65 minute read

Right Hand Face Configuration

Left Hand Face Configuration

Right Hand Face Configuration

D I S P L A Y G L O S S A R Y

:Default Displays:

Following are the displays that can appear on the PMC-R as the default in different situations.

#123, Shearer Zone

Default display: this shield is in the shearer safety zone

#123, -Wedge Advance

Default display: shield is in wedge advance group

#123, -Tapered Push

Default display: shield is in tapered push group

#123, -Wedge -Taper

Default display: shield is in wedge advance group and in tapered push group

#123, BTP Lockout

Btp Control lock button is pressed.; no push allowed on these shields.

#123, SYSTEM TRIPPED!

Default display: system is tripped; to reset system, press Start key and then P key.

#123, SERVER LOCKED!

Default display: Can't set up dumpvalve because server is either locked or has no SDM or an SDM error and therefore can't activate valve.

#123, FILTER LOCKED!

Default display: Can't reset system because filter station is either locked or has no SDM or an SDM error.

#123,SRV,150, Network! -

Default display: network is broken - communications is successful over range shown. Probably caused by broken shield to shield cable or network params are set wrong.

#123 Shearer Paused

Default display (on Server only) when pause command has been sent to the shearer because shearer was ready to continue endgate operations but shields had not all advanced yet. Once the shields catch up, the pause command is lifted and this display goes away.

#123, No Net Number

Default display: SCU has no network number due to invalid parameter settings in Configuration->Network section or due to faulty cabling. Can be numbered manually using D-Enter.

#123, No Network

Network is not correctly established. Check network parameters in Configuration>Network section.

SRVR, BTP Station Lost

Unrecognized signal from Belt Tailpiece Control.

#123,#35 AFC STOP

Large red external AFC stop button is pressed somewhere on face. AFC is not allowed to run until button is pulled back out.

#123 AFC Station Lost

Expected AFC Button Station not found.

#123 Unrgstrd AFC Box

Unexpected AFC Button Station exists. Check parameters.

#123 AFC Box Shorted

Pins 2 and 3 are shorted on the AFC Control Box cable.

#123 AFC Redndncy Fail

Digital signal and analog signal on AFC control box port don't match.

#123,4, < ULOCK More

Umbrella Lock is active here and X shlds to the left.

#123,6, ULOCK > More

Umbrella Lock is active here and X shlds to the right.

#123, ULOCK !!!

Umbrella Lock is active; this is the center shield.

#123, ULOCK Overlap

This shield is in two umbrella lock zones; zones cannot be cleared or moved from this shield.

#123, Maint. Lock !!!

Maintenance Lock is active, centered on this shield.

#123, Maint. Lock #

Maintenance Lock is active, started & centered from the indicated shield.

#123, Sol Driver Error

Solenoid driver has indicated a fault. Clear Solenoid Driver error to correct using E-key and Enter. If it happens again, replace solenoid driver, cable or PMC-R.

#123, No Solenoid Drvr

No solenoid driver detected! Connect solenoid driver to clear this display. If one is connected, replace cable, driver, or PMC-R.

#123, Stuck Key!

A key is stuck on PMC-R keyboard. Replace PMC-R.

#123 Soft Locked!

Because a neighbor shield lockout button is pressed, this shield is soft locked - not allowed to activate any solenoids.

#123, LOCKED

Large black lockout button is pressed on this PMC-R. No functions can occur on this shield; no functions are allowed on neighbor shields.

#123 AFC STOP

Large red external AFC stop button is pressed somewhere on face. AFC is not allowed to run until button is pulled back out.

#123,#100, QUICKSTOP

Large red quickstop button is pressed somewhere on face. No shield functions are allowed until button is pulled back out.

#123,#122, ! SLAVE ! - #

This shield is in slave mode - being controlled by the indicated shield.

#123,30, LockPush s

Locking Push Fct is active, pushing for time set by param Max Time under Configuration, Conveyor Push.

#123,85, LockPush tgt:

Locking Push Fct is active, pushing to tgt stroke set by param Locking Push Tgt Stk under Configuration, Conveyor Push.

#123,status GatePush

Gatepush Fct is active, pushing shields that are near the endgate. The number of shields is set by parameter Headgate Push Ctl and Tailgate Push Ctl under the Configuration ->

Conveyor Push menu section. Status shows 'active' when valve is On or 'gateend-' when valve is off and waiting for the Push Ctl shield to catch up. The Push Ctl shield is the shield that is exactly the distance from the endgate set by the Push Ctl parameter.

#123,status ! BSpray !

Shield is part of Bank Waterspray operation.

#123,status ! BFlush !

Shield is part of Bank Backflush operation.

#123, ! POSITIVE SET !

Positive Set is actively setting the legs.

#123,status ! CPULL !

Shield is part of a Conveyor Pullback operation.

#123,status ! BPUSH !

Shield is part of Bankpush operation.

#123, 120 PUSH-Drag #

Shield #123 is pushing either due to SRB or a Bankpush and is causing an AutoDrag to be executed on shield #120.

