1 minute read

CHAPTER 8 LUBRICATION

General Information Caution

NEVER attempt to lubricate this unit when any part of the machine is in motion. ALWAYS BE SURE to exercise the MANDATORY SAFETY SHUTDOWN PROCEDURE (page 8) BEFORE proceeding to lubricate this equipment.

NOTE: Before starting the Baler, make sure the entire unit is properly lubricated and that the Main Gear Housing is filled to the proper oil level.

It is well to remember that a sufficient amount of oil and grease will prevent excessive part wear and early failure.

Main Gear Housing

The Main Gear Housing should be checked at the start of each season of Baler operation and after every 100 hours of operation, thereafter. Replenish the oil level, as necessary. The Housing requires approximately 7 U.S. quarts (6.7 liters) of EP80W90 Gear Lube. Order and obtain a 1 Quart Bottle by Gehl Part Number 127178.

NOTE: Do NOT overfill the Gear Housing; only fill to the bottom of the Oil Level Plug hole.

Oiling

Lubricate all Drive Chains using a good grade of foaming aerosol lubricant, such as NAPA Chain and Cable Lubricant. This type of lubricant increases the life of the Chain 3 to 4 times over those lubricated at 8 hour intervals with new or used motor oil. The recommended method is to spray the entire length of Chain on the center of the Rollers. It is better to lubricate Chains when they are warm (after use, rather than before).

In addition to the Roller Chains, apply motor oil on all other points listed at the intervals specified.

Lubricate Every 10 hours (or daily)

All Roller Drive Chains

Lubricate Every 50 hours

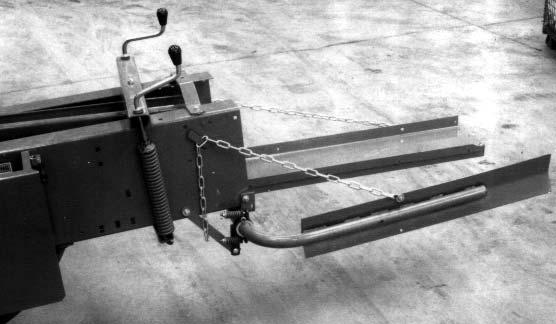

Drawbar Position Control Latch

Lubricate Every 500 hours (or annually)

All Pivot Points and the Bale Chamber Plunger Rails

Greasing

NOTE: Grease all fittings on a prescribed basis, at the intervals of operation listed, before and after storing the unit, and as otherwise listed. Use a good grade of Lithium base grease.

Wipe dirt from the fittings before greasing to prevent the dirt from being forced into the Bearing or pivot. Replace any missing fittings, when noted. Force the grease into the fitting until it comes out at the Bearing Seal or at the Shaft. To minimize dirt build-up, avoid excessive greasing.

NOTE: In addition to the fittings, check and repack (if necessary) the Wheel Bearings once a year and before placing Baler into storage.

Grease Fitting Locations

Grease Every 50 hours

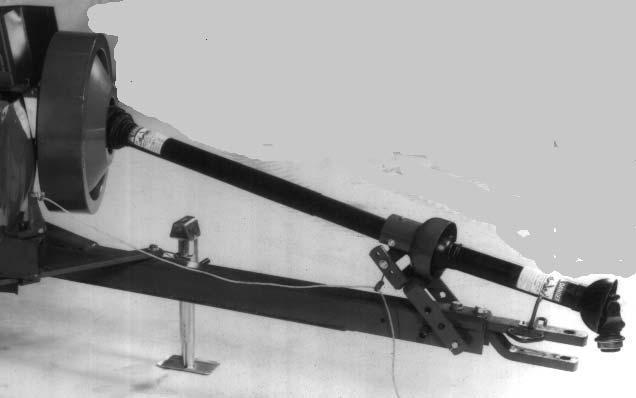

1.Telescoping Section of PTO Drive (2 Places at 180° apart)

2.PTO U-Joint Crosses (3 Places)

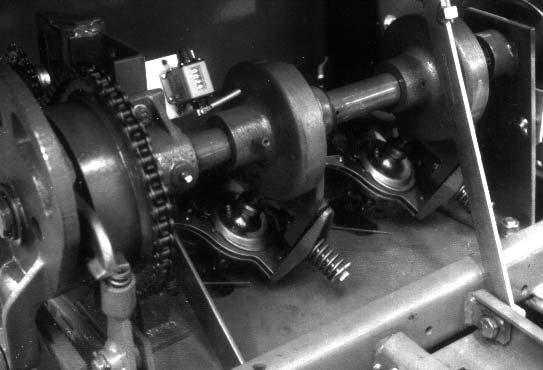

3.Main Drive Chain Fixed Idler Sprocket

4.Plunger Bushing

5.Packer Gearbox (Access Hole in Shield)

6.Packer Fork Assembly Bushing

7.Pickup Gauge Wheel

8.Knotter Drive Sprocket

Grease ONLY Once a Year

9.Knotter Assembly Bearings (3 Places)

10.Both Knotter Mechanisms (1 Each Disc)