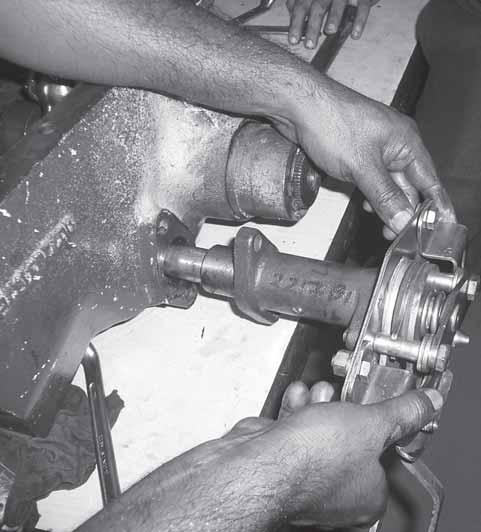

B)Removal of Control Valve assembly.

1Remove the 8 bolts (1/2” UNC) of the CV Assembly with spring washer.

12Remove sensing bottom sleeve.

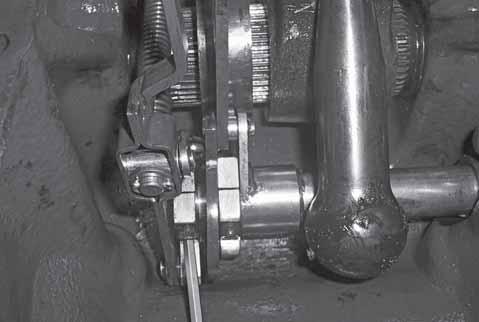

13Remove external circlip of the DC feedback link & remove draft sensing link.

2Remove the control valve. Remove two small attaching cap screw and draw of the cylinder head realising spring.

14Remove the roll pin of DC outer rocker.

8Remove the spacer of DC Outer rocker.

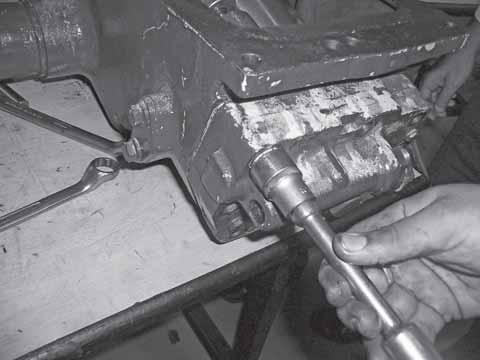

CRemoval of Linkages -

1Remove cotter pin of DC linkage.

Hy-tec Hydraulic

Hy-tec Hydraulic

DRemoval of Quadrant assembly.

1Remove two bolts of quadrant assembly (Bolt Size M10 x 1.5)