2 minute read

REPAIR INSTRUCTIONS, PART 1

NOfE

i¡áke suÉ lhal rubber isolatoE áre corectty ¡nsialled and thal lh€ grcund sl@p is gounded 10

4. Uslng alorque sr6nch,lighteñ1hé hstenere in séquence adordinq to spéciÍcation.

Fuel L¡nes añd Filter Housing lnstallation

Note

Thesequencéinwhichthéluélf ltérhous¡¡q, tuet lines and EECU areassembled on lhe enqiné depends on lh€ Vpé ol engine siand ced. For engine slands that lse án adápler plalé ana.hed lo lhe láft side ol lhe engine,lhese componéñ1s cannol bé inst¿l sd uff I altér lhe engine has been removed lom lhe ¡epair sland.

Usi.q a loque wrench, riqhlen rhe fasieners adording to specil ca1 on.

Assemblé lhe coo 6ron lh€ EECU. When pcilioning lhe module, ñake sureihallhe snalgmund sl@p al lhe uppef r¡stf oi ihe unil s properly secured ánd prcssád in

NOfE

FisuEs Fü.r

Firsf ¿nd HoG¡nq

As Bt

1, Asemble lh€ tuél finer housing onlh6 btock.

2, Using á lorquo w€nch. t¡ghten the taslénerc acmding lo speciliEi on.

3. Allach lhe p¡pe bellveen the s¡de ot the h€ád al lhe réaf a¡d the lilte.hous ng.

Atach the line lo the bl@k with a P-clamp, lnslalllhé iuél rélum liné be¡réen rhe cyliñder h*d at lh€ lorn and lh€ lifter válw lnsrallrhe line ro rhe b¡ock w¡rh P-clamps. lnsrall lhe lue I relu rn line con¡ect lng the liller Etue housing lo thé EECU ód¿i lnsrall lh6 lu€l supply and ré1un I nes belween lhe lue¡ pump and thelillér

U3ing aloque wE¡6h,lighlen lhe bahlo llttlnqs accordino to specif calio¡.

Crankcase Ventilation Separator

1. Clean lhe cankÉse venlilallon sepaáto¡ malinq sulacé o. lhe éngine btock. lnstalt a n4 rubber aáskel iffo {ré s6pa6ror

2. Assemble the sepaábr on lhe blóck and

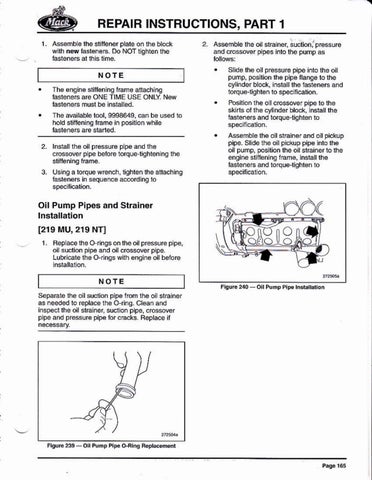

BEPAIB INSTRUCTIONS, PART 1

1. Assémblé the .Enkshafl vibration'damper ánd I¿¡ puloyon rhe cÉñlshail hub Ging

Note

3. l.rsing a ioque w€nch, l¡ghlen lhe lasleneB ac6rdi¡g lo specif calion

4. Assemble lhe ouíel hose on lhe separalor ou el conneclor a¡d instal hose clámps.

5. ljslng a torque wrench, liqhlBn the hc6 clamp laslenerc ac@rding !o sp4¡l¡*¡on.

6. Assmblé 1¡e lnler hce on the separator inlel and pr€pa€ fo¡ € re cov6r connslion in a iulu@ slep, lnsiattho* ctamps.

7. Using a lorque wench, tlghlen the h66 clamp tasl€nerc ác@.ding lo sp4iti€lion.

Crankshaft Vibration Damper and Fan Pulley lnslallatlon

AcaurroN

When handling a tbnton darpéL bé a6tul na¡ to dañage llÉ fo6kg. Denls ln the au¡er hús¡ng s¡l¡ rcndq the danpet inefecfive. rhe v¡b@üú danpe. @nnol be Epated. Failure to h*d ¡h¡s autim nay re'u|t in see engine lnspecllhe vibElion damper lof dents, n¡cks or llu d leaks in lhe outer housing. ll any oi l¡ese are widénr, rhe dampermustbe reptac6d. Duelolhe clos€ cloaEnce beñveen lhe damper housing ¡nd lhe rolorinsids, denrs ór nrcks nayeuse conlact belween lhe two componenls. Fluid loss will dele o¡ate lhe dampeñi¡q eftucl oJ rhé

F¡duress.FanDvePu'le'.ndc t2 virüaion o¿npér t3 c,¡nrshaft Hub

Using aloquewcnch,tghlenlhe ataching l6léneF in sequence in two stéps a@odhg to sp6cilicalion.

3.

Asseñb e lh€ fonl engine p@er láke of (FEPTO) il equ¡pped. Tighrén rhe atachlng last6néc in sequencé in ldo sleps a@ordina ro spe.ilication.