#123 ! AUTODRAG !

Because this shield is back and nearby shields are pushing, this shield is autodragging. It will lower then let nearby shields push. When all nearby shields are done pushing, this shield will set to the top again.

<< Different Pgm! >>

This PMC-R has a different program than both neighbor PMC-Rs.

Different Pgm! >>

This PMC-R has a diff program than the neighbor PMC-R over there>>>

<< Different Pgm!

This PMC-R has a diff program than the neighbor PMC-s over there<<<

<< Diff. Params! >>

This PMC-R has different global parameters than both neighbor PMC-Rs. This should correct itself within 1 minute.

Diff. Params! >>

This PMC-R has different global parameters than PMC over there >>>. This should correct itself within 1 minute.

This PMC-R has different global parameters than PMC over there <<<. This should correct itself within 1 minute.

Diff Params from #142

This PMC-R has different global parameters than the PMC-R indicated.

~~~ No Net Number

SCU has no netnumber. Fix connection between this location and server or number manually by pressing the #-key end Enter and then entering the correct shield number.

#123 Shield Type Error

Shield type parameter and coding plug (B2 port) do not match. Shield is not operable because the program does not know what type of shield this is.

ERROR - SDM Appl.

Solenoid driver has wrong program internally. Driver must be reprogrammed.

ERROR - SDM Loader

Solenoid driver has wrong program internally. Driver must be reprogrammed.

ERROR - Display Appl.

SCU display board has wrong program internally. Display board must be reprogrammed replace PMC-R.

ERROR - Display Loader

SCU display board has wrong program internally. Display board must be reprogrammed replace PMC-R.

ERROR - Wrong System!!

Wrong firmware program! Load new firmware or replace PMC-R.

ERROR - Wrong Booter!!

Wrong booter version is installed. Load new booter or replace PMC-R.

! ASQ ! status

Default display: ASQ is active!

#123, Broken Net -->

Default display: data connection has failed or network parameters are set wrong.

#123, <-- Broken Net

Default display: data connection has failed or network parameters are set wrong.

FACE CONVEYOR (AFC) To start, press Start.

This display appears after pressing external green button and will start the conveyor after pressing Start key. •:Filter Station:

Section for filter station parameters and control. ••FLT AS:2,0 MS: Filter station default display. AS is the AutoState which shows which filter station function is active: 0-idle 1-Std High pressure backflush seq 2-QuickStop High pressure dump seq 3-shield water backflush seq 4-shearer water backflush seq 5-manual mode. MS is the Manual State: 0-manual mode not active 1-manual mode active.

••Emulsion1 Remote Bflsh

Options: OFF, ON Def: OFF

This parameter is only visible on the VCU; setting this to On will trigger an emulsion 1 backflush. It will reset to Off automatically.

••Emulsion2 Remote Bflsh

Options: OFF, ON Def: OFF

This parameter is only visible on the VCU; setting this to On will trigger an emulsion 2 backflush. It will reset to Off automatically. ••Start Emulsion1

••Backflush Sequence (P)

Press P to start backflush sequence on high-pressure 1 emulsion filters. ••Start Emulsion2

••Backflush Sequence (P)

Press P to start backflush sequence on high-pressure 2 emulsion filters. ••Start Shearer Water

••Backflush Sequence (P)

Press P to start backflush sequence on water filters feeding shearer sprays. ••Start Shield Water

••Backflush Sequence (P)

Press P to start backflush sequence on water filters feeding shield sprays. ••Set Emulsion1 Pressure

••Correction [6] (P)

Only use when there is no emulsion flowing! Press P-key to set the correction factor that compensates for slightly different readings between emulsion In and Out pressure

••Set Emulsion2 Pressure

••Correction [6] (P)

Only use when there is no emulsion flowing! Press P-key to set the correction factor that compensates for slightly different readings between emulsion In and Out pressure sensors.

••Set Shearer H2O Press

••Correction [4] (P)

Only use when there is no water flowing! Press P-key to set the correction factor that compensates for slightly different readings between water pressure In and shearer water pressure Out sensors. ••Set Shield H2O Press

••Correction [7] (P)

Only use when there is no water flowing! Press P-key to set the correction factor that compensates for slightly different readings between water pressure In and shield water pressure Out sensors.

••Emulsion1 AutoBflush

Options: OFF, ON Def: ON

Set to On so that emulsion 1 filters are automatically backflushed if pressure difference across them exceeds the set value.

••Emulsion2 AutoBflush

Options: OFF, ON Def: ON

Set to On so that emulsion 2 filters are automatically backflushed if pressure difference across them exceeds the set value.

••Shearer H2O AutoBflush

Options: OFF, ON Def: ON

