90 minute read

Sketchesofspecialtools1

NOTE: Komatsu cannot accept any responsibility for special tools manufactured according to these sketches. A4Plate A4Pushtool

14D475A,D475ASD-5E0

NOTE: Komatsu cannot accept any responsibility for special tools manufactured according to these sketches.

A5Pushtool E2Pushtool

D475A,D475ASD-5E015

N2Bracket

20D475A,D475ASD-5E0

Engine and cooling system (SAA12V140E-3) 1

Removal and installation of engine assembly

Special tools

1

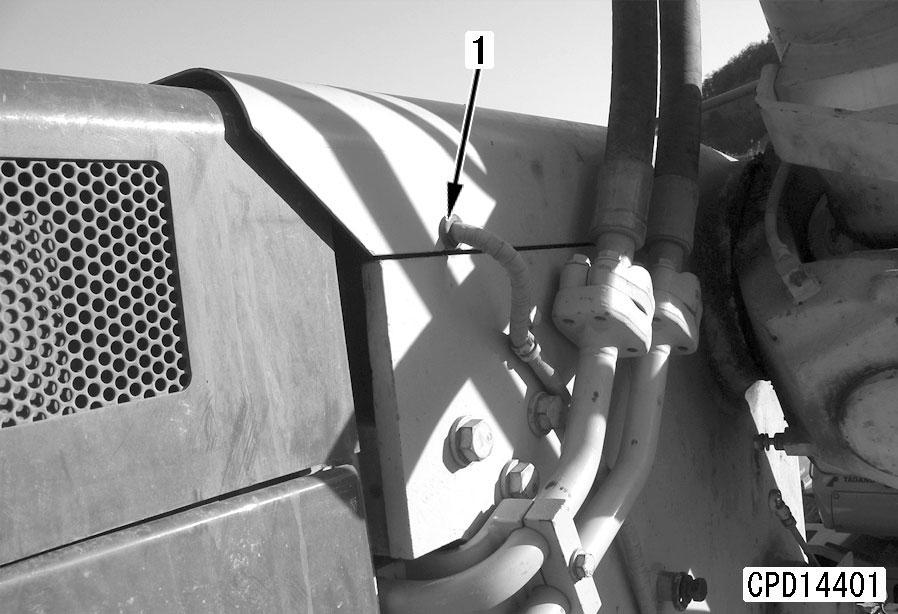

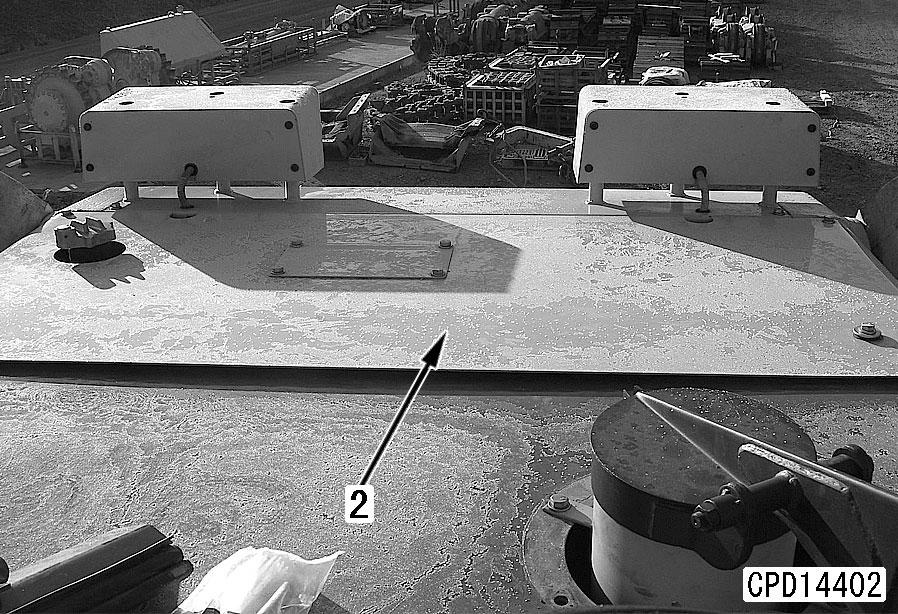

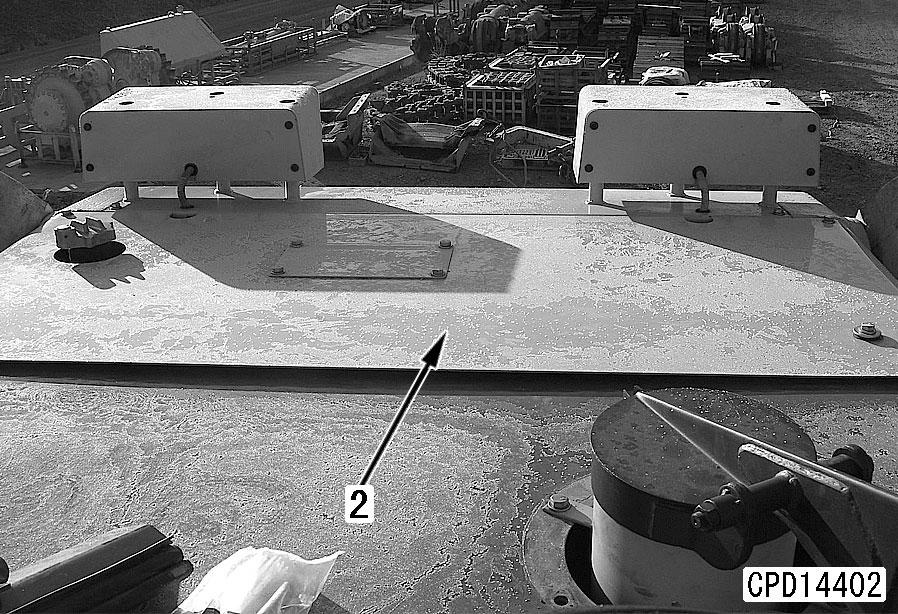

3.Lift off radiator upper cover (2).

4 Radiator upper cover assembly: 85 kg

799-703-1200Service tool kit t 1

799-703-1100Vacuum pump t 1

799-703-1111Vacuum pump t 1

799-703-1121Vacuum pump t 1

799-703-1401 Gas leak detector t 1

Removal k Lower the work equipment to the ground and stop the engine. k Set the parking brake lever and work equipment lock lever in the lock position. k Disconnect the cable from the negative (–) terminal of the battery.

1.Drain the coolant.

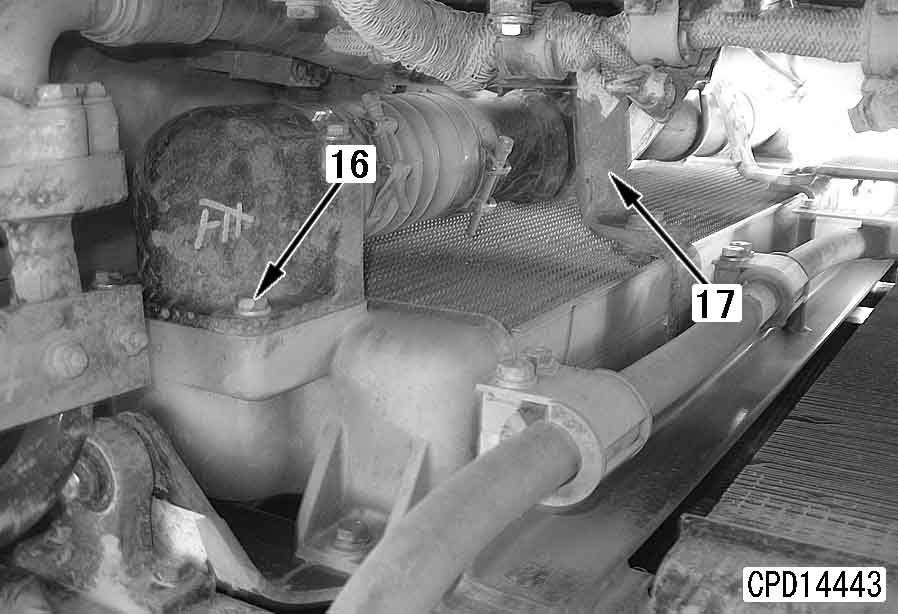

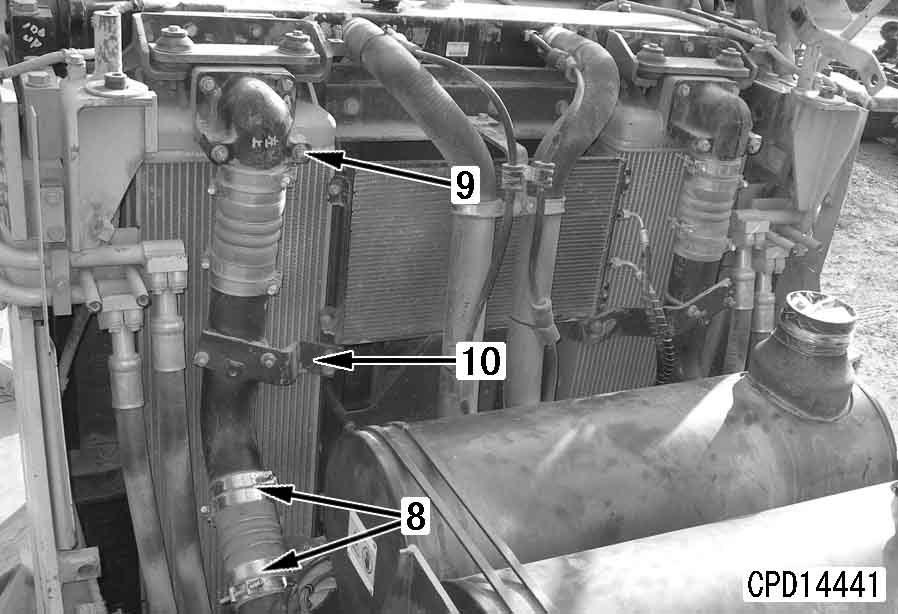

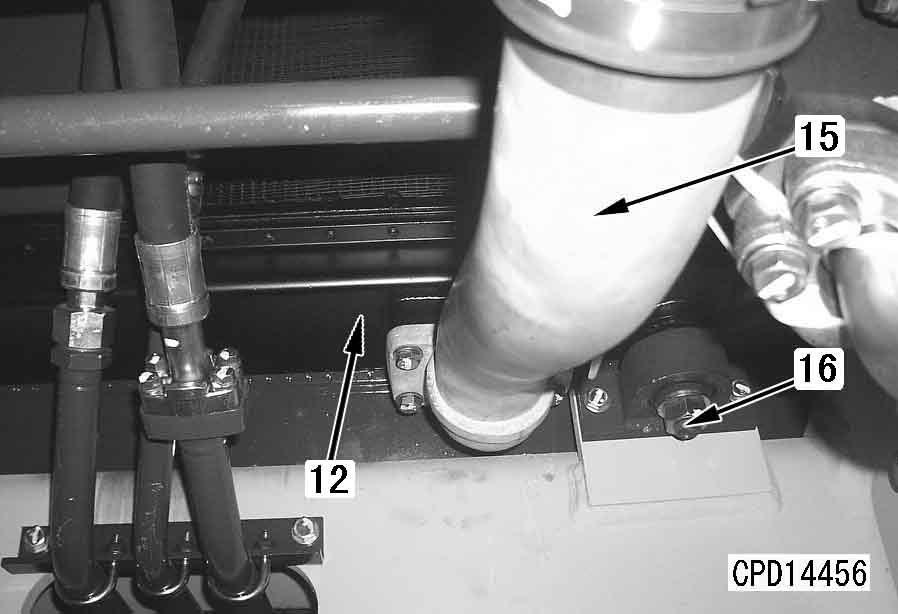

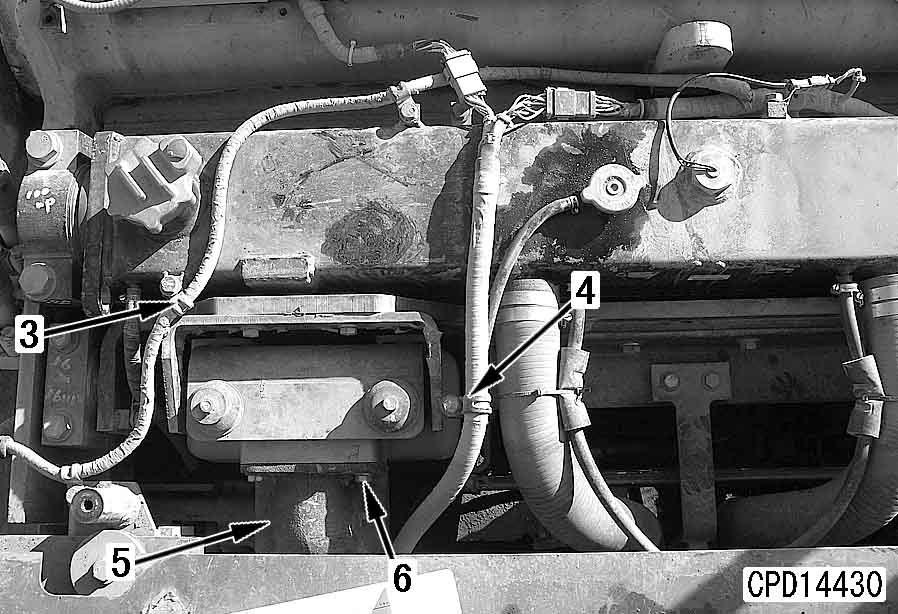

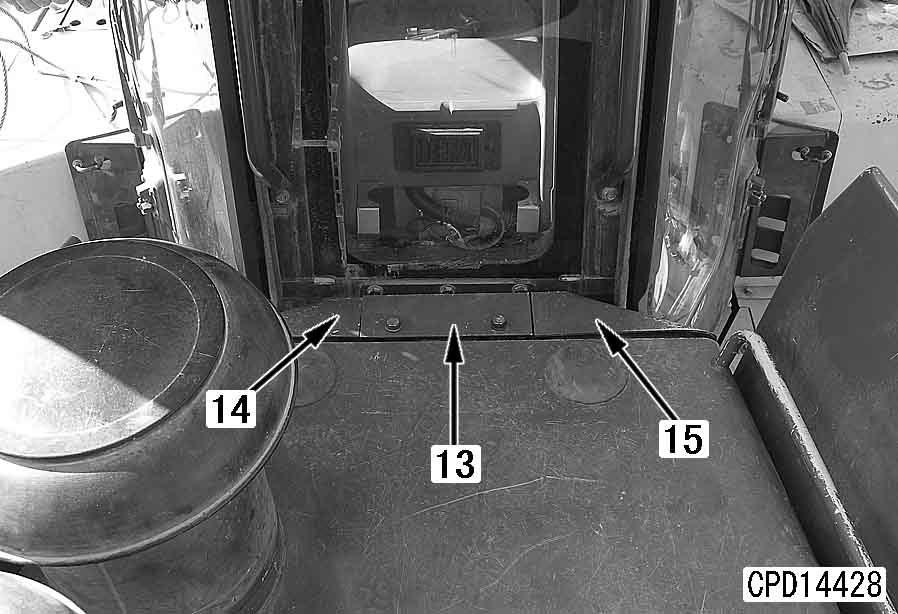

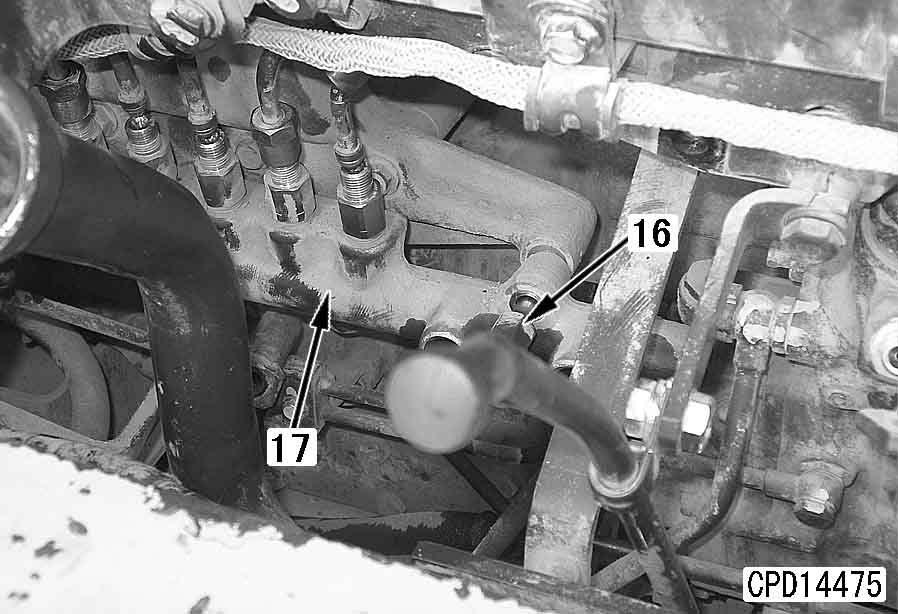

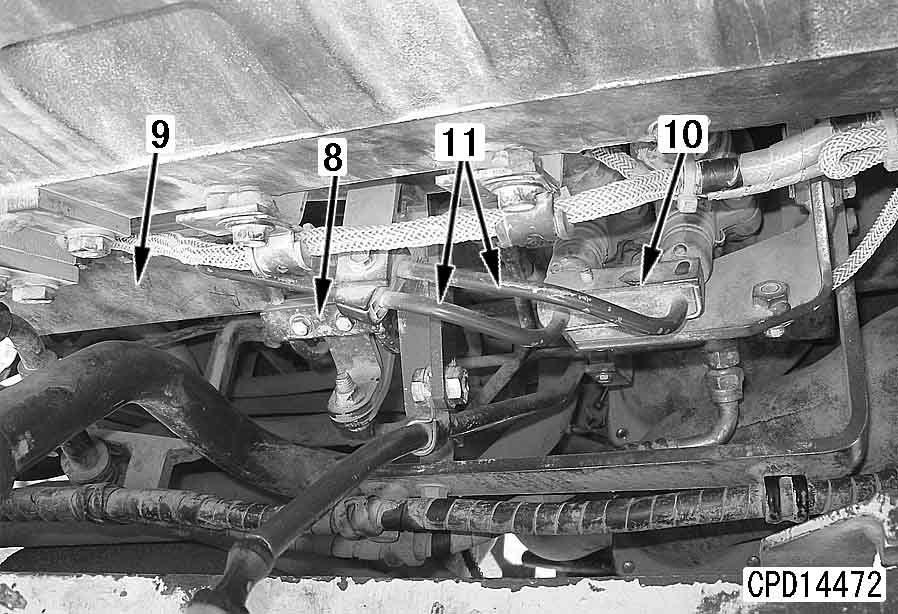

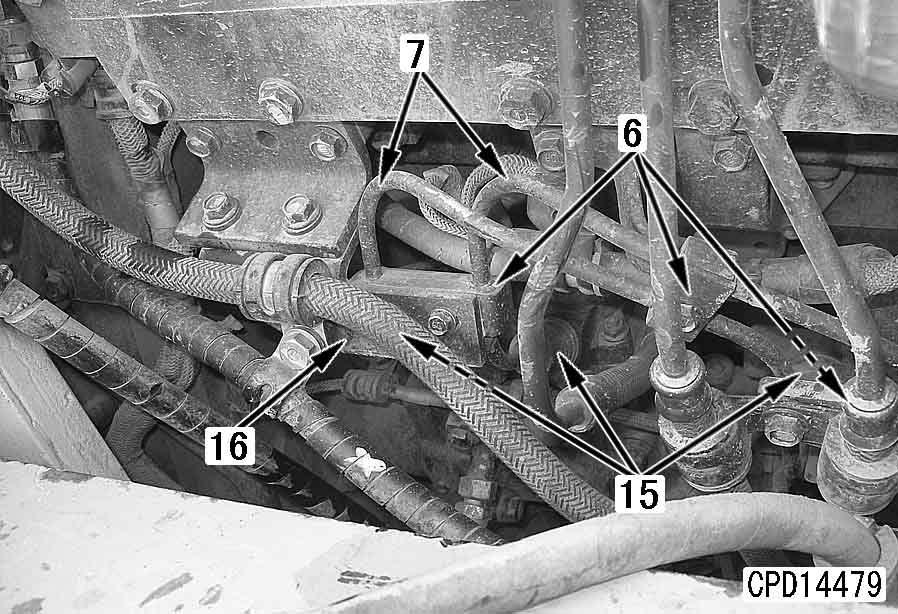

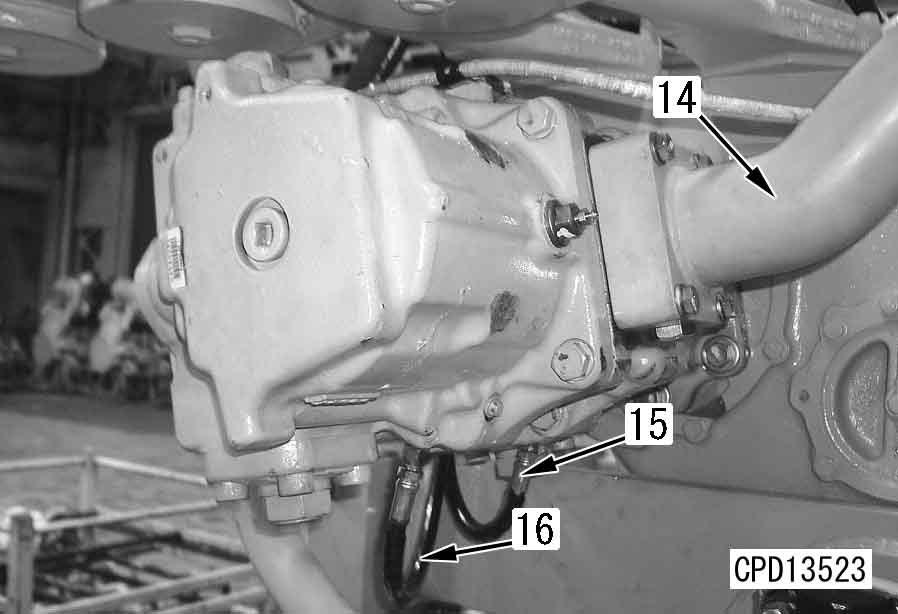

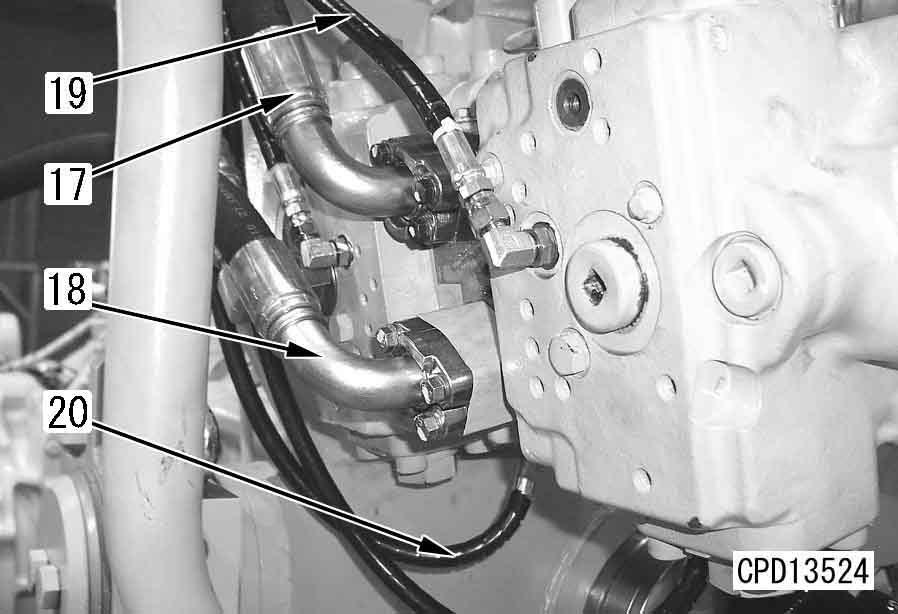

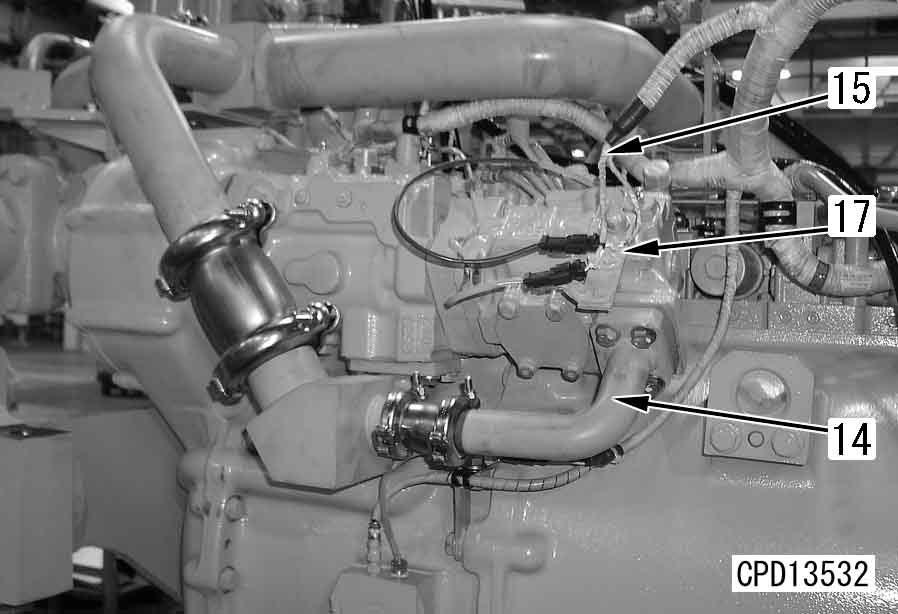

6 Coolant: 210 l a Loosen hose clamp (15). a Remove pipe mounting bolt (16). a Remove piping fixing bracket (17). a Loosen hose clamps (8). a Remove pipe mounting bolt (9). a Remove piping fixing bracket (10).

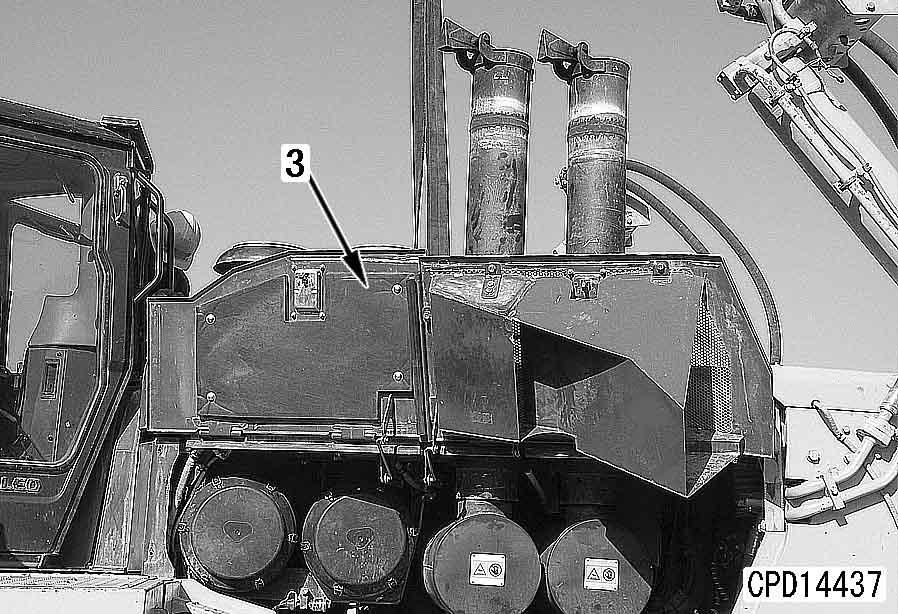

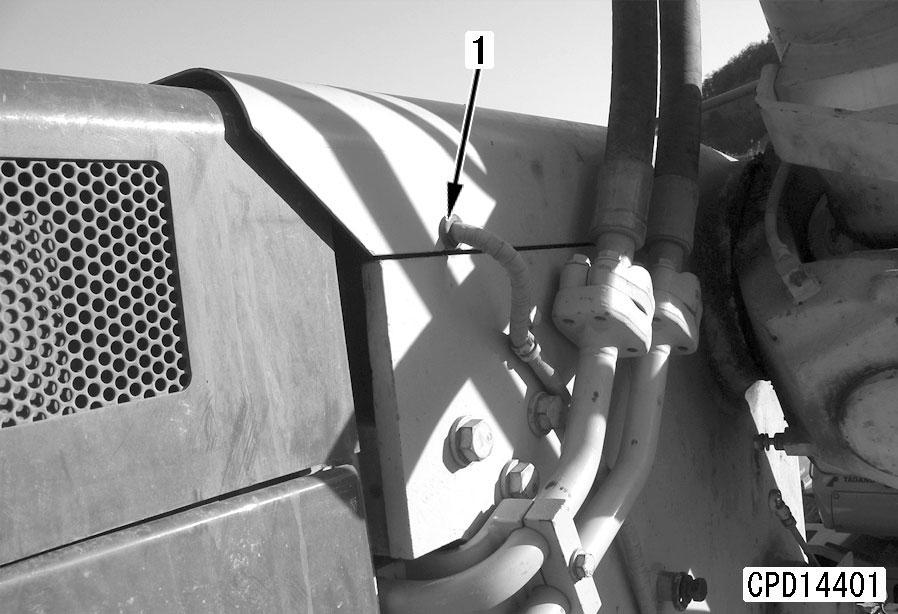

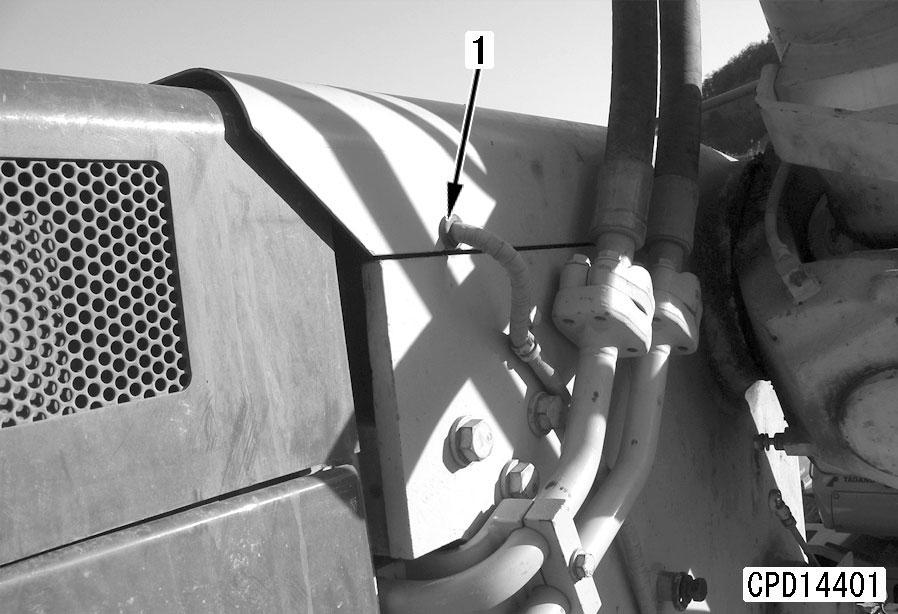

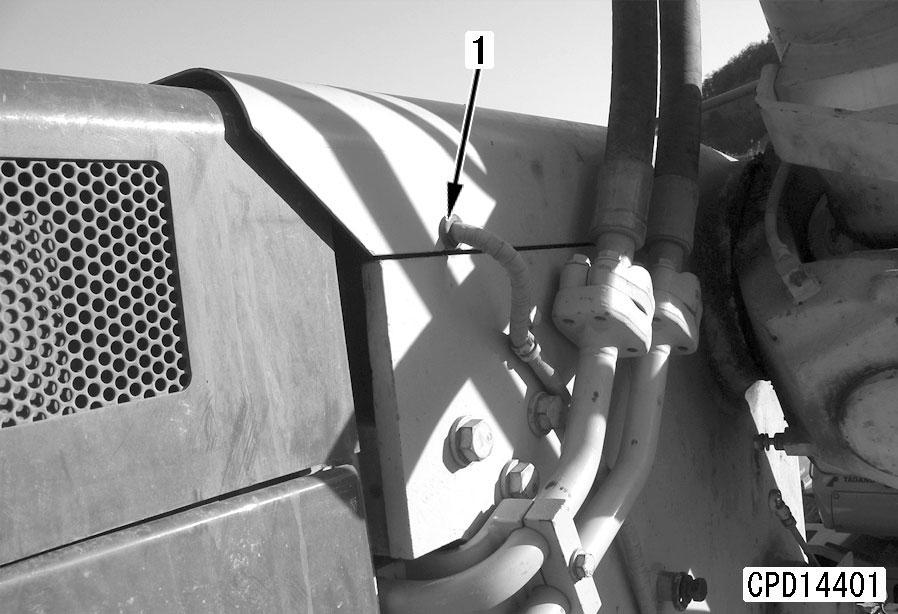

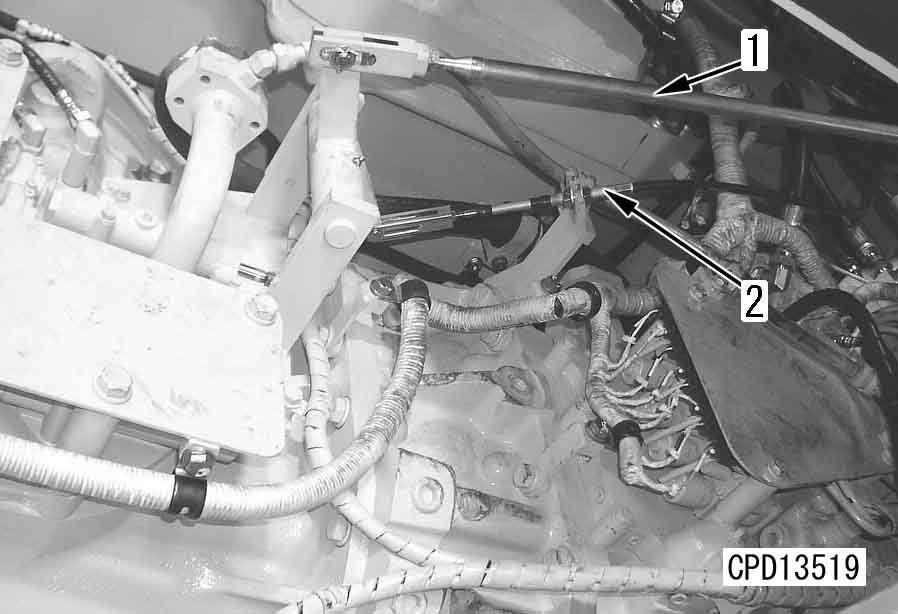

2.Remove right and left potentiometer wiring grommets (1) from the cover.

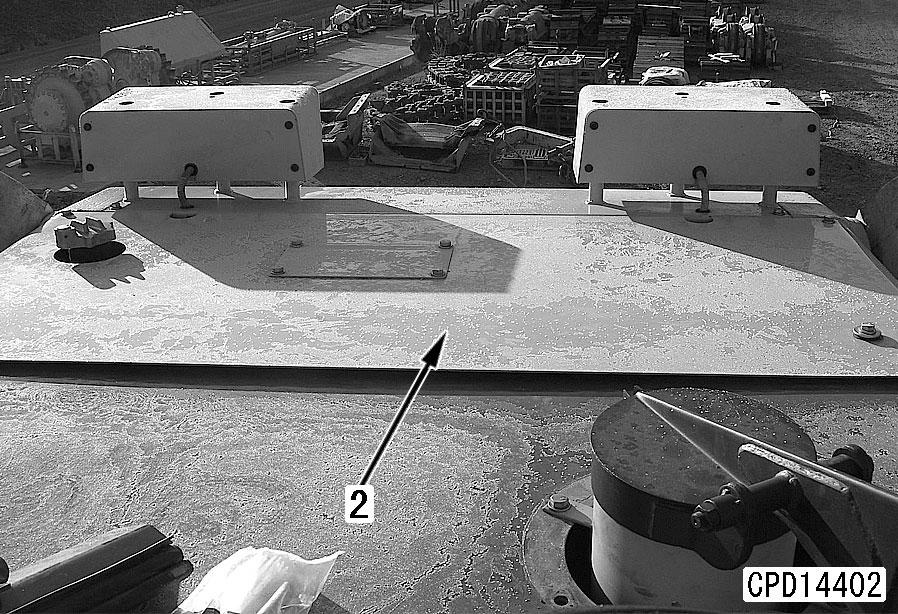

4.Remove engine hood assembly (3). For details, see "Removal and installation of engine hood assembly".

