5 minute read

Hydraulic Fluids of Group HFA 6

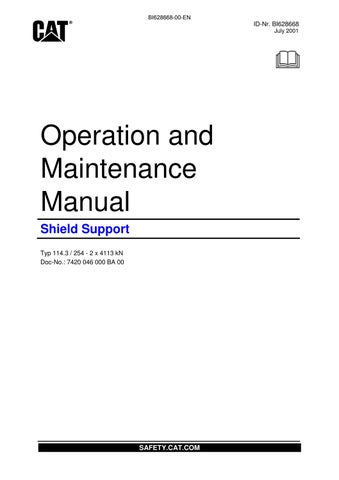

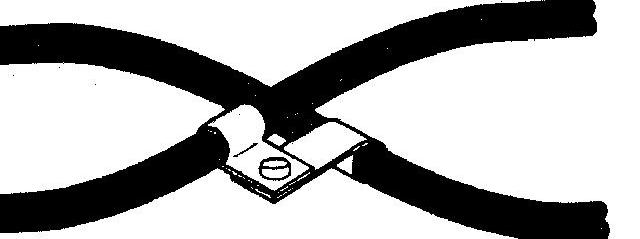

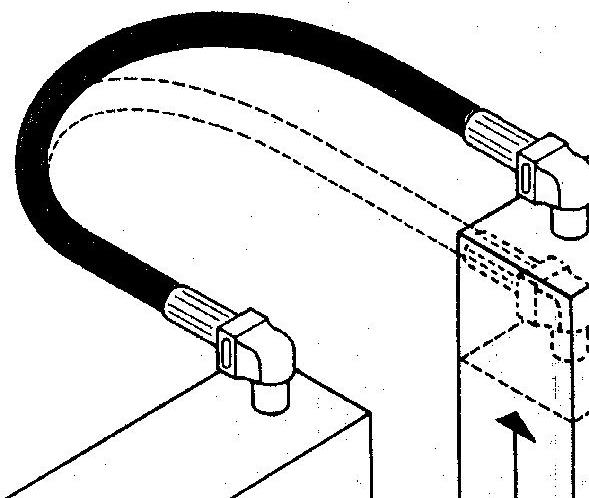

J Cannot chafe.

Fig. 6 Secure that crossing hydraulic lines cannot chafe

RIGHT WRONG

J Are not kinked. J Do not have to withstand tensile strains. J Are protected against thermal radiation. J Are accessible at all times.

Push hydraulic hoses into the sockets only by hand. Never try to drive the hydraulic hoses in with a tool as this will damage the connections.

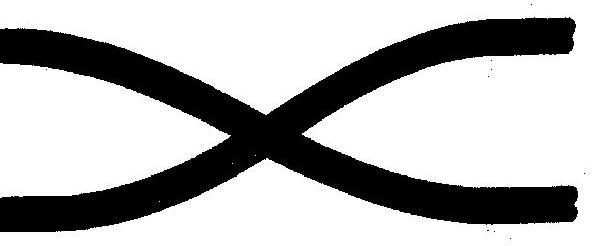

When installing the hydraulic hoses, ensure that they cannot be: J Torn out, J Kinked, J Crushed, J Driven over or J twisted by the movement of the shield (Fig.: 7).

Fig. 7 Hydraulic hoses must not be twisted caused by moving parts of the shield support RIGHT WRONG

Overview of the safety instructions

This is a summary of all the safety instructions which have to be observed in the following chapters. This summary is intended only to give you an overview of all the instructions. In some cases, there is no logical relationship between the individual instructions.

Chapter 3: Storage and Transport DANGER If the shield is raised above fastening points S1 and S2, the base may swing downward. This could result in serious injury or death. Join the base and canopy, for instance, with the use of turnbuckles, or lift the shield only by means of fastening points S1 and S3 with the use of a cross beam.

WARNING! Use only load handling devices complying with the technical and legal regulations for transporting loads. You could be seriously injured or even killed by falling loads. Use only suitable load handling devices.

CAUTION! There is a highly danger of hardly damaging or destroying the hydraulic components, if you do not replace the emulsion by an suitable anti-corrosive fluid. The emulsion possibly will change its properties within short time - caused e.g. by microbial attack - to an aggressive acting fluid. Flush the hydraulic components respectively system carefully and replace the emulsion completely by an suitable anti-corrosive agent.

Hoisting and hauling equipment with which the complete support shield unit is to be moved must be attached exclusively at the fastening points indicated in detail in the following figure! Any other fastening points additionally present on the support shield unit are not suited for this purpose! Take care that all transport safety devices are fitted properly. These are the fixing elements for the relay bar at face and gob side and the turnbuckles between canopy and base. IMPORTANT! Ensure when storing that any new supplies are stored separately from existing stocks in such a way that on removal, old stocks are always taken first.

Chapter 4: Installation WARNING! First start-up and executing the test-run must only be performed by a well trained crew of skilled personnel which is very familiar with working in underground mining and the special safety regulations. The personnel must also be very familiar with the equipment and the appertaining operating instructions.

CAUTION! Hoisting and haulage equipment with which the complete support shield unit is to be moved must be attached exclusively at the fastening points indicated in detail in the following figure!

Any other fastening points additionally present on the support shield unit are not suited for this purpose!

Temporarily pressure drop may occur during operation, if your pressure supply equipment for the face hydraulic is not amply dimensioned or instable caused by other reasons. In case the pressure drops down to 180 bar or less, there is a highly danger of malfunction of the hydraulic control system. Valve functions possibly will not be executed. Under certain circumstances valves possibly get a tendency to oscillate. This may be the cause for damages at valves. Under bad conditions this possibly results in dangerous situations and may be the cause of accidents within people may be hurt seriously. For this reason You must take all measures to secure, that the system pressure cannot drop down to 180 bar or less at any location of the face hydraulic system. NOTICE! Make sure that all securing elements, needed during transportation, have been removed.

IMPORTANT! The shields are numbered consecutively. Be certain to observe the shield number.

Chapter 5: Operations and Maintenance DANGER Jammed or blocked push-buttons can result in uncontrolled movements of the shield. This can then result in very serious personal injury or even death!

WARNING! Ignoring the safety regulations will cause accidents and may result in serious bodily injuries or death. The regulations about safe working of your mine must be followed strictly. Apply the following instructions analogously in addition and in accordance to the individual safety regulations of your mine. In all cases, always remain clear of all possible movements of a shield being advanced. Unusual occurrences (such as a shield becoming lodged) can result in unpredictable shield movement and should be treated with extreme caution. Failure to comply with this warning may result in serious bodily injury or death. During normal operation, the shield-type support is operated only with the electronic controller. Observe the separate operating manual for the control unit. If the control unit forms part of the DBT scope of supply, you will find the corresponding operating manual in the DBT documentation on the system. Do not put the filter into operation, prior making sure that all connections have been made properly. Never put both levers into backflush position simultaneously, because the emulsion flow will be completely shut off and backflushing will be impossible. The control elements on the control block may only be used in an emergency and during repairs and only in compliance with the special operating instructions of the mine for such opera-