Set to On so that shearer water filters are automatically backflushed if pressure difference exceeds the set value.

••Shield H2O AutoBflush

Options: OFF, ON Def: ON

Set to On so that shield water filters are automatically backflushed if pressure difference exceeds the set value.

••Shearer H2O AutoBflush

••Diff Trip Point Range: 0-1000 Def: 6

Max desired pressure difference across shearer water filters before automatic backflush is triggered.

••Shield H2O AutoBflush

Range: 0-1000 Def: 6

••Diff Trip Point

Max desired pressure difference across shield water filters before automatic backflush is triggered. ••:Backflush Counters:

Section for backflush counters.

•••Emulsion1 Auto Count

•••4 RESET Range: 0-65535 Def: 0

Keeps a count of the number of times that the emulsion 1 filter backflushed due to differential pressure. Press P-key to reset count to 0. •••Emulsion1 Manual Count

•••1 RESET Range: 0-65535 Def: 0

Keeps a count of the number of times that the emulsion 1 filter was manually backflushed. Press P-key to reset count to 0. •••Emulsion2 Auto Count

•••7 RESET Range: 0-65535 Def: 0

Keeps a count of the number of times that the emulsion 2 filter backflushed due to differential pressure. Press P-key to reset count to 0. •••Emulsion2 Manual Count

•••2 RESET Range: 0-65535 Def: 0

Keeps a count of the number of times that the emulsion 2 filter was manually backflushed. Press P-key to reset count to 0. •••Shearer H2O Auto Count

•••3 RESET Range: 0-65535 Def: 0

Keeps a count of the number of times that the shearer water filter backflushed due to differential pressure. Press P-key to reset count to 0. •••Shearer H2O Man Count

•••1 RESET Range: 0-65535 Def: 0

Keeps a count of the number of times that the shearer water filter was manually backflushed. Press P-key to reset count to 0. •••Shield H2O Auto Count

•••5 RESET Range: 0-65535 Def: 0

Keeps a count of the number of times that the shield water filter backflushed due to differential pressure. Press P-key to reset count to 0. •••Shield H2O Man Count

•••2 RESET Range: 0-65535 Def: 0

Keeps a count of the number of times that the shield water filter was manually © Caterpillar

•:Group Automatic Fcts:

Section for automatic functions that operate on groups of shields. ••:Bank Waterspray:

••1,>,150,(spray type)

Bank Waterspray: scroll right to see parameters or press grp select key to select a group then Start-key to start. Toggle spray type selection with P key; swap begin & end shield with N key. •••Beginning Shield First shield of Bank Waterspray operation.

Range: 0-300 Def: 7

•••Ending Shield

Range: 0-300 Def: 12

Ending shield of Bank Waterspray operation.

•••Spray Type Selection

Options: Curtain Def: Curtain

Toggle which sprays will be activated - canopy, curtain, etc. •••Max # of Sprays Active

Range: 1-50 Def: 50

# of sprays that will be on at the same time. •••Spray Active Time

Range: 100-6000 Def: 3000

How long each spray will be activated.

••:Bank Backflush:

•• 15,<,172,

Bank Backflush: press R to see parameters or F/G to select group and Start-key to start. (swap begin & end shield with N key) •••Beginning Shield

Range: 1-310 Def: 1

First shield of Bank Backflush operation. •••Ending Shield

Range: 1-310 Def: 1

Ending shield of Bank Backflush operation. •••Valve On Time

Range: 100-400 Def: 200

How long each backflush valve will remain on.

••:Bank Push: •• 1,<,172,80,

Bankpush: press R to see parameters or F/G to select group and Start-key to start. (swap direction with N key) •••Beginning Shield

Range: 1-310 Def: 1

First shield for Bankpush operation. •••Ending Shield Ending shield for Bankpush operation. •••Tgt Stroke

Range: 1-310 Def: 1

Range: 10-100 Def: 100

Sets stroke which Bankpush will attempt to reach (in percent). Ex: set to 90 will push pan almost all the way.

••:Batch Pullback:

•• 26,<,30,20 %

Batch Pullback: scroll right to see parameters or press grp select key to select group then either Start-key to start automatic pullback or press & hold Pullback key (4) for manual pullback. Swap begin and end with N key. Last value is stroke reading where both autopullback and manual pullback will stop. •••Tgt Stroke

Range: 0-100 Def: 20

Stroke which Batch Pullback will attempt to reach. •••Group Size

Range: 1-30 Def: 10

# of shields selected by group select keys F and G.

••:Batch Advance: •• 26,>,30,standard

Batch Advance: scroll right to see parameters or press grp select keys to select group then Start-key to start. (swap begin & end with N key; toggle batch type with P key) •••Group Size

Range: 2-10 Def: 5

# of shields selected by group select keys F and G. •••Max Time

Range: 1000-6000 Def: 3000

Max time allowed for Batch Advance to trigger all ASQs; only has effect in Rabbit and Sequential. © Caterpillar

•••Batch Status

Options: Not Allowed, Allowed Def: Allowed

Local setting that makes Batch Advance either Allowed or Not Allowed.

••:Set Wedge Advance:

••#1,0,50,100, #,