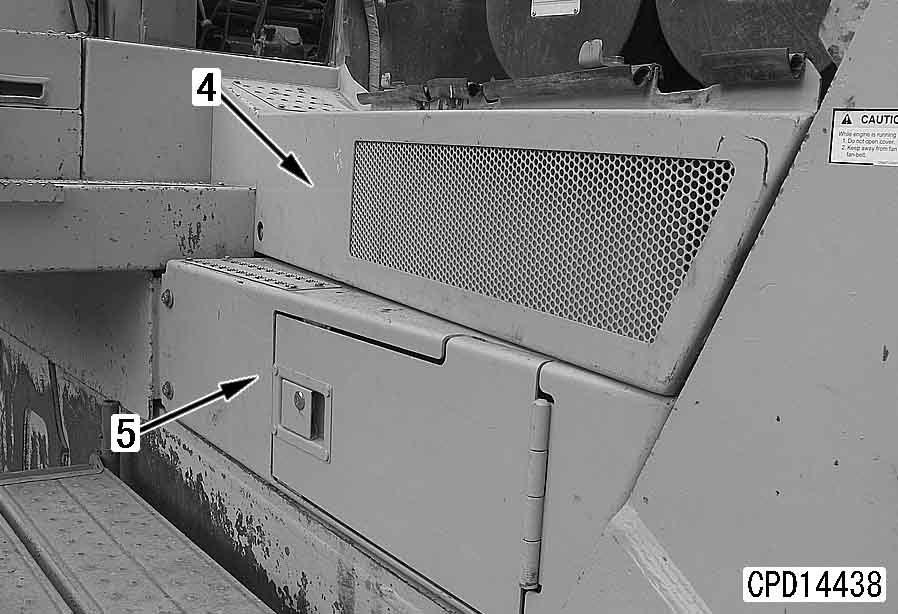

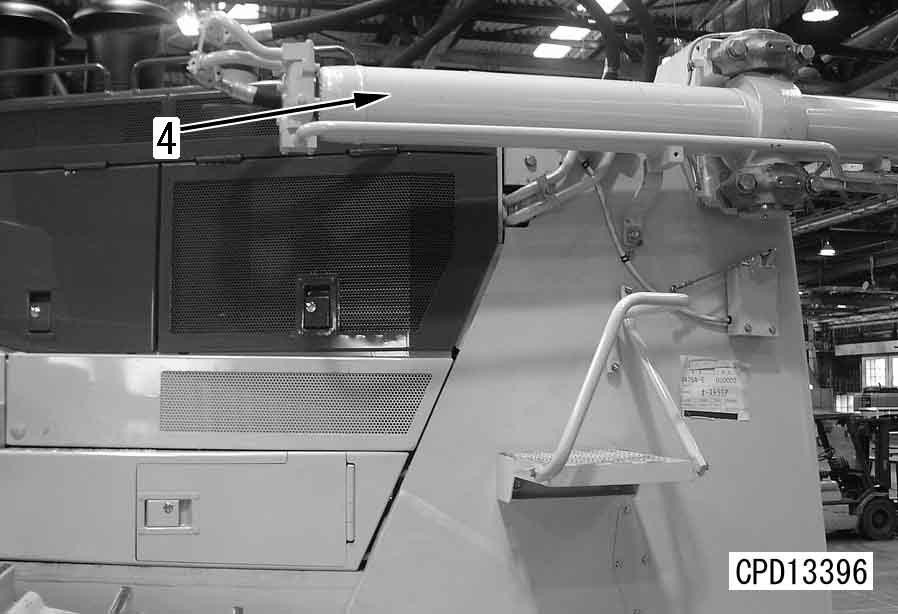

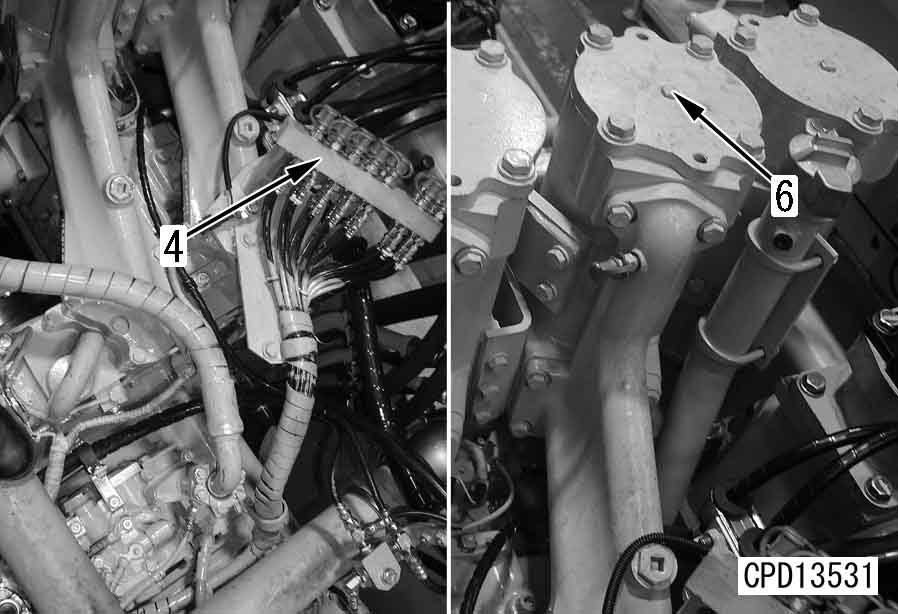

5.Remove right and left engine side covers (4) and right and left covers (5).

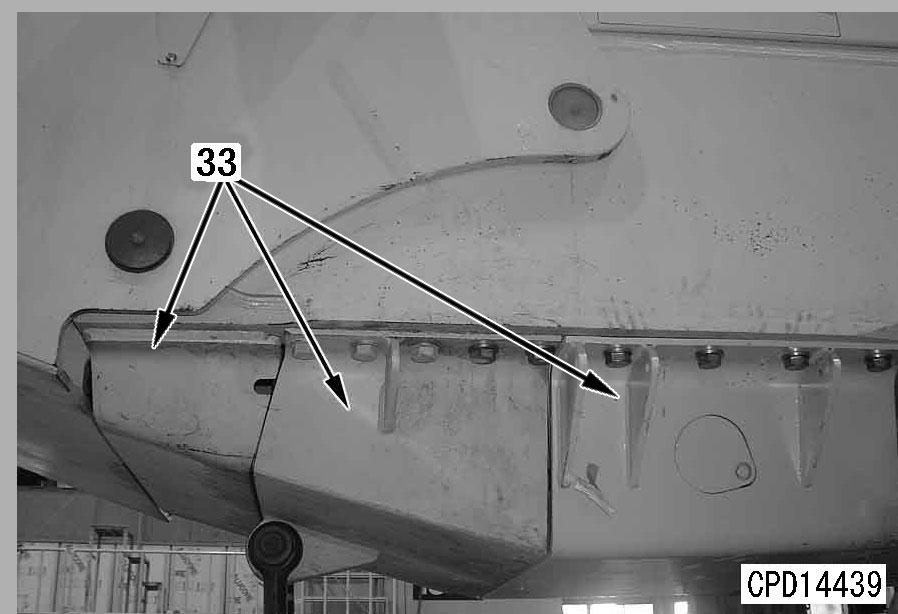

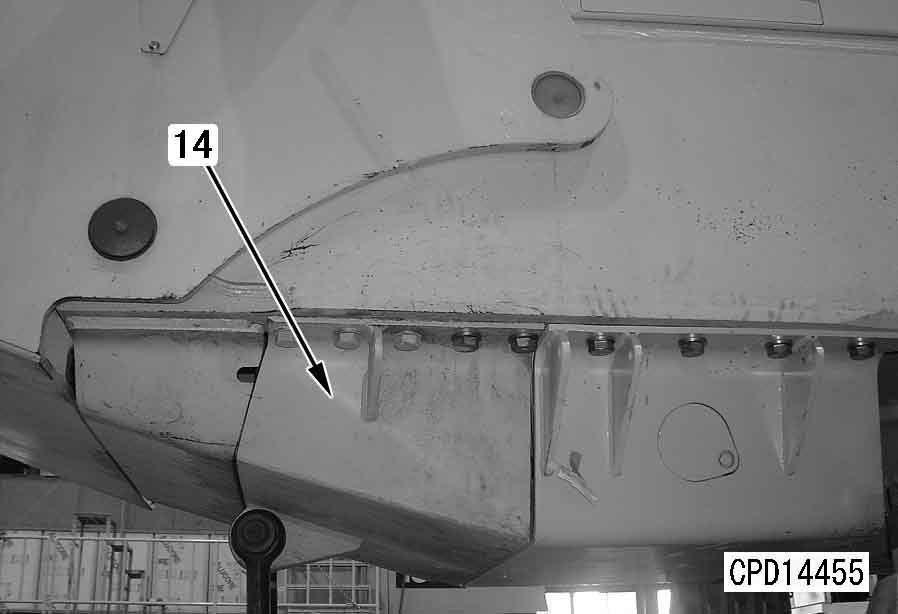

6.Remove undercovers (1st, 2nd and 3rd ones from the front) (33).

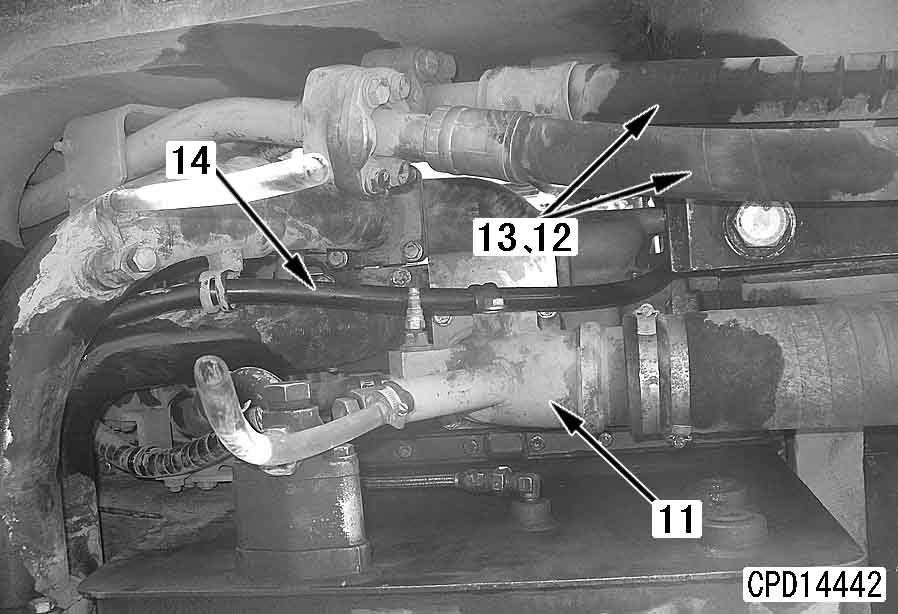

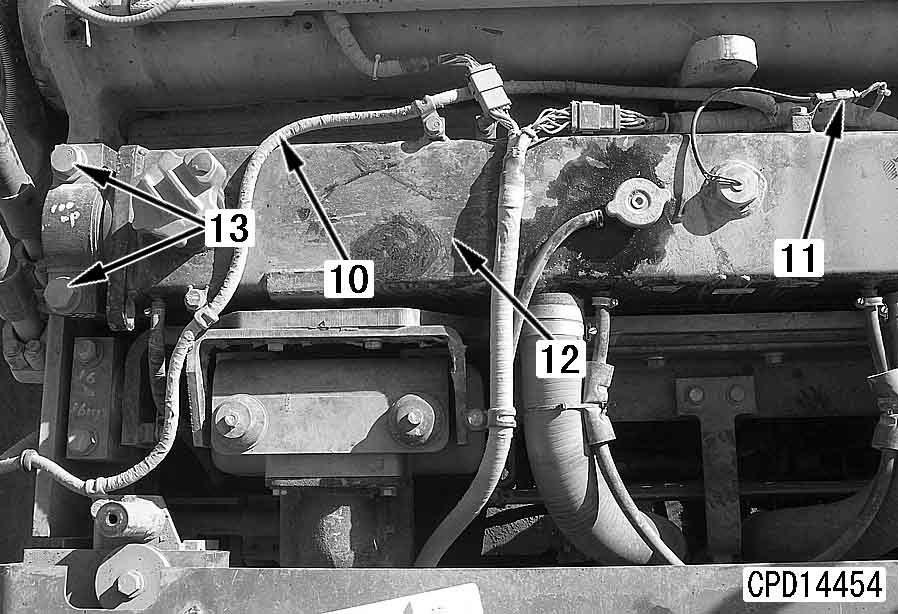

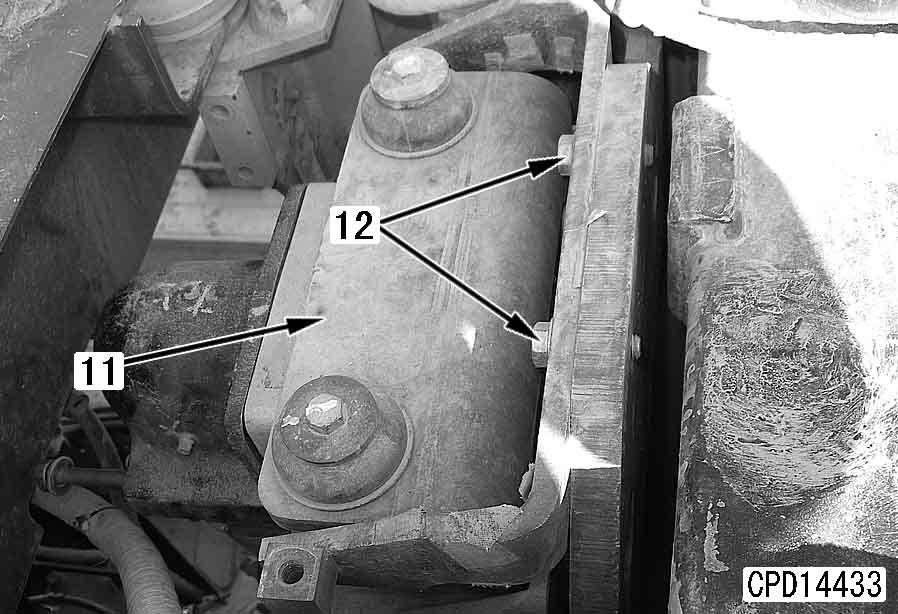

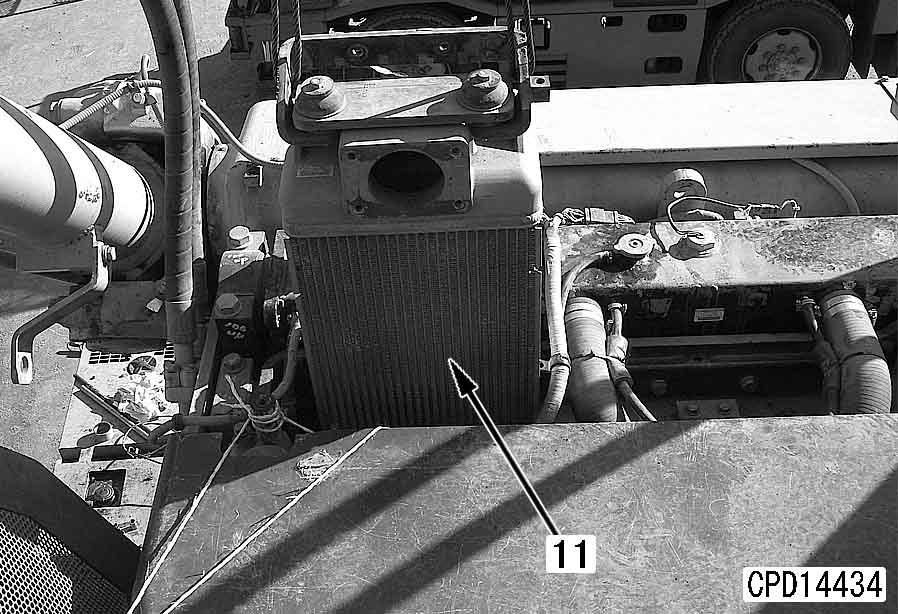

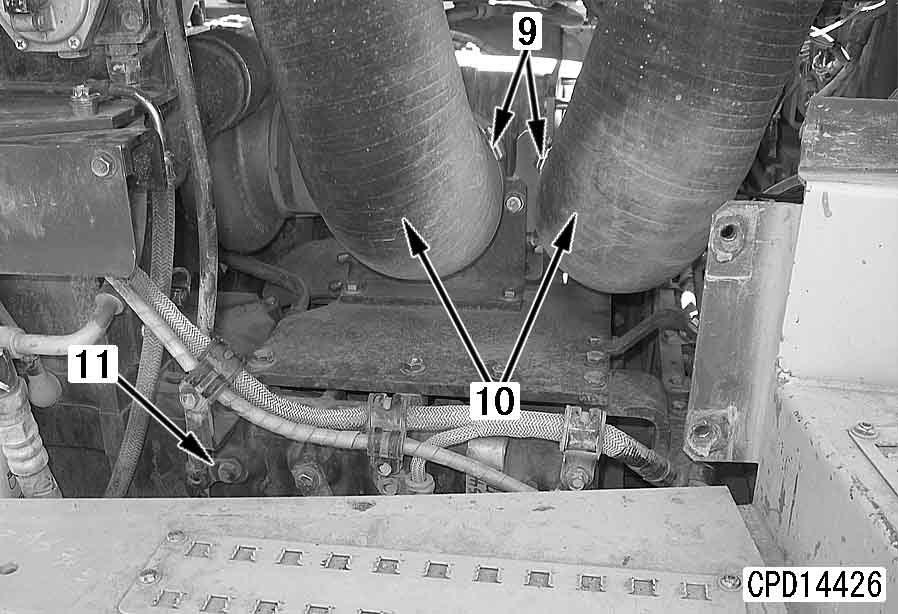

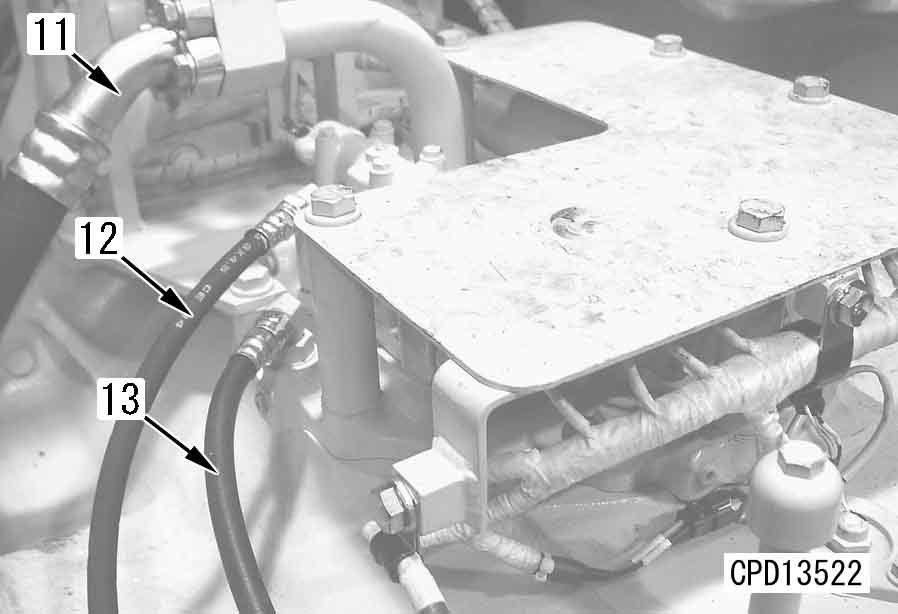

9.Disconnect radiator outlet tube (11).

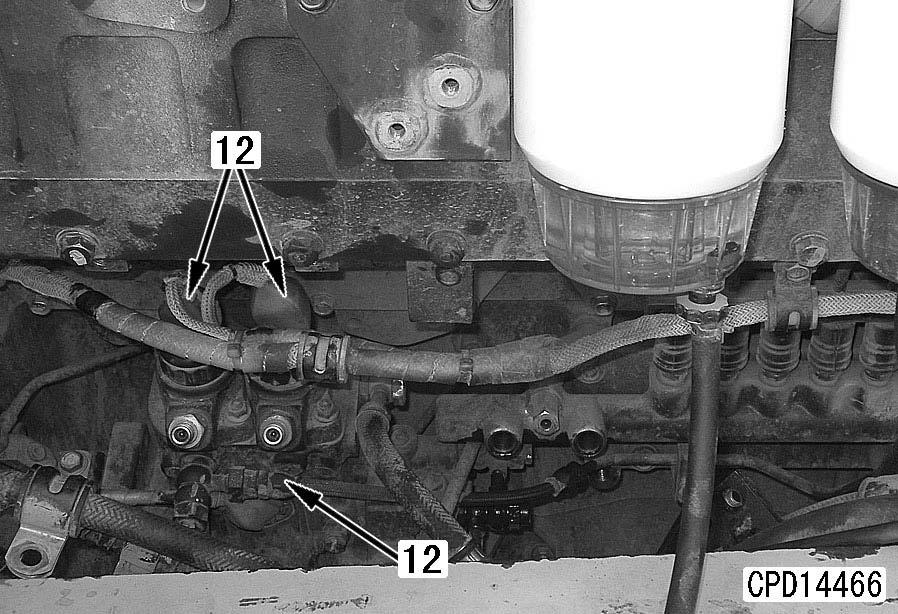

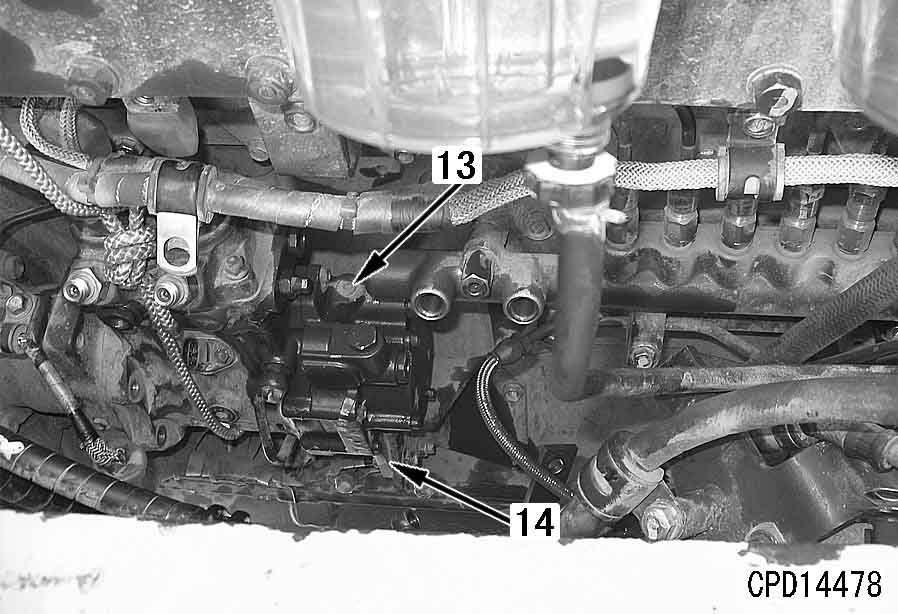

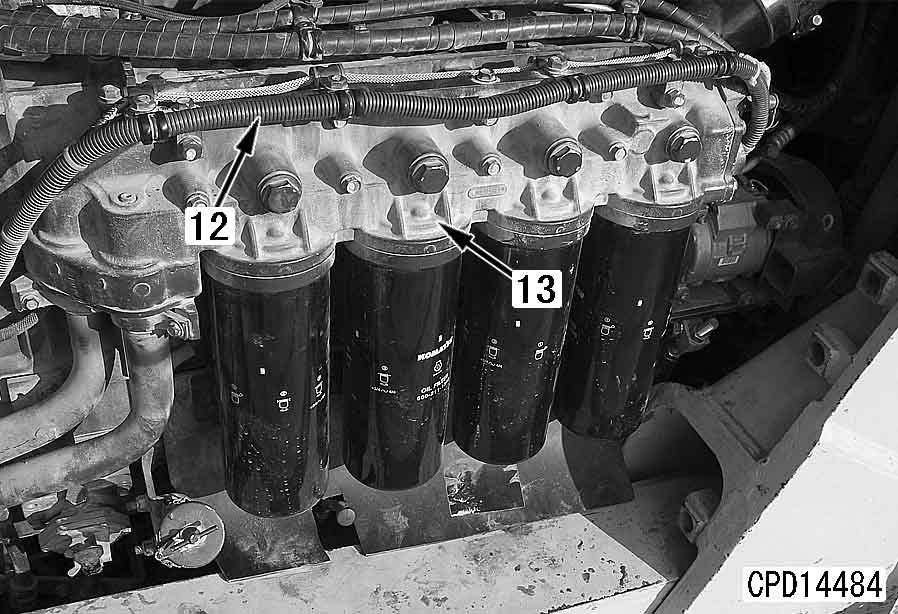

10.Disconnect torque converter oil cooler tubes (12) and (13).

11.Disconnect heater hose (14).

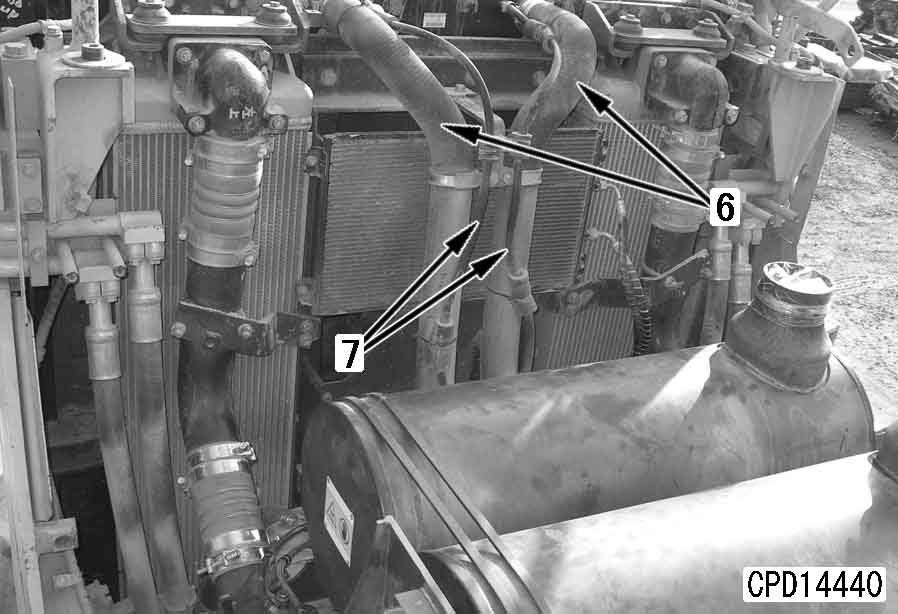

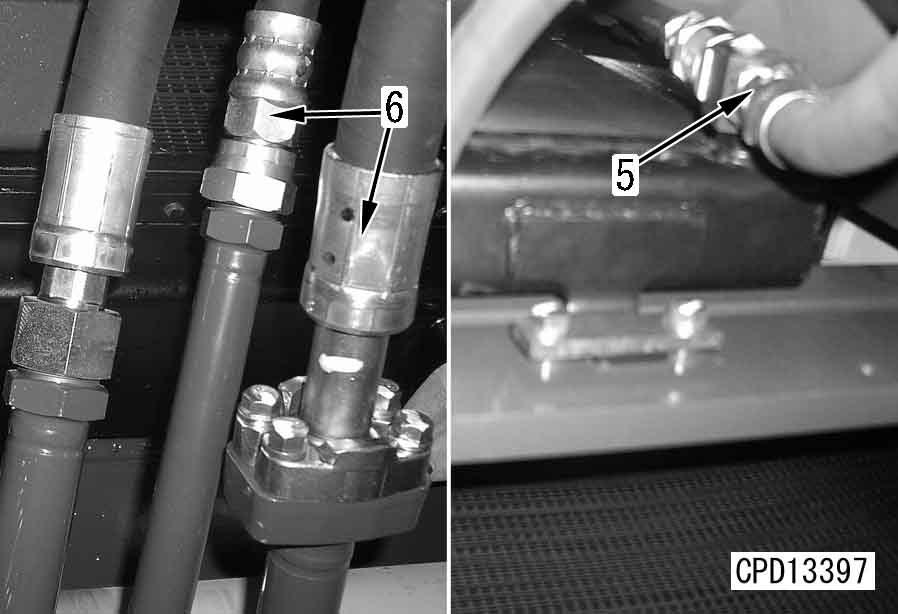

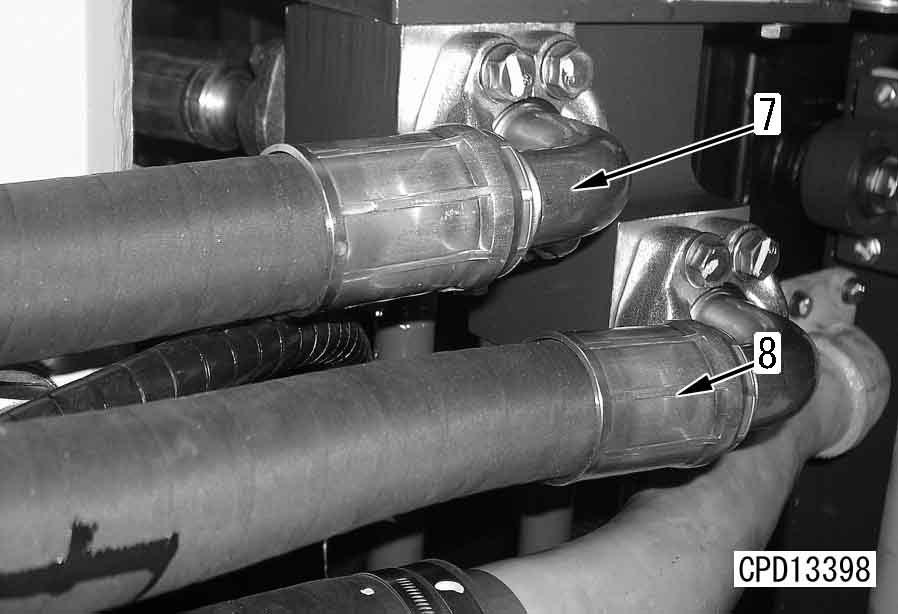

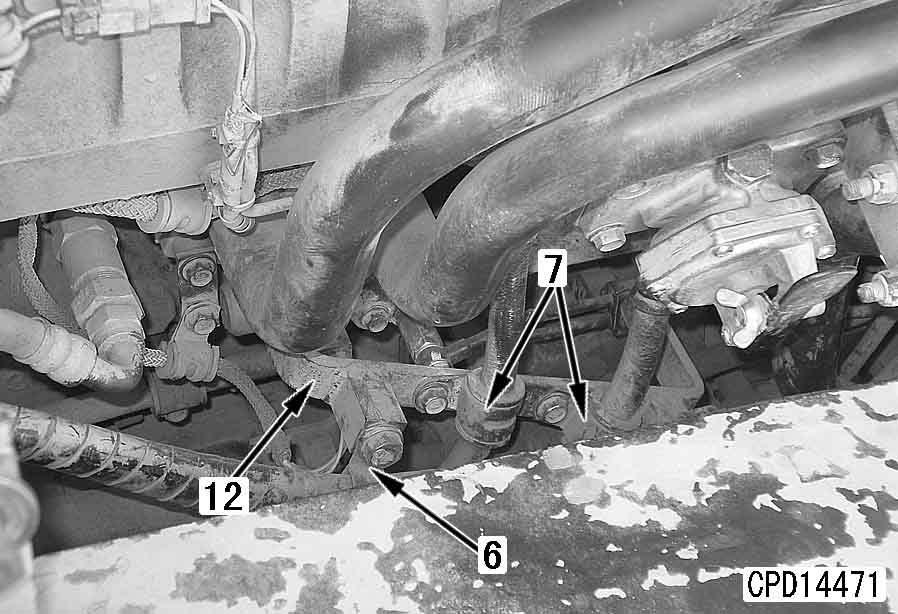

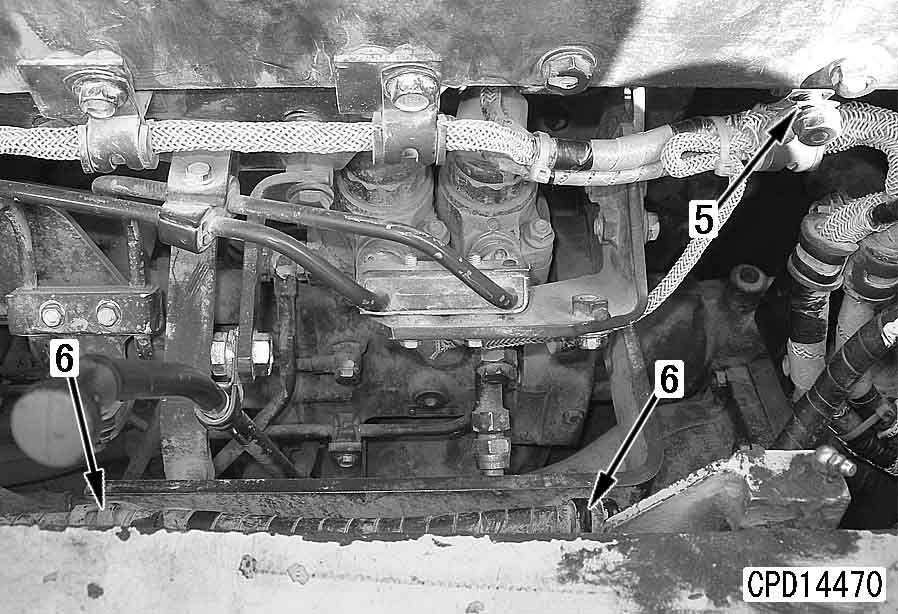

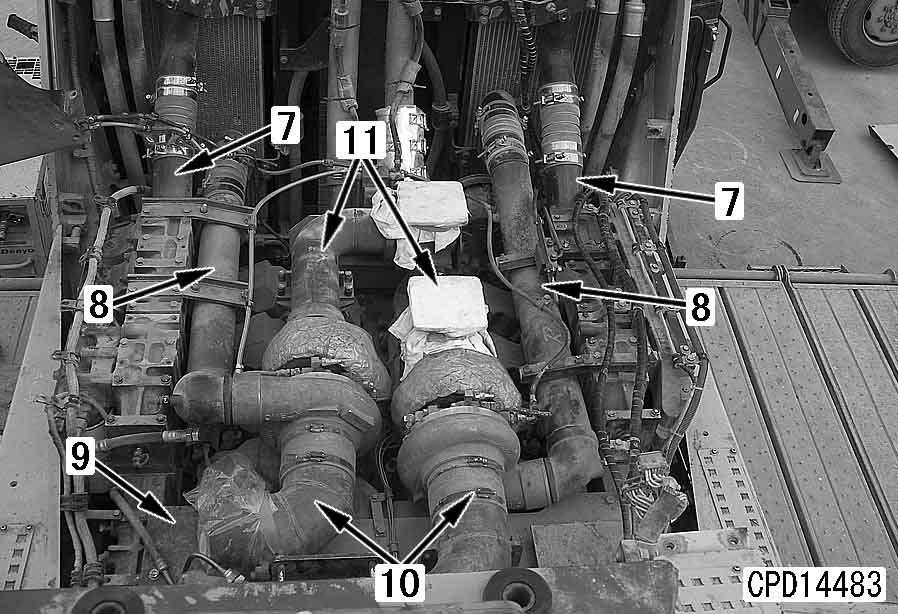

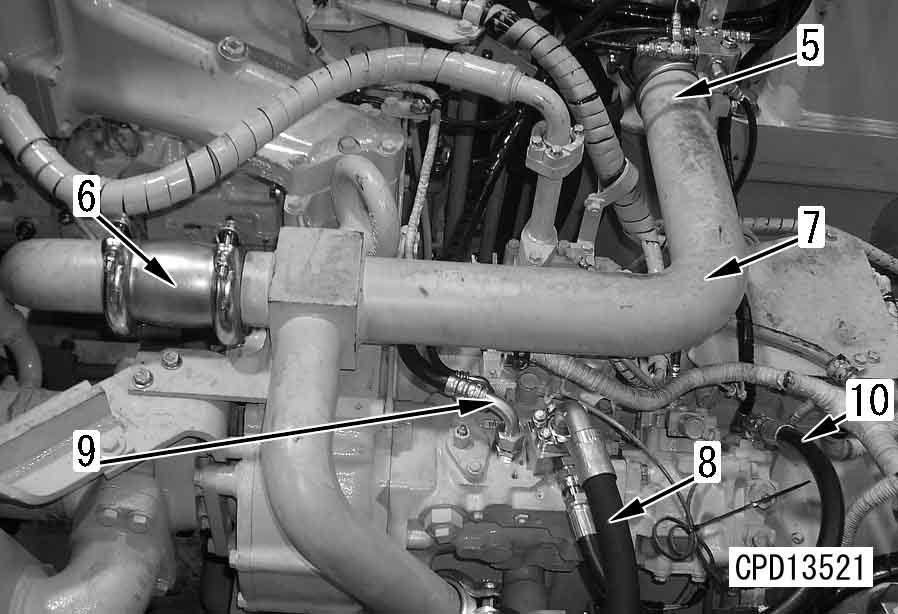

7.Disconnect radiator inlet hoses (6) and aeration hoses (7).

12.Lift off the right and left aftercooler outlet piping assemblies.

8.Lift off the right and left aftercooler inlet piping assemblies.

