7 minute read

2000 Hours Service

1. Engine

1.1. Check/adjust PDE injector rocker arms

• Checking/adjusting PDE injector rocker arms shall also be carried out after the first 500 hours of operation. • Contact Moxy Dealer for checking/adjusting of the PDE injector rocker arms • The checking/adjusting of the PDE injector rocker arms must only be carried out by qualified personnel.

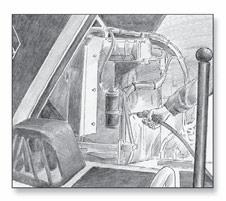

FLYWHEEL

Cylinder numbering

TDC position No. 6 cylinder TDC position No. 1 cylinder

FLYWHEEL

Intake valve

Exhaust valve

The readings can only be taken from underneath

1.2. Check/adjust valve clearance

• Checking/adjusting valve clearance shall also be carried out after the first 500 hours of operation. • Contact Moxy Dealer for checking/adjusting of the valve clearance

• The checking/adjusting of the valve clearance must only be carried out by qualified personnel. • The air filter and air filter bracket has to be removed before adjustment takes place. Adjust if necessary: • Inlet: 0,45 mm • Exhaust: 0,70 mm seeinstruction sign on one of the rocker covers. Valves should be adjusted when the engine is cold, at least 30 minutes after operation. Rocker cover gaskets must be changed if necessary. • Tightening torque: 26 Nm 1.Set no. 1 cylinder to TDC (Top Dead Centre) by turning the engine in its direction of rotation until all four valves are closed.

2.Adjust the following valves:

Cylinder 1 Inlet and exhaust 2 Inlet 3 Exhaust 4 Inlet 5 Exhaust

3.Set no. 6 cylinder to TDC (Top Dead Centre) by turning the engine one revolution in its direction of rotation. 4.Adjust the following valves:

Cylinder 2 Exhaust 3 Inlet 4 Exhaust 5 Inlet 6 Inlet and exhaust

Covers for reading on flywheel casing

WARNING

Block the starter device when working on the engine! If the engine starts out of control, there is a SERIOUS RISK OF INJURY!

1.3. External cleaning of the radiator, at least once a year 5*

If necessary, the cooling system should be cleaned more often.

1.Clean externally the radiator fins and hoses by using a brush.

The radiator can also be washed with water from the backside.

2.Check that the radiator is not blocked on the air side and that the fins are not damaged. 3.Carefully scrape the deposit away from the radiator fins.

If necessary, a paraffin-based engine cleaner may be used. 4.Check the fins, rubber hoses, clamps and pipes for corrosion, damage and leakages. 5.Bent fins can be carefully straightened, e.g. using a steel wire brush.

CAUTION

The cooling system must not be cleaned using caustic soda. It can damage aluminium parts.

Coolant:

Water + Anti-freeze or Water + Anti-corrosive

(see text)

1.4. Check the coolant, at least once a year 5*

NOTE

Coolant composition: If there is a danger of freezing: • at least 30% glycol by volume (15 litres by total volume) • max. 60% glycol by volume (30 litres by total volume) If there is no danger for freezing: •10% anti-corrosive by volume (5 litres by total volume)

1.4.1Check the appearance of the coolant, at least once a year

• Take a little coolant in a vessel and check that it is clean and clear.

• If the coolant is contaminated or cloudy: Consider changing the coolant. • The water for the coolant should be free of dirt.

• Use drinking water with a pH of 6 - 9.

Freezing point (OC) Antifreeze - 16 30 % 15 L

- 22 35 % 18 L

- 27 40 % 20 L

- 36 45 % 23 L

- 46 50 % 25 L

1.4.2Coolant with glycol only:

Check glycol content, at least once a year

If there is risk of ambient temperature below 0 °C, use only glycol as protection against corrosion in the coolant. • Cooling system with glycol must contain at least 30% glycol by volume (15 litres by total volume) to offer sufficient protection against corrosion. • 30% glycol by volume (15 litres by total volume) provides anti-freeze protection down to -16 °C. If more protection is required, see the table for calculating the necessary amount of glycol. The amount of glycol (anti-freeze) is determined acc. to lowest expected temperature. Always be sure that it is enough glycol (anti-freeze) mixed with the water in the cooling system to avoid freezing, see table.