Wedge Advance display: Press Start Key to set the Wedge Advance based on values shown; then next time shields advance they will lineup evenly between first and last shield # shown and stroke settings shown. Scroll right to adjust values shown and also see other parameters. The example shown will setup a wedge advance for shield #1 to advance all the way (0% target stroke) and shield #50 to not advance at all (100% target stroke); all other shields will advance so they are in a straight line between #1 and #50. •••Beginning Shield

Range: 1-310 Def: 1

First shield for Wedge Advance operation. •••Beginning Shld Stroke

Range: 0-100 Def: 0

Desired stroke for first shield in Wedge Advance operation (in percent; 10 means shield will pull almost all the way in) •••Ending Shield

Range: 1-310 Def: 1

Last shield for Wedge Advance operation. •••Ending Shield Stroke

Range: 0-100 Def: 0

Desired stroke for last shield in Wedge Advance operation (in percent; 10 means shield will pull almost all the way in) •••Clear All Wedges

•••Facewide (N)

Press N to clear all Wedge Advance settings on the face; this sets parameter Next Advance Tgt Stk in ASQ section to 0 on all shields.

••:Set Tapered Push: ••#100,0,180,100, #,

Tapered Push display: Press Start Key to set the Tapered Push based on values shown; then next time shields push (either Bankpush or SRB Push) they will push evenly between the first and last shield # shown and stroke settings shown. Scroll right to adjust values shown and also see other parameters. The example shown will setup a Tapered Push for shield #100 to push to 0% and shield #180 to push to 100%; all shields in between will push so the conveyor is tapered evenly between 100 and 180. Other shields on the face will push to the normal Bankpush or SRB Push target strokes.

•••Beginning Shield First shield for setting up Tapered Push. •••Beginning Shld Stroke Desired target stroke for first shield in Tapered Push (in percent; 100 means shield will completely push the conveyor). •••Ending Shield Last shield for setting up Tapered Push. •••Ending Shield Stroke Desired target stroke for last shield in Tapered Push (in percent; 100 means shield will completely push the conveyor). •••Clear All Taper Pushes

•••Facewide (N)

Press N to clear all Tapered Push settings on the face; this sets parameter Next Push Target Stk in Configuration, Conveyor Push section, to 100 on all shields.

•:Single Auto Fcts:

Section for automatic functions that act on individual shields.

••:Positive Set Auto:

Feature to keep shields set tight by monitoring leg pressures and activating set function when leg pressure drops. •••Send Facewide Command

••• OFF ON

Press N key to disable PSA on all shields facewide; press P key to send PSA ON command facewide - this will enable PSA on all shields unless local PSA Status parameter is set to Off.

•••PSA Status

Options: Not Allowed, Allowed Def: Allowed

Local setting that make PSA either Allowed or Not Allowed; when not allowed the only way to activate PSA on this shield is to change this parameter! •••Min Pressure

Range: 80-500 Def: 100

Below this pressure, PSA is not allowed to activate; this prevents PSA from setting a shield that is intentionally off the top. •••Trigger Pressure © Caterpillar

Range: 100-500 Def: 180

If leg pressure is above Min Pressure and below this pressure, PSA will activate the leg set function and attempt to reach Set Pressure. •••Set Pressure

Range: 180-500 Def: 215

PSA tries to set shield to this pressure.; PSA will stop setting when both legs have reached this pressure. •••Setting Time

Range: 500-5000 Def: 500

PSA tries this long to set shield.; leg set function stays active no longer than this value when trying to reach Set Pressure. •••Wait Time

Range: 500-5000 Def: 1000

Waiting time between setting attempts.; if Set Pressure is not reached, it will wait this long and then it may try again. •••Max # of Attempts

Range: 0-3 Def: 3

Number of setting attempts PSA is allowed to make after being triggered. Each setting attempt lasts until Set Pressure is reached or until Setting Time expires. If Set Pressure was not reached, PSA will try again after Wait Time expires until all attempts have been used. If unable to reach set pressure after all attempts, then if both legs are above Trigger Pressure, PSA resumes monitoring; if pressure could not even reach Trigger Pressure, PSA posts an error & disables itself (2-key blinks).

••:AutoSequence:

Automatic Sequence to lower, advance and set shield; also has options to most other shield functions during the sequence.

•••ASQ Status

Options: Not Allowed, Allowed Def: Allowed

Local setting that makes ASQ either Allowed or Not Allowed; when not allowed, the only way to activate ASQ on this shield is to change this parameter!

•••Baselift During Lower

Options: OFF, ON Def: ON

If On, baselift function is activated during leg lower. •••Initial Lowering Time

Range: 200-1000 Def: 450