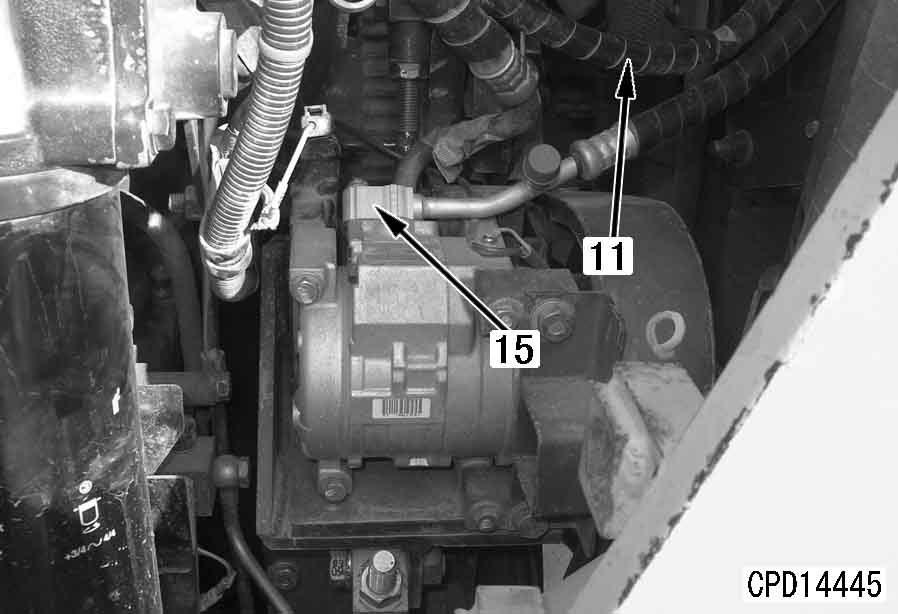

D475A, D475ASD-5E0 a Collect the air conditioner refrigerant (R134a) from the air conditioner circuit. a Cover the hoses so that dirt, water, etc. will not enter them. a Disconnect all the clamps of hose (11).

13.Disconnect air conditioner hose (15) and remove the compressor assembly.

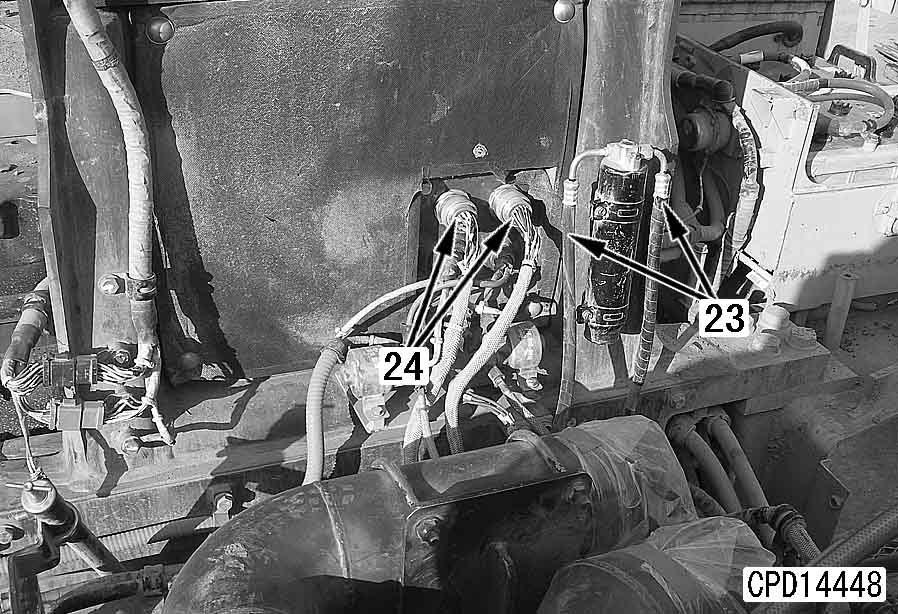

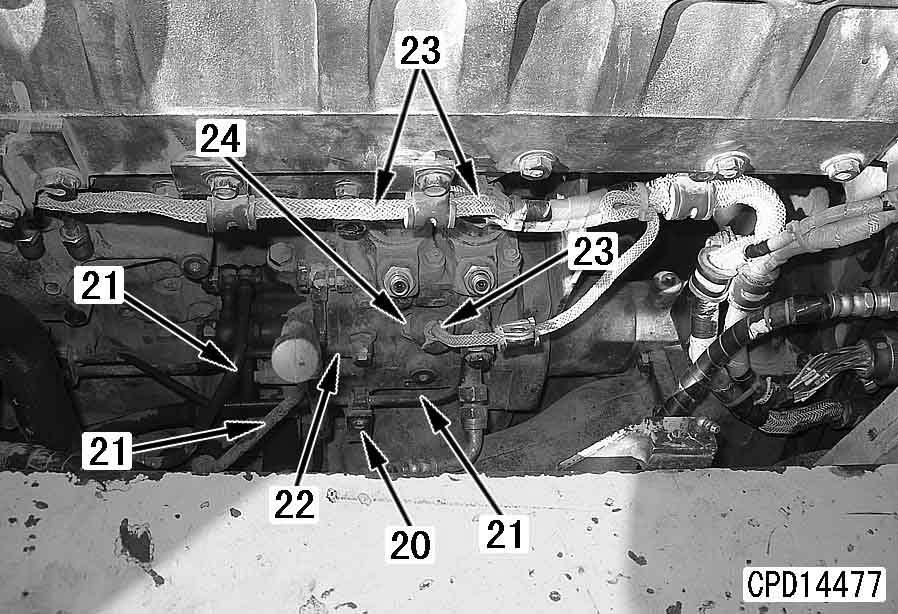

16.Disconnect engine rear-side air conditioner hoses (23) and wiring connectors (24).

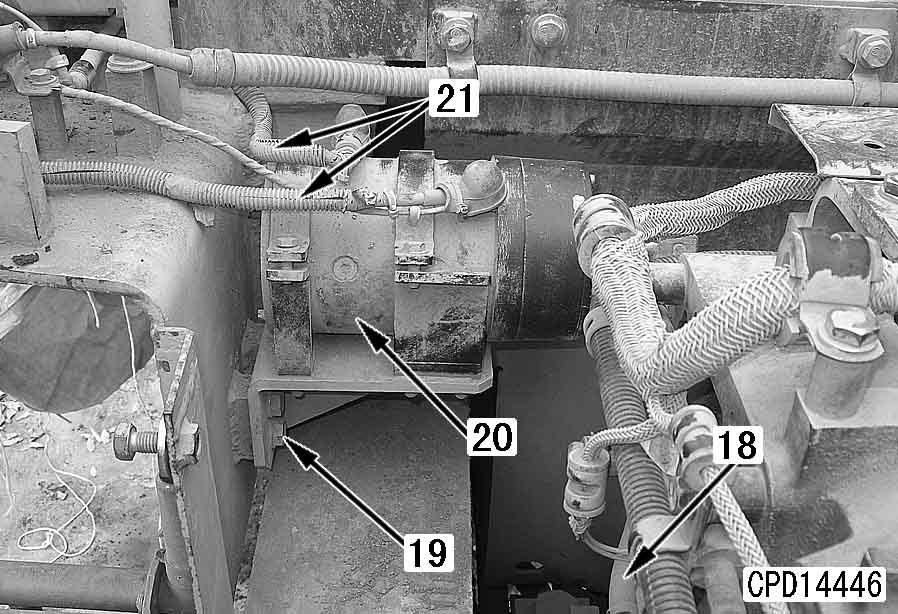

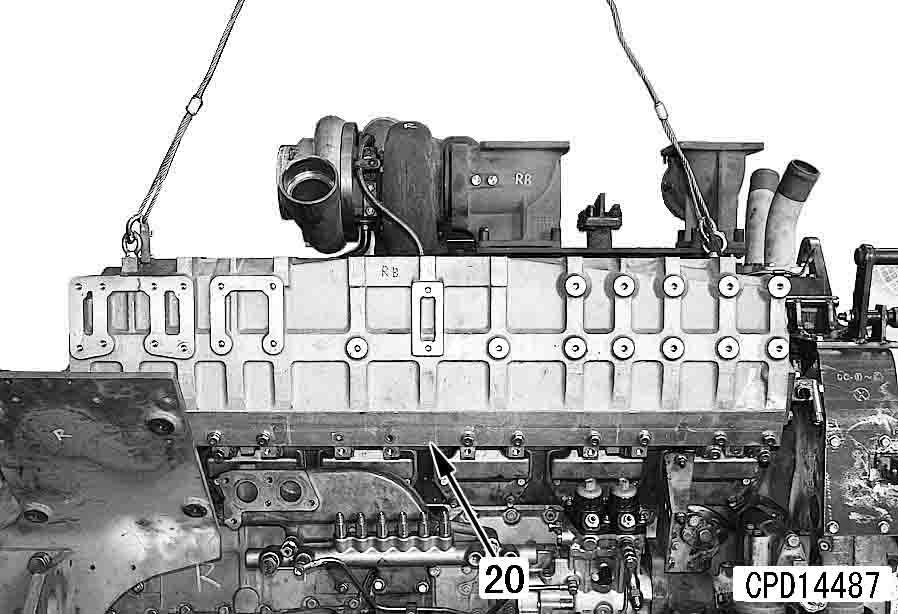

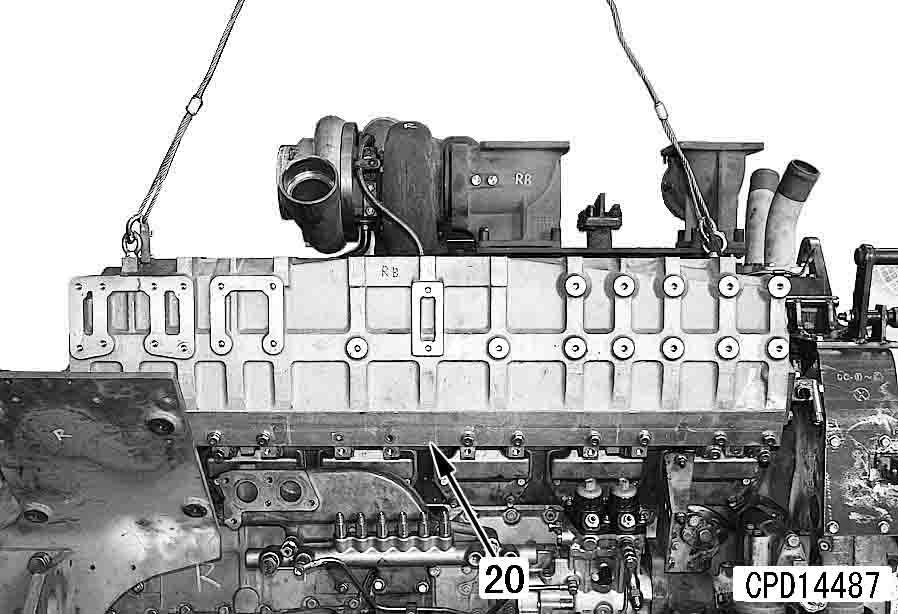

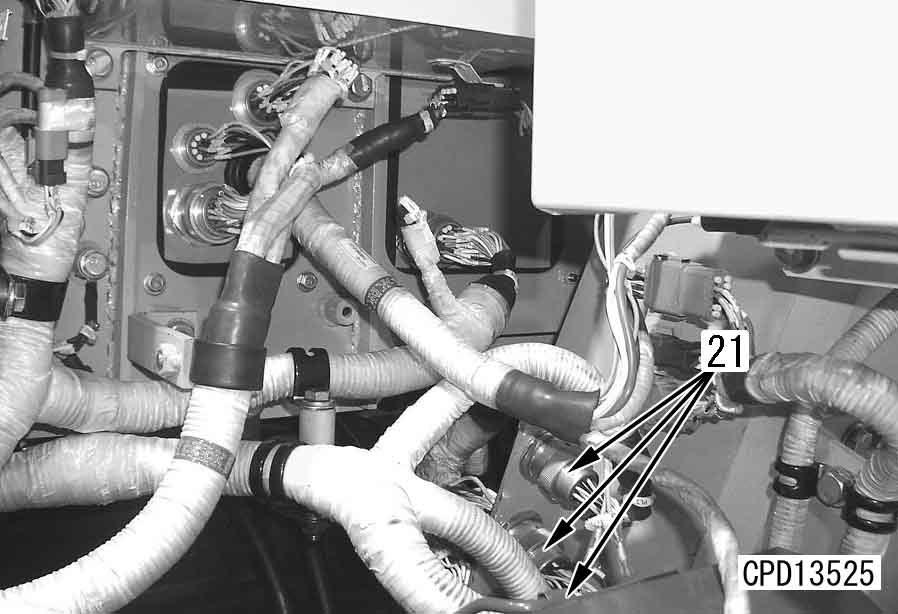

14.Remove engine lubricating oil pump hose (18), pump mounting bracket mounting bolts (19), and pump and bracket assembly (20). a Remove cables (21).

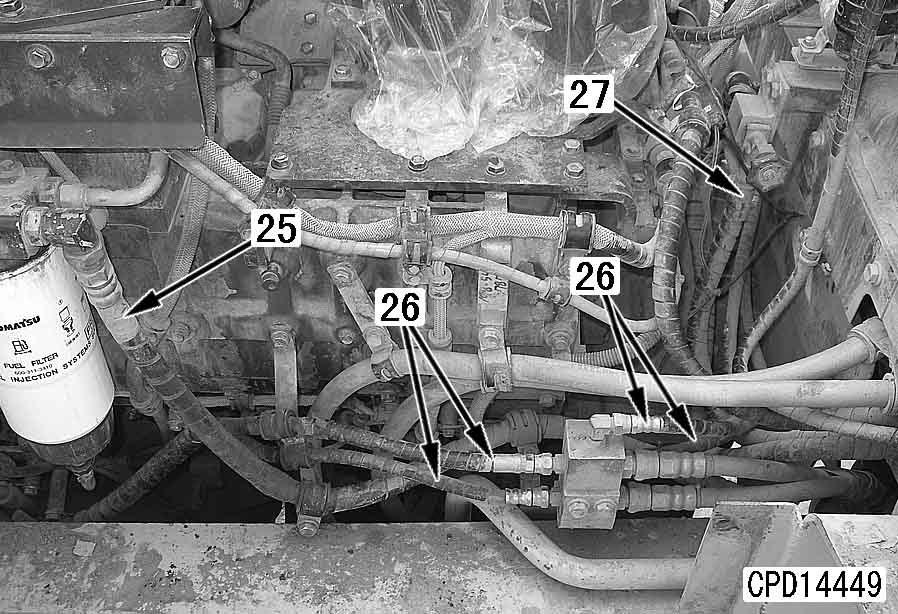

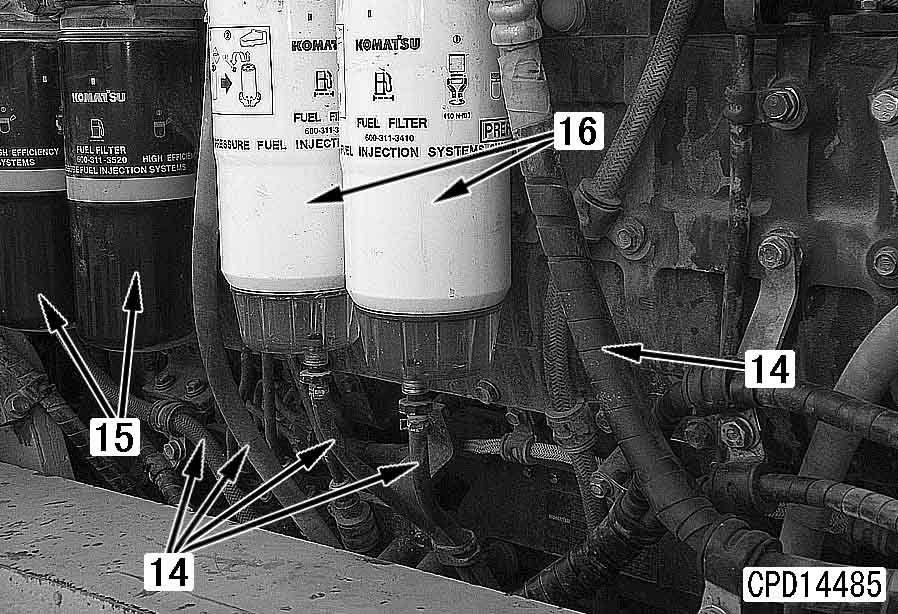

17.Disconnect fuel filter hose (25), 4 hoses (26) and heater hose (27) between the valve and engine.

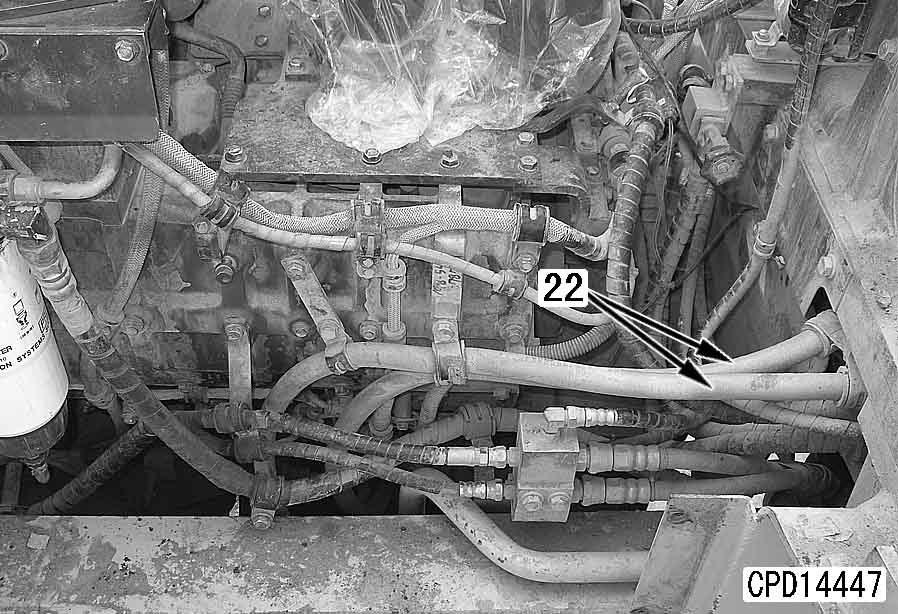

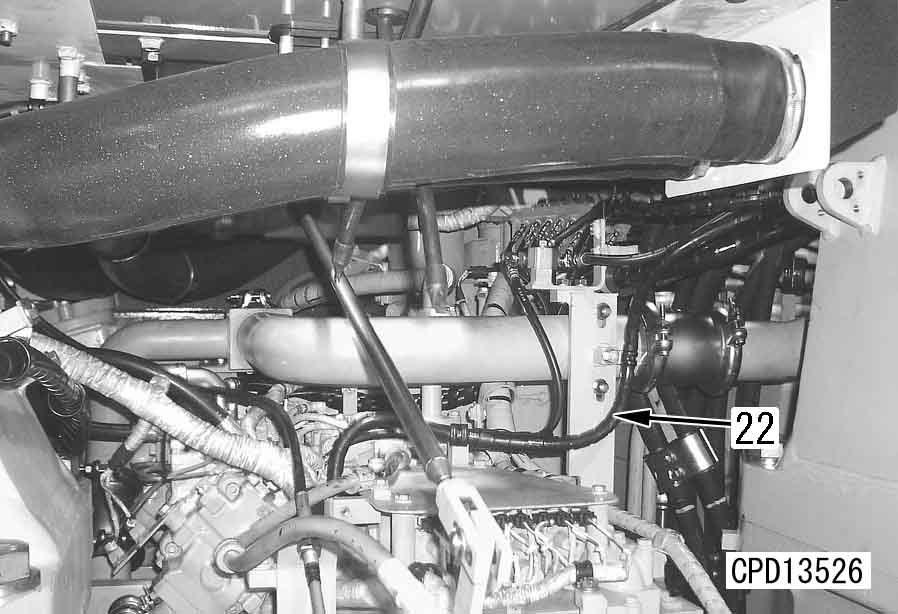

15.Remove cables (22) from the starting motor.

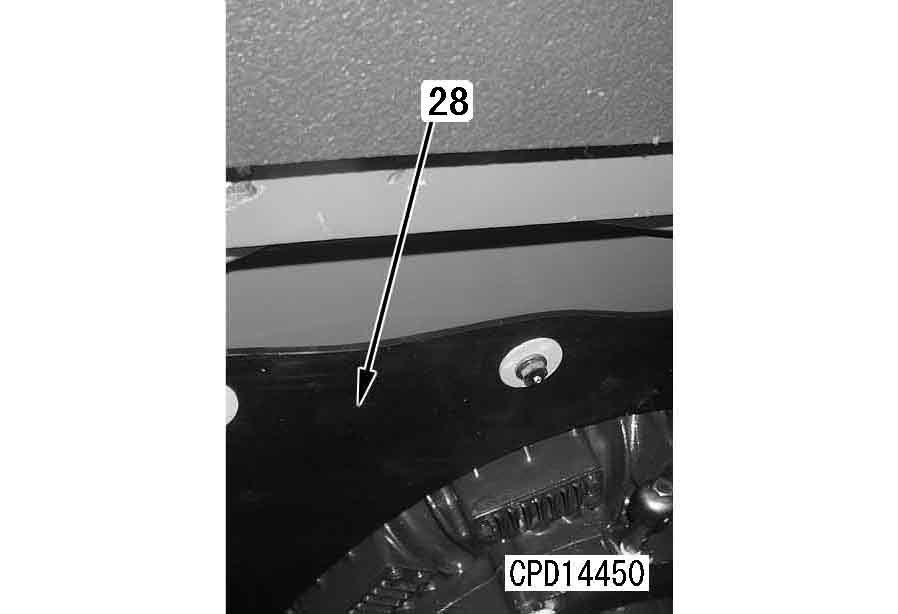

18.Remove damper rubber shield (28).

19.Sling universal joint (29), remove the mounting bolts, and lift off the universal joint.

4 Universal joint: 65 kg

Installation q Carry out installation in the reverse order to removal. q Refilling with coolant

Add coolant to the specified level, and run the engine to circulate the coolant through the system. Then check the coolant level again.

5 Coolant: 210 l

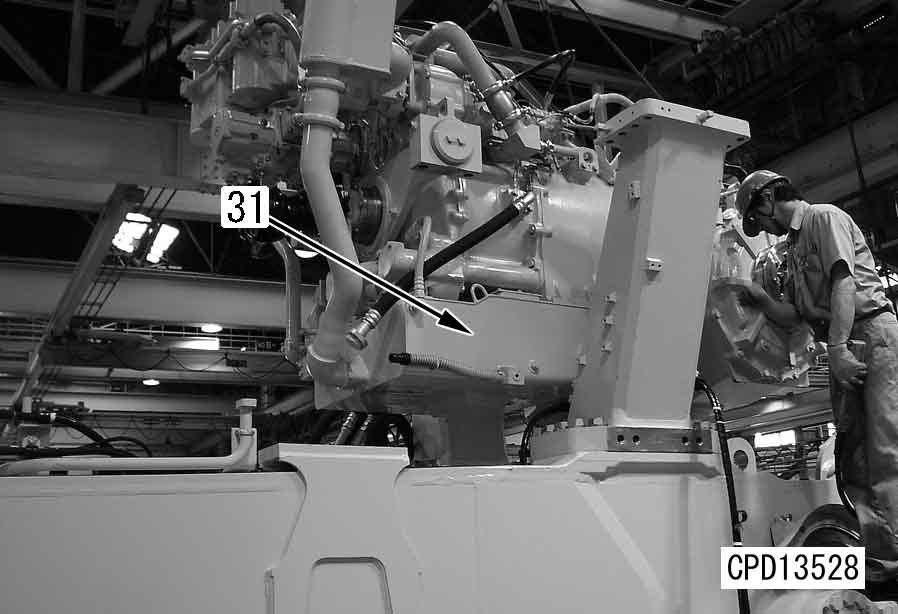

20.Remove front mounting bolt (30) and rear mounting bolt (31).

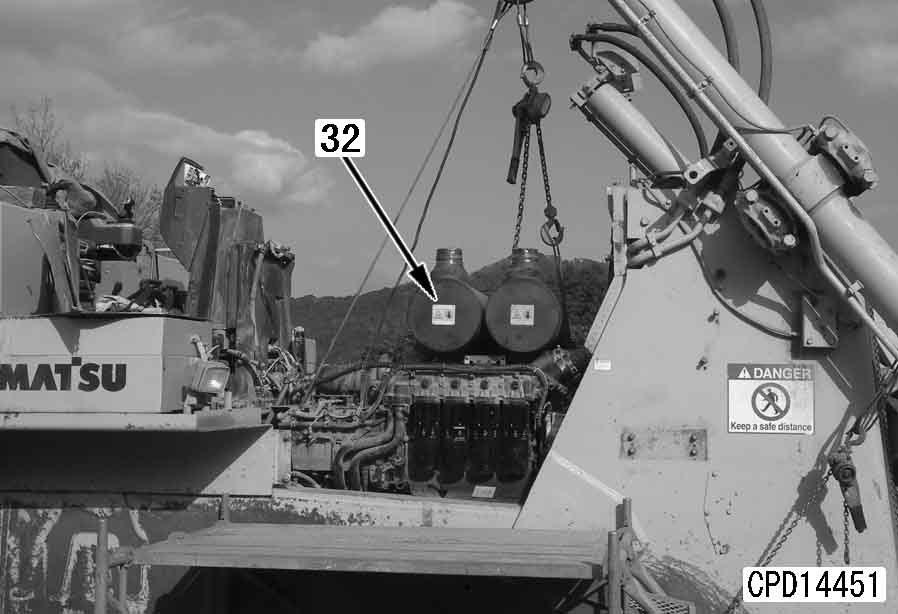

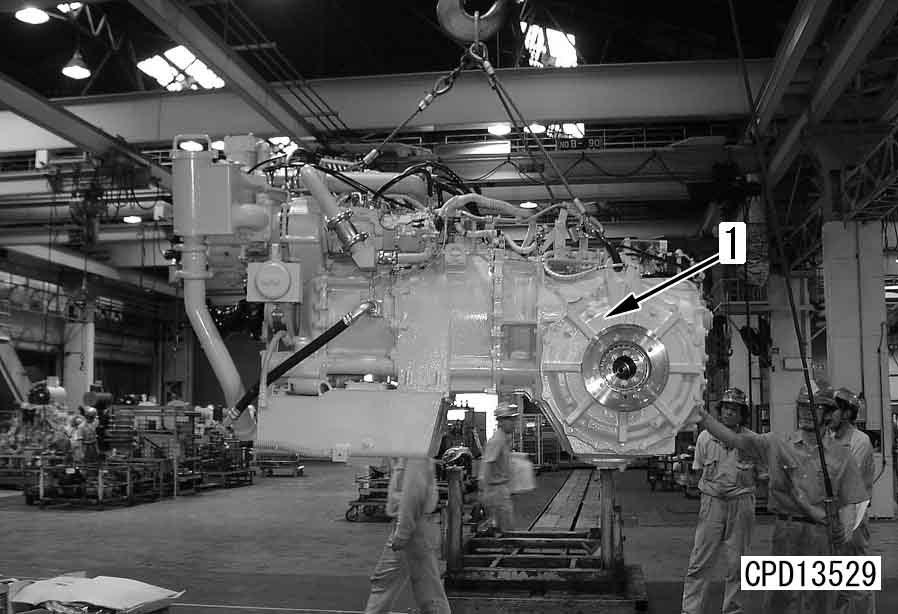

21.Remove engine assembly (32).

4 Engine assembly: 3,900 kg a When removing the engine assembly, check that all the wirings and pipings are disconnected and the engine assembly does not interfere with other parts.

D475A, D475ASD-5E0

Removal and installation of radiator assembly 1

Removal

1.Drain the coolant.

6 Coolant: 210 l

2.Remove right and left potentiometer wiring grommets (1) from the cover.

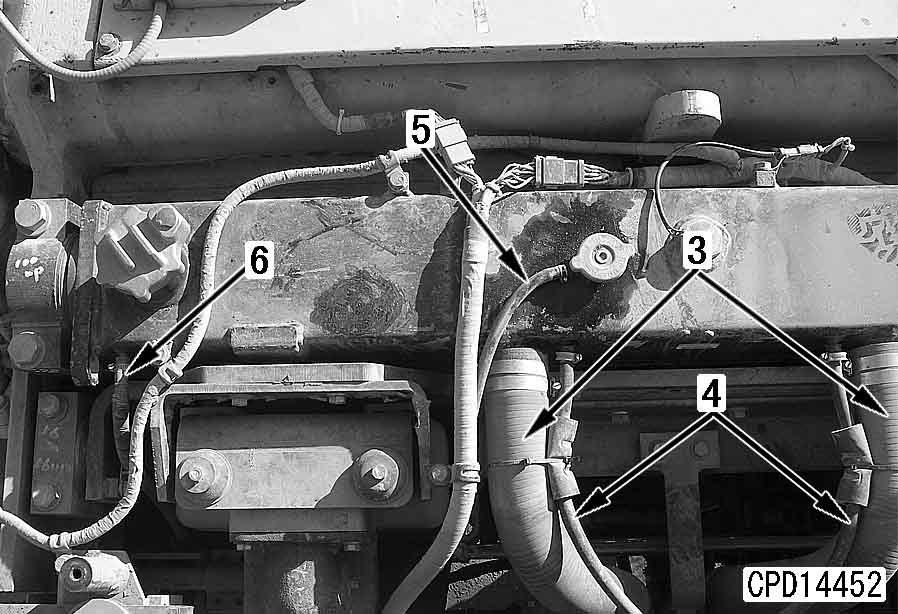

4.Disconnect radiator inlet hoses (3) (right and left) and aeration hoses (4) (right and left).

5.Disconnect sub-tank hose (5).

6.Disconnect power line cooler aeration hose (6).

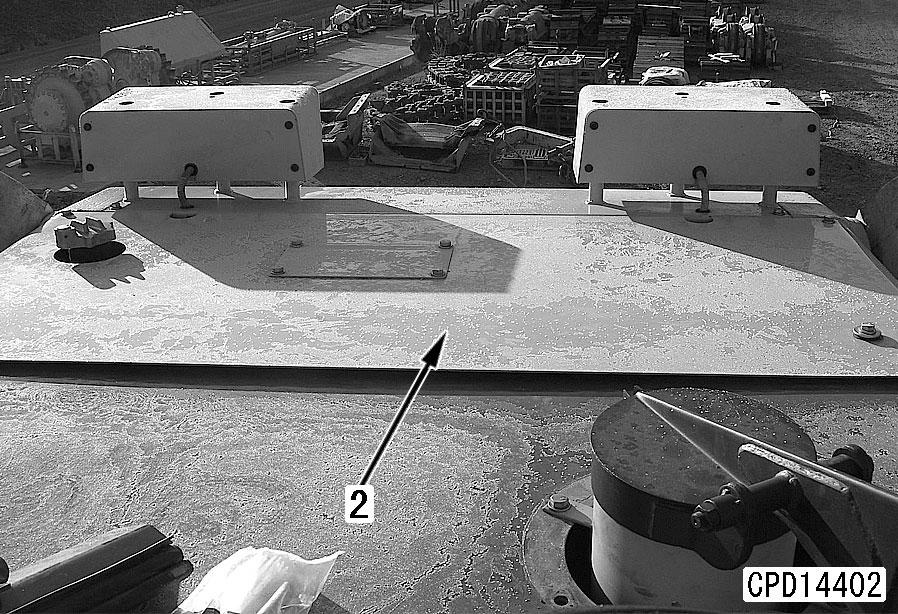

3.Lift off radiator upper cover (2).

4 Radiator upper cover assembly: 85 kg a Remove the fan motor assembly. For details, see "Removal and installation of fan motor assembly". a When removing the radiator assembly, take care not to damage its core.

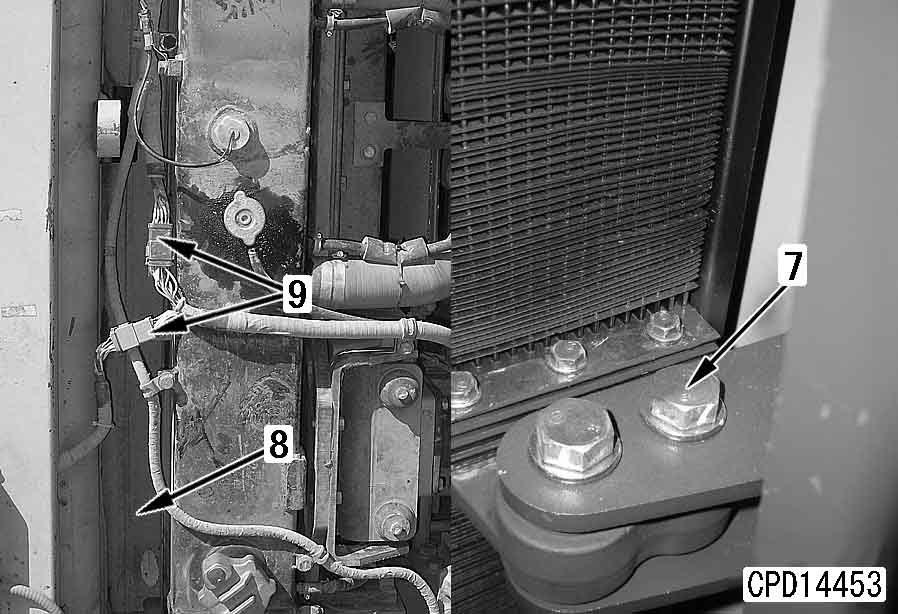

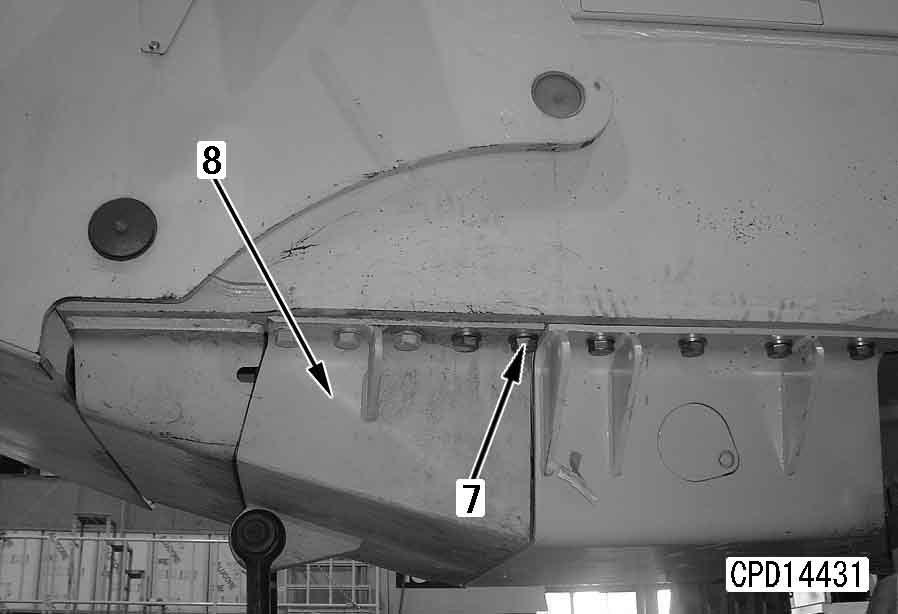

7.Remove isolator bolts (7) (2 each on the right and left sides).

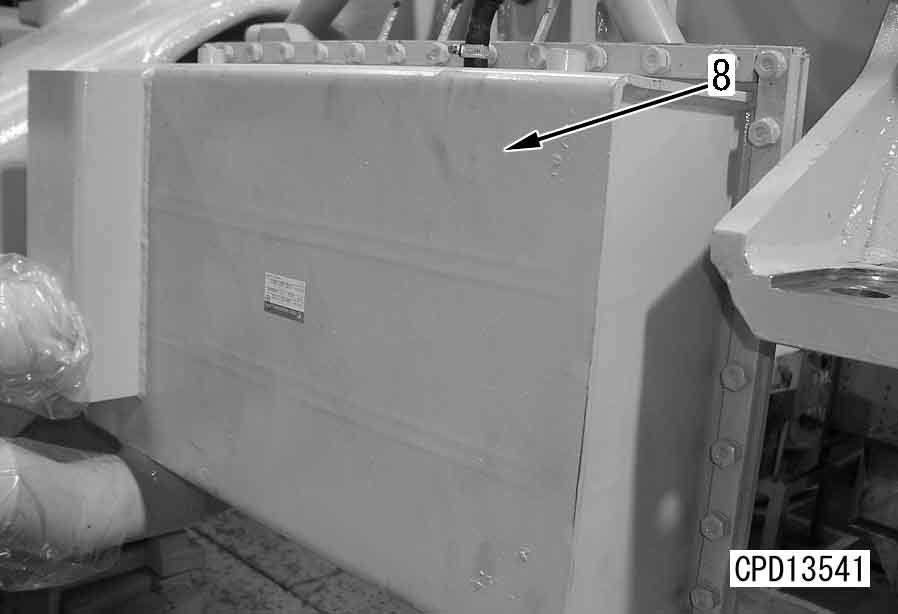

8.Remove wind breaker panels (8) (upper, lower, right and left).

9.Disconnect headlamp connectors (9).

