2 minute read

Half-Web (or Partial) Cutting Cycle

The shearer is now in the tailgate and all shields are advanced and fully pushed. The system is now ready for the shearer to start cutting to the headgate in any of the unidirectional cycles.

In half-web cutting, a partial-web cut of coal, both top and bottom, is taken on both passes. On one pass, the shields are advanced behind the shearer and then the pan is partially pushed. On the next pass, as the shearer travels in the opposite direction, the shields do not move but the conveyor is pushed to full stroke. It is generally better to advance shields on the tail to head pass so that the operators are not in the dust generated by the shield advances. Below is a picture showing the initial position of the shields, conveyor, and shearer when the unidirectional cycle is started.

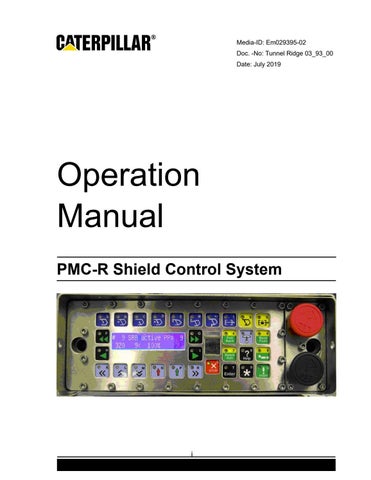

Half-Web Cycle – Initial Position

The picture below shows the shearer leaving the TG and the shields starting to pull.