Length of time to allow for legs lower at start of ASQ; legs must reach Advancing Pressure during this time. •••Advancing Pressure

Range: 50-150 Def: 80

Legs must get down to this pressure or less during Initial Lowering time or shield advance is not allowed and ASQ will fail.

•••Contact Advance

Options: OFF, ON Def: OFF

When Contact Advance is On, the Initial Lowering stops as soon as the legs reach Advancing Pressure. Generally, the leg lower function will be released and the shield advance function activated immediately. To continue lowering for some time while the shield is advancing, set Extra Lowering Time greater than 0. To allow some of the extra lowering to occur before activating the shield advance function, also set Advance Delay Time greater than 0. For faster ASQ & less fluid use, set to Contact Advance to On; for better baselift & less top contact set to Off. For some of both Set Contact Advance to On, Extra Lowering Time to 100-300 and Advance Delay Time to 50-100. •••Extra Lowering Time

Range: 0-1000 Def: 100

Continue lowering legs during advance for this amount of time. •••Pre-Baselift Time

Range: 0-200 Def: 150

If Baselift During Lower is Off and Baselift During Adv is On, then baselift will be activated for this long before advance is started. This delays the advance and makes the ASQ longer. •••Tip Up Time

Range: 0-100 Def: 75

After Initial Lowering, shield will tip up for this length of time; not allowed if Contact Advance is On. (Only for line and tailgate shields. See HG Tip Down Group parameter.) •••Tip Up Time

••• X by Contact Advance

This line is seen instead of the normal Tip Up Time parameter display (above) when Contact Advance is On. Tipping up after the initial leg lower is not allowed when Contact Advance is On. Switching Contact Advance to Off will restore the normal Tip Up Time display. •••HG Tip Down Group

Range: 0-5 Def: 3

After Initial Lowering, this number of headgate shields will tip down instead of tipping up; used to avoid hitting roof bolts with canopy. •••HG Tip Down Time

Range: 0-100 Def: 50

Length of time for tip down action (after lowering before advancing) in area set by HG Tip Down Group.

•••SideSeal Retract

Options: OFF, ON Def: OFF

Option to retract side seals during ASQ. •••SideSeal Retract Time

Range: 0-1000 Def: 50

Time to retract side seals during ASQ and on one touch auxiliary function. •••SideSeal Extend © Caterpillar

Options: Def: OFF

Option to extend side seals during ASQ. •••SideSeal Extend Time

Range: 0-1000 Def: 50

Time to extend side seals during ASQ and on one touch auxiliary function. •••Advance Delay Time

Range: 0-300 Def: 0

Only when Contact Advance is On and Extra Lowering is > 0; delay advance for this time to allow extra roof clearance before advance begins. •••Float Canopy While Advancing Options: OFF, ON

Def: OFF

When On, canopy float valve will be activated while the shield is advancing. •••Baselift Drop Stroke

Range: 0-80 Def: 0

Drop baselift when shield reaches this stroke while advancing; used to reduce chance of shield toes hitting cable trough on conveyor.

•••Baselift During Adv

Options: OFF, ON Def: ON

Option to activate baselift while shield is advancing; if this is On and Baselift During Lower is Off, then Pre-Baselift Time applies. •••Maximum Advancing Time

Range: 0-1500 Def: 800

Maximum time allowed for shield advance. This should be set to approximately twice the time normally required for a shield to fully advance. The shield advance normally stops when the ram stroke reading reaches the target stroke set by parameter Advancing Tgt Stroke. This time setting is for cases when the ram sensor is invalid or ignored. •••Advancing Tgt Stroke

Range: 2-100 Def: 2

Shield stops advance at this ramstroke reading. This is usually set on 2 so shield will advance completely but not error-out if the ram stroke reading doesn't go completely to 0. This can be set to higher numbers to partially advance shields. •••Retry Count

Range: 0-3 Def: 3

Sets number of retries that will be made if shield fails to advance to Advancing Tgt Stroke within time set by Maximum Advancing Time; retries consist of more leg lowering for time set by Relowering Time and another advance attempt limited by Max Readvance Time. To avoid failed ASQ, recommended min for this parameter is 1. To avoid excessive lowering, recommended max for this paraemter is 2. •••Tip Down on Retry

Range: 0-3 Def: 2

Sets which retry attempt will also activate tip down function to reduce roof contact; ex: if set on 2 then second retry attempt will operate tip down function for Tip Down Time before readvancing.

•••Tip Down Time

Range: 0-200 Def: 50

Length of time for tip down function activated by Tip Down on Retry parameter. •••Relowering Time

Range: 0-500 Def: 200

Length of time for leg lower function as part of retry. The leg pressure readings are not used - this is a time-only function!. If this time is set too high and the Retry Count is too high, the shield could lower completely to pan line. The recommended setting is 100-200.