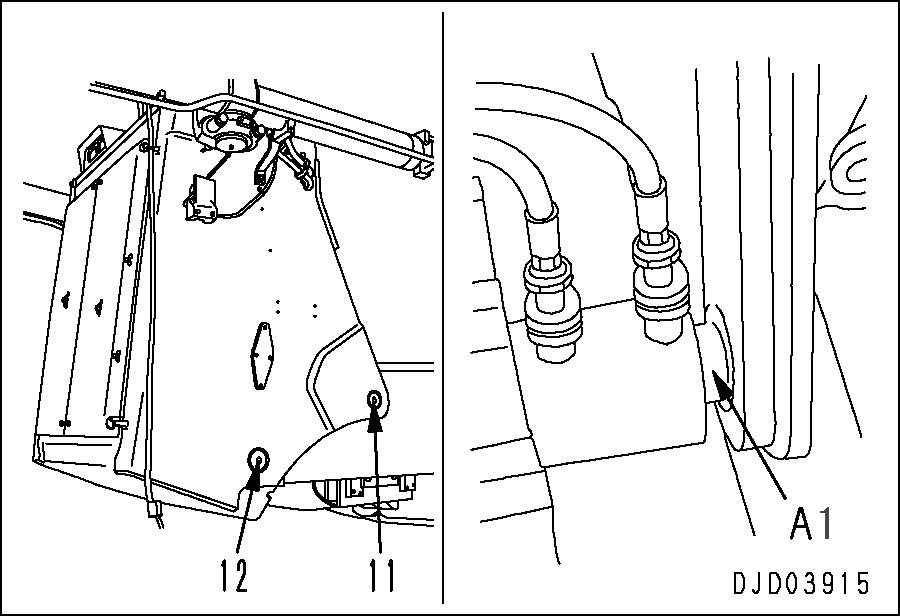

10.Disconnect radiator upper wiring harness (10) and radiator coolant level sensor connector (11).

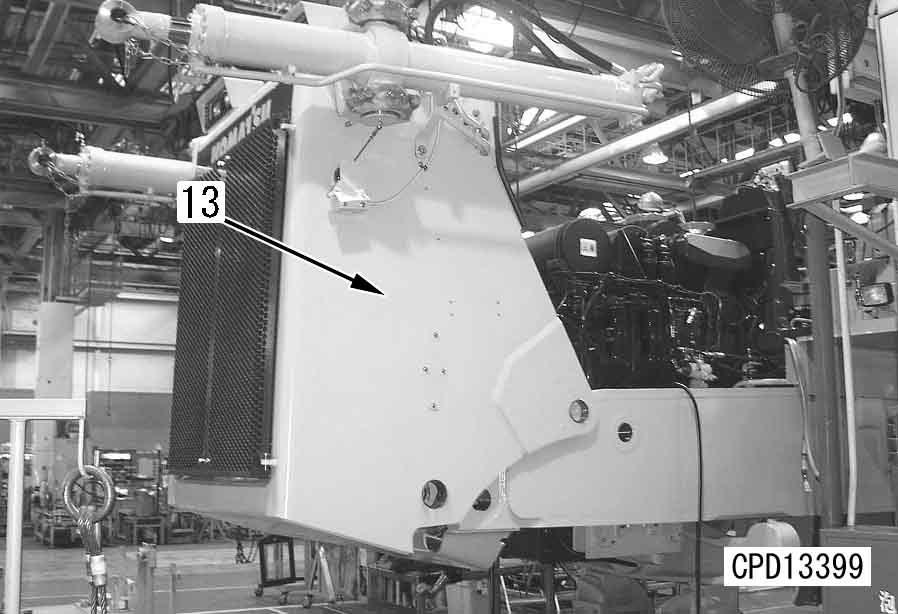

11.Sling radiator assembly (12) and remove upper mounting bolts (13) (2 each on the right and left sides).

13.Remove tube (15).

14.Lift off lower mounting bolts (16) (right and left).

15.Lift off radiator assembly (12).

4 Radiator assembly: 485 kg

12.Remove

D475A, D475ASD-5E0

Installation q Carry out installation in the reverse order to removal. q Refilling with coolant

Add coolant through the coolant filler to the specified level. Run the engine to circulate the coolant through the system. Then, check the coolant level again.

5 Coolant: 210 l

Removal and installation of aftercooler assembly 1

Removal

1.Remove right and left potentiometer wiring grommets (1) from the cover.

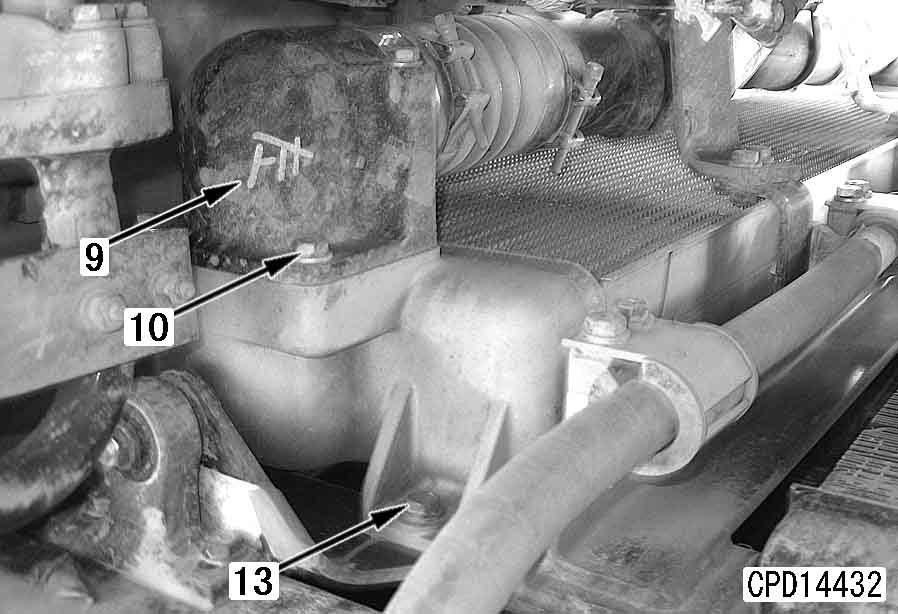

3.Disconnect radiator upper clamp (3) and aftercooler upper clamp (4).

4.Remove mounting bolt (6) of aftercooler upper pipe (5).

2.Lift off radiator upper cover (2). 4 Radiator upper cover assembly: 85 kg

5.Remove lower cover bolts (7) and open lower cover (8).

6.Remove mounting bolt (10) of aftercooler lower pipe (9) and aftercooler lower mounting bolt (13).

7.Sling aftercooler (11) and remove upper mounting bolts (12).

8.Move aftercooler upper pipe (5) and lower pipe (9) toward the engine and lift off aftercooler (11), taking care that the aftercooler will not interfere with the pipes.

Removal and installation of radiator guard assembly 1

Special tools

Symbol

790-431-1120Adapter t 1

791-520-4140Screw t 1

791-181-1020Sleeve t 1

791-765-1150Plate t 1

791-112-1180Nut t 1

790-101-2540Washer t 1

790-101-2102 Puller (294 kN {30 ton}) t 1

790-101-1102Pump t 1

Removal

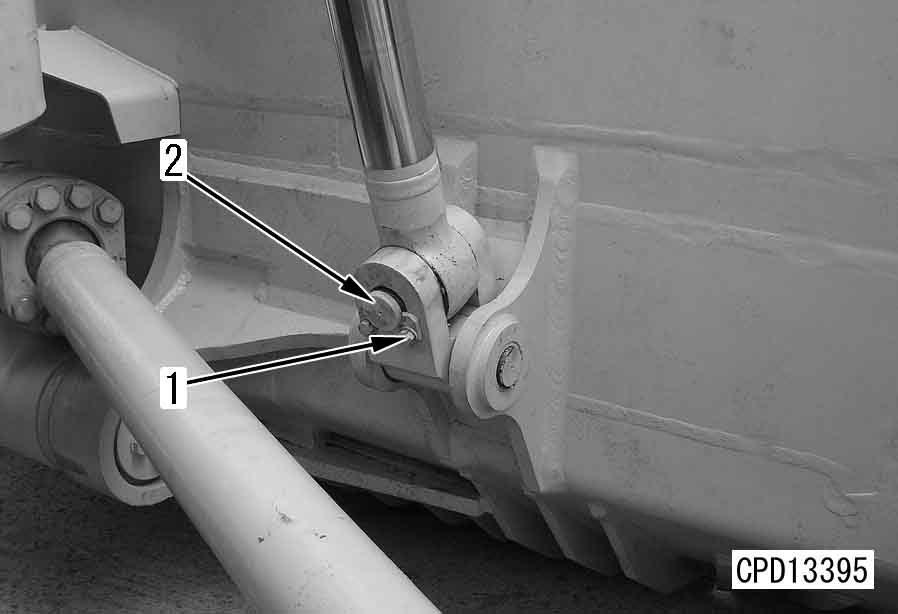

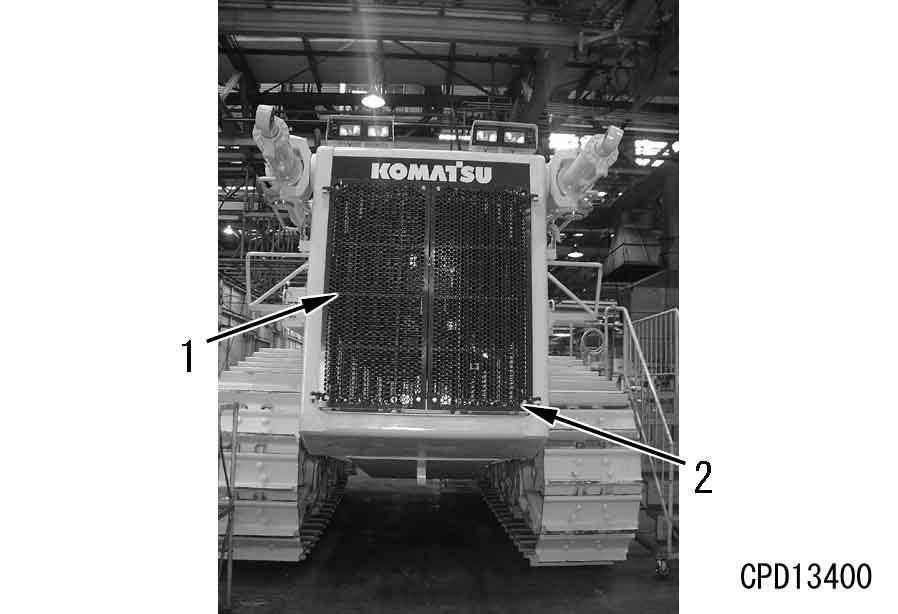

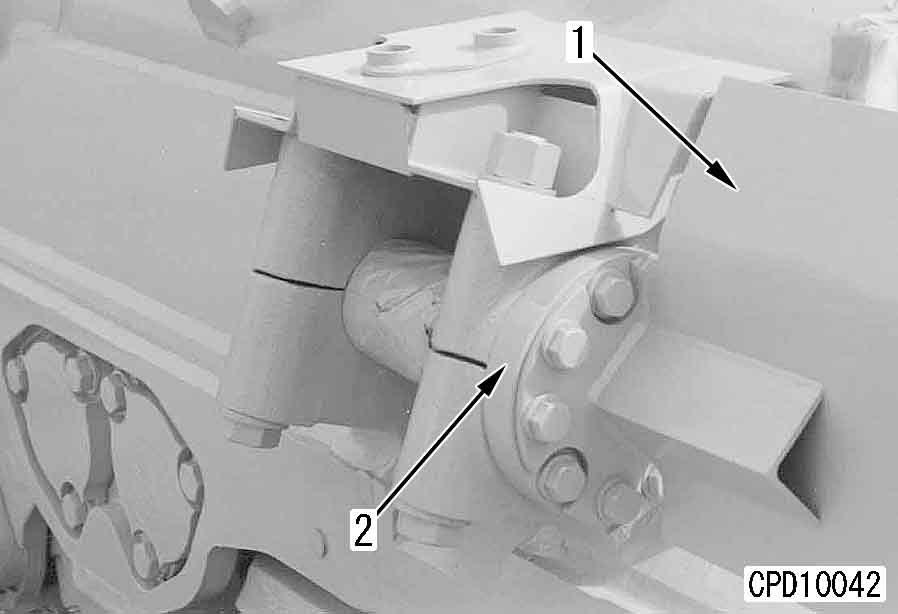

1.Remove lock plate (1) of the lift cylinder rod pin, then remove pin (2).[*1] a Start the engine and retract the piston rod fully, then tie the piston rod with wire to prevent it from coming out. a Tie the piston rod on the opposite side in the same way.

3.Sling blade lift cylinder assembly (4), then fit cylinder holder tool and secure to radiator guard.

4.Drain coolant.

6 Coolant: 210 l k Release the remaining pressure from the hydraulic circuit. For details, see Testing and adjusting, Releasing residual pressure from work equipment circuit. a Fit a cover to prevent dirt from entering the piping.

2.Remove hood assembly.

For details, see "Removal and installation of hood assembly".

Remove engine side covers (left and right).

5.Disconnect radiator inlet and outlet hoses, aeration hose, and wiring harness clip. For details, see "Removal and installation of radiator assembly".

6.Disconnect hydraulic cooler hose (5). Disconnect fan motor hose (6).

7.Disconnect

Installation q Carry out installation in the reverse order to removal.

[*1] a Standard shim thickness: 4 mm q Refilling with coolant

Add coolant to the specified level, and run the engine to circulate the coolant through the system. Then check the coolant level again.

5 Coolant: 210 l

Removal and installation of fuel tank assembly 1

Removal

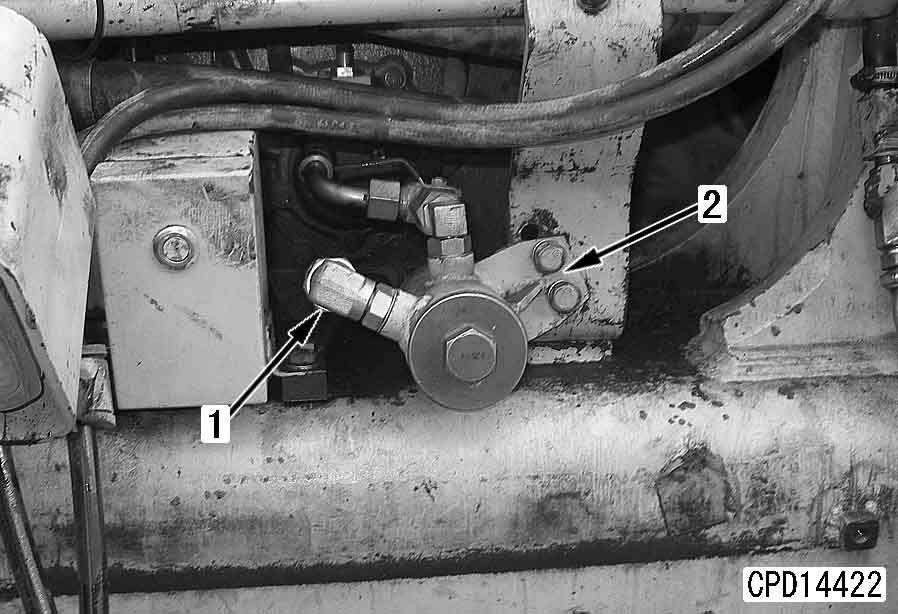

1.Disconnect hose (1). a Before disconnecting the hose, close the fuel valve.

2.Remove case (2).

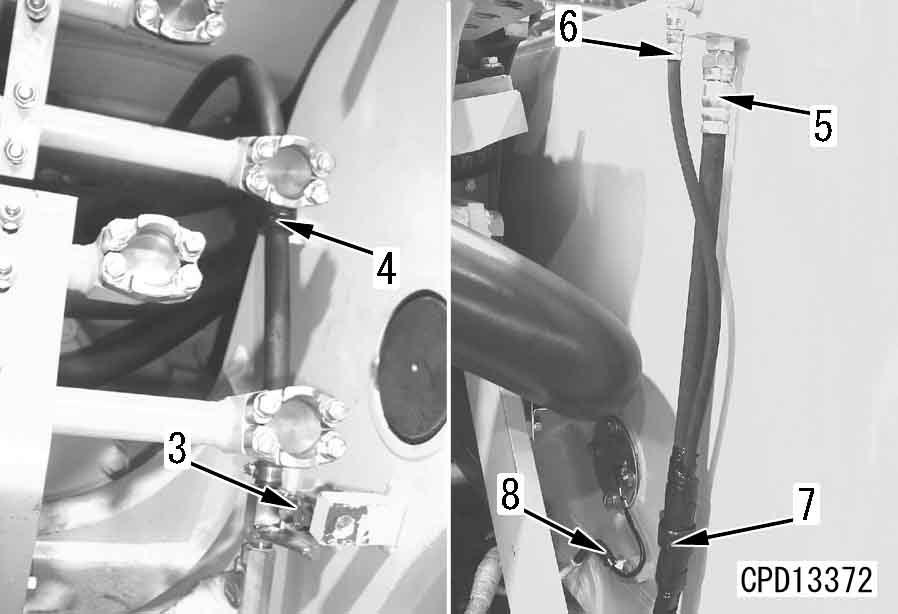

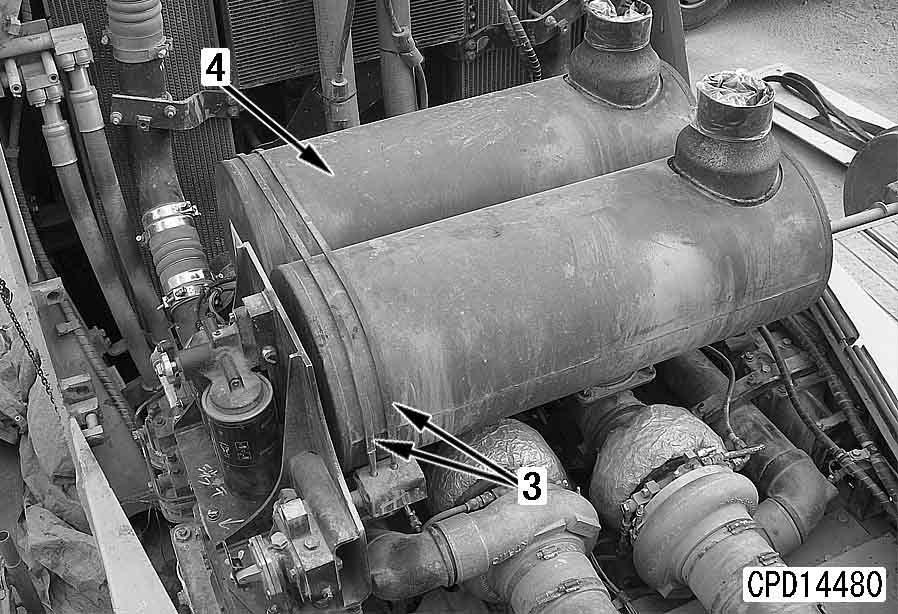

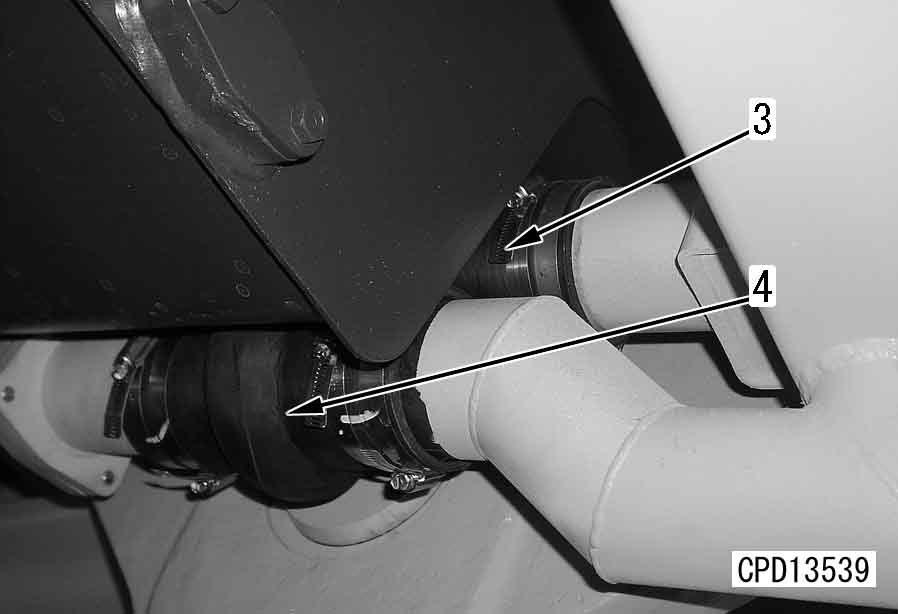

3.Remove joint (3) and hose clamp (4).

4.Disconnect fuel return hoses (5) and (6), and remove hose clamp (7).

5.Disconnect fuel gauge wiring connector (8).

6.Remove fuel tank mounting bolt (9).

7.Lift off fuel tank assembly (10).

4 Fuel tank assembly (when full): 2,335kg

Installation q Carry out installation in the reverse order to removal.

Removal and installation of engine hood assembly 1

Removal k Disconnect the cable from the negative (–) terminal of the battery.

1.Remove right and left potentiometer wiring grommets (1) from the cover.

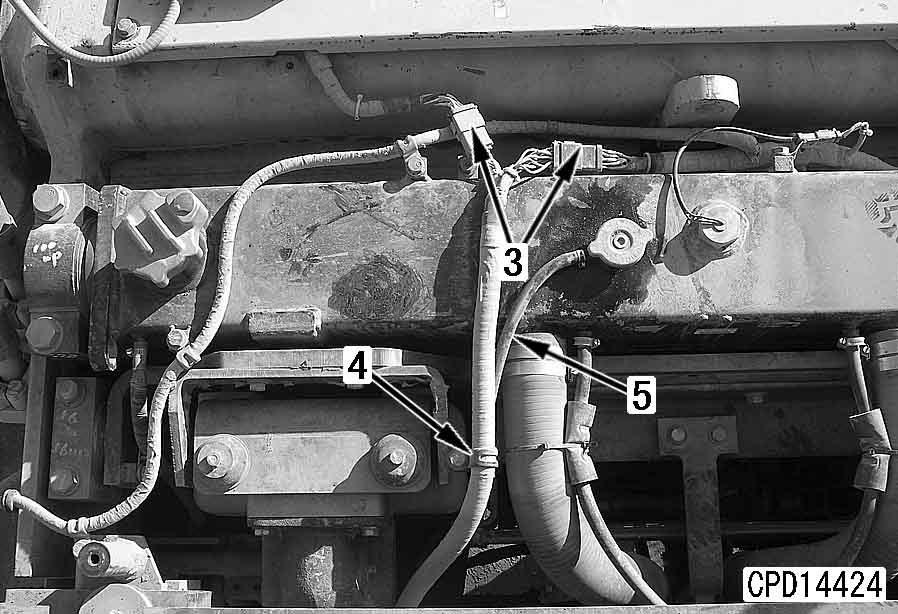

3.Disconnect wiring connectors (3) (201 and 209) and remove clamp (4).

4.Disconnect hose (5) to the sub-tank and remove hose clamp (4).

2.Lift off radiator upper cover (2). 4 Radiator upper cover assembly: 85 kg

5.Open right and left covers (6) and (7).

6.Remove right and left side covers (8).

7.Loosen clamps (9) and disconnect air cleaner hoses (10).[*1]

8.Remove sub-tank drain hose clamp (11).

12.Lift off hood assembly (18). 4 Hood assembly: 600 kg

Installation q Carry out installation in the reverse order to removal.

Hose inserted length: Min. 40 mm 3 Hose clamp: 8.83 ± 0.5 Nm {0.9 ± 0.05 kgm}

Removal and installation of fan drive assembly 1

Removal

1.Drain the hydraulic oil.

6 Hydraulic tank: Approx. 340 l

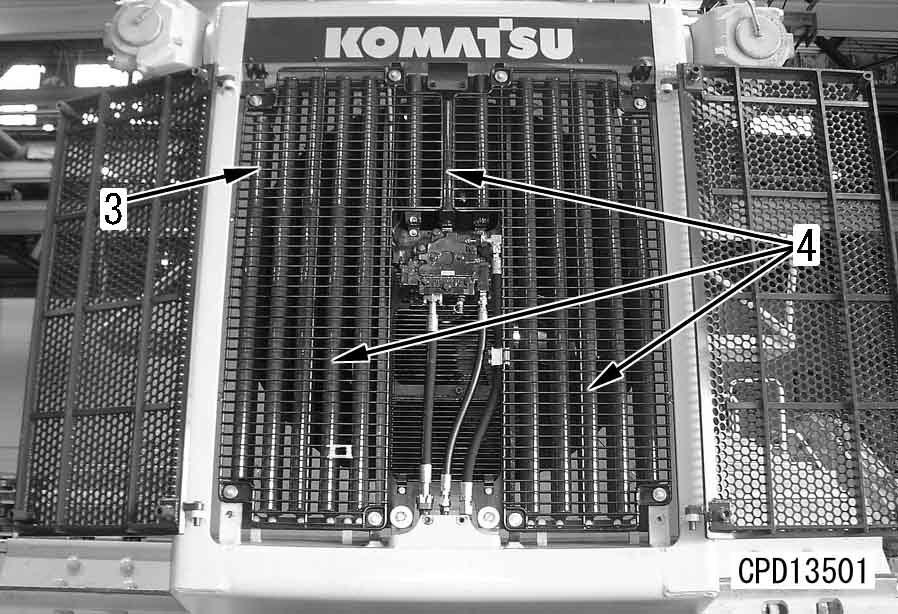

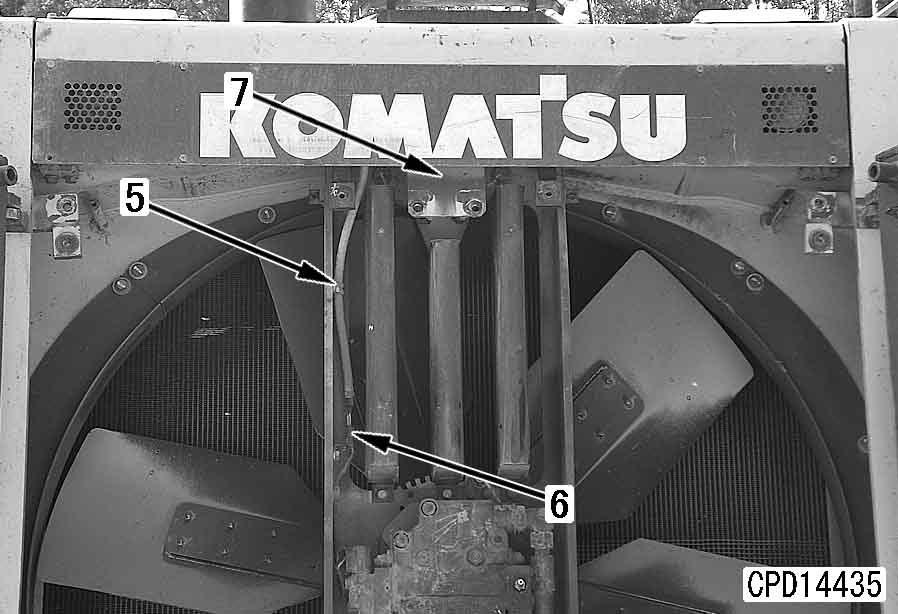

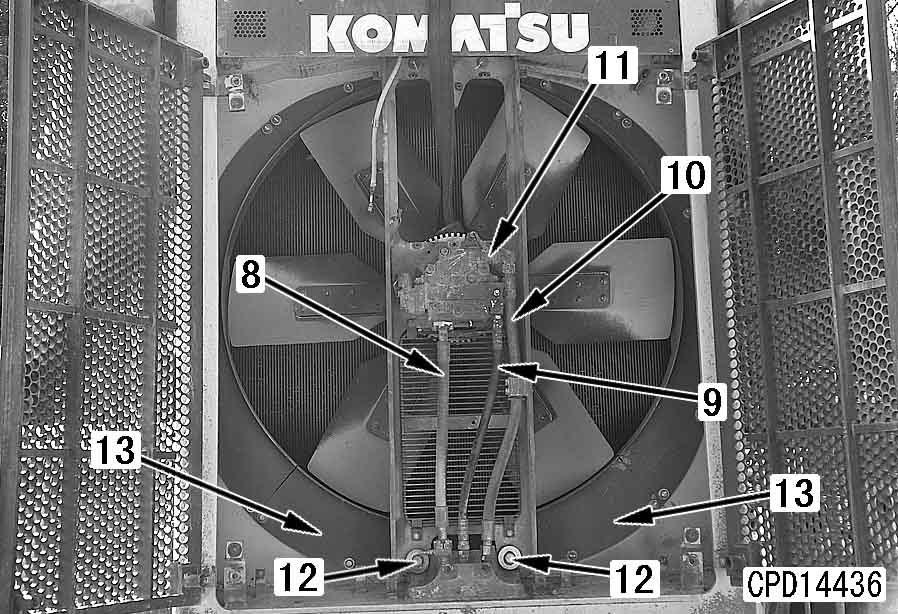

2.Remove 8 mounting bolts (2) of radiator mask (1) and open the radiator mask.

5.Remove wiring harness clamp (5) and disconnect connector (6).

6.Bracket (7).

3.Remove net (3).

4.Remove fan blade (4).

7.Disconnect fan motor hoses (8), (9) and (10).

8.Sling fan drive assembly (11) and remove bracket mounting bolts (12).

9.Lift off fan drive assembly (11). 4 Fan drive assembly: 250 kg a Loosen mounting bolts (13) of the lower right and left shrouds. a Move the fan to the position shown in the photo.

Installation q Carry out installation in the reverse order to removal. q Refilling with oil (Hydraulic tank)

Add oil through the oil filler to the specified level. Run the engine to circulate the oil through the system. Then, check the oil level again.

Removal and installation of fan motor assembly

Removal

1.Remove the fan drive assembly. For details, see "Removal and installation of fan drive assembly".

2.Remove the mounting bolt and lock plate (1). [*1]

3.Remove nut (2). [*2]

4.Remove fan (3).

5.Remove the 4 mounting bolts and fan motor assembly (4).[*3]

4 Fan motor assembly: 65 kg

Installation q Carry out installation in the reverse order to removal.

[*1]

Be sure to adjust the hole of lock plate (1) by turning nut (2) in the tightening direction.

[*2]

3 Mounting nut (2): 1,080 – 1,275 Nm {110 – 130 kgm} a After tightening the nut, check dimension (d) shown below. q MIN: 2.0 mm q MAX: 4.0 mm

[*3] a When fitting the fan motor and fan, clean and degrease them thoroughly.

D475A, D475ASD-5E0

D475ASD-5E0

Engine (SAA12V140E-3)

Removal and installation of fuel supply pump assembly

1

Removal of fuel supply pump on left bank side k Lower the work equipment to the ground and stop the engine. k Set the parking brake lever and work equipment lock lever in the lock position. k Disconnect the cable from the negative (–) terminal of the battery. a Do not remove the undercover.

1.Close the fuel valve under the fuel tank.