Half-Web Cycle – Step 1 – Cutting Tail to Head

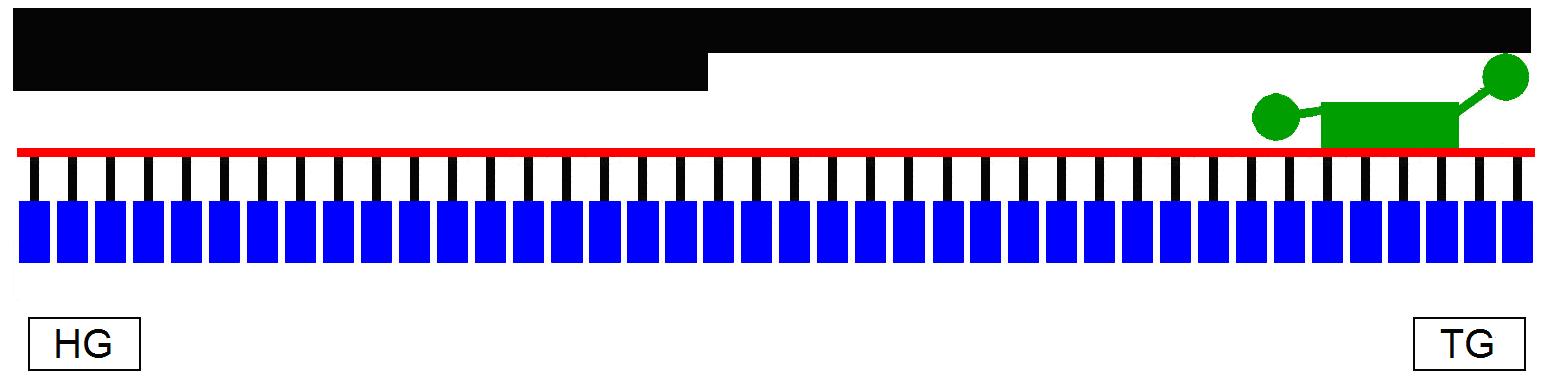

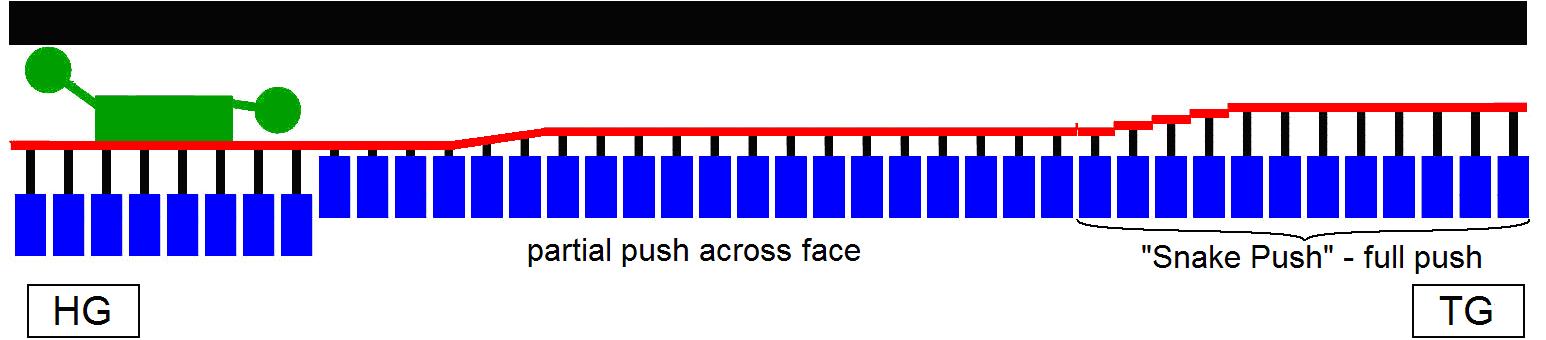

When the shearer has traveled far enough and enough shields have advanced, the conveyor push will begin to follow from the tailgate toward the headgate. Some of the

shields at the TG will push to completely so that the shearer can snake back in to a “full-web” cut when it re-enters the tailgate on the next pass. The number of shields that push completely is determined by SRB parameter “Snake push”. After that, the rest of the shields will only push to the stroke set by SRB parameter “T->H Push Stroke”.

SRB Parameters "Snake Push” “T->H Push Stroke”

This stroke setting determines how much of the web is cut when traveling back to the TG on the next pass. For evenly balanced half-web cutting, this should be set to 50%. It may be preferable to change this value depending upon the grade of the seam and the conveyor loading. The picture below shows the longwall state when the shearer reaches the headgate.