•••Float Canopy While Setting

Options: OFF, ON Def: ON

When On, canopy float valve will be activated while the shield is setting. •••Final Set Time

Range: 0-2000 Def: 1000

Length of time after roof contact (50 bar) that setting continues while trying to reach Final Set Pressure.

•••Final Set Pressure

Range: 0-350 Def: 210

Leg pressure desired at end of ASQ; leg set function will stop when this pressure is reached.

•••Ram Refill Time

Range: 0-150 Def: 40

Length of time for ram push fct to stay active at end of ASQ to tighten clevis connection. Activates once legs reach 50 bar. Typically set to 25 - 50. •••Next Advance Tgt Stk

Range: 0-100 Def: 0

Overrides Advancing Tgt Stroke on next ASQ; usually 0 - it gets set to calculated number when a Wedge Advance is programmed. •••HG Seq First Shield

Range: 1-15 Def: 4

Shields between HG Seq First Shield and HG Seq Last Shield pull sequentially, beginning with HG Seq First Shield. This allows gate shields and transition shields to be advanced in correct order. If there are 3 actual headgate shields and 1 actual transition shield, HG Seq First Shield should be set on 3 and HG Seq Last Shield should be set on 5 so that #3 pulls first, followed by #4 and finally #5. This prevents #5 from pulling before #4 and prevents #4 from pulling before #3. #1 and #2 can pull in either order since they are both gate shields. This does allow #1 and #3 to pull at the same time. If this is not desirable, HG Seq First Shield can be set on #1 then shields 1 - 5 will all pull sequentially. •••HG Seq Last Shield See description above.

Range: 1-15 Def: 6

•••TG Seq First Shield

Range: 1-15 Def: 3

Shields between TG Seq First Shield and TG Seq Last Shield pull sequentially, beginning with TG Seq First Shield. This allows gate shields and transition shields to be advanced © Caterpillar

in correct order. Both values are measured as the number of shields from the tailgate instead of actual shield numbers. If there are 3 actual tailgate shields and 1 actual transition shield, TG Seq First Shield should be set on 3 and TG Seq Last Shield should be set on 5 so that the third shield from the end pulls first, followed by the fourth and finally the fifth from the end. •••TG Seq Last Shield

Range: 1-15 Def: 7

See description above. •••Cycle Time Autobflush

Range: 1000-2550 Def: 1800

In-shield backflush will trigger if cycle time meets or exceeds this value.

•:SRB Face Automation:

Section for SRB parameters. SRB is face automation that advances and pushes shields automatically based on shearer position. ••Serial Tracking Track shearer based on data provided from shearer. Can only be switched from Off to On. To switch Off, toggle another tracking mode to On. ••Infrared Tracking Track shearer based on IR transmitter mounted on shearer. Can only be switched from Off to On. To switch Off, toggle another tracking mode to On. ••Serial Tracking Type Use this parameter to switch between CAT and Joy shearer type communication to the PLC. PMCP = CAT. PLC = Joy

••Endgate Integration

Options: OFF, ON Def: OFF

Endgate integration allows the shield system to communicate to the shearer to pause tramming during turnarounds until the shields have caught up. This allows full automation of the shearer which includes fixed turnpoints. Since the turnpoints are fixed, the shearer cannot change the length of the double cut if it turned around before the shield system was caught up. Instead, it will stop tramming and wait until the final shield has pulled. ••Beginning Shield First shield on face that SRB will control.

Range: 1-30 Def: 1

••Ending Shield from TG

Range: 1-30 Def: 1

# of shields from TG that marks last shield that SRB will include. (1 means last shield; 2 means next to last shield, etc.) ••Cycle

Options: Def: BIDI

© Caterpillar

BIDI , UNIDI

Toggle between UniDi or Bidi SRB cycle. Bidi expects double cuts at each end; UniDi expects no double cut at either end. ••:H->T Options:

Parameters for head-to-tail pass.

•••H->T Asq

Options: NONE, ALL

Toggle ASQ options on H->T pass for unidirectional mode.

•••H->T Push Mode

Options: NONE, ALL Def: ALL

Def: ALL

Toggle push options on H->T pass. •••H->T Push Stroke

Range: 10-100 Def: 98

Set target push stroke for H->T pass. Ex: if set on 40, pan will stop pushing when ramstroke reads 40.

•••H->T Push Trig Shld

Range: 1-310 Def: 1

Begin pushing when shearer reaches this shield. Set high to delay push.

•••H->T Push Reverse

Options: OFF, ON Def: OFF

Reverse push once shearer reaches Trig Shield and follow normally from that point; most useful when H->T Push Trig Shld is set high.

•••H->T Push Protection

Options: NONE , PARTIAL, FULL Def: FULL

Set level of conveyor protection during push for H->T pass.

•••H->T Pull Over Shearer

Options: OFF, ON Def: OFF

Enables shield autosequences over the shearer during the H->T pass in addition to the normal ASQs behind the shearer. If this is On, shields advance over the shearer and any that fail will be tried again behind the shearer, before the push.

