1 minute read

1.1.1 Installation procedure

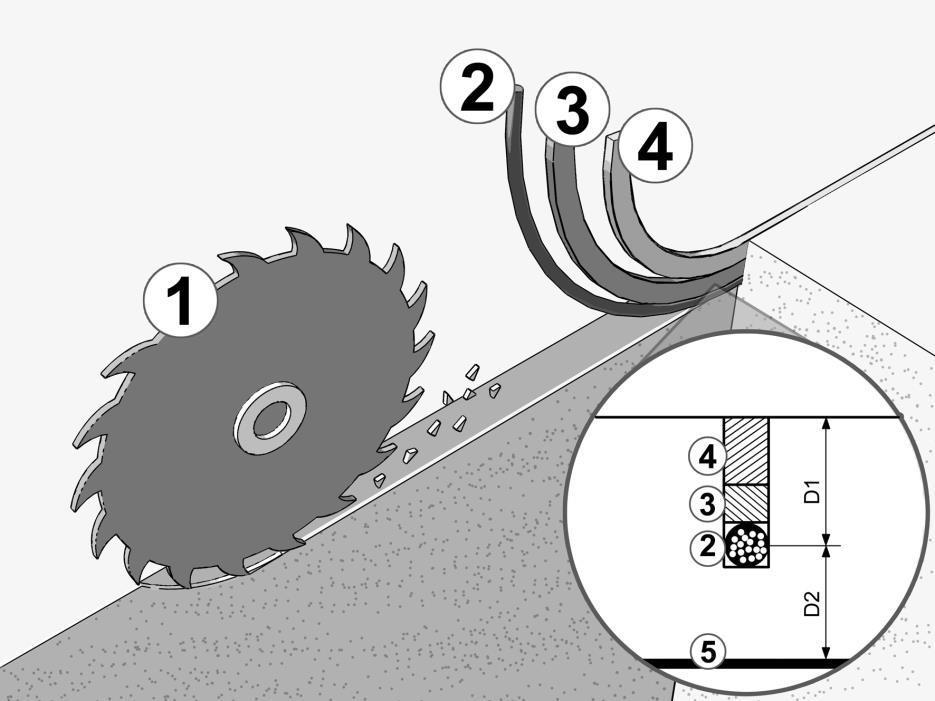

Figure 3. Installing inductive wire into the floor

1.1.1 Installation procedure

1. Saw a track and clean it.

The distance from the floor level to the center of an inductive wire (D1) is recommended to be between 10 mm and 20 mm but it should not be closer than 10 mm to the surface. Deviation in the wire depth must not exceed ± 2 mm anywhere in the warehouse.

The distance between a reinforcing wire mesh or a rebar (5) to the inductive wire (D2) must be greater than 50 mm if the diameter of a rebar is less than 9 mm. If a thicker rebar is used, the distance must be greater.

2. Lay the wire on the bottom of the track.

3. Place a thin foam rubber over the wire to prevent the epoxy resin (4) to stick to the wire.

If the resin sticks to the wire and there is any movement in the floor, the wire can be cut. Foam rubber also keeps the wire in the bottom of the track during the installation.

4. Fill the track up to the floor level and after the epoxy resin has cured, grind down overabundant epoxy.

Before filling the track, check that the wire guidance system works as intended and measure loops resistance and an insulation resistance from the wire to the ground.