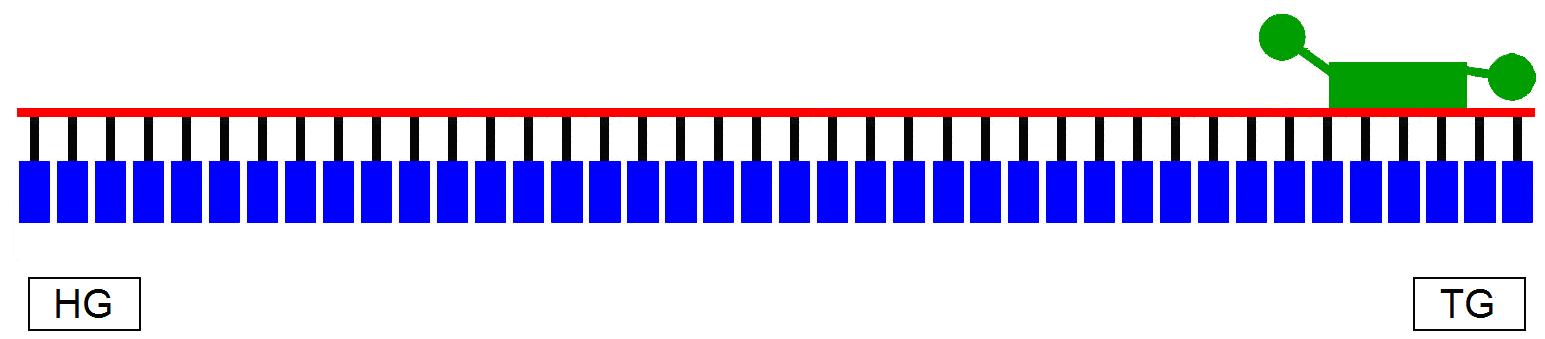

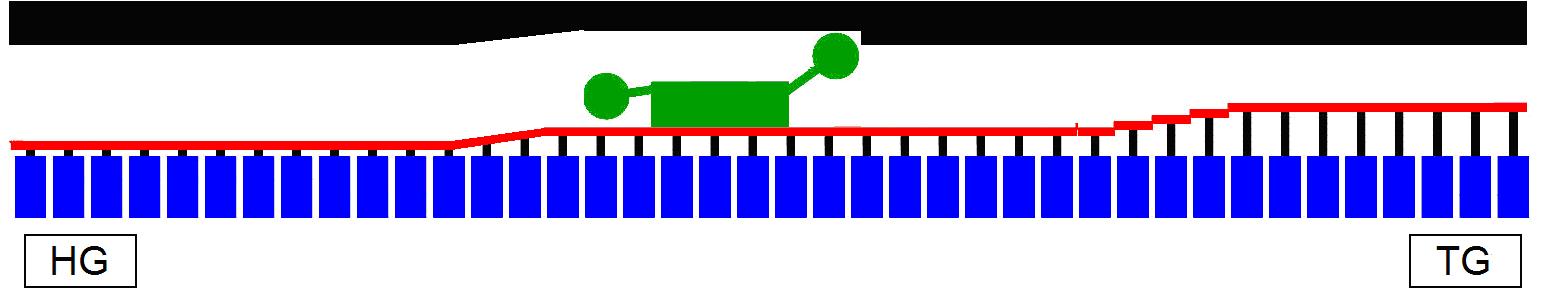

Half-Web Cycle – Step 2 – Shearer at HG

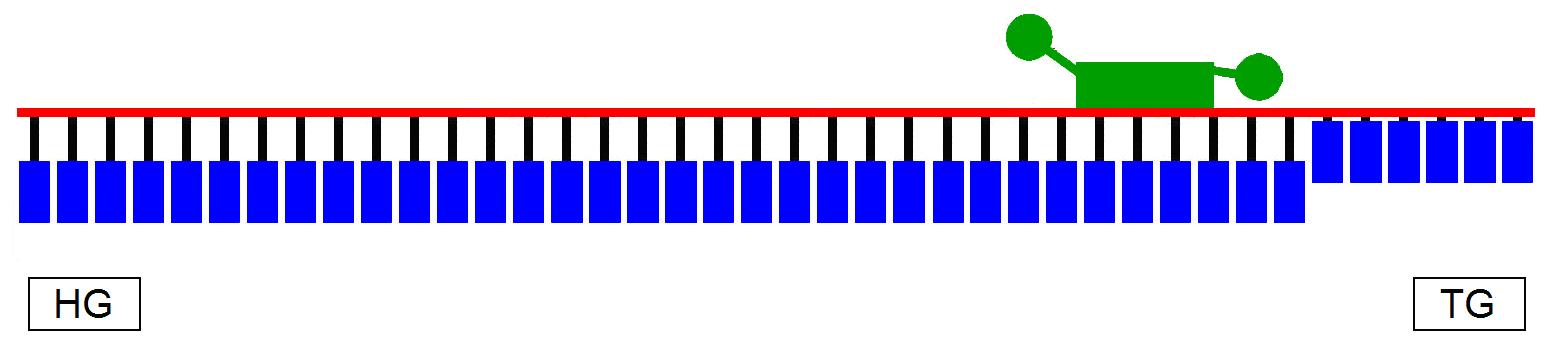

All shields except at the headgate have been advanced. The tailgate is fully pushed; across the face the conveyor has been partially pushed; in the headgate the conveyor has not yet been pushed. The conveyor has a double snake and the coal seam is straight (no snake). The HG shields that have not yet advanced will be triggered as the shearer leaves the HG Cleanup area and goes back into the partially pushed area on its way to the TG. This can be seen in the picture below. (Notice that the HG shields have not yet begun to push.)

Half-Web Cycle – Step 3 – Cutting Head to Tail

As the shearer continues to move toward the TG, the conveyor will then start pushing to the stroke set by SRB parameter “H->T Push Stroke”, usually 98% or higher.