••:T->H Options:

Parameters for tail-to-head pass.

•••T->H Asq

Options: NONE, ALL Def: ALL

•••T->H Push Mode

Options: NONE, ALL Def: ALL

Toggle push options on T->H pass. •••T->H Push Stroke

Range: 10-100 Def: 98

Set target push stroke for T->H pass. Ex: if set on 20 and pan is already at 40, it won't push at all because it is already past 20. •••T->H Push Trig Shld

Range: 1-310 Def: 211

Begin pushing when shearer reaches this shield. Set low to delay push.

•••T->H Push Reverse

Options: OFF, ON Def: OFF

Reverse push once shearer reaches Trig Shield and follow normally from that point; most useful when T->H Push Trig Shld is set high.

•••T->H Push Protection

Options: NONE , PARTIAL, FULL Def: FULL

Set level of conveyor protection during push for T->H pass.

•••T->H Pull Over Shearer

Options: OFF, ON Def: OFF

Enables shield autosequences over the shearer during the T->H pass in addition to the normal ASQs behind the shearer. If this is On, shields advance over the shearer and any that fail will be tried again behind the shearer, before the push.

••Manual Safety Zone

Range: 0-10 Def: 7

Distance away from shearer position that first shield ASQs when using manual tracking.. ••Auto HG Safety Zone

Range: 3-15 Def: 5

For serial or IR tracking, # of shields on HG side of shearer position that are in shearer safety zone. No automatic functions can occur in this area. Must be 3 more than HG Drum Distance if Pull-Over-Shearer option is included. ••Auto TG Safety Zone

Range: 4-15 Def: 5

For serial or IR tracking, # of shields on TG side of shearer position that are in shearer safety zone. No automatic functions can occur in this area. Must be 3 more than TG Drum Distance if Pull-Over-Shearer option is included. ••HG Drum Distance

Range: 0-7 Def: 2

Distance from tracking point to HG shearer drum. This determines where shields will begin pulling over the shearer when cutting to the HG and where shields will stop pulling over the shearer when cutting to the TG. Must be 3 less than Auto HG Safety Zone. ••TG Drum Distance

Range: 0-7 Def: 2

Distance from tracking point to TG shearer drum. This determines where shields will begin pulling over the shearer when cutting to the TG and where shields will stop pulling over the shearer when cutting to the HG. Must be 3 less than Auto TG Safety Zone. ••Push Dist Behind Prime

Range: 2-15 Def: 7

# of shields after ASQs before SRB pan push will happen. This keeps push from overrunning ASQs. Must be at least one more than Conveyor Push Abort Dist. ••Push Delay Time

Range: 50-500 Def: 50

Shield-to-shield delay for the delayed/reversed SRB push. ••:HG Area Options:

Parameters for SRB operation in HG area. •••HG Cleanup Area

Range: 5-20 Def: 10

Size of HG area where shearer can move (cleanup) without triggering ASQs. •••HG Turn Point

Range: 1-15 Def: 8

Set to lowest shield number that shearer will reach every time it cuts out at HG. Usually 8 to 10.

•••HG DoubleCut Point

Range: 10-40 Def: 22

On HG double cut, shearer must come back at least this far. Usually set around 25 or 30. •••HG Gate Readvance Grp

Range: 0-15 Def: 0

Sets how many HG shields will readvance after HG push. •••HG Trans Readvance Grp

Range: 0-15 Def: 0

Sets how many HG transition shields will readvance after HG push. •••HG Trans Readvance Stk

Range: 0-100 Def: 50

Sets stroke value for HG transition shield readvance after HG push.

•••HG DblCut Shield Adv

Options: OFF, ON Def: OFF

Option to pull shields as shearer cuts from doublecut point back into the headgate. This provides better roof support but may make it difficult for operators to get past the shields since the conveyor will not be pushed yet. •••HG DblCut Prime Throw © Caterpillar

Range: 0-3 Def: 0

Distance from shearer position that prime gets thrown when shearer reaches double cut point and begins to cut back into headgate. Determines highest shield number triggered to ASQ as shearer cuts back into headgate. 0 = shearer position; 1 = shearer position + 1, etc. •••Start Push at Shield #

Range: 1-30 Def: 1

First shield at HG that SRB is allowed to push. Used to prevent SRB from pushing headgate automatically.

••:TG Area Options:

Parameters for SRB operation in TG area. •••TG Cleanup Area

Range: 5-20 Def: 10

Size of TG area where shearer can move (cleanup) without triggering ASQs. Set to # of shields, not a shield number. Ex: set to 10 for a 10 shield area no matter how long face is.

•••TG Turn Point from TG

Range: 1-15 Def: 5

# of shields from TG that marks the point shearer will reach every time it cuts out at TG. Usually 6 to 10. •••TG DblCut Pt from TG

Range: 10-40 Def: 20

On TG double cut, shearer must come back at least this far. Value is number of shields, not a shield number. Usually 27 to 33. •••TG Gate Readvance Grp

Range: 0-15 Def: 3

Sets how many TG shields will readvance after TG push. •••TG Trans Readvance Grp