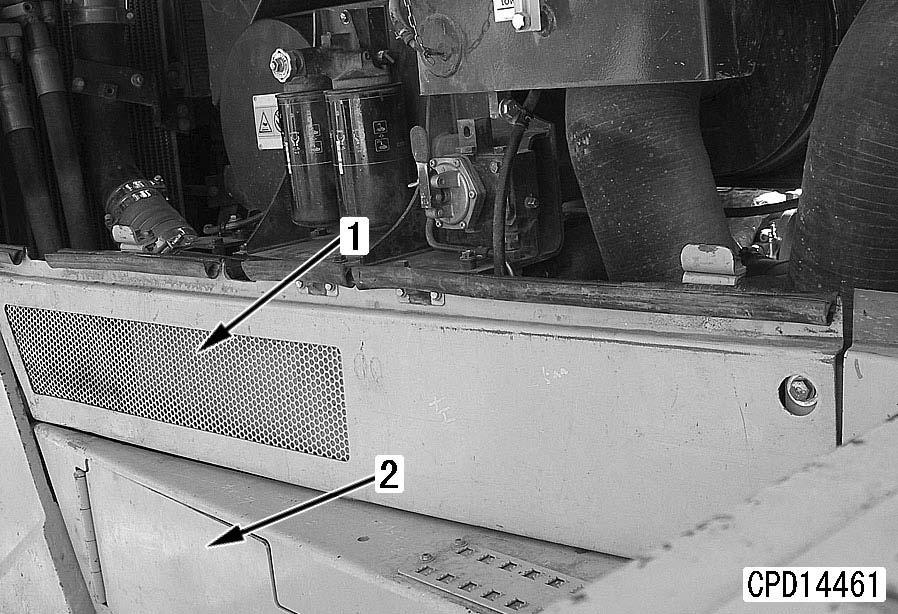

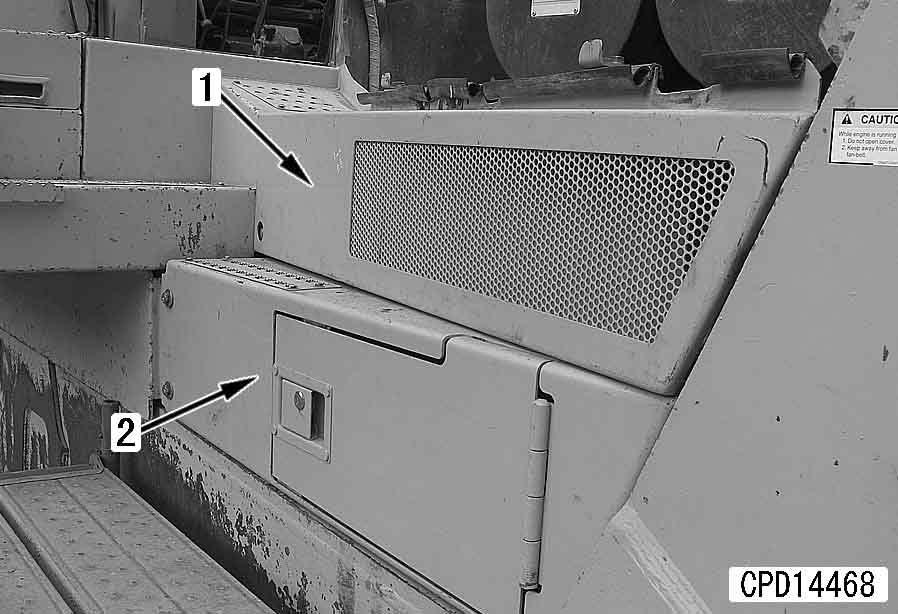

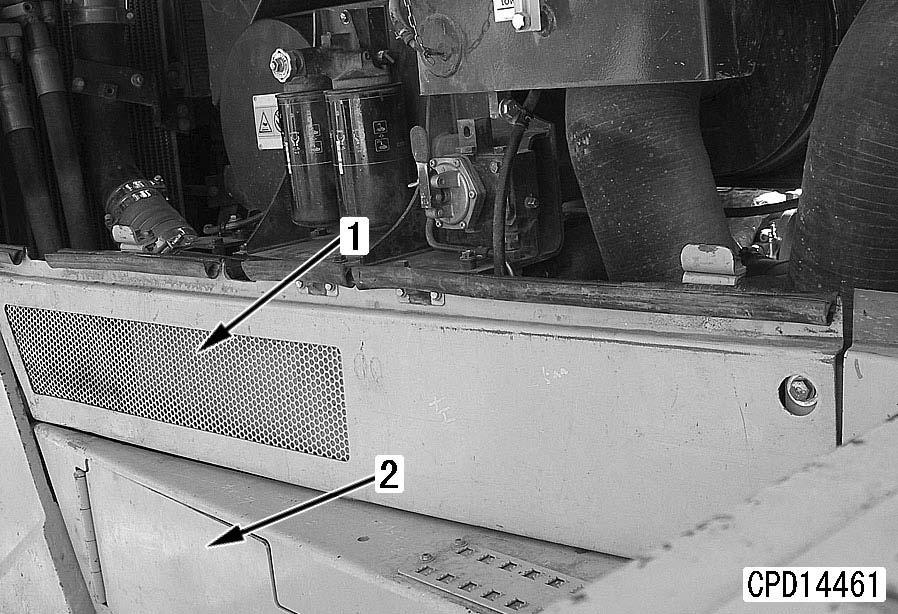

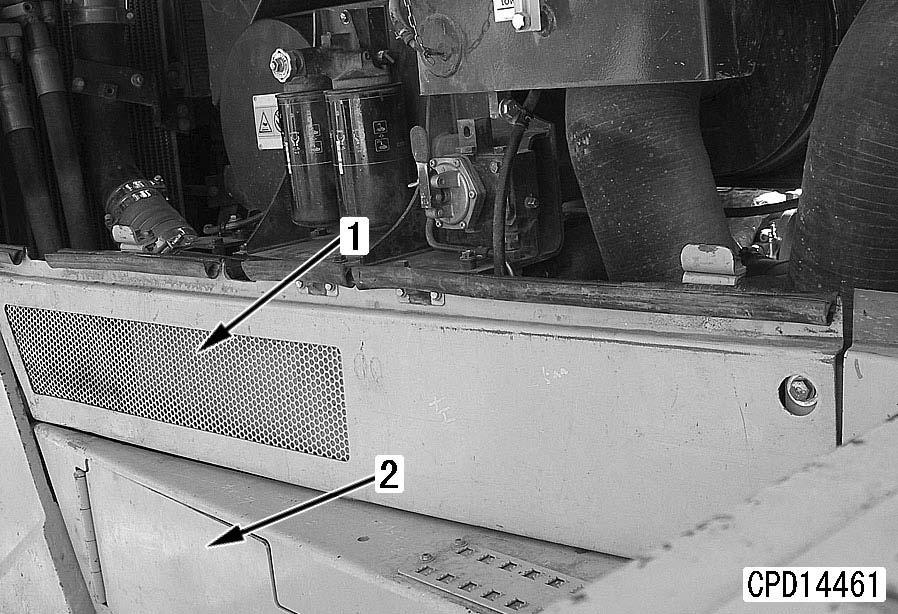

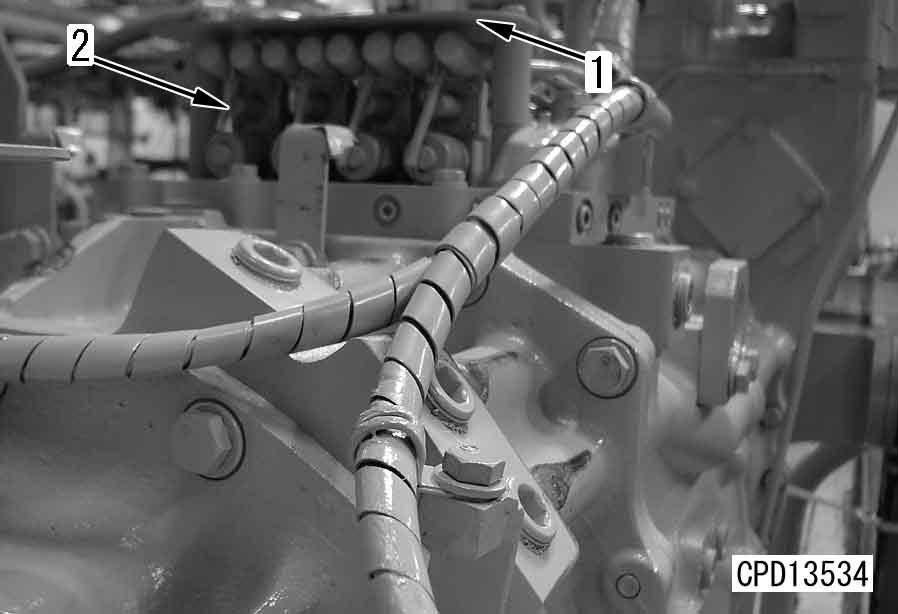

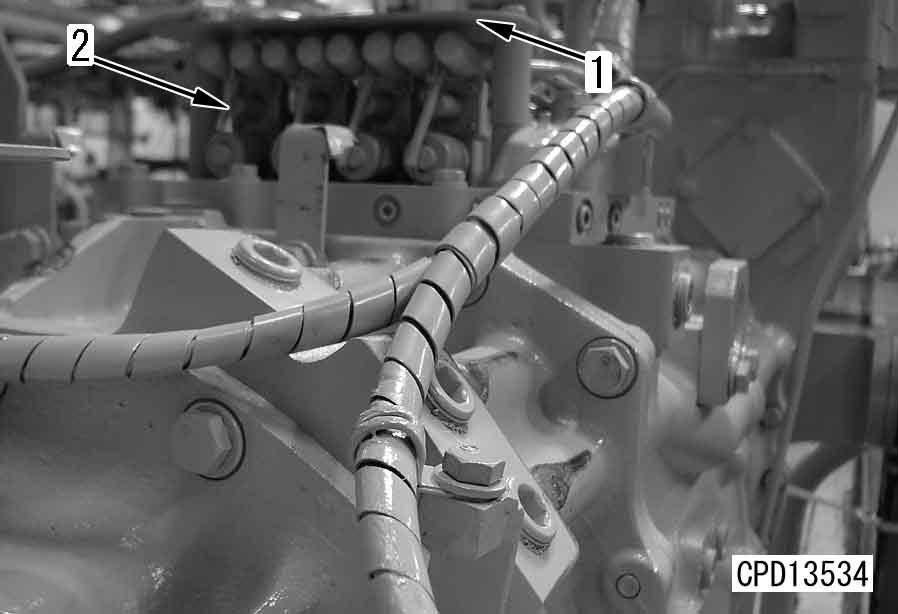

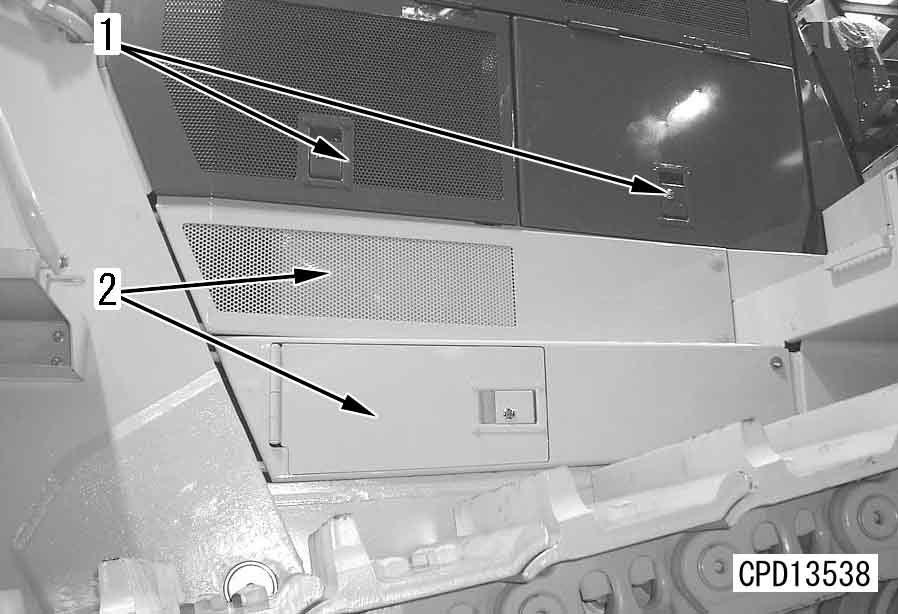

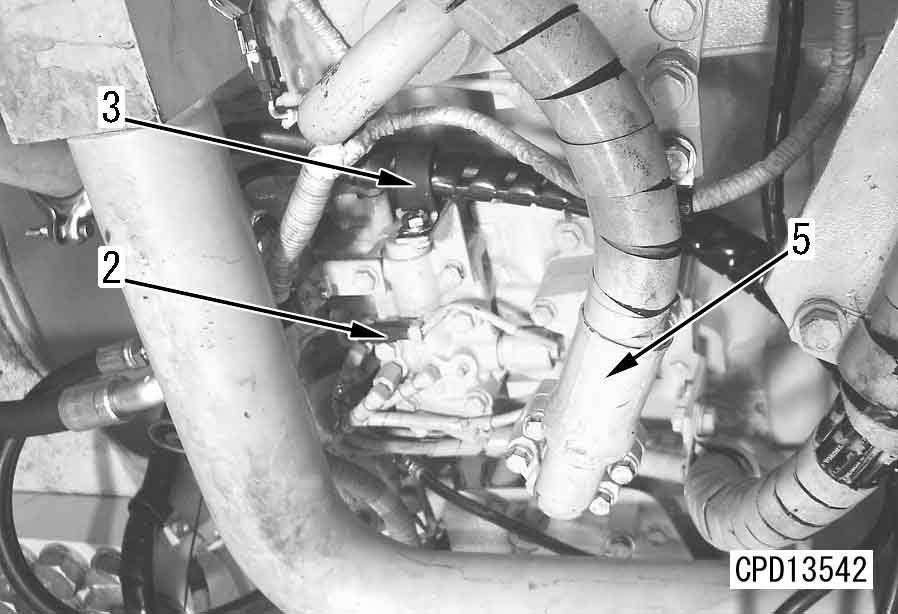

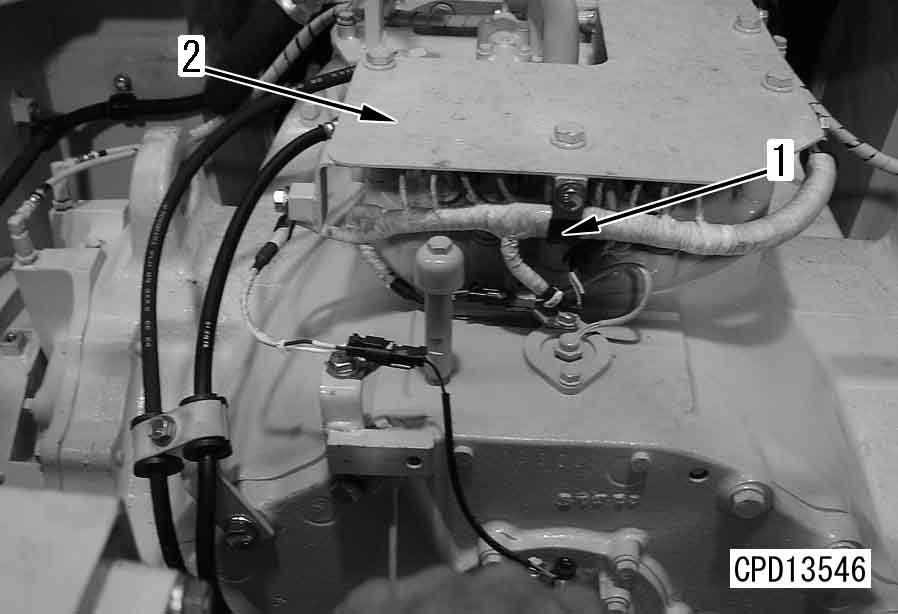

2.Remove left side cover (1) and left cover (2).

4.Remove fuel hose clamp (4) and bracket (5).

1

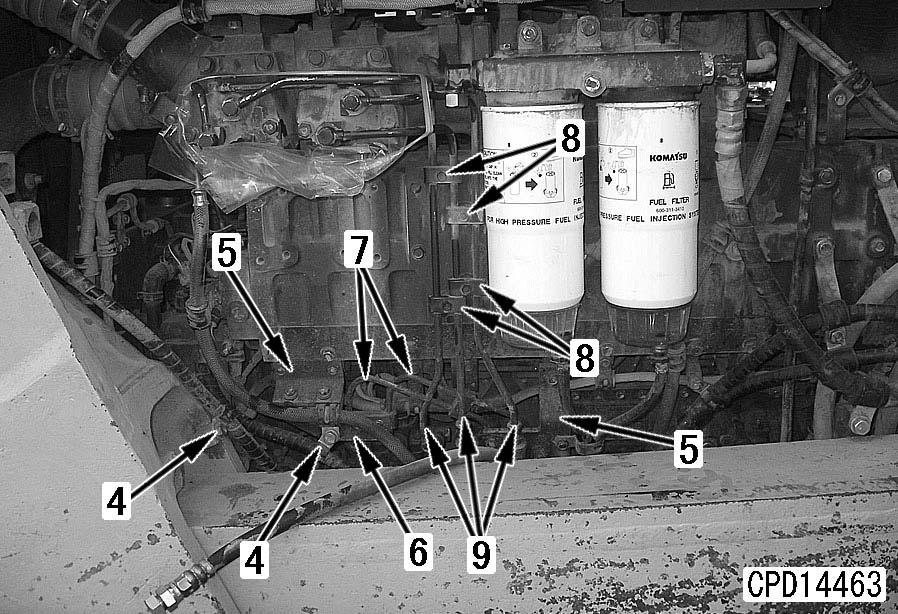

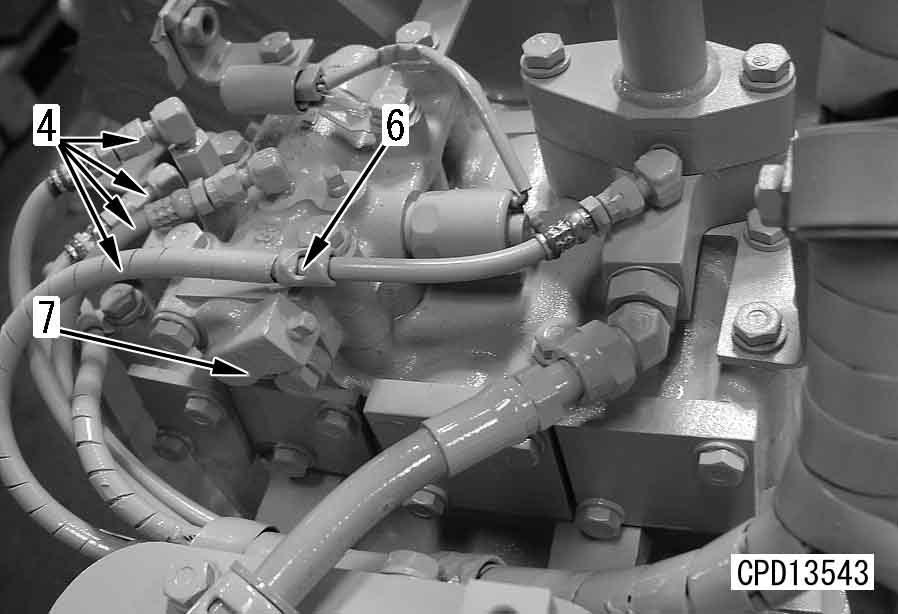

5.Remove high-pressure pipe clamp (6) and high-pressure pipe (7).

6.Remove clamp (8) and fuel tube (9). [*1]

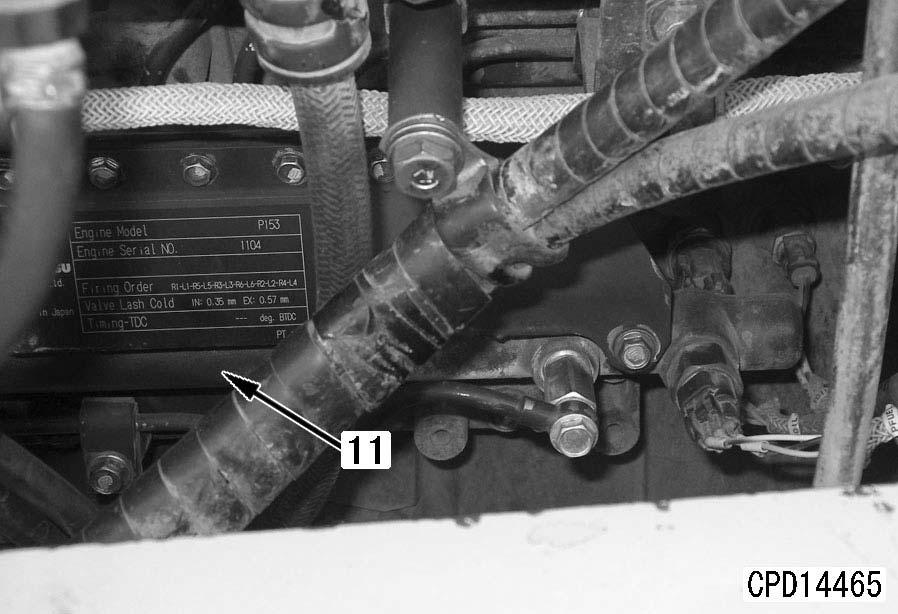

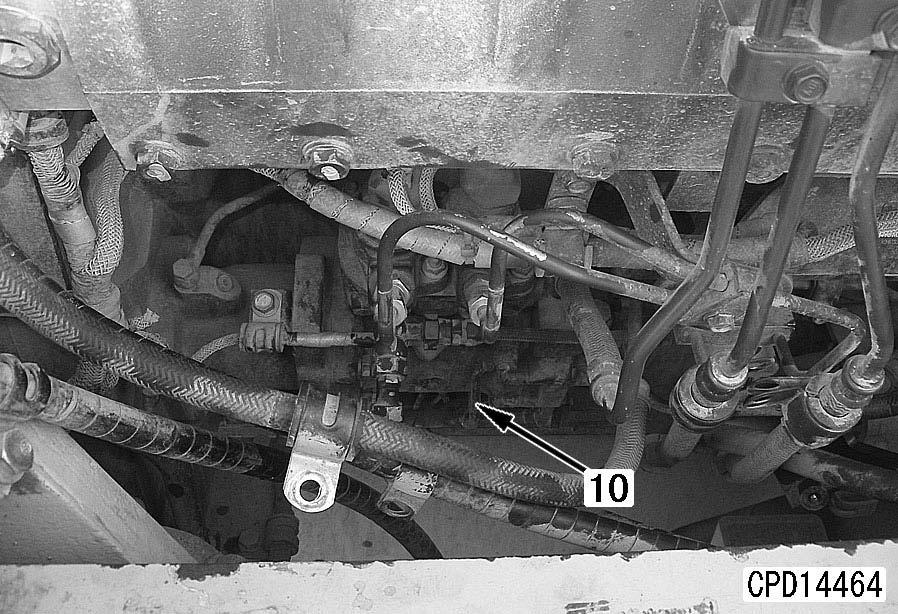

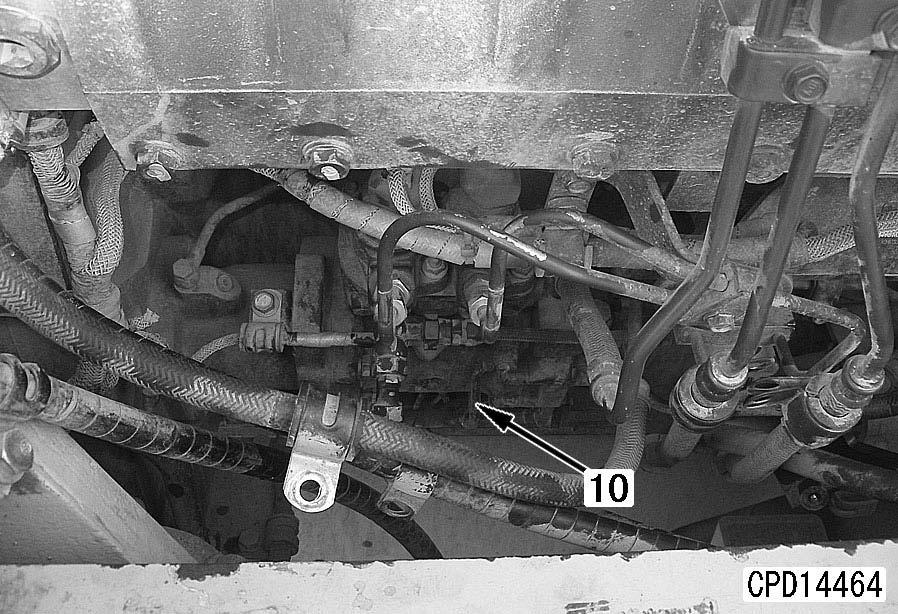

7.Remove lubrication tube (10).

9.Disconnect wiring connectors (12). a Connectors: PCV1, PCV2 and G

Removal of fuel supply pump on right bank side k Lower the work equipment to the ground and stop the engine. k Set the parking brake lever and work equipment lock lever in the lock position. k Disconnect the cable from the negative (–) terminal of the battery. a Do not remove the undercover. a Wind a rope around the fuel supply pump and sling it. a Remove the high-pressure pipe clamp just under the fuel supply pump without fail.

1.Close the fuel valve under the fuel tank.

2.Remove right side cover (1) and right cover (2).

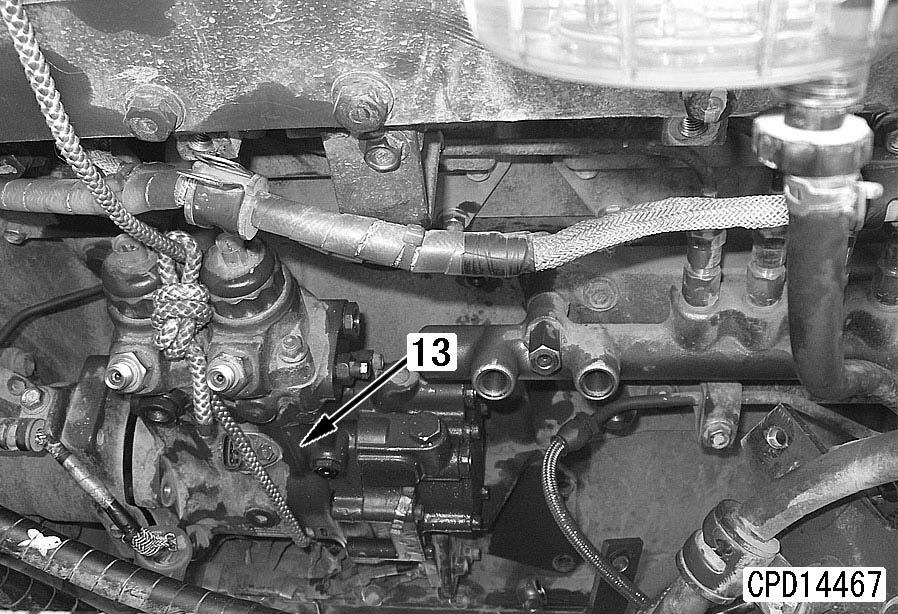

10.Remove the mounting bolts of fuel supply pump assembly (13) and pull out the fuel supply pump assembly and mounting bracket together.

4 Left fuel supply pump assembly: 17 kg a After the fuel supply pump is removed, the coupling on the drive case moves out of position. Accordingly, rotate the crankshaft to set the drive case in position when installing the fuel supply pump.

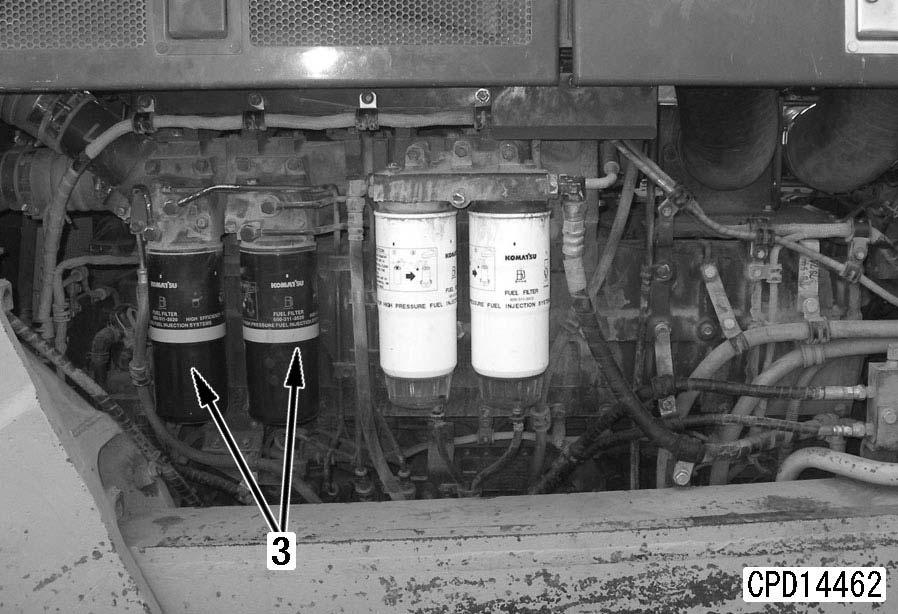

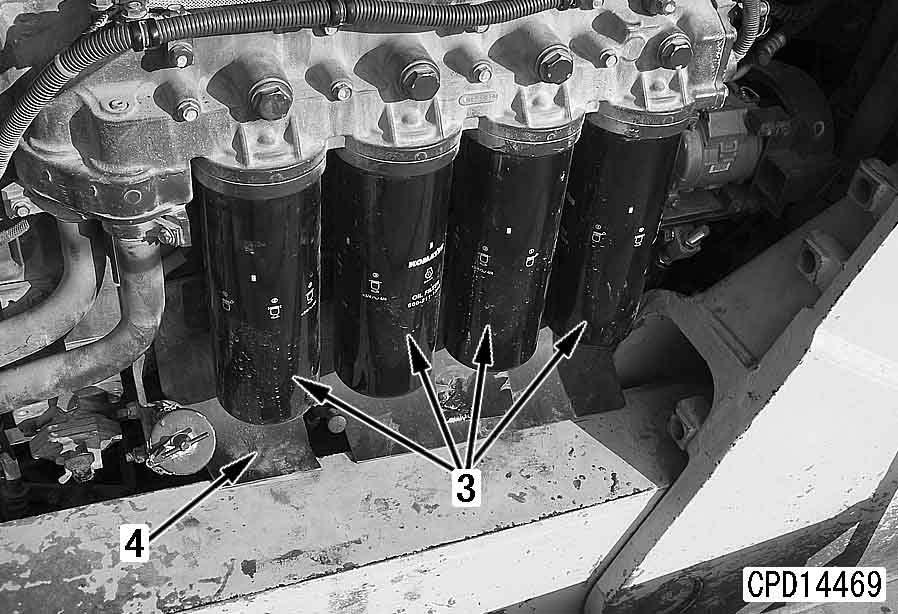

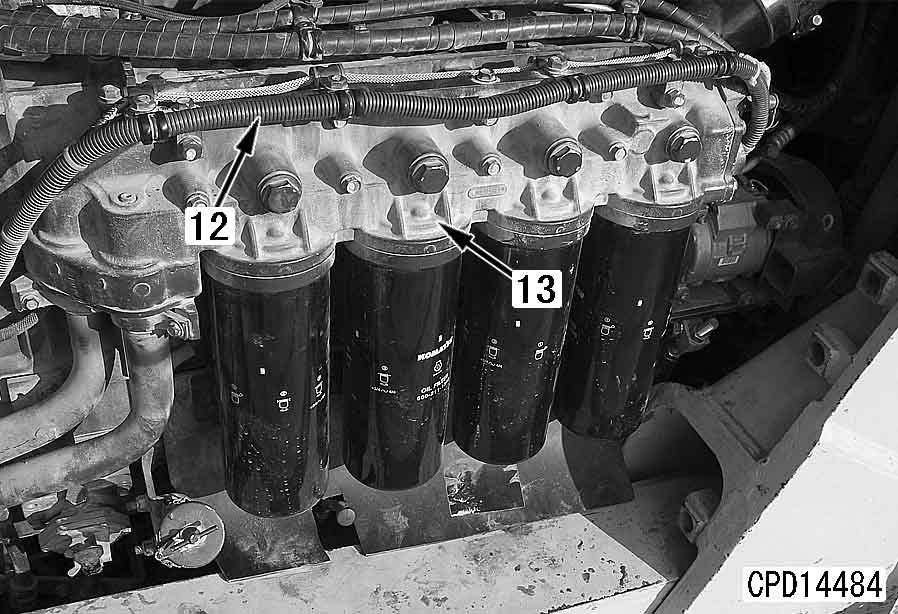

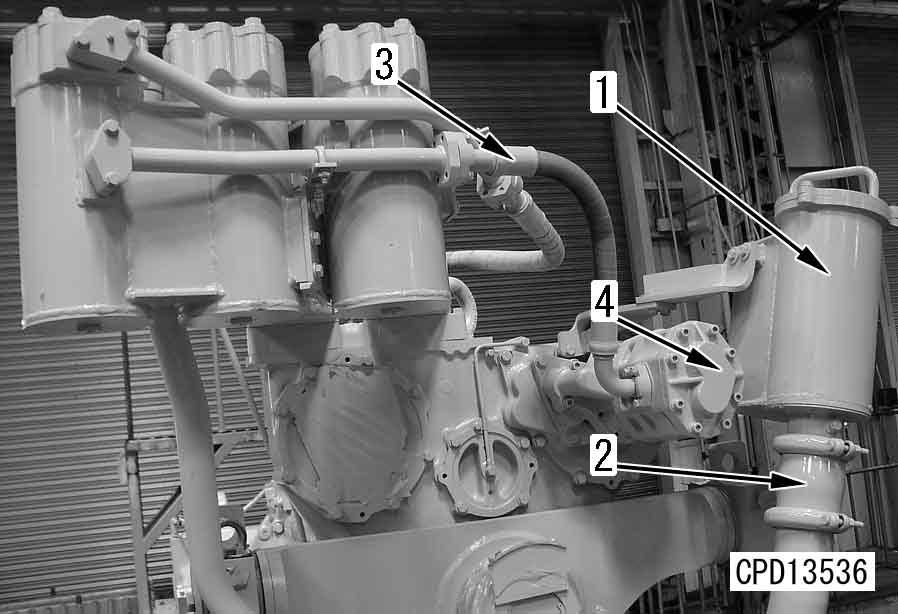

3.Remove 4 engine oil filters (3). a Use a filter wrench etc. to remove the filters.

4.Remove heat insulation plate (4).

D475A, D475ASD-5E0

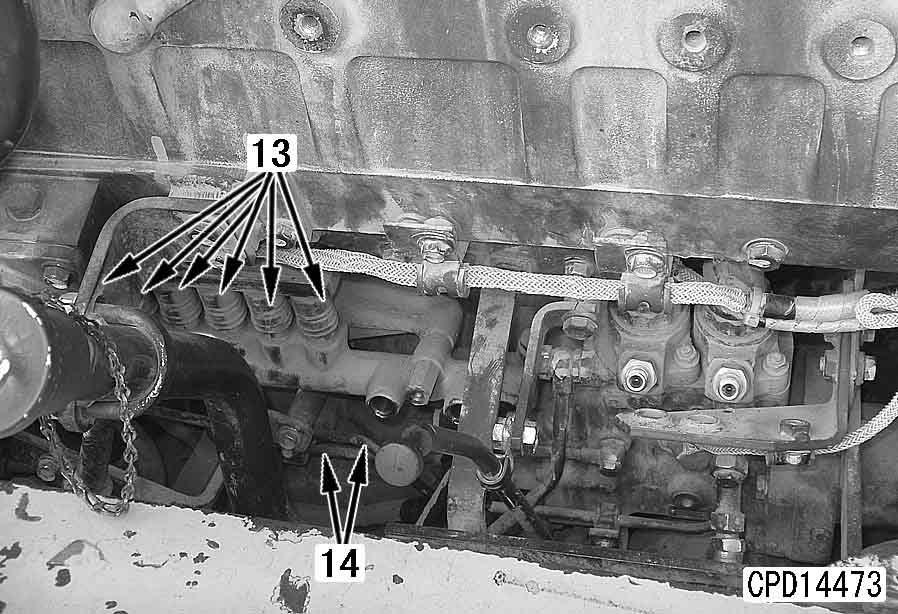

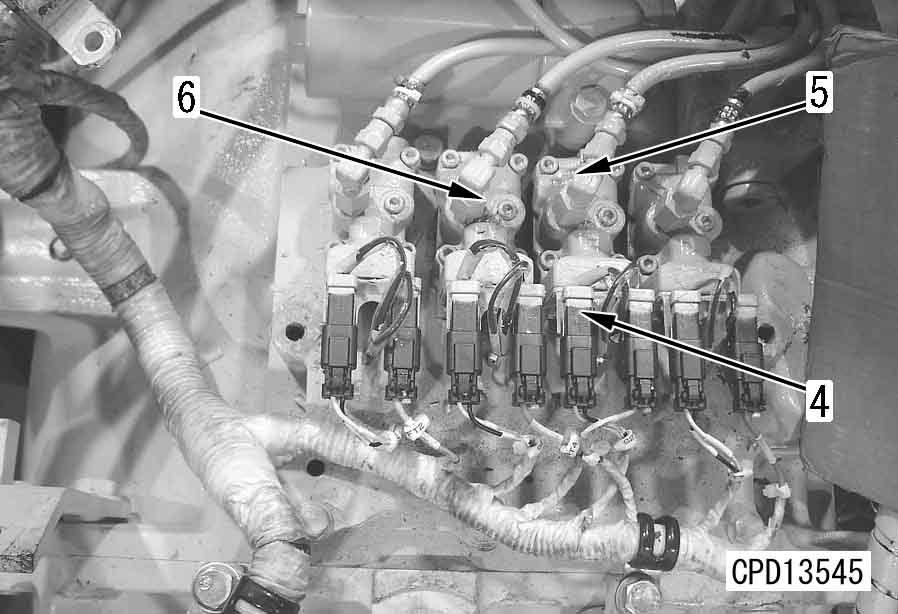

5.Disconnect wiring clamp (5) and fuel hose clamps (6).

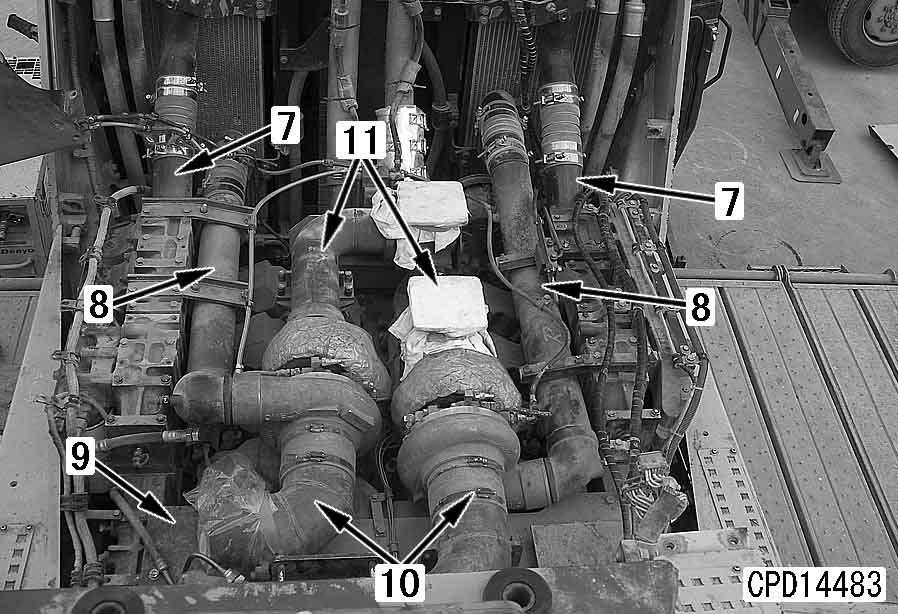

7)Disconnect 6 upper high-pressure pipes (13) of the common rail and high-pressure pipes (14) on this side.

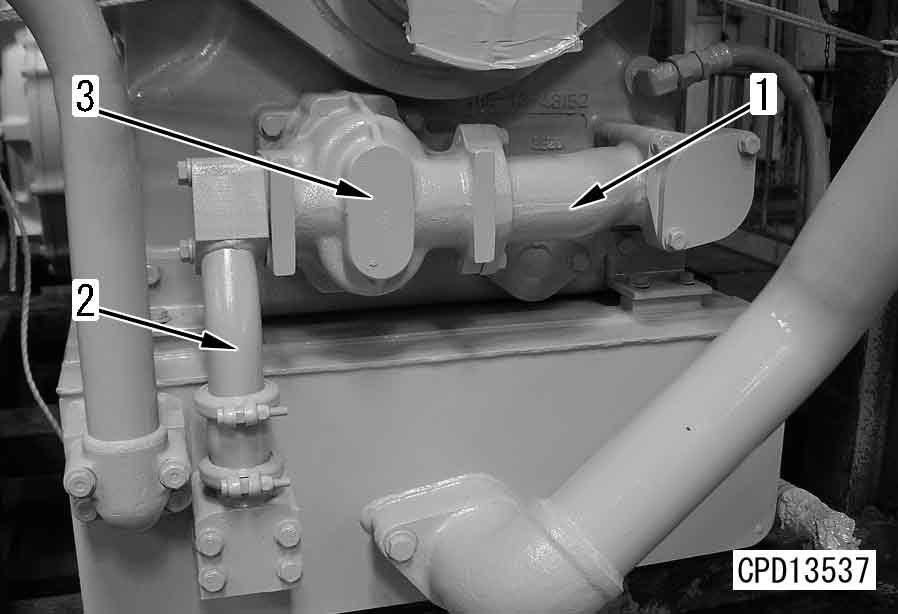

7.Remove the common rail according to the following procedure.

1)Remove clamp (8).

2)Remove the common rail cover mounting bolts to drop cover (9).

3)Remove clamp (10).

4)Remove high-pressure pipe (11).

5)Remove bracket (12).

6)Remove common rail cover (9).

8)Disconnect common rail wiring connector (15).

9)Remove right and left mounting bolts (16) to remove common rail (17).

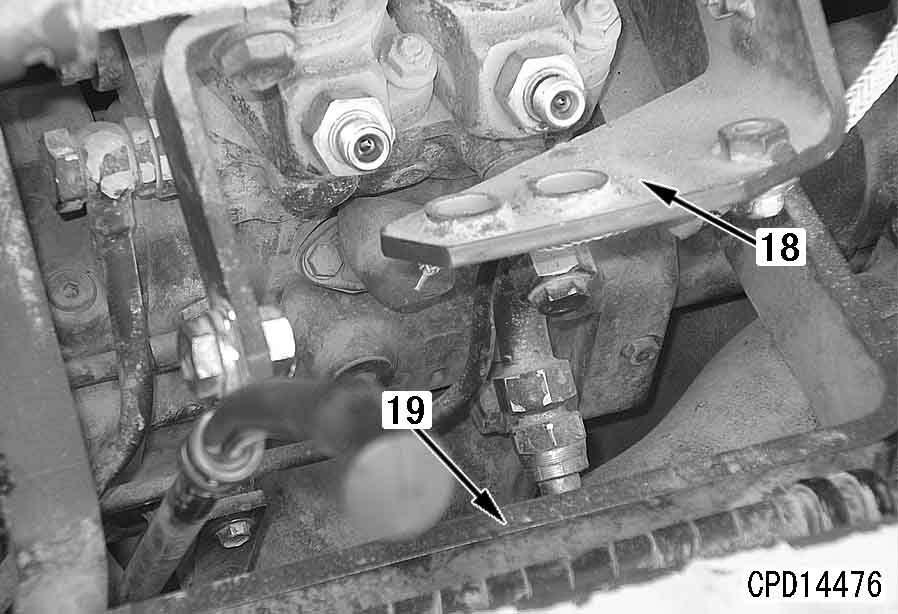

8.Remove brackets (18) and (19).

Installation a

The following is the installation procedure for the left bank fuel supply pump assembly. The basic installation procedure for the right fuel supply pump assembly is the same.

1.Install supply pump assembly (13) temporarily.

2 Supply pump assembly mounting bolt: Adhesive (LT-2) a Before tightening the mounting bolt on the pump side and mounting bolt (14) on the engine mounting bracket side to the specified torque, tighten the sleeve nuts of the high-pressure pipe (between the supply pump and common rail).

