1 minute read

SEALING TEST

– Smear the brake discs with transmission oil. – Refit the discs.

N.B.: Check that the disc slides freely on the planetary.

– Carry out the tightness test. – Refit the axle tubes (Refer to section: "0240"). – Fill the circuit with "LHM" liquid. – Drain the main brake circuit. – If mounted: Drain the trailer brake circuit. – Check the seals on the dismantled elements. – Perform road braking tests.

Important: When intervening on the brake piston and O-rings, it is highly recommended to check the sealing.

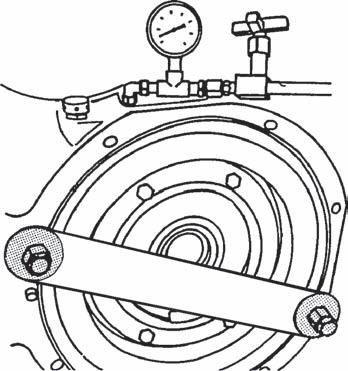

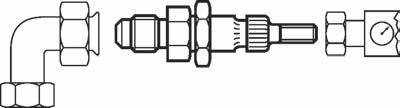

– Maintain the piston in its housing (Fig.11) using the locally manufactured tool (Fig. 9). – Adapt a pneumatic inflating piece (C) onto a DIN(A) fitting. – Screw the assembly onto the elbow (5). – Connect up a conventional inflation valve with its pressure gauge. – Fit the pressure regulator nr.6005005310 upstream. – Connect to a conventional inflation handle fitted with its pressure gauge and place a presssure release valve n° 6005005310 upstream. – Supply the circuit with 5-bar compressed air to ensure the proper operation of the piston. – Reduce the pressure to 0,3 bar. – Close the pressure regulator valve. After 1 minute, no pressure drop should be observed at the pressure gauge. – Remove the pressure gauge. Remove the restraining tool. – Connect the brake hose.

5 A B

C D

362msm08

5

Fig. 10

362msm07 Fig. 11