Range: 0-15 Def: 3

Sets how many TG transition shields will readvance after TG push. •••TG Trans Readvance Stk

Range: 0-100 Def: 60

Sets stroke value for TG transition shield readvance after TG push.

•••TG DblCut Shield Adv

Options: OFF, ON Def: OFF

Option to pull shields as shearer cuts from doublecut point back into the tailgate. This provides better roof support but may make it difficult for operators to get past the shields since the conveyor will not be pushed yet. •••TG DblCut Prime Throw

Range: 0-3 Def: 0

Distance from shearer position that prime gets thrown when shearer reaches double cut point and begins to cut back into tailgate. Determines lowest shield number triggered to

••Max # of ASQs

Range: 3-30 Def: 6

Limit on number of ASQs that SRB can have running at once.

••Ram Refill @ Shearer

Options: OFF, ON Def: OFF

Option to activate conveyor push around shearer if pan is fully pushed.

••Snake Location

Options: HEAD, TAIL Def: TAIL

UniDirectional snake location - HG or TG. Shields in the snake will push 100% after ASQ. ••Snake Advance

Range: 0-40 Def: 25

The number of shields that advance in the snake area for a unidirectional cutting cycle. If all shields are being advanced when cutting from the snake-end of the face to the other end, then this parameter does not matter. But if shields are being advanced when cutting from the other end to the snake end, then this parameter must be set high-enough to allow the snake to be pushed. This value should be at least 6 greater than the Snake Push parameter. ••Snake Push

Range: 0-30 Def: 20

The number of shields that attempt to push 100% to create the snake for a unidirectional cutting cycle. If not advancing all shields when cutting from the snake-end of face to other end, then make sure this value is at least 6 less than Snake Advance parameter.

•:Water Curtain:

Section for Water Curtain parameters. Water Curtain feature activates water curtain in defined zones based on shearer position.

••H->T Water Curtain

Options: OFF, ON Def: OFF

Enable or disable water curtain on head to tail pass.

••T->H Water Curtain

Options: OFF, ON Def: OFF

Enable or disable water curtain on tail to head pass. ••H->T Lead Offset

Range: 0-50 Def: 3

For H->T pass, Zone 1 begins this far ahead of shearer position. ••H->T Zone 1 Size © Caterpillar

Range: 0-50 Def: 6

For H->T pass, Zone 1 covers this many shields starting at shield that is Lead Offset ahead of prime point. ••H->T Zone 2 Size

Range: 0-50 Def: 6

For H->T pass, Zone 2 covers this many shields following Zone 1. ••H->T Zone 3 Size

Range: 0-50 Def: 7

For H->T pass, Zone 3 covers this many shields following Zone 2. ••H->T Zone 4 Size

Range: 0-50 Def: 7

For H->T pass, Zone 4 covers this many shields following Zone 3. ••H->T Zone 5 Size

Range: 0-50 Def: 1

For H->T pass, Zone 5 covers this many shields following Zone 4.

••H->T Zone 1 Spray Opt

Options: OFF, ON Def: OFF

For H->T pass, enable or disable sprays in Zone 1.

••H->T Zone 2 Spray Opt

Options: OFF, ON Def: OFF

For H->T pass, enable or disable sprays in Zone 2.

••H->T Zone 3 Spray Opt

Options: OFF, ON Def: OFF

For H->T pass, enable or disable sprays in Zone 3.

••H->T Zone 4 Spray Opt

Options: OFF, ON Def: OFF

For H->T pass, enable or disable sprays in Zone 4.

••H->T Zone 5 Spray Opt

Options: OFF, ON Def: OFF

For H->T pass, enable or disable sprays in Zone 5. ••T->H Lead Offset

Range: 0-50 Def: 5

For T->H pass, Zone 1 begins this far ahead of the shearer position. ••T->H Zone 1 Size

Range: 0-50 Def: 10

For T->H pass, Zone 1 covers this many shields starting at the shield that is Lead Offset ahead of the prime point. ••T->H Zone 2 Size

Range: 0-50 Def: 12

For T->H pass, Zone 2 covers this many shields following Zone 1.

••T->H Zone 3 Size

Range: 0-50 Def: 1

For T->H pass, Zone 3 covers this many shields following Zone 2. ••T->H Zone 4 Size

Range: 0-50 Def: 0

For T->H pass, Zone 4 covers this many shields following Zone 3. ••T->H Zone 5 Size

Range: 0-50 Def: 0

For T->H pass, Zone 5 covers this many shields following Zone 4.

••T->H Zone 1 Spray Opt

Options: OFF, ON Def: OFF

For T->H pass, enable or disable sprays in Zone 1.

••T->H Zone 2 Spray Opt

Options: OFF, ON Def: OFF

For T->H pass, enable or disable sprays in Zone 2.

••T->H Zone 3 Spray Opt

Options: OFF, ON Def: OFF

For T->H pass, enable or disable sprays in Zone 3.

••T->H Zone 4 Spray Opt

Options: OFF, ON Def: OFF

For T->H pass, enable or disable sprays in Zone 4.

••T->H Zone 5 Spray Opt

Options: OFF, ON Def: OFF

For T->H pass, enable or disable sprays in Zone 5.

•:Prohibit Actions:

Section for parameters that enable or disable individual functions on this shield only.

••Baselift Function

Options: Not Allowed, Allowed Def: Allowed

Enable or disable baselift function.

••Tip Functions

Options: Not Allowed, Allowed Def: Allowed

Enable or disable tip up/down functions.

••Canopy Float Function