9.Remove clamp (20) and fuel tube (21).

10.Remove lubrication tube (22).

11.Disconnect wiring connectors (23). a Connectors: PCV1, PCV2 and G a Wind a rope around the fuel supply pump and sling it. a Remove the high-pressure pipe clamp just under the fuel supply pump without fail.

12.Remove the mounting bolts of fuel supply pump assembly (24) and pull out the fuel supply pump assembly and mounting bracket together.

4 Right fuel supply pump assembly: 17 kg a After the fuel supply pump is removed, the coupling on the drive case moves out of position. Accordingly, rotate the crankshaft to set the drive case in position when installing the fuel supply pump.

2.Connect the wiring connector (12).

3.Remove common rail cover (11).

D475A, D475ASD-5E0

High-pressure pipe

k When handling the high-pressure pipe and clamp, observe the following.

q Never bend the high-pressure pipe to correct before installing or use it for another section.

q Install the specified clamp to the specified position securely and tighten it to the specified torque.

q Do not apply lubricant to the high-pressure pipe sleeve nut and the threads of the mating part.

a If lubricant is applied, the axial tension is increased too much and the highpressure pipe may be broken when the sleeve nut is tightened.

k Before installing the high-pressure pipe, check it. If it has any defect, replace it since fuel may leak.

q Check the taper seal of the connecting part (Part "a": Part of 2 mm from the end) for visible lengthwise slit "b" and dent "c".

q Check part "d" (End of the taper seal: Part at 2 mm from the end) for stepped-type wear (fatigue) which your nail can feel.

3 Bracket mounting bolt (14): 19.6 – 29.4 Nm {2.0 – 3.0 kgm}

4)Install lubrication tube (10).

3 Lubrication tube joint bolt: 9.8 – 12.7 Nm {1.0 – 1.3 kgm} a When tightening the high-pressure pipe clamp mounting bolts, take care extremely that an excessive force will not be applied to the mounting area on the supply pump side.

5)Install high-pressure pipe clamp (6) according to the following procedure.

1]Finger tighten all the mounting bolts of high-pressure pipe clamp (6) and bracket (16).

2]Tighten the high-pressure pipe clamp (6) mounting bolts permanently.

3 Clamp bolt: 9.8 ± 1 Nm {1 ± 0.1 kgm} a Install the rubber covers so that their slits will be directed as follows. q Supply pump side: Down q Common rail side: Inward (Facing each other) a Using a spanner-type torque wrench (commercially available), control the tightening torque.

3]Tighten bracket (16) mounting bolts permanently.

6)Install 4 rubber covers (15) to the highpressure pipe sleeve nuts.

4.Install the high-pressure pipe according to the following procedure.

1)Install high-pressure pipe assembly (7) and then tighten the sleeve nuts to the specified torque.

3 High-pressure pipe sleeve nut

(Supply pump side):

39.2 – 49 Nm {4 – 5 kgm}

High-pressure pipe sleeve nut (Common rail side):

39.2 – 58.8 Nm {4 – 6 kgm} q Carry out the following installation in the reverse order to removal.

2)Tighten the supply pump assembly mounting bolts.

3)Tighten supply pump assembly bracket (14) mounting bolts.

[*1]

3 Joint bolt on main fuel filter (upper) side: 24.5 – 34.3 Nm {2.5 – 3.5 kgm}

3 Joint bolt on fuel supply pump side: 14.8 – 19.6 Nm {1.5 – 2.0 kgm} k Check that each high-pressure pipe is at least 10 mm apart from the wiring harness around it.

D475A, D475ASD-5E0

Removal and installation of cylinder head assembly

Special tools

1

Removal k Lower the work equipment to the ground and stop the engine. k Set the parking brake lever and work equipment lock lever in the lock position. k Disconnect the cable from the negative (–) terminal of the battery.

1.Close the fuel valve under the fuel tank.

2.Remove the engine hood. For details, see "Removal and installation of engine hood".

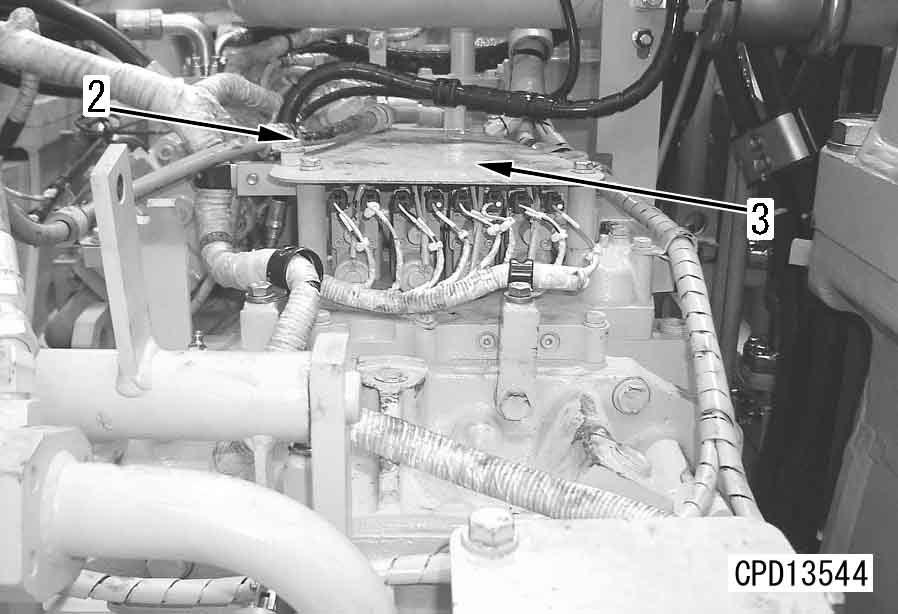

3.Remove right and left engine side covers (1) and right and left covers (2).

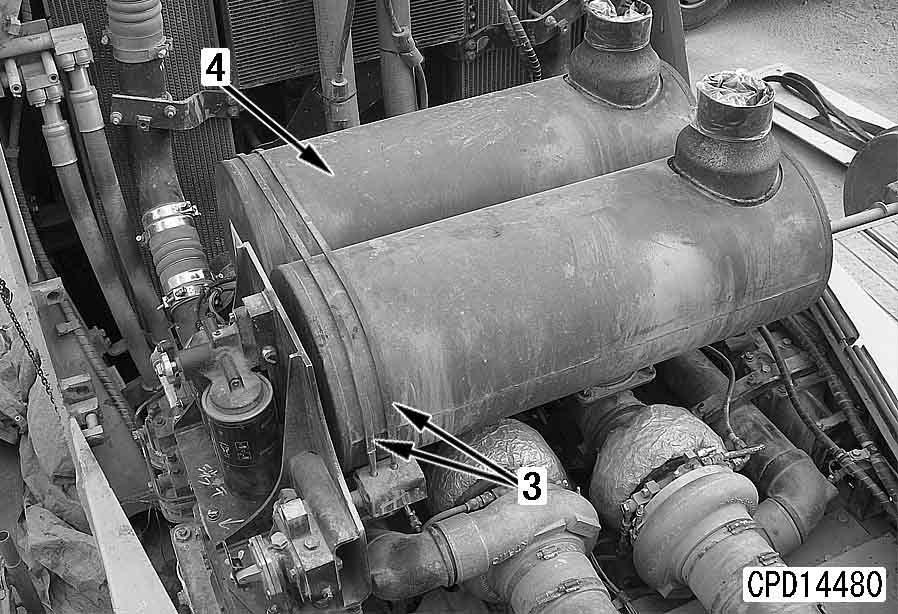

4.Remove mounting bands (3) and connector nuts and then wind a rope around muffler assembly (4) and lift it off.

4 Muffler assembly: 60 kg (1 piece)

5.Remove the piping and then remove the corrosion resistor, air bleeding valve and mounting bracket (5) together.

4 Corrosion resistor, air bleeding valve and mounting bracket: Approx. 35 kg

6.Remove muffler mounting bracket (6).

4 Muffler mounting bracket: 38 kg

7.Remove aftercooler inlet pipe (7) and aftercooler outlet pipe (8). [*1]

8.Remove bracket (9) and turbocharger intake connector (10) together. [*2]

9.Remove turbocharger exhaust connector (11).

14.Remove the common rail cover. For details, see "Removal and installation of fuel supply pump assembly".

15.Remove right and left rubber covers (17) and (18).

16.Remove right and left high-pressure pipes (19).

10.Disconnect right and left main wirings (12).

11.Remove engine oil filter assembly (13).

17.Remove right and left air intake manifolds (20). 4 Air intake manifold: 35 kg

12.Disconnect fuel hose and piping (14). [*3]

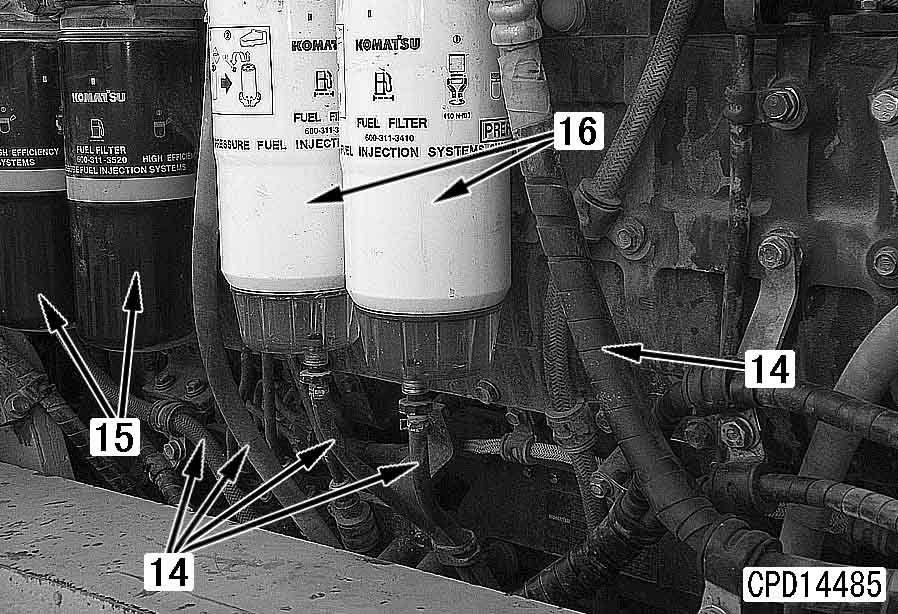

13.Remove main fuel filter assembly (15) and fuel prefilter assembly (16).

D475A, D475ASD-5E0 q Lubrication tube (21) q Lubricating oil drain tube (22) q Coolant tube (23)[*4] q Coolant drain tube (24)[*4]

18.Remove each tube of the turbocharger.

19.Remove heat insulation cover (25).

20.Sling turbocharger and exhaust manifold assembly (26), remove the mounting bolts, and lift off the turbocharger and exhaust manifold assembly.[*5]

4 Turbocharger and exhaust manifold assembly: 60 kg

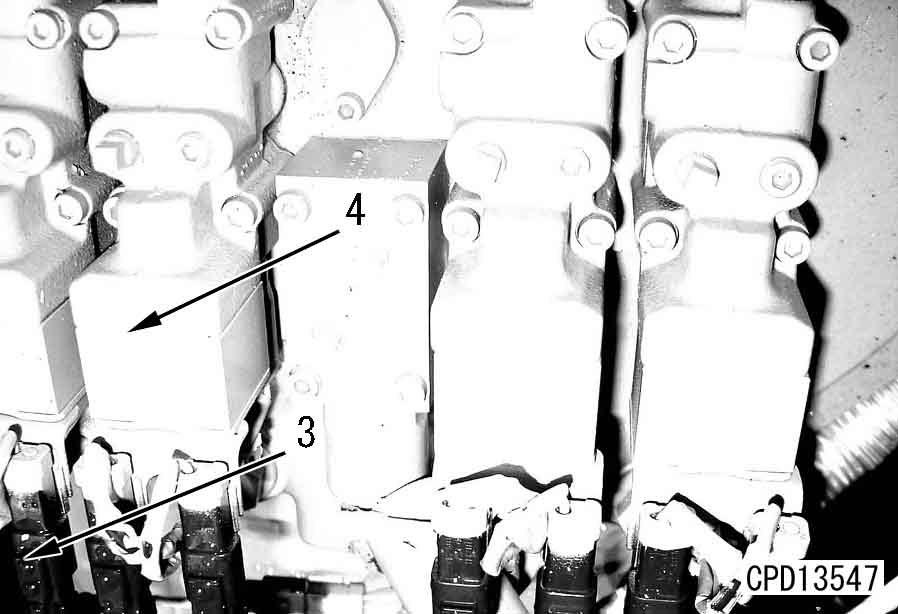

21.Removal of injector external wiring

1)Remove cover plate (27).

2)Disconnect connector (28) from each cylinder head and disconnect wiring harness (29).

22.Remove air vent tubes (30) and (31). [*6]

23.Remove spill tube (32).

24.Remove head cover (33).

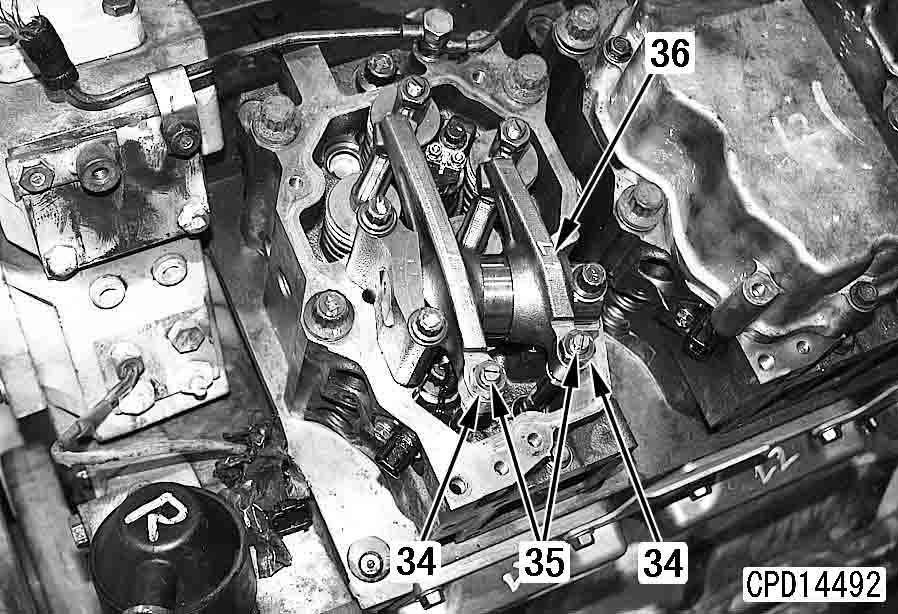

25.Removal of rocker arm assembly

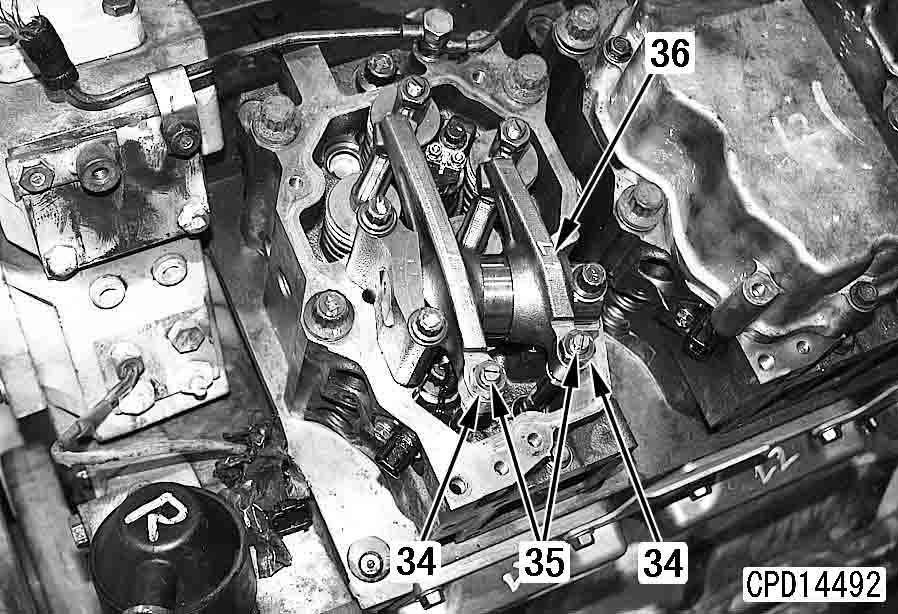

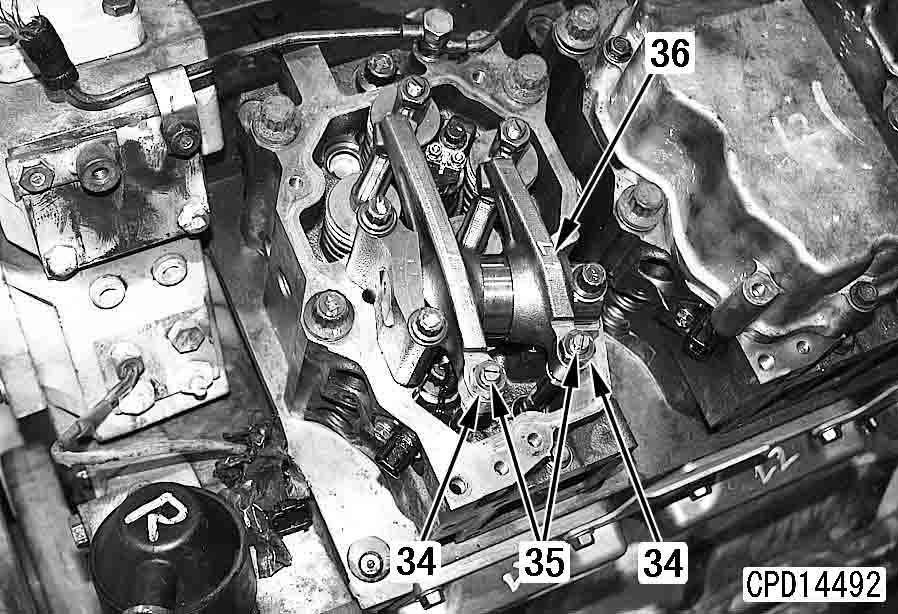

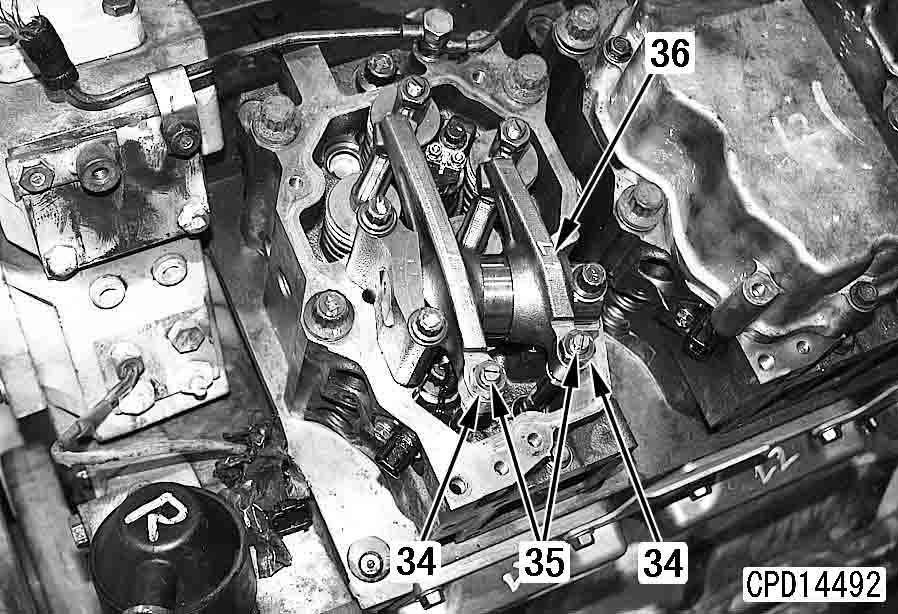

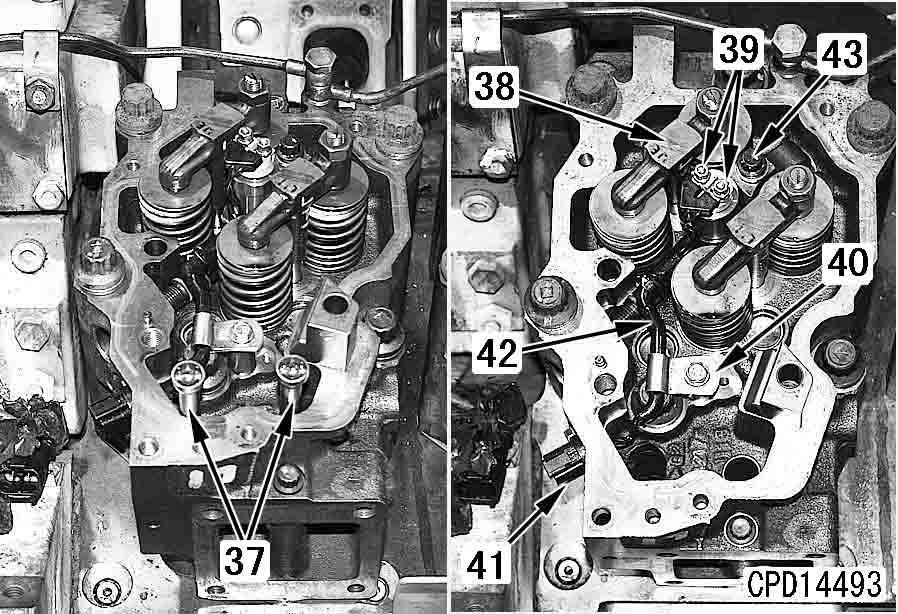

1)Loosen locknuts (34) and then loosen adjustment screws (35) fully. a Check that the rocker arm is not affected by the valve tension but it is free.

2)Remove rocker arm assembly (36). a Put a location tag to each rocker arm assembly before storing.

26.Remove push rods (37).

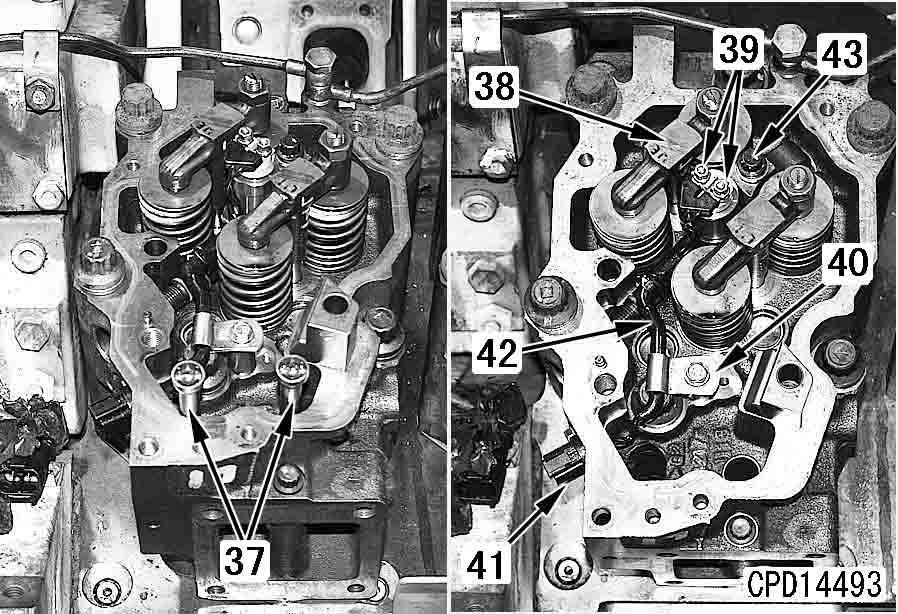

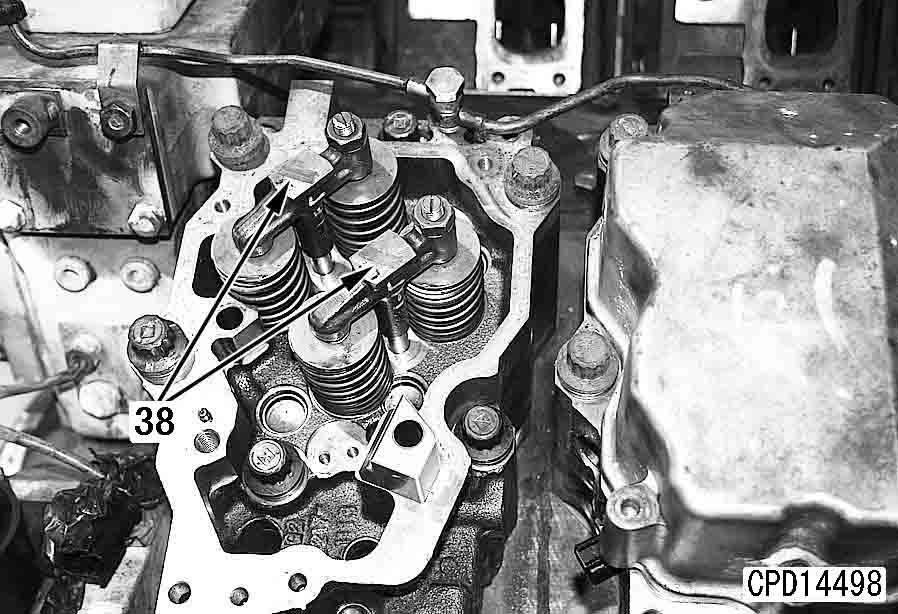

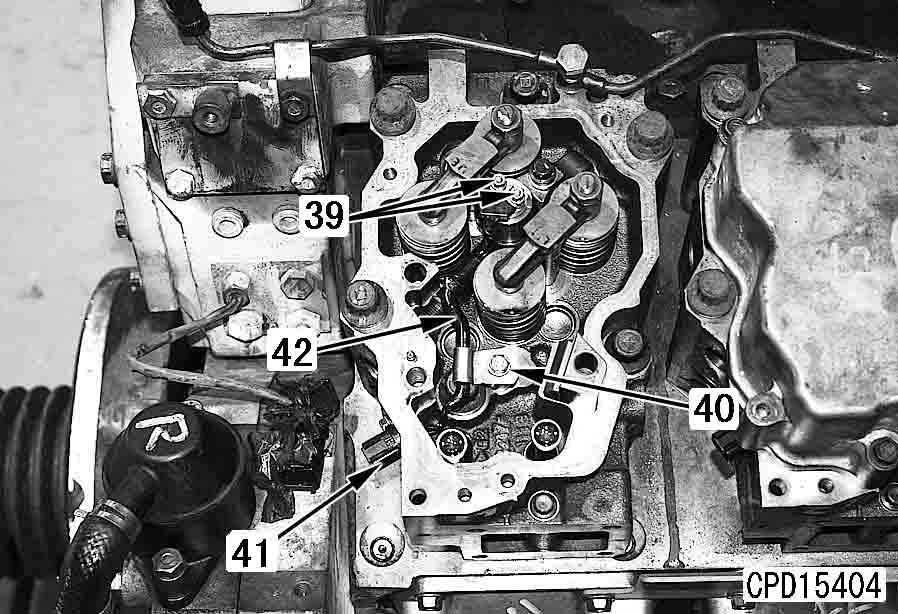

27.Remove crossheads (38).

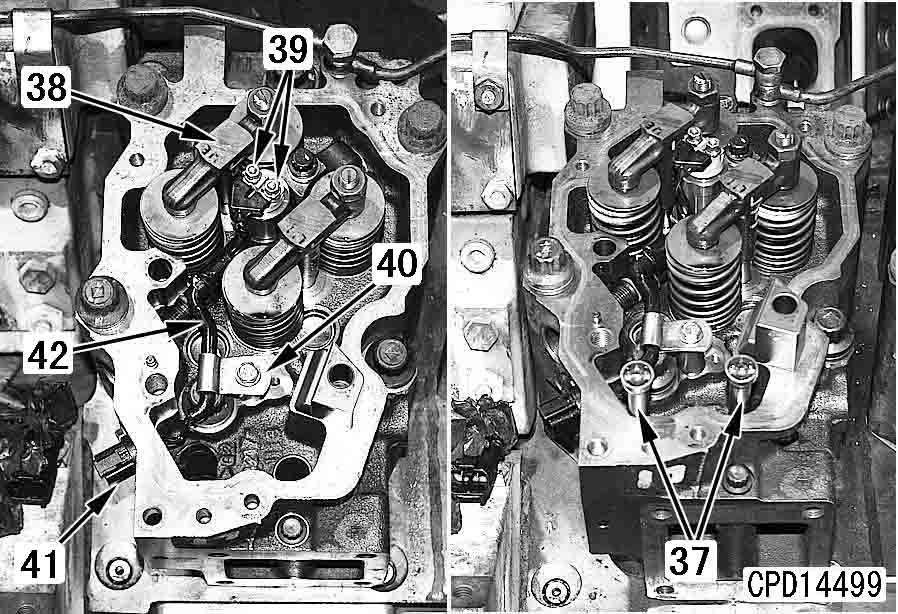

28.Removal of fuel injector

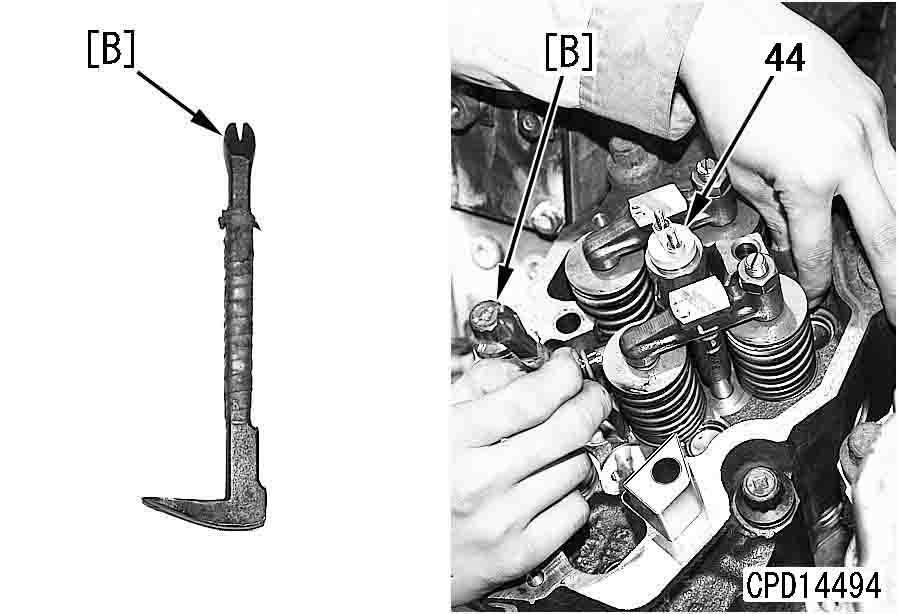

1)Remove injector terminal mounting nuts (39).

2)Remove clamp mounting bolt (40).

3)Push connector (41) into the cylinder head and remove injector wiring harness (42).

4)Remove holder mounting bolt (43).

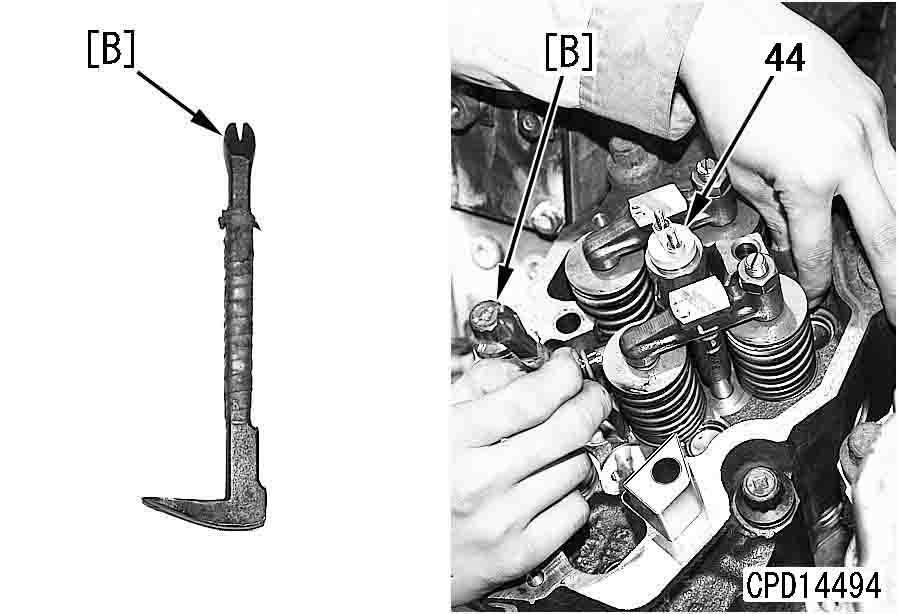

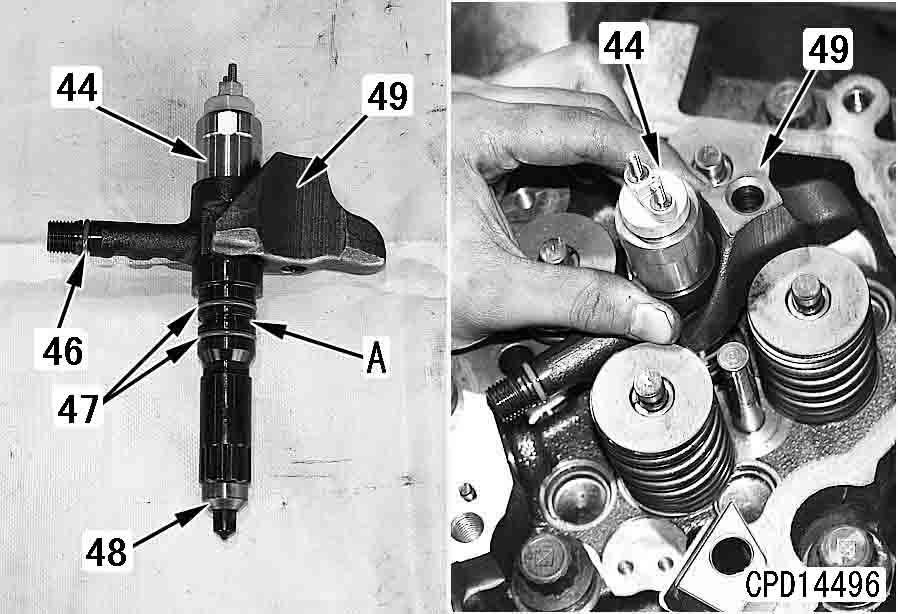

5)Insert small L-bar [B] under the fuel connector and pry out fuel injector (44) slowly. a Do not grip the solenoid valve at the top of the injector with pliers to pull out the injector.

Installation

Cylinder head assembly

1.Install the cylinder head gasket.

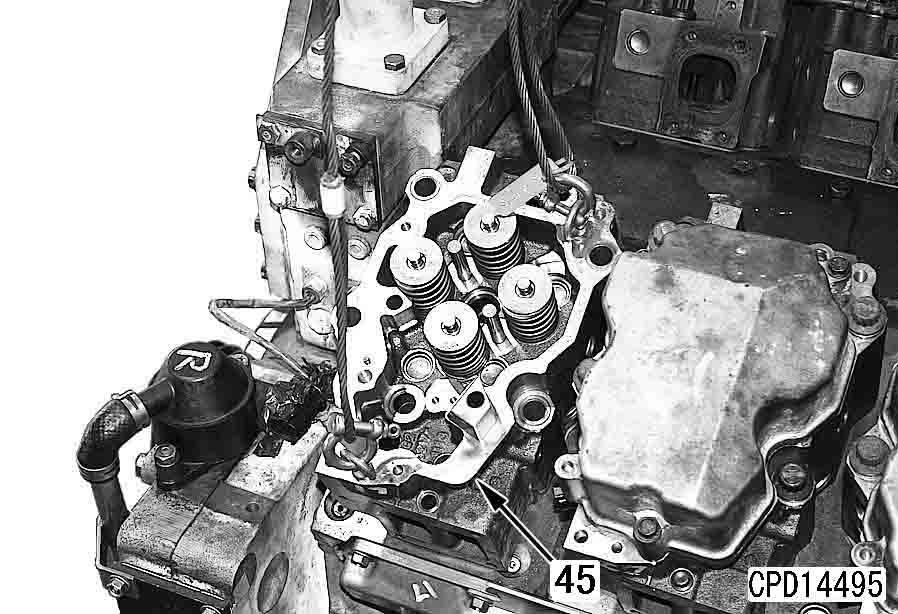

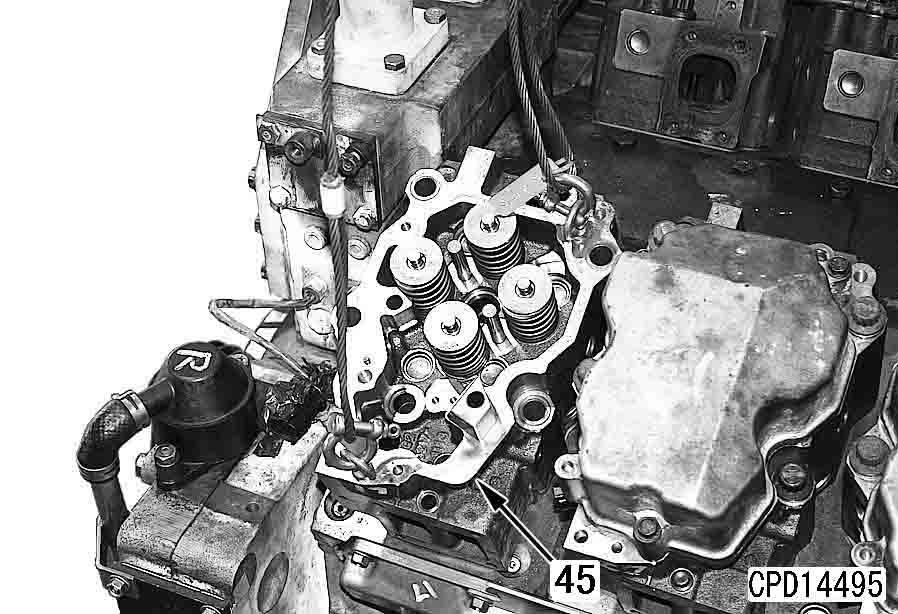

2.Sling and install cylinder head assembly (45).