We recommend only nitrite-free anti-freeze glycols with the following supplier designation:

• BASF Glysantin G48

• Always fill up the anti-freeze if the glycol content drops below 30% by volume (15 litres by total volume). A glycol content above 60% by volume (30 litres by total volume) will not improve the protection against corrosion.

WARNING

• Ethylene glycol is highly dangerous if consumed and can prove fatal. • Avoid contact with the skin.

• The coolant should be mixed before it is filled into the cooling system. Never top up with only water or only glycol. • The recommended glycols must not be mixed with glycol which has nitrite-based anti-corrosive nor with other anti-corrosive. This could cause sludging and reduced cooling capacity. • The coolant should be changed when the cooling system is cleaned. Every 4000 hours or at least every 4th year.

NOTE

1.4.3Coolant with only anti-corrosive:

Check protection against corrosion, at least once a year

There must always be sufficient anti-corrosive (inhibitor) in the coolant to protect the cooling system against corrosion. • If there is no danger of freezing use only Anti-corrosive. • The inhibitor in the Anti-corrosive must be nitrite-free with the following supplier designation: •BASF Glysacorr G93. • The correct level of Anti-corrosive is 10% by volume (5 litres by total volume). • Fill with Anti-corrosive as indicated on the packaging. • Filling up with 1% by volume (0.5 litres by total volume) of Anti-corrosive should be done after every 2000 operating hours. • Never fill up with water only or Anti-corrosive only. Lost fluid should always be replaced by pre-mixed coolant: water + 10% Anti-corrosive by volume. • Anti-corrosive content must not be lower than 5% by volume or exceed 30% by volume.

NOTE

• Anti-corrosive must not be mixed with glycol. • Mixing or over concentration can cause sludging and reduced cooling capacity. • Any coolant filter must not contain inhibitor. • The coolant should be changed when the cooling system is cleaned. Every 4000 hours or at least every 4th year.

2. Hydraulic system

2.1. Change oil 40*

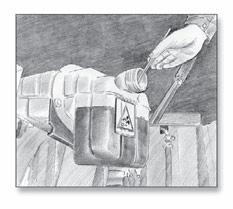

1.Accumulators contain oil under high pressure! Empty the accumulators, before draining the hydraulic oil. . Procedure is described in chapter 2, item 27. 2.The drain plugs both for the main reservoir and the emergency steering reservoir are to be found on the right hand side of the hydraulic tank (on the bottom). Remove the cover to get into the drain plugs. 3.Place a suitable container to catch spillage. 4.Remove the cap from both drain plugs. 5.Install the draining hose with nipple to the first drain plug and drain the oil into the container.

6.Install the draining hose to the second drain plug and drain the oil into the container.

7.Remove the draining hose and reinstall both caps. 8.The oil filler is located on the top of the hydraulic filter unit under the cover on the top of the hydraulic tank. 9. Fill new oil through the oil filler, according to the oil specification sheet, chapter 6. • The accumulators will be recharged with oil when the engine is re-started.

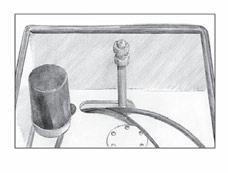

Oil filler

3. Brake system

3.1. Inspect brake lines, at least once a year.

Replace pipes, hoses and fittings which are corroded (deep seated rust), deteriorated (aged), leaking or otherwise damaged.

CAUTION

Check more often when operating in salty condtions or similar environment that may affect the brake system!

4. Tandem housings

2

4.1. Change oil 32*

• Change of tandem housing oil shall also be carried out after the first 500 hours of operation. 1.The dump truck and tandem housings must be horizontal. 2.Unscrew drain plugs (1) on the inside of the housings. 3.Drain the oil into a suitable container.

4.Clean plugs, replace seal if necessary and reinstall. •Tightening torque: 80 Nm. 5.Fill new oil, according to the oil specification sheet (chapter 6), through the filler plugs (2) to correct level. 6.Clean plugs, replace seals if necessary and reinstall. •Tightening torque: 80 Nm. 7.After test driving, check that level is at lower edge of the level plug.

1