7 minute read

Hydraulics

THE C MODEL

General Description

The combine has three separate hydraulic circuits: traction hydraulics, the combined lifting and steering hydraulics and the low-pressure connection hydraulics. All the circuits use the same oil tank and filter. There are two pumps in the system. They are located at the rear of the engine in the distribution gear and form an entity. Hydrostatic steering and working hydraulics use a joint pump. Hydrostatic steering gets its oil by means of a priority valve. The valve always supplies the amount of oil needed in steering and the rest can be used in other working hydraulics. Traction hydraulics works in a closed circuit. The engine return oil returns straight into the pump. Connection hydraulics uses the feed oil in traction hydraulics. Depending on the specification, the combine may have 4WD. 4WD gets the oil from the main transmission by means of a connection valve on the rear axle. With the drive switched off the rear wheels rotate freely and there is no oil circulating in the final drives. There is also an oil cooler in the system located in the traction hydraulics return line before the filter. The cooler functions are controlled by means of a thermostat valve. The control valves in working hydraulics are electrically controlled and located at the front beneath the cab. There are two valves: the valve further front houses the control valves of table height and free circulation; the one further back houses the control valves of the reel lift and the turning of the unloading pipe. Movement speeds are regulated by restrictors at the control valve gates except for the table lowering speed, which can be adjusted by the operator.

The control valve for connection hydraulics is also located on the left-hand side, below the oil tank.

Pump output in working hydraulics is 27 l/min. Working pressure is restricted to 180 Bar.

Pump output in traction hydraulics is 217 l/min. Maximum working pressure is 420 Bar. Feed pressure in traction hydraulics is approx. 25 Bar.

HYDRAULICS

THE STANDARD MODEL

General Description

The combine has four separate hydraulic circuits: traction hydraulics, the combined lifting and steering hydraulics, the combined drive hydraulics for the reel and the chaff spreader and the low-pressure connection hydraulics. All the circuits use the same oil tank and filter. There are three pumps in the system. They are located at the rear of the engine, in the distribution gear and form an entity. Hydrostatic steering and working hydraulics use a joint pump. Hydrostatic steering gets its oil by means of a priority valve. The valve always supplies the amount of oil needed in steering and the rest can be used in other working hydraulics. There is a separate pump for reel rotation, which also drives the optional chaff spreader. The spreader gets switched on when the threshing mechanism is started. Traction hydraulics works in a closed circuit. The engine return oil returns straight into the pump. Connection hydraulics uses the feed oil in traction hydraulics. Depending on the specification, the combine may have 4WD. 4WD gets the oil from the main transmission by means of a connection valve on the rear axle. With the drive switched off the rear wheels rotate freely and there is no oil circulating in the final drives. There is also an oil cooler in the system located in the traction hydraulics return line before the filter. The cooler functions are controlled by means of a thermostat valve. The control valves in working hydraulics are electrically controlled and located at the front beneath the cab. There are two valves: the valve further front houses the control valves of table height and free circulation; the one further back houses the control valves of the reel lift and for/aft, the cutting table side tilt and the turning of the unloading pipe. Movement speeds are regulated by restrictors at the control valve gates except for the table lowering speed, which can be adjusted by the operator. The valve for reel rotation is located under the left-side guard below the oil tank. It contains the connection valve, the torque regulator valve and the speed regulator valve. The connection and torque regulator valve for the optional chaff spreader is located next to the reel valve. The control valve for connection hydraulics is also located on the left-hand side, below the oil tank.

Pump output in working hydraulics is 27 l/min. Working pressure is restricted to 180 Bar. Pump output in reel drive hydraulics is 27 l/min. Maximum working pressure for the reel has a factory setting of 75 Bar. The chaff spreader is connected to the series before the reel regulator valve. Its pressure setting is 125 Bar, which means that there is a minimum of 50 Bar pressure difference for the spreader. Pump output in traction hydraulics is 217 l/min. Maximum working pressure is 420 Bar. Feed pressure in traction hydraulics is approx. 25 Bar.

R9

Adjustment of Table Lowering Speed

The table lowering speed can be adjusted steplessly by regulating knob A, fig. R9, on the valve.

The oil tank is in the engine compartment. Periodic service measures include checking of the oil level and changing of the oil and filters. To check the oil level, there is transparent measuring hose A, fig, R10, on the oil tank. The oil level must be visible in the hose, near the maximum, with the cutting table and the reel lowered. New pure oil is added through filler B, when necessary. Before unplugging the filler, clean the whole area carefully to prevent any impurities from getting into the tank. Keep the area around the oil tank always clean. Daily service measures also include checking and, if necessary, cleaning of the oil cooler. The cooler is positioned at the front of the engine radiator. At the base of the oil filter there is a sensor that indicates flow loss through the filter. If the control light on the instrument panel comes on with the engine running at full speed and the oil in its operating temperature, the filter cartridge is blocked and shall be replaced. R10

Change of Oil and Filter

The oil and filters are changed every 600 h or at least once a year before the beginning of the harvesting season to remove any condensed water from the system after the winter. The oil is drained by opening drain A, on left hand side of the combine, fig. R11. After draining of the oil, replace filter cartridge C, fig R10. Clean the area round the filter carefully before removing the filter. Check and, if necessary, change the filter cover gasket before refitting. Use original filters only to ensure perfect functioning of transmission. Fill the filter housing with pure oil before closing the cover. Used oil and filter are problem waste, which shall be disposed of in an appropriate manner. Use an oil type in accordance with the oil table. Make sure the oil is free from any impurities. Always R11 use a clean funnel. After oil change let the engine idle for some 15 minutes during which time no hydraulics must be used. During this time the oil circulates through the filters several times and the impurities in the oil are filtered off. Monitor the oil level and check for leaks in the filter. Air is bled from the system by turning the steering wheel several times from one extreme to the other with the engine running. Monitor the oil level in the measuring hose and add oil if necessary. Also the breather, which functions as a filler, shall be changed every 1200 h or every two years. Check the condition of the hydraulic hoses periodically. Replace damaged hoses immediately with new original ones.

4WD uses the pump and oil in traction hydraulics. The only service required is annual greasing of dust seal.

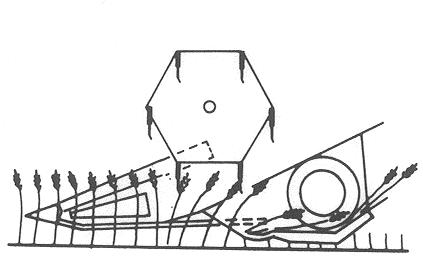

Chaff Spreader

The optional chaff spreader is located behind the shaker shoe. The spreader has three different quick settings. The two front-most ones are working settings. The rear-most setting is used when the shaker shoe is serviced or when the chaff is not spread. If necessary the spreader is easy to remove. If removed, the hoses in the working circuit are to be connected and the oil line is to be plugged. Otherwise the oil does not get to the reel control valve. There are no features that would require periodic service measures.