4 Cylinder head assembly: 30 kg

29.Lift off cylinder head assembly (45).

4 Cylinder head assembly: 30 kg a If the cylinder head assembly is removed without removing the fuel injector, the injector tip projects from the bottom of the cylinder head. Accordingly, use a block, etc. to prevent the injector from interfering with the floor. a If there are 5 punch marks on the head of a bolt, do not reuse that bolt but replace it. a Tighten the mounting bolts in the order shown in the figure.

2 Cylinder head assembly mounting bolt: Molybdenum disulfide grease (LM-P)

3 Cylinder head assembly mounting bolts (1) – (6):

1st time: 137 – 157 Nm {14 – 16 kgm}

2nd time: 284 – 294 Nm {29 – 30 kgm}

3rd time: Retighten by 90 – 120°

3 Cylinder head assembly mounting bolt (7): 66.2 ± 7.4 Nm {6.75 ± 0.75 kgm} a Use tool A2 (See the tool table) to retighten the mounting bolts. When not using tool A2 , make marks on the bolts and cylinder head, and then retighten each bolt by 90 – 120° a After tightening the bolts, make punch mark "a" on the main bolt head (Do not make it when new bolts are used, however).

6.Install spherical washer (50) to injector holder mounting bolt (43) and tighten injector holder (49) temporarily.

2 Spherical washer: Engine oil (EO30) a Tighten injector holder (49) permanently after tightening the high-pressure pipe temporarily.

Fuel injector a Check that there is no dirt in the injector sleeve.

2 O-ring: Engine oil (EO30)

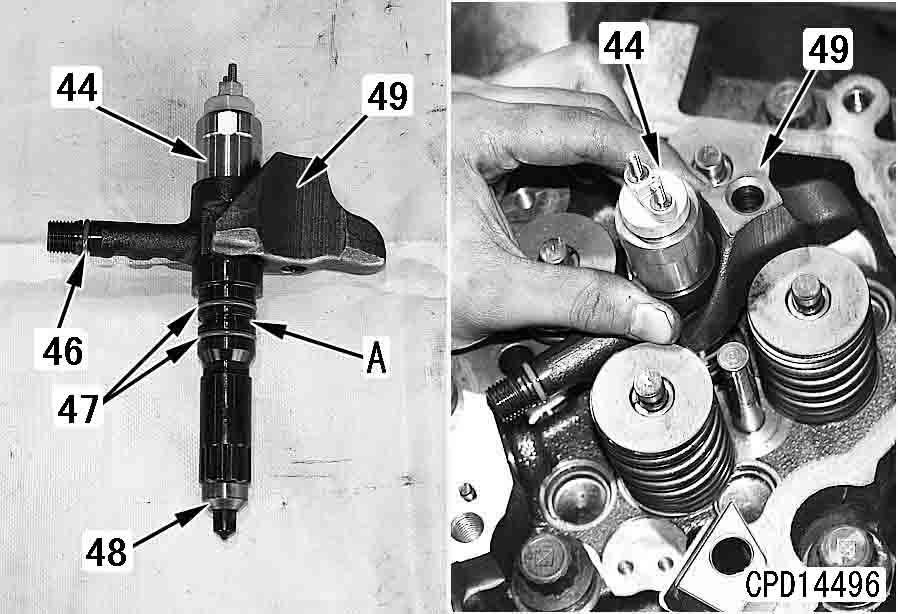

3.Fit O-rings (46) and (47) to fuel injector (44). a Take care not to fit O-ring (47) to center groove (A)

4.Install gasket (48) to fuel injector (44).

5.Insert fuel injector (44) and injector holder (49) together in the cylinder head.

Crosshead

7.Install crossheads (38).

2 Sliding parts of crosshead: Engine oil (EO30)

8.Adjust the crosshead according to the following procedure.

1)Loosen locknut (102) and then loosen adjustment screw (103) to a position where it will not touch valve stem (104).

2)Hold the contact face to the rocker arm with the finger to keep crosshead in contact with valve stem (105) on the push rod side.

3)Tighten adjustment screw (103) slowly and check the point at which adjustment screw (103) touches valve stem (104).

4)Tighten adjustment screw (103) further by 20 – 30° from the above point.

5)While holding adjustment screw (103), tighten locknut (102).

3 Locknut: 58.8 ± 5.9 Nm {6.0 ± 0.6 kgm} a Check that each push rod end is fitted in the receiving area of the cam follower.

10.Install push rods (37).

2 Both ends of push rod: Engine oil (EO30)

9.Injector wiring harness a Tighten injector terminal mounting nuts (39) alternately.

1)Push out connector (41) from inside of the cylinder head and inst all injector wiring harness (42) in the cylinder head.

2)Tighten injector terminal mounting nuts (39) and clamp mounting bolt (40).

3 Injector terminal mounting nut: 2 ± 0.2 Nm {0.2 ± 0.02 kgm} a After tightening the injector terminal mounting nuts, press the wiring harness against the injector body to take up the slack.

11.Install rocker arm assembly (36).

2 Rocker shaft: Engine oil (EO30)

2 Threaded part and seat of rocker arm assembly mounting bolt: Engine oil (EO30) a Check that the ball of adjustment screw (35) is fitted in the push rod socket. a When tightening the mounting bolt, check that adjustment screw (35) does not press the push rod.

3 Rocker arm assembly mounting bolt: 93 – 103 Nm {9.5 – 10.5 kgm} a Tighten locknut (34) after adjusting the valve clearance. a Adjust the valve clearance. For details, see Testing and adjusting, "Testing and adjusting valve clearance".

3 Tightening torque for locknut: 52.9 – 64.7 Nm {5.4 – 6.6 kgm} a After tightening the locknut, check the valve clearance again.

14.Fuel injector and high-pressure pipe (between common rail and fuel injector) k When handling the high-pressure pipe and clamp, observe the following. q Never bend the high-pressure pipe to correct before insta lling or use it for another section. q Install the specified clamp to the specified position securely and tighten it to the specified torque. q Do not apply lubricant to the highpressure pipe sleeve nut and the threads of the mating part. a If lubricant is applied, the axial tension is increased too much and the high-pressure pipe may be broken when the sleeve nut is tightened. k Before installing the high-pressure pipe, check it. If it has any defect, replace it since fuel may leak.

12.Install spill tube (32).

3 Joint bolt: 9.8 – 12.7 Nm {1.0 – 1.3 kgm} q Check the taper seal of the connecting part (Part "a": Part of 2 mm from the end) for visible lengthwise slit "b" and dent "c". q Check part "d" (End of the taper seal: Part at 2 mm from the end) for stepped-type wear (fatigue) which your nail can feel.

13.Place cylinder head cover (33). (Place it to prevent dirt from entering. It will need to be removed again.)

1)Fit O-ring (52) to the high-pressure pipe sleeve nut (51).

2 O-ring: Engine oil (EO30) a If sleeve nut (51) does not catch the threads, press its end with a small rod, etc. toward the injector and turn the spanner.

2)Tighten sleeve nut (51) temporarily into fuel injector (44).

3)Tighten sleeve nut (53) on the common rail side temporarily, too.

4)Tighten injector holder (49) permanently.

3 Injector holder mounting bolt (43): 58.9 – 73.5 Nm {6.0 – 7.5 kgm} a Using a spanner-type torque wrench (commercially available), control the tightening torque.

5)Tighten the sleeve nut to the specified torque.

3 High-pressure pipe (19) sleeve nut

(Injector side):

39.2 – 49 Nm {4 – 5 kgm}

3 High-pressure pipe (19) sleeve nut

(Common rail side):

39.2 – 49 Nm {4 – 5 kgm} a After tightening each sleeve nut (51), check that O-rings (46) and (52) are not projected from the sleeve nut.

6)Install the cylinder head cover.

3 Cylinder head cover mounting bolt: 14.7 – 34.3 Nm {1.5 – 3.5 kgm} a Install the rubber covers so that their slits will be directed as follows. q Injector side (17): Down q Common rail side (18): Cylinder block side

7)Install rubber covers (17) and (18) to the sleeve nuts of high-pressure pipes (19).

15.Air intake manifold assembly

1)Install the gasket.

a Direct the side having the mark of "UP" up and direct it toward the air intake manifold.

2 Threaded part and seat of mounting bolt:

Molybdenum disulfide grease (LM-P) a Tighten the mounting bolts according to the following procedure.

3 Air intake manifold mounting bolt: 58.8 – 73.5 Nm {6.0 – 7.5 kgm} a For precautions, see the section of the high-pressure pipe (between the common rail and fuel injector). a Using a spanner-type torque wrench (commercially available), control the tightening torque. q Carry out the following installation in the reverse order to removal.

16.Install the high-pressure pipe clamps (between the common rail and fuel injector). For details, see "Removal and installation of fuel supply pump assembly".

17.Install the high-pressure pipes (between the common rail and fuel supply pump). For details, see "Removal and installation of fuel supply pump assembly".

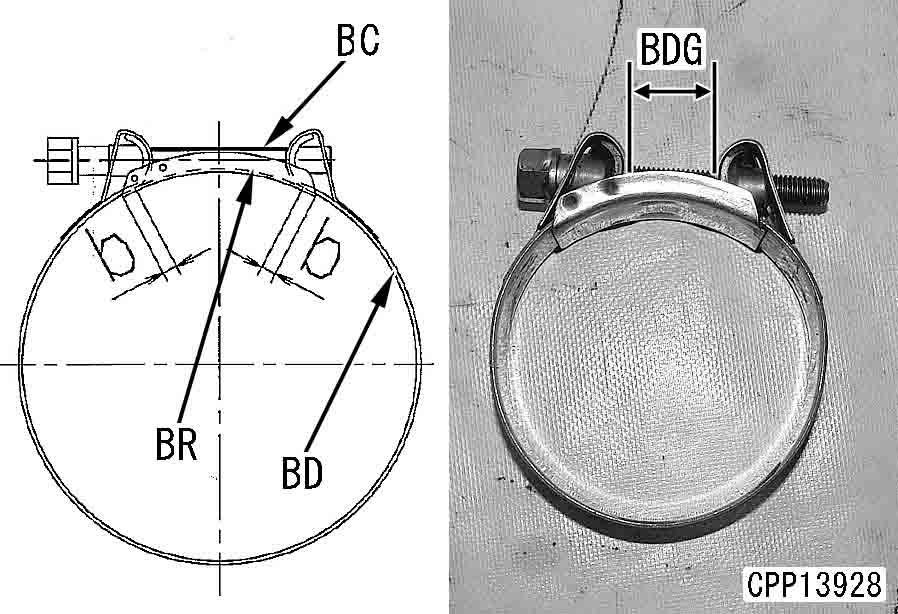

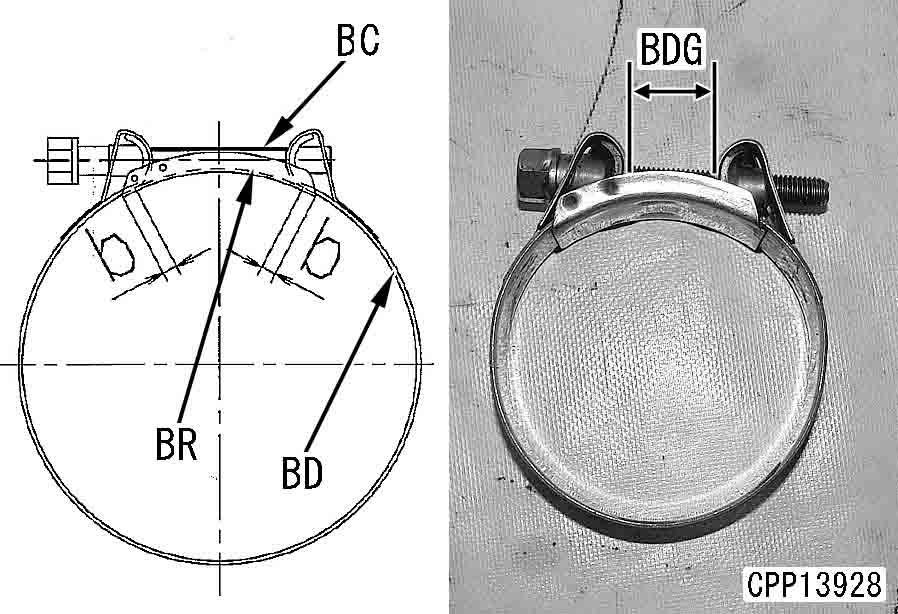

[*1] q Air hose a Use a new MIKALOR clamp.

1)Set the hose to the original position (marked position). (Insertion depth of air hose: Min. 80 mm)

2)Set the bridge (BR) under the clamp bolt and lap it over the band at least 3 mm (b). Dimension (b): Min. 3 mm

2 Threaded part (BC) of clamp bolt: Lubricating oil (Threebond PANDO 18B) a Do not use an impact wrench. q When reusing used hose

3)Set the clamp to the trace of the clamp on the hose.

3 Clamp bolt: Min. 6 Nm {0.6 kgm} q When using new hose

4)Tighten until dimension BDG becomes as follows.

BDG: 17 – 20 mm

[*2]

3 Air intake connector mounting bolt: 49 – 68.6 Nm {5.0 – 7.0 kgm}

[*3]

3 Fuel tube joint bolt: 24.5 – 34.3 Nm {2.5 – 3.5 kgm}

3 Fuel hose joint bolt: 24.5 – 34.3 Nm {2.5 – 3.5 kgm}

3 Spill tube joint bolt

Cylinder head side:

9.8 – 12.7 Nm {1.0 – 1.3 kgm}

Air intake manifold side:

19.6 – 29.4 Nm {2.0 – 3.0 kgm}

[*4]

3 Turbocharger coolant tube joint bolt (upper side): 24.5 – 34.3 Nm {2.3 – 3.5 kgm}

3 Turbocharger coolant tube sleeve nut (lower side): 24.5 – 59 Nm {2.3 – 6 kgm}

3 Turbocharger coolant hose:

29.4 – 39.2 Nm {3.0 – 4.0 kgm}

[*5]

Exhaust manifold assembly a Direct the side having the mark of "OUT" toward the exhaust manifold. a Tighten the mounting bolts in the numeric order shown in the figure. a After tightening the mounting bolts, tighten them again to the same torque.

1) Install the gasket.

2 Threaded part and seat of mounting bolt: Molybdenum disulfide grease (LM-P)

3 Exhaust manifold mounting bolt:

44.1 – 53.9 Nm {4.5 – 5.5 kgm}

Reference

Turbocharger assembly

2 Turbocharger assembly mounting bolt and nut: Molybdenum disulfide grease (LM-P)

3 Turbocharger assembly mounting bolt: 44.1 – 53.9 Nm {4.5 – 5.5 kgm}

[*6]

3 Air vent tube mounting bolt:

9.8 – 12.7 Nm {1.0 – 1.3 kgm} q Refilling with coolant k Check that each high-pressure pipe is at least 10 mm apart from the wiring harness around it.

Add coolant through the coolant filler to the specified level. Run the engine to circulate the coolant through the system. Then, check the coolant level again.

Removal and installation of fuel injector assembly

Removal

1 k Lower the work equipment to the ground and stop the engine. k Set the parking brake lever and work equipment lock lever in the lock position. k Disconnect the cable from the negative (–) terminal of the battery.

1.Close the fuel valve under the fuel tank.

2.Remove the engine hood. For details, see "Removal and installation of engine hood".

3.Remove right and left engine side covers (1) and right and left covers (2).

4 Corrosion resistor, air bleeding valve and mounting bracket: Approx. 35 kg

4.Remove mounting bands (3) and connector nuts and then wind a rope around muffler assembly (4) and lift it off.

4 Muffler assembly: 60 kg (1 piece)

6.Remove muffler mounting bracket (6). 4 Muffler mounting bracket: 38 kg

5.Remove the piping and then remove the corrosion resistor, air bleeding valve and mounting bracket (5) together.

7.Remove aftercooler inlet pipe (7) and aftercooler outlet pipe (8). [*1]

8.Remove bracket (9) and turbocharger intake connector (10) together. [*2]

9.Remove turbocharger exhaust connector (11).

10.Disconnect right and left main wirings (12).

11.Remove engine oil filter assembly (13).

12.Disconnect fuel hose and piping (14).[*3]

13.Remove main fuel filter assembly (15) and fuel prefilter assembly (16).

17.Remove right and left air intake manifolds (20). 4 Air intake manifold: 35 kg

14.Remove the common rail cover. For details, see "Removal and installation of fuel supply pump assembly".

15.Remove right and left rubber covers (17) and (18).

16.Remove right and left high-pressure pipes (19).

18.Removal of injector external wiring

1)Remove cover plate (27).

2)Disconnect connector (28) from each cylinder head and disconnect wiring harness (29).

19.Remove head cover (30).

20.Removal of rocker arm assembly a Check that the rocker arm is not affected by the valve tension but it is free.

1)Loosen locknuts (34) and then loosen adjustment screws (35) fully.

2)Remove rocker arm assembly (36). a Put a location tag to each rocker arm assembly before storing.

5)Insert small L-bar [B] under the fuel connector and pry out fuel injector (44) slowly. a Do not grip the solenoid valve at the top of the injector with pliers to pull out the injector.

21.Removal of fuel injector

1)Remove injector terminal mounting nuts (39).

2)Remove clamp mounting bolt (40).

3)Push connector (41) into the cylinder head and remove injector wiring harness (42).

4)Remove holder mounting bolt (43).

Installation

Fuel injector a Check that there is no dirt in the injector sleeve.

2 O-ring: Engine oil (EO30)

1.Fit O-rings (46) and (47) to fuel injector (44). a Take care not to fit O-ring (47) to center groove (A)

2.Install gasket (48) to fuel injector (44).

3.Insert fuel injector (44) and injector holder (49) together in the cylinder head.

4.Install spherical washer (50) to injector holder mounting bolt (43) and tighten injector holder (49) temporarily.

2 Spherical washer: Engine oil (EO30) a Tighten injector holder (49) permanently after tightening the high-pressure pipe temporarily.

6.Install rocker arm assembly (36).

2 Rocker shaft: Engine oil (EO30)

2 Threaded part and seat of rocker arm assembly mounting bolt:

Engine oil (EO30) a Check that the ball of adjustment screw (35) is fitted in the push rod socket. a When tightening the mounting bolt, check that adjustment screw (35) does not press the push rod.

3 Rocker arm assembly mounting bolt: 93 – 103 Nm {9.5 – 10.5 kgm} a Tighten locknut (34) after adjusting the valve clearance. a Adjust the valve clearance. For details, see Testing and adjusting, "Testing and adjusting valve clearance". a Tighten injector terminal mounting nuts (39) alternately.

1)Push out connector (41) from inside of the cylinder head and inst all injector wiring harness (42) in the cylinder head.

2)Tighten injector terminal mounting nuts (39) and clamp mounting bolt (40).

3 Injector terminal mounting nut:

2 ± 0.2 Nm {0.2 ± 0.02 kgm} a After tightening the injector terminal mounting nuts, press the wiring harness against the injector body to take up the slack.

3 Tightening torque for locknut: 52.9 – 64.7 Nm {5.4 – 6.6 kgm} a After tightening the locknut, check the valve clearance again.

7.Place the cylinder head cover. (Place it to prevent dirt from entering. It will need to be removed again.)

8.Fuel injector and high-pressure pipe (between common rail and fuel injector) k When handling the high-pressure pipe and clamp, observe the following. q Never bend the high-pressure pipe to correct before installing or use it for another section. q Install the specified clamp to the specified position securely and tighten it to the specified torque. q Do not apply lubricant to the highpressure pipe sleeve nut and the threads of the mating part. a If lubricant is applied, the axial tension is increased too much and the high-pressure pipe may be broken when the sleeve nut is tightened. k Before installing the high-pressure pipe, check it. If it has any defect, replace it since fuel may leak. q Check the taper seal of the connecting part (Part "a": Part of 2 mm from the end) for visible lengthwise slit "b" and dent "c". q Check part "d" (End of the taper seal: Part at 2 mm from the end) for stepped-type wear (fatigue) which your nail can feel.

1)Fit O-ring (52) to the high-pressure pipe sleeve nut (51).

2 O-ring: Engine oil (EO30) a If sleeve nut (51) does not catch the threads, press its end with a small rod, etc. toward the injector and turn the spanner.

2)Tighten sleeve nut (51) temporarily into fuel injector (44).

3)Tighten sleeve nut (53) on the common rail side temporarily, too.

4)Tighten injector holder (49) permanently.

3 Injector holder mounting bolt (43): 58.9 – 73.5 Nm {6.0 – 7.5 kgm} a Using a spanner-type torque wrench (commercially available), control the tightening torque.

5)Tighten the sleeve nut to the specified torque.

3 High-pressure pipe (19) sleeve nut (Injector side):

39.2 – 49 Nm {4 – 5 kgm}

3 High-pressure pipe (19) sleeve nut (Common rail side):

39.2 – 49 Nm {4 – 5 kgm} a After tightening each sleeve nut (51), check that O-rings (46) and (52) are not projected from the sleeve nut.

6)Install the cylinder head cover.

3 Cylinder head cover mounting bolt: 14.7 – 34.3 Nm {1.5 – 3.5 kgm} a Install the rubber covers so that their slits will be directed as follows. q Injector side (17): Down q Common rail side (18): Cylinder block side

7)Install rubber covers (17) and (18) to the sleeve nuts of high-pressure pipes (19).

Removal q Carry out the following installation in the reverse order to removal.

[*1] q Air hose a Use a new MIKALOR clamp.

1)Set the hose to the original position (marked position). (Insertion depth of air hose: Min. 80 mm)

2)Set the bridge (BR) under the clamp bolt and lap it over the band at least 3 mm (b). Dimension (b): Min. 3 mm

2 Threaded part (BC) of clamp bolt: Lubricating oil (Threebond PANDO 18B) a Do not use an impact wrench. q When reusing used hose

3)Set the clamp to the trace of the clamp on the hose.

3 Clamp bolt: Min. 6 Nm {0.6 kgm} q When using new hose a For precautions, see the section of the high-pressure pipe (between the common rail and fuel injector). a Using a spanner-type torque wrench (commercially available), control the tightening torque.

9.Install the high-pressure pipe clamps (between the common rail and fuel injector). For details, see "Removal and installation of fuel supply pump assembly".

10.Install the high-pressure pipes (between the common rail and fuel supply pump). For details, see "Removal and installation of fuel supply pump assembly".

4)Tighten until dimension BDG becomes as follows.

BDG: 17 – 20 mm

[*2]

3 Air intake connector mounting bolt: 49 – 68.6 Nm {5.0 – 7.0 kgm}

[*3]

3 Fuel tube joint bolt: 24.5 – 34.3 Nm {2.5 – 3.5 kgm}

3 Fuel hose joint bolt: 24.5 – 34.3 Nm {2.5 – 3.5 kgm} k Check that each high-pressure pipe is at least 10 mm apart from the wiring harness around it.

Removal and installation of engine front seal

Special tools

1

Installation q Carry out installation in the reverse order to removal.

[*1] a Align the dowel pin when installing the crankshaft pulley. a Tighten the mounting bolts in the order shown in the diagram below.

3 Crankshaft pulley mounting bolt:

1st step: 73.5 ± 19.6 Nm {7.5 ± 2 kgm}

2nd step: 245 ± 19.6 Nm {25 ± 2 kgm}

Removal

1.Remove radiator guard assembly. For details, see "Removal and installation of radiator guard assembly".

2.Remove crankshaft pulley (1). [*1]

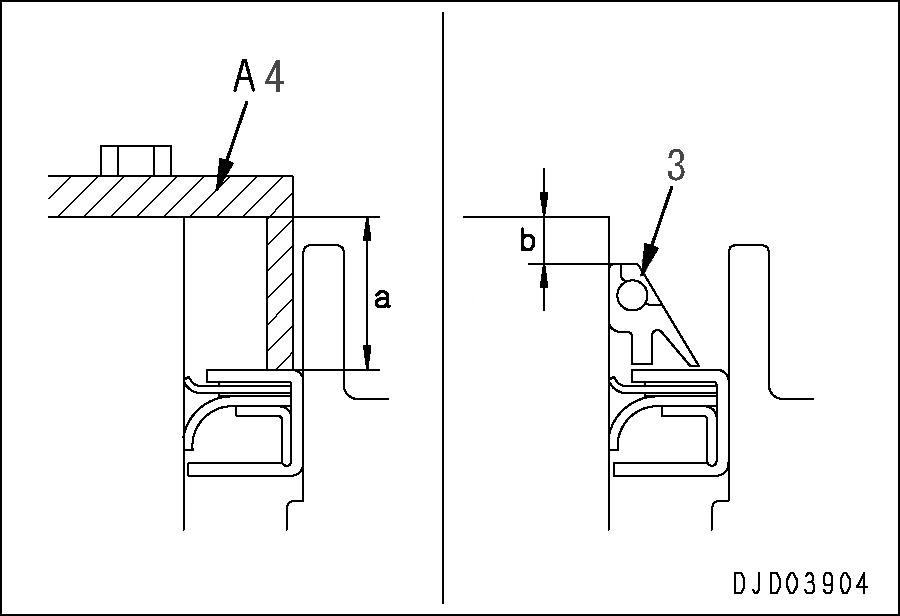

3rd step: 744.8 ± 19.6 Nm {76 ± 2 kgm} [*2] a Do as follows according to the wear of the crankshaft seal contact surface.

1)When crankshaft is a new part or when there is no wear of oil seal contact surface.

1]Press fit by tool A4

2]After press fitting, check mounting dimension (a)

Front seal mounting dimension (a): 17.5 mm

3]Install dust seal (3).

3.Remove

Dust seal mounting dimension (b): approx. 7 mm

D475A, D475ASD-5E0

Installation

1.Using guide bolt, and install flywheel (2).

Special tools

Removal

1.Remove damper assembly. For details, see "Removal and installation of damper assembly".

2.Sling with eyebolts [1] (M16, P=2), remove mounting bolts (1), screw in forcing screws [2] (M12, P=1.75), then remove flywheel (2).

4 Flywheel: 140 kg

2.Secure flywheel (2) and housing with plate [3].

3.Remove rear seal (3).[*1] a Tighten the mounting bolts in the order shown in the diagram below.

3 Flywheel mounting bolt:

1st step: 98 ± 19.6 Nm {10 ± 2 kgm}

2nd step: 294 ± 19.6 Nm {30 ± 2 kgm}

3rd step: 539 ± 19.6 Nm {55 ± 2 kgm} q Face runout: Max. 0.30 mm q Radial runout: Max. 0.30 mm

3.After installing flywheel, use dial gauge [4] to measure radial and face runout of flywheel.

[*1] a Do as follows according to the wear of the crankshaft seal contact surface.

1)When crankshaft is a new part or when there is no wear of oil seal contact surface.

1]Press fit by tool A5.

2]After press fitting, check mounting dimension (a)

Front seal mounting dimension (a): 18.5 mm

D475A-5E0

D475ASD-5E0

Power train, Part 1

Removal and installation of damper assembly

Removal

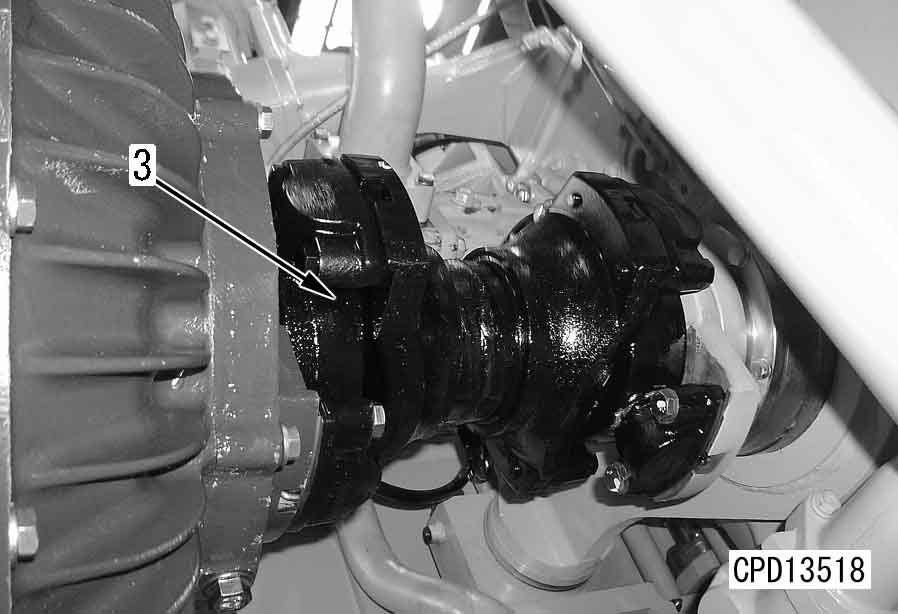

1.Remove hood assembly. For details, see Removal and installation of hood assembly.

2.Open underguard (3rd from front of machine).

3.Remove drain plug (1) and drain damper oil.

6 Damper case: Approx. 2.2 l

4.Remove dipstick and dipstick guide (2).

6.Remove holder (4) and coupling (5).[*2] k Install guide bolts (12 mm, P = 1.75, l = 100) in 2 mounting bolt holes in the top of the damper cover so that the damper cover does not come out suddenly.

7.Remove retainer (6).

8.Sling damper cover (7), then use forcing screw [1] (12mm, P=1.75) to remove damper cover.

4 Damper cover: 50 kg

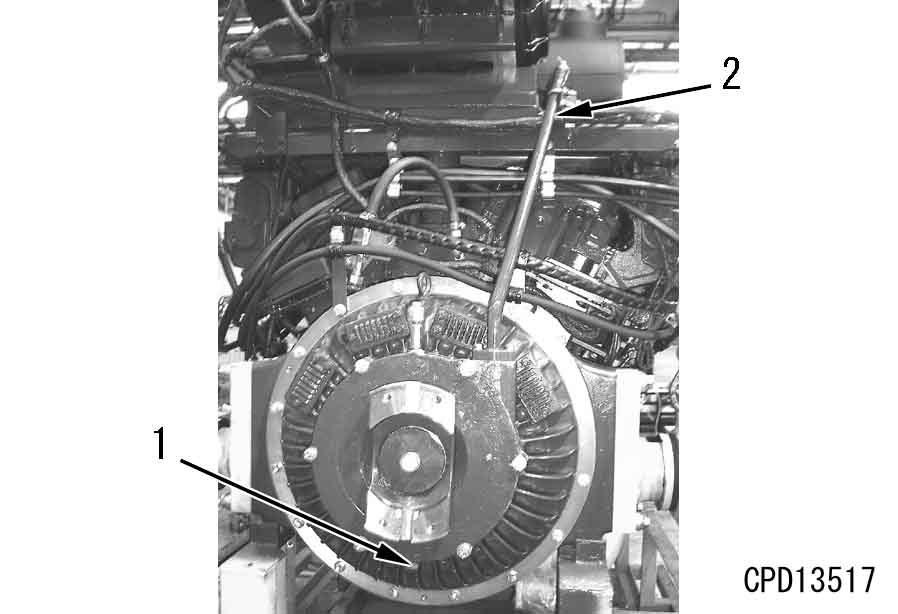

5.Sling universal joint (3), then remove mounting bolts, and lift off. [*1]

4 Universal joint: 65 kg

9.Sling damper assembly (8), then using guide bolt [2] (16 mm, P = 2.0) and nut [3], loosen nut slowly so that damper assembly does not come out suddenly, then remove.

4 Damper assembly: 85 kg

Installation q Carry out installation in the reverse order to removal.

[*1]

3 Universal joint mounting bolt: 156.8 – 196 Nm {16 – 20 kgm}

[*2]

2 Holder mounting bolt thread: Thread tightener (LT-2)

3 Holder mounting bolt: 490 – 607.6 Nm {50 – 62 kgm} q Refilling with oil (damper case)

Add oil through the oil filler to the specified level, and run the engine to circulate the oil through the system. Then check the oil level again.

D475A, D475ASD-5E0

Disassembly and assembly of damper assembly

Disassembly

1.Remove bolt (1), then remove flange (2).

2.Remove seal (3).

3.Remove shaft (4).

4.Remove rubber (5).

5.Remove flange (6) from body (7).

6.Remove seal (8).

7.Remove bearing (9).

Assembly a Install the seal with the lip facing the inside as shown in the diagram.

1.Using push tool, press fit bearing (9).

2 Flywheel pilot portion: Grease (G2-U) a Fill 50% (approx. 55 g) of clearance (a).

2.Install seal (8) to flange (6), and seal (3) to flange (2).

Disassembly of damper cover assembly

8.Remove bearing (10) and seal (11) from cover (12).

9.Remove oil seal (13) from retainer (14).

3.Align the bolt holes with body (7), then install flange (6).

2 Flange mating surface:

Gasket sealant (LG-4) a Check that there are no dents, rust, oil or grease, or water on the mating surface, then coat both the flange and body surfaces with gasket sealant. a Coat with a thickness of about 0.1 – 0.2 mm, leave to dry for 2 – 3 minutes, then tighten. a When assembling the rubber, coat the whole surface of the rubber, the outside circumference of the shaft, and the inside circumference of the body with grease (G2-LI). a After assembling the rubber, fill approx. 50% (approx. 400 g) of the space ((b) portion: 16 places) between the shaft and body with grease (G2-LI).

4.Set shaft (4) to flange and body assembly in position.

5.Assemble rubber (5).

7.Tighten bolt (1).

6.Install flange (2).

2 Flange mating surface: Gasket sealant (LG-4) a Check that there are no dents, rust, oil or grease, or water on the mating surface, then coat both the flange and body surfaces with gasket sealant. a Coat with a thickness of about 0.1 – 0.2 mm, leave to dry for 2 – 3 minutes, then tighten.

Assembly of damper cover assembly

8.Using push tool [1], press fit oil seal (13) to retainer (14).

2 Oil seal press-fitting surface: Gasket sealant (LG-1) a Coat the inside surface of the retainer thinly with gasket sealant and wipe off any sealant that is forced out.

2 Lip of oil seal: Grease (G2-LI)

9.Using push tool [2], press fit bearing (10) to cover (12).

10.Using push tool [1], press fit oil seal (11) to cover (12).

2 Oil seal press-fitting surface: Gasket sealant (LG-1) a Coat the inside surface of the cover thinly with gasket sealant and wipe off any sealant that is forced out.

2 Lip of oil seal: Grease (G2-LI)

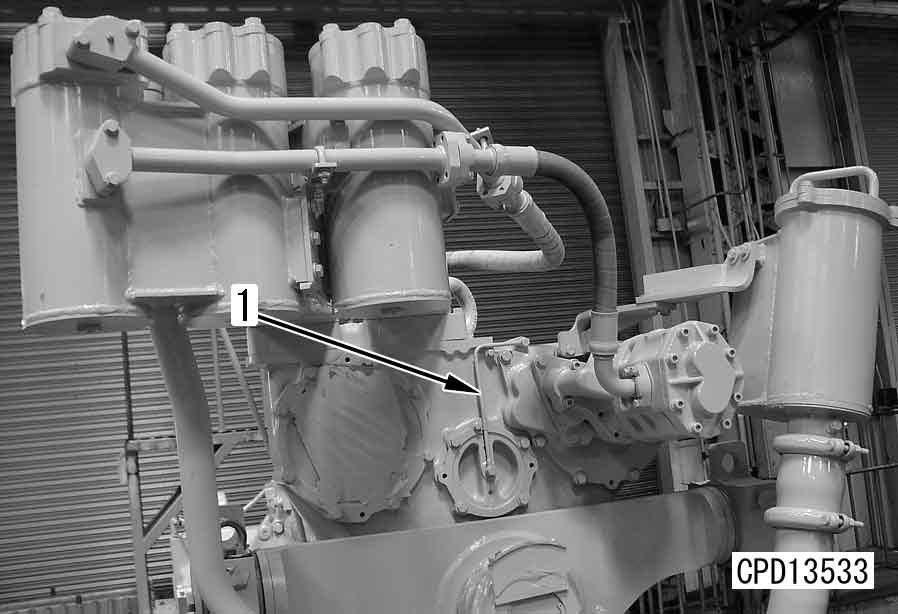

Removal and installation of power train unit assembly

Removal

1.Drain oil from hydraulic tank and power train case.

6 Hydraulic tank: Approx. 120 l

6 Power train case: Approx. 150 l

2.Remove floor frame assembly. For details, see "Removal and installation of floor frame assembly".

3.Remove fuel tank assembly. For details, see "Removal and installation of fuel tank assembly".

4.Remove brake rod (1).

5.Disconnect cable (2).

8.Remove hydraulic pump inlet tube coupling (5) and hydraulic tank side coupling (6), and remove tube (7).

9.Disconnect fan motor hose (8).

10.Disconnect hoses (9) and (10).

11.Disconnect steering hose (11).

12.Disconnect hoses (12) and (13).

6.Disconnect lubrication hose (3).

7.Disconnect fan motor pump tube coupling (4).

13.Remove hydraulic pump inlet tube (14).

14.Disconnect hydraulic pump PPC hoses (15) and (16).

15.Disconnect hydraulic pump outlet hoses (17) and (18).

16.Disconnect hydraulic PPC hoses (19) and (20).

19.Remove universal joint (23).[*1]

4 Universal joint: 65 kg

17.Disconnect wiring connector (21) (PL1, PL2, PL3).

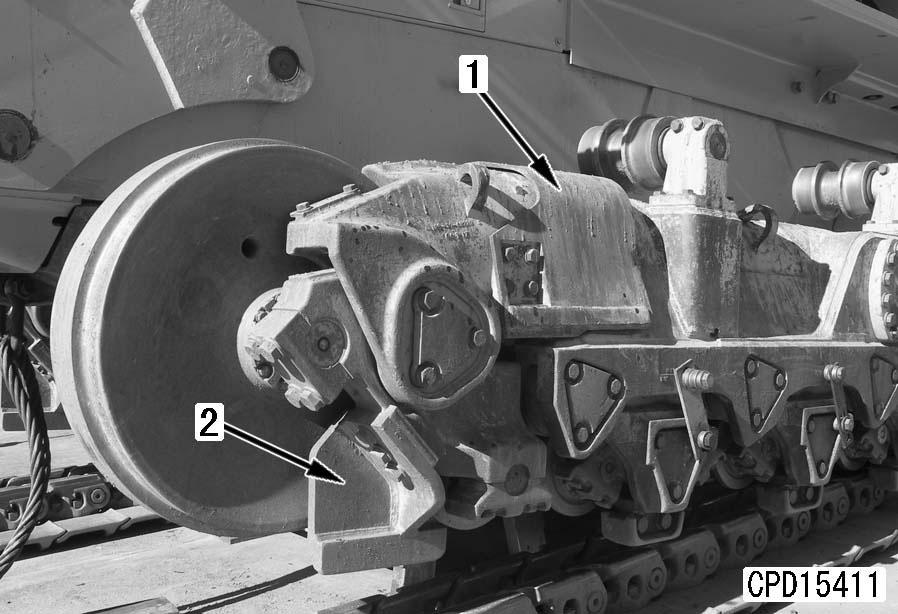

20.Remove front mount bolt (24).[*2]

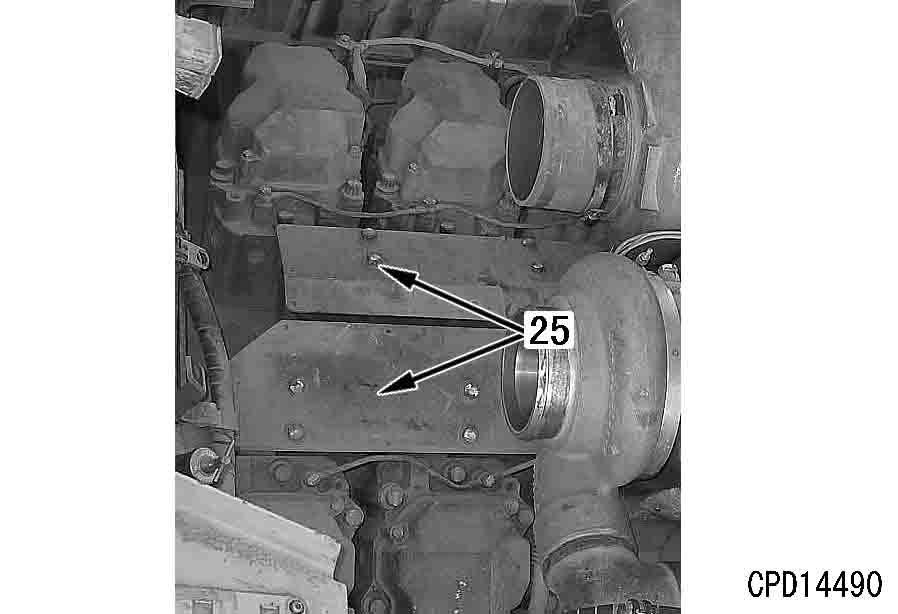

21.Remove rear mount bolt (25), then remove mount cap (26).[*3]

4 Mount cap: 30 kg

18.Disconnect hose (22), then disconnect clamp (1 place) on top of steering case.

22.Remove housing clip (27), and move flange (28) towards final drive end.[*4] a Pull out the shaft with forcing screws [2]. a If the shaft will not come out, set jack [3] on the ground and push the shoe grouser up, then move the sprocket to the front or rear to a position where the shaft will come out, and remove the shaft.

23.Using forcing screws [1], remove cover (29).

24.Remove shaft (30).

Installation q Carry out installation in the reverse order to removal.

[*1]

3 Universal joint mounting bolt: 156.8 – 196 Nm {16 – 20 kgm}

[*2]

3 Front mount bolt: 1,519 – 1,911 Nm {155 – 195 kgm}

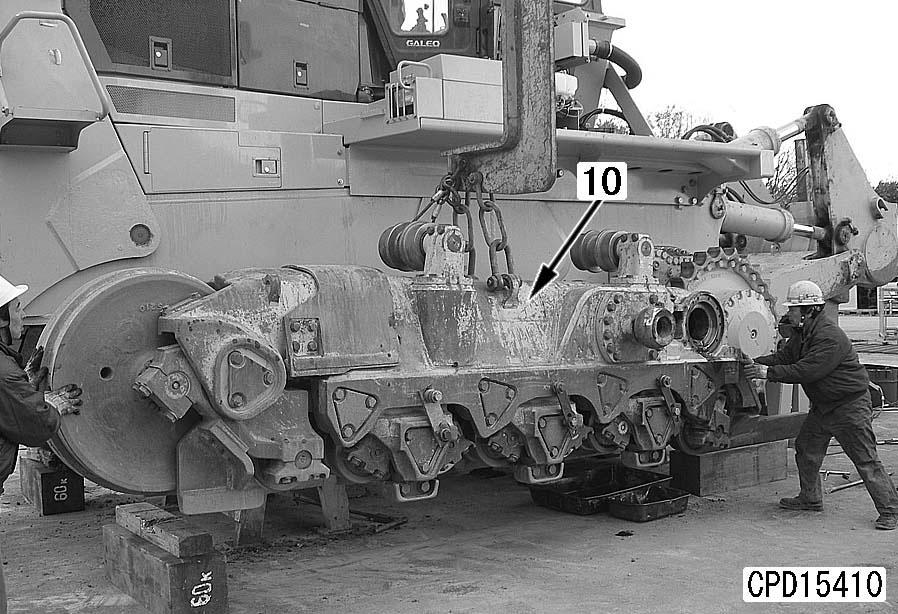

25.Lift off power train unit assembly (31).[*5]

4 Power train unit assembly: 5,500 kg

[*3]

3 Rear mount bolt: 823.2 – 1,029 Nm {84 – 105 kgm}

[*4] a Check that the housing clip is fitted securely in the flange.

3 Housing clip: 4.9 – 8.8 Nm {0.5 – 0.9 kgm}

[*5] a When installing the power train unit assembly, pay attention to the mating surface of the coupling, and be careful not to damage the seal of the rear mount coupling. q Refilling with oil

Add oil through the oil filler to the specified level, and run the engine to circulate the oil through the system. Then check the oil level again.

5 Power train case: Approx. 210 l

5 Hydraulic tank: Approx. 140 l

D475A, D475ASD-5E0

Removal and installation of PTO, torque converter assembly

Removal a Set blocks under the front of the oil pan, transmission rear case, and steering case.

1.Remove power train unit assembly. For details, see "Removal and installation of power train unit assembly".

2.Raise power train unit assembly (1) and set on block.

6.Sling filter assembly (6), then remove.

4 Transmission filter assembly: 40 kg

4 Torque converter, transmission lubrication filter assembly: Approx. 80 kg a Before removing the pressure detection hoses, mark them with tags to prevent any mistake in the mounting position when installing. k Sling the power train pump, then remove together with the strainer.

4.Disconnect central pressure detection hose (3), then remove together with central pressure detection bracket (4).

7.Remove power train pump (7) and strainer assembly (8).

4 Power train pump, strainer assembly: 100 kg

8.Lift off mount bracket (9).[*2]

4 Mount bracket: 70 kg k Sling the scavenging pump, then remove the mounting bolts.

9.Remove tube (10) and scavenging pump (11).

4 Scavenging pump: 24 kg

10.Remove hose (12).

11.Remove gauge guide (13).

14.Remove PTO and torque converter assembly (19).[*3] k Sling the PTO and torque converter assembly, then remove the mounting bolts. a Using a lever block, lift off the PTO and torque converter assembly horizontally.

4 PTO, torque converter assembly: 830 kg

12.Removal of fan pump

1)Remove tube (14).

2)Remove wire (15).

3)Remove connector (16).

4)Lift off pump assembly (17).

4 Fan pump assembly: 75 kg

Installation q Carry out installation in the reverse order to removal.

[*1]

[*2] k Bend the cotter pin securely.

2 PTO boss rotating portion: Grease (G2-LI) a Remove the block under the oil pan, sling the oil pan, then remove the mounting bolts and disconnect the oil pan.

13.Remove oil pan (18).

4 Oil pan: 120 kg

[*3] a Using a lever block, raise the PTO and torque converter assembly horizontally, align it with the spline of the shaft at the steering case end, then install.

D475A, D475ASD-5E0

Disconnection and connection of PTO, torque converter assembly

Special tools

790-413-1010Bracket t 1

790-501-5000Repair stand t 1

Disconnection

1.Set PTO and torque converter assembly (1) to tool C

5.Remove oil seal (6).[*2] a Remove snap ring (8), then remove the spacer. a Remove snap ring (4), then remove the cap.

6.Remove spacer (7).

2.Remove coupling assembly (2).

3.Remove cap (3).

4.Remove retainer assembly (5). [*1] a Using forcing screws, remove the cover, retainer assembly, and shims. a Check the number and thickness of the shims, and keep in a safe place. a Using eyebolts [1], raise the PTO assembly, then disconnect it from the torque converter assembly.

7.Remove PTO assembly (9) and torque converter assembly (10).

4 PTO, torque converter assembly: 830 kg

Connection q Carry out connection in the reverse order to disconnection.

[*1] a Measure clearance (a) at four points ( A , B , C , D ) around the circumference, and take the average as clearance (a). q (a) – (0 to 0.05 mm) a Shim thickness: 0.15 mm, 0.20 mm, 0.50 mm

Adjust the clearance of the taper roller bearing as follows.

1)Assemble the oil seal to the retainer assembly, then install the cover, and tighten to 9.8 Nm {1 kgm}.

2)Using a clearance gauge, measure clearance (a) between the retainer and the housing.

3)Measure shim thickness.

4)Assemble the selected thickness of shim, and tighten the retainer assembly to the specified torque.

3 Retainer mounting bolt: 58.8 – 73.5 Nm {6 – 7.5 kgm} a Assemble the shim as shown in the diagram below so that it does not come at position (b) of the retainer removal tap.

[*2]

2 Outer circumference of oil seal: Gasket sealant (LG-5)

Disassembly and assembly of torque converter assembly

Special tools

790-413-1010Bracket t 1

790-501-5000Repair stand t 1

Disassembly q Set the torque converter assembly to tool C a Disassemble the lockup clutch and drive case assembly as follows.

2)Using eyebolts [1], remove lockup clutch and drive case assembly (4).

1]Remove seal ring (5), and using forcing screws [2], remove input shaft (6).

1.Torque converter valve assembly

Remove torque converter valve assembly (1).

2.Draining oil

Remove 2 drain plugs (2), and drain oil from pump case. a After draining the oil, tighten the plugs.

3.Lockup clutch, drive case assembly a When the assembly is removed, the piston will fall out, so support it by hand when removing. a After removing the discs and plates, keep them in a flat place to prevent them from becoming distorted.

1)Leaving 2 mounting bolts (3) in position, remove mounting bolts, then place input shaft side on top and remove remaining mounting bolts.

2]Remove snap ring (7), then remove plate (8).

3]Set clutch housing side at bottom, and using forcing screws [3], remove turbine (9).

4]Set clutch housing at top, then using eyebolts [4], remove housing and piston assembly (10).

5]Remove piston (11) from housing (12).

9]Remove 3 discs (16) and 2 plates (17) from drive case (18).

6]Remove seal ring (13) from piston.

7]Remove seal ring (14) from housing.

4.Stator assembly

1)Remove snap ring (19), then remove stator assembly (20).

2)Disassemble stator assembly as follows.

1]Remove snap ring (21), then remove race (22) from stator (23).

8]Using push tool [5], remove bearing (15) from housing.

2]Remove snap ring (24) from stator (23).

5.Pump assembly

1)Remove snap ring (25).

2)Remove pump assembly (26).

3)Disassemble pump assembly as follows.

1]Remove retainer (27).

2]Remove bearing and guide assembly (28) from pump (29).

9.Pin

Remove pin (37).

3]Remove bearing outer race (30) from guide (31).

6.Stator

Set stator clutch housing at top and remove stator clutch housing (32).

10.Inner gear

Remove snap ring (38), then remove inner gear (39).

11.Piston

1)Remove piston (40) from case (41).

7.Spring

Remove spring (33).

8.Springs, discs, plate a After removing the discs and plates, keep them in a flat place to prevent them from becoming distorted.

Remove springs (34), 2 discs (35), and 1 plate (36).

2)Remove seal ring (42) from piston.

3)Remove seal ring (43) from case.

12.Stator shaft assembly

1)Tap stator shaft assembly (44) with a plastic hammer, and remove from case (45).

2)Disassemble stator shaft assembly as follows.

1]Using push tool [6], remove shaft assembly (46) from stator shaft assembly.

5]Using push tool [7], remove bearing (55), then remove plate (56).

2]Remove snap ring (47), then remove bearing inner race (48), bushing (49), and seal ring (50) from shaft.

3]Remove seal ring (51) from stator shaft (52).

4]Remove snap ring (53), then remove plate (54).

Assembly

a Wash all parts in clean flushing oil (in particular, oil holes, etc.), then dry them, and check for dirt or damage. Coat the sliding surfaces of all parts with engine oil before installing.

q Set case (41) to tool C.

1.Stator shaft assembly

1)Assemble plate (56) to stator shaft (52), and using push tool, press fit bearing (55).

a Put drops (approx. 6 cc) of engine oil (SAE10W-CD or SAE30-CD) on the bearing and rotate about 10 times.

2)Install plate (54), and secure with snap ring (53).

3)Install seal ring (51) to stator shaft (52).

a After installing the seal ring, coat it with grease (G2-LI) to fix it to the shaft securely.

7)Install snap ring (47), and secure inner race.

4)Install seal ring (50) to shaft.

a After installing the seal ring, coat it with grease (G2-LI) to fix it to the shaft securely.

5)Using push tool [9], press fit bushing (49) to shaft.

a Be careful not to deform the bushing when press fitting.

6)Using push tool [10], press fit inner race (48) to shaft.

8)Tap stator shaft (52) with a plastic hammer and press fit bearing portion to case.

9)Set shaft (46) to stator shaft, then using push tool, press fit bearing portion.

10)Turn over case and tighten mounting bolts of shaft from case end.

2 Mounting bolt: Thread tightener (LT-2)

3 Mounting bolt: 58.8 – 73.5 Nm {6 – 7.5 kgm}

2.Piston

1)Install seal ring (43) to case.

2 Outer circumference of seal ring: Grease (G2-LI) a Be careful to assemble the seal ring facing in the direction shown in the diagram below.

2)Install seal ring (42) to piston.

2 Outer circumference of seal ring: Grease (G2-LI) a Be careful to assemble the seal ring facing in the direction shown in the diagram below.

6.Spring

Install spring (33).

3)Install piston (40) to case (41).

2 Contact surface of seal ring: Grease (G2-LI)

3.Inner gear

Install inner gear (39) and secure with snap ring (38).

7.Stator clutch housing a Check that the springs are fitted securely in the holes in the housing and piston.

Install stator clutch housing (32).

2 Mounting bolt: Thread tightener (LT-2)

3 Mounting bolt: 98 – 122.5 Nm {10 – 12.5 kgm}

8.Pump assembly a Put drops (approx. 6 cc) of engine oil (SAE10W-CD or SAE30-CD) on the bearing and rotate about 10 times.

1)Assemble pump assembly as follows.

1]Using push tool, press fit bearing outer race (30) to guide (31).

4.Pin Install pin (37).

5.Plate, discs, springs

Install 1 plate (36), 2 discs (35), and springs (34).

2]Set bearing and guide assembly (28) to pump (29), then tap with a plastic hammer and press fit bearing portion.

3]Install retainer (27).

2 Mounting bolt: Thread tightener (LT-2)

3 Mounting bolt: 58.8 – 74.5 Nm {6 – 7.5 kgm} a When installing the pump, be careful not to damage the seal ring assembled to the shaft.

2)Install pump assembly (26).

3)Install snap ring (25).

10.Lock-up clutch, drive case assembly

1)Assemble lock-up clutch and drive case assembly as follows.

1]Set turbine (9) to block [11], and set drive case (18) to turbine.

9.Stator assembly

1)Assemble stator assembly as follows.

1]Install snap ring (24) to stator (23).

2]Install 3 discs (16) and 2 plates (17).

2]Assemble race (22) to stator (23), and secure with snap ring (21).

2)Install stator assembly (20) to stator shaft, and secure with snap ring (19).

3]Install seal ring (14) to housing.

2 Outer circumference of seal ring: Grease (G2-LI)

4]Install seal ring (13) to piston.

2 Outer circumference of seal ring: Grease (G2-LI)

5]Install piston (11) to housing (12).

2 Contact surface of seal ring: Grease (G2-LI) a When installing, be careful not to damage the seal ring. a Support the piston assembly by hand to prevent it from falling out when installing.

6]Using eyebolts [4], install housing and piston assembly (10).

2 Mounting bolt: Thread tightener (LT-2)

3 Mounting bolt: 98 – 122.5 Nm {10 – 12.5 kgm} a Align the positions of the turbine oil groove ( mark) and drain plug (2) when installing. a Put drops (approx. 6 cc) of engine oil (SAE10W-CD or SAE30-CD) on the bearing and rotate about 10 times.

2)Using eyebolt [1], install lock-up clutch and drive case assembly (4).

7]Using push tool, press fit bearing (15).

8]Install plate (8), and secure with snap ring (7).

9]Install input shaft (6).

2 Mounting bolt: Thread tightener (LT-2)

3 Mounting bolt: 156.8 – 196 Nm {16 – 20 kgm}

10]Install 2 seal rings (5).

3)Tighten mounting bolts (3). a Check that drain plug (2) is tightened.

3 Mounting bolt: 49 – 58.8 Nm {5 – 6 kgm}

3 Drain plug: 9.8 – 12.7 Nm {1 – 1.3 kgm}

D475A, D475ASD-5E0

11.Torque converter valve assembly

Install torque converter valve assembly (1). a Tighten the mounting bolts uniformly in turn and be careful not to tighten them unevenly.

3 Mounting bolt: 43.1 – 53.9 Nm {4.4 – 5.5 kgm}

Disassembly and assembly of PTO assembly

Disassembly

1.PTO lubrication tube a Remove the 3 lubrication tubes on the opposite side also, set the torque converter end at the bottom, then lower.

Sling PTO assembly and remove lubrication tube (1).

3)Using puller [2], remove bearings (5) and (6) from gear (7).

2.Hydraulic pump gear assembly

1)Using forcing screws [1], pull out cover assembly (2) and lift off.

2)Using puller [2], remove gear assembly (3) from cover (4).

3.Power train and PPC pump gear assembly

1)Using forcing screw [1], pull out cover assembly (8) and lift off.

2)Using puller [2], remove bearing (9).

3)Remove gear (10).

4)Using push tool [3], remove boss (11) and bearing (12) from cover.

5)Using forcing screw [4], remove bearing (12) from boss (11).

4.Scavenging drive gear

Remove snap ring (13) from bottom of PTO case, then remove gear (14).

5.Shaft assembly

1)Remove plate (15) of idler gear.

6.Idler gear assembly

1)Remove idler gear assembly (19) and bearing (20) from bottom of PTO case.

2)Remove outer race (21).

2)Turn over PTO case, then using forcing screw [1], remove shaft assembly (16). a The bearing outer race and key assembly will come out from the bottom of the PTO case, so place a wooden block in position and be careful not to damage the assembly.

3)Remove plug (17), then using forcing screw, push out bearing (18). a After removing the bearing, assemble the plug again in the correct position.

7.PTO case

1)Remove race assembly (24) together with bearing outer race (25).

2)Remove bearing inner races (26) and (27) from race (28).

3)Remove bearing outer race (29).

4)Remove sleeve (30).

Assembly a Clean all parts, and check for dirt or damage. a Check that the snap ring is fitted securely in the groove.

1.Bearing a Put drops (approx. 6 cc) of engine oil (SAE10W-CD or SAE30-CD) on the bearing and rotate about 10 turns.

1)Using push tool, press fit bearing (23) to case.

2)Install snap ring (22).

8.Bearing

1)Remove snap ring (22).

2)Remove bearing (23).

2.PTO case a Install the sleeve with the chamfered inside circumference facing down. a Expand-fit the sleeve.

1)Install sleeve (30) to case.

2)Using push tool, press fit bearing outer race (29).

D475A, D475ASD-5E0

3)Using push tool, press fit bearing inner races (27) and (26) to race (28).

4.Shaft

Assembly

1)Using push tool [6], press fit bearing inner race (18) to shaft.

2)Fit O-ring, align shaft assembly (16) with idler gear, then insert.

4)Install race assembly (24).

2 Internal surface of race: Anti-friction compound (LM-P) a Put drops (approx. 6 cc) of engine oil (SAE10W-CD or SAE30-CD) on the bearing and rotate about 10 turns.

5)Using push tool, press fit bearing outer race (25).

5.Bearing

1)Turn over PTO case, and press fit bearing spacer (31) and bearing inner race (20) to shaft, then tighten mounting bolts of shaft assembly. a Put drops (approx. 6 cc) of engine oil (SAE10W-CD or SAE30-CD) on the bearing, then rotate approx. 10 turns.

3.Idler gear

1)Using push tool [5], press fit bearing outer race (21) to gear (19).

2)Position idler gear to PTO case.

2)Install plate (15).

2 Mounting bolt: Thread tightener (LT-2)

3 Mounting bolt: 98 – 123 Nm {10 – 12.5 kgm}

6.Scavenging drive gear

1)Install gear (14).

2 Spline portion: Grease (G2-LI)

2)Using push tool [8], press fit boss (11) and bearing (12) to cover. a Expand fit the bearing.

2 Boss spline portion: Grease (G2-LI)

3)Install gear (10).

2 Gear spline portion: Grease (G2-LI)

2 Gear mounting bolt: Thread tightener (LT-2)

3 Gear mounting bolt: 98 – 122.6 Nm {10 – 12.5 kgm}

2)Install snap ring (13) from bottom of PTO case.

7.Power train, PPC pump gear assembly

1)Using push tool [7], press fit bearing (12) to boss (11).

4)Using push tool [7], press fit bearing (9) to gear (10).

5)Raise cover assembly (8) and install. a If the cover assembly is stiff and does not enter the case, use a plastic hammer and tap evenly on the side face to install.

D475A, D475ASD-5E0

8.Hydraulic pump gear assembly

1)Using push tool [7], press fit bearings (5) and (6) to gear (7).

9.Lubrication tube

Sling PTO assembly, then install lubrication tube (1).

a Install 3 lubrication tubes also on the opposite side.

3 Mounting bolt:

19.6 – 29.4 Nm {2 – 3 kgm} a Expand fit the bearing. a Set the end where the bearing end face and gear end face are level so that it faces the cover.

2)Using push tool [8], press fit gear assembly (3) to cover (4).

2 Gear spline portion: Grease (G2-LI) a If the cover assembly is stiff and does not enter the case, use a plastic hammer and tap evenly on the side face to install.

3)Fit O-ring, then raise cover assembly (2) and install to case.

Removal and installation of TORQFLOW transmission assembly

Removal q Remove PTO and torque converter assembly. For details, see "Removal and installation of PTO, torque converter assembly".

1.Remove TORQFLOW transmission assembly (1).[*1] k Sling the transmission assembly, then remove the mounting bolts. a Using a lever block, raise the transmission horizontally, then remove from the steering.

4 TORQFLOW transmission assembly: 1,330 kg

Installation q Carry out installation in the reverse order to removal.

[*1] a Using a lever block, sling transmission assembly (1) horizontally, align with spline of shaft at steering case end, then install.

Disassembly and assembly of TORQFLOW transmission assembly

Special tools

790-413-1010Bracket t 1

790-501-5000Repair stand t 1

799-301-1600Oil leak tester t 1

Disassembly q Set the transmission assembly on the block.

1.Control valve assembly

1)Remove cover (1).

2)Remove control valve assembly (2) together with seat.

3.Transmission case

1)Turn over transmission assembly, and remove plate (10).

2)Using eyebolts, remove transmission case (11).

2.Sleeve

1)Remove plug (8).

2)Using eyebolts [1], pull out sleeve (9).

4.Housing

1)Remove 17 tie bolts (12).

2)Using eyebolts, remove housing (13).

3)Remove seal ring (14) from housing.

5.Spring

Remove spring (15).

6.Discs, plates, springs a Keep the discs and plates in a flat place to prevent them from becoming deformed.

Remove discs (16), plates (17), and springs (18) in turn.

7.No. 1 ring gear

Remove ring gear (19).

11.Sleeve, guide pin

1)Remove sleeve (27).

2)Remove guide pin (28).

8.No. 1 housing, piston

1)Using eyebolts, remove No. 1 housing and piston assembly (20).

2)Remove piston (22) from housing (21).

12.Shaft, No. 1, 2, 3 carrier assembly

Using eyebolts, remove No. 1, 2, and 3 carrier assembly (29).

4 Shaft, No. 1, 2, 3 carrier assembly: 200 kg

1)Disassemble the shaft and carrier assembly as follows.

1]Remove snap ring (130), then remove sun gear (30).

2]Using eyebolts, remove shaft and No. 1 carrier assembly (31) from No. 2 and 3 carrier assembly (32).

9.Spring

Remove spring (23).

10.Discs, plates, springs a Keep the discs and plates in a flat place to prevent them from becoming deformed.

Remove discs (24), plates (25), and springs (26) in turn.

D475A, D475ASD-5E0

2)Disassemble the shaft and No. 1 carrier assembly as follows.

1]Raise the assembly, then using forcing screw [2], remove shaft and cage assembly (33).

2]Using plastic hammer, remove cage assembly (34), spacer (35), and bearing (36).

3]Remove seal ring (37) from cage assembly.

4]Remove seal ring (38) from cage.

5]Remove seal ring (40) from shaft (39).

3)Disassemble the No. 2, No.3 carrier assembly as follows.

1]Remove sun gear (48).

2]Using eyebolts, remove plate and gear assembly (49).

6]Remove shaft (42), ball (43), thrust washer (44), gear (45), and bearing (46) from No. 1 carrier assembly (41).

7]Remove seal rings (47) and (131).

3]Remove ring (50), and disassemble plate (51) and gear (52).

4]Remove plate (54) from No. 2, 3 carrier assembly (53).

5]Remove seal ring (55) from plate.

6]Remove shaft (56), ball (57), thrust washer (58), gear (59), and bearing (60).

7]Using push tool, remove collar and bearing assembly (61) from carrier.

8]Using push tool, remove bearing (62).

15.No. 3 piston

Remove No. 3 piston (71).

16.Spring

Remove spring (72).

17.Discs, plates, springs a Keep the discs and plates in a flat place to prevent them from becoming deformed.

Remove discs (73), plates (74), and springs (75) in turn.

9]Using puller and push tool, remove bearing (63) and spacer (64) from collar (65).

10]Remove seal ring (66).

18.Seat

Remove seat (76).

19.No. 3 housing

Using eyebolts, remove No. 3 housing (77).

4 No. 3 housing: 55 kg

20.No. 4 piston

Remove No. 4 piston (78).

13.No. 2 ring gear

Remove ring gear (67).

14.No. 2 housing, piston

1)Using eyebolts, remove No. 2 housing and piston assembly (68).

4 No. 2 housing, piston: 80 kg

2)Remove piston (70) from housing (69).

21.Spring

Remove spring (79).

22.Discs, plates, springs a Keep the discs and plates in a flat place to prevent them from becoming deformed.

Remove discs (80), plates (81), and springs (82) in turn.

23.Guide pin

Remove guide pin (83).

24.Sun gear

Remove snap ring (132), then remove sun gear (84).

26.No. 3 ring gear

1)Remove ring gear (91).

2)Remove ring (92) from ring gear.

25.Plate, bearing

1)Using eyebolts, remove plate and bearing assembly (85).

2)Using push tool [3], remove bearing (87) from plate (86).

3)Using puller [4] and push tool [3], remove bearing (88).

4)Using push tool, remove bearing (90) from collar (89).

27.Plate, ring gear

1)Using forcing screws, remove plate and ring gear assembly (93).

2)Remove ring gear (94).

28.No. 4 carrier, No. 5 clutch assembly

Using eyebolts, remove No. 4 carrier and No. 5 clutch assembly (95).

1)Disassemble the No. 4 carrier and No. 5 clutch assembly as follows.

1]Remove 2 mounting bolts, then install guide bolts.

2]Remove remaining mounting bolts, then loosen guide bolts [5] slowly, and remove No. 4 carrier assembly (96) from No. 5 clutch assembly (97).

4 No. 4 carrier assembly, No. 5 clutch assembly: 160 kg

3]Remove shaft (98), ball (99), thrust washer (100), gear (101), and bearing (102).

9]Remove piston (112) from No. 5 housing (111).

10]Remove spacer (113) and seal ring (114) from No. 5 housing.

29.Shaft a Keep the discs and plates in a flat place to prevent them from becoming deformed.

Remove shaft (115).

4]Remove spring (103) and pin (104).

5]Remove discs (105), plates (106), and springs (107).

6]Remove guide pin (108).

7]Remove inner gear (109).

8]Remove seal ring (110) from inner gear.

30.Shaft assembly

Set case so that shaft is at bottom, then using eyebolts, remove shaft assembly (117) from case (116).

4 Shaft assembly: 80 kg

1)Disassemble the shaft assembly as follows.

1]Remove snap ring, then using eyebolts, sling shaft assembly, knock out bearing portion, and remove shaft assembly (118).

2]Remove cage (119).

3]Using stand [6], remove bearing (120).

9]Remove snap ring (135), then remove boss and bearing (127).

10]Remove snap ring (136), then using push tool, remove bearing (129) from boss (128).

4]Remove snap ring (134), then remove bearing (121) from cage (133).

5]Remove seal ring (122).

6]Remove cover (123).

Assembly

a Wash all parts in clean flushing oil (in particular, oil holes, etc.), then dry them, and check for dirt or damage. Coat the sliding surfaces of all parts with engine oil before installing.

a Set the seal ring facing its pressure receiving side for the housing, then coat with grease (G2-LI) and install uniformly so that it is positioned correctly.

a Align the notches of the oil groove when installing the discs.

7]Remove bearing (124).

8]Remove seal ring (126).

1.Shaft assembly

1)Assemble the shaft assembly as follows.

1]Install seal ring (126).

2]Using push tool, install baring (124).

8]Using eyebolts, sling shaft assembly (118), then press fit bearing, and secure with snap ring.

2)Set the case so that the side for installing the steering assembly is at the top, then using eyebolts, install shaft assembly (117) in the case (116).

3]Install cover (123).

4]Install seal ring (122).

5]Install bearing (121) to cage (133) and secure with snap ring (134).

2.No. 4 carrier, No. 5 clutch assembly

1)Assemble the No. 4 carrier and No. 5 clutch assembly as follows.

1]Using push tool, install spacer (113) to No. 5 housing (111).

2]Install seal ring (114).

3]Install piston assembly (112) to No. 5 housing (111).

6]Using push tool, press fit bearing (120).

7]Fit seal ring and install cage (119).

4]Install seal ring (110) to inner gear.

5]Install inner gear (109).

6]Install guide pin (108).

7]Install springs (107), plates (106), and discs (105) in turn.

8]Install pin (104) and spring (103). a Free length of spring: 103.5 mm

11]Set No. 4 carrier assembly (96) to No. 5 clutch assembly (97), and using 2 guide bolts [5], compress spring, then tighten mounting bolts. a Check that the spring is fitted securely in the hole of the housing, then tighten the mounting bolts.

2 Mounting bolt: Thread tightener (LT-2)

3 Mounting bolt: 157 – 196 Nm {16 – 20 kgm}

9]Assemble bearing (102) in gear (101), and fit thrust washers (100) to both sides, then set in position in carrier.

10]Assemble ball (99) to shaft (98), and push shaft into carrier.

2)Using eyebolts, install No. 4 carrier and No. 5 clutch assembly (95).

3.Plate, ring gear a To ensure that the plate is fitted facing in the correct direction, check the bolt hole, then knock in the dowel pin portion with a plastic hammer until there is no clearance at the mating surface.

1)Using eyebolts, align with dowel pin, then install plate (93).

2)Install ring gear (94).

4.No. 3 ring gear

1)Install ring gear (92).

2)Install No. 3 ring gear (91).

5.Plate, bearing a Set the large protrusion of the bearing assembly on top as shown in the diagram below, and install to the plate.

1)Using push tool, press fit bearing (90) in collar (89).

2)Using push tool, press fit bearing (88).

3)Using push tool, press fit bearing (87) in plate (86).

4)Using eyebolts, install plate and bearing assembly (85).

6.Sun gear

Install sun gear (84), and secure with snap ring (132).

7.Guide pin

Install guide pin (83).

8.Discs, plates, springs

Install springs (82), plates (81), and discs (80) in turn.

9.Spring

Install spring (79). a Free length of spring: 81.7 mm

10.No. 4 piston

Fit seal ring and install No. 4 piston (78).

11.No. 3 housing

Using eyebolts, fit seal ring and install No. 3 housing (77).

12.Seat Install seat (76).

13.Discs, plates, springs

Install springs (75), plates (74), and discs (73) in turn.

14.Spring

Install spring (72). a Free length of spring: 84 mm

15.No. 3 piston

Fit seal ring and install No. 3 piston (71).

17.No. 2 ring gear

Install ring gear (67).

16.No. 2 housing, piston a Check that the spring is fitted securely in the hole of the housing.

1)Fit seal ring, and install piston (70) to housing (69).

2)Using eyebolts, install No. 2 housing and piston (68).

18.Shaft, No. 1, 2, 3 carrier assembly

1)Assemble the No. 2, No. 3 carrier as follows.

1]Install seal ring (66) to carrier.

2]Using push tool, press fit spacer (64) and bearing (63) in collar (65).

3]Using push tool, press fit bearing (62).

4]Using push tool, press fit collar and bearing (61) in carrier.

5]Assemble bearing (60) in gear (59), then fit thrust washers (58) to both sides, and set in carrier.

6]Assemble ball (57) to shaft (56), and push shaft into carrier.

2)Assemble the shaft and No. 1 carrier assembly as follows.

1]Install seal rings (47), (131) to carrier.

2]Assemble bearing (46) in gear (45), then fit thrust washers (44) to both sides, and set in carrier.

3]Assemble ball (43) to shaft (42), and push shaft into carrier case (41).

7]Install seal ring (55) to plate.

8]Install plate (54) to No. 2, 3 carrier assembly (53).

9]Set plate (51) to gear (52), and install ring (50).

4]Install seal ring (40) to shaft (39).

5]Install seal ring (38) to cage.

10]Using eyebolts, install plate and gear assembly (49).

11]Install sun gear (48), and secure with snap ring.

6]Using push tool, press fit bearing (37) in cage.

7]Press fit bearing (36) in shaft.

8]Set spacer (35) to bearing and cage assembly (34), and press fit shaft (39).

2]Set carrier assembly on its side, then install sun gear (30), and secure with snap ring (130).

Using eyebolts, install shaft and No. 1, 2, 3 carrier assembly (29) to housing.

9]Using eyebolts, install shaft and cage assembly (33).

3)Assemble the shaft and carrier assembly as follows.

1]Using eyebolts, install shaft and No. 1 carrier assembly (31) to No. 2, 3 carrier assembly (32). a Align the sun gear with the tooth face of the planetary gear, and tap with a plastic hammer to install.

19.Sleeve, guide pin

1)Install guide pin (28).

2)Install sleeve (27).

20.Discs, plates, springs

Install springs (26), plates (25), and discs (24) in turn.

21.Spring Install spring (23). a Free length of spring: 112 mm

22.No. 1 housing, piston

1)Fit seal ring and install piston (22) to housing (21).

2)Using eyebolts, install No. 1 housing and piston (20).

a Check that the spring is fitted securely in the hole of the housing.

26.Housing

1)Install seal ring (14) to housing.

2)Using eyebolts, set housing (13) in position.

3)Tighten 17 tie bolts (12) in turn.

3 Tie bolts: 353 – 392 Nm {36 – 40 kgm}

23.No. 1 ring gear

Install ring gear (19).

24.Discs, plates, springs. Install springs (18), plates (17), and discs (16) in turn.

25.Spring Install spring (15). a Free length of spring: 112 mm

27.Checking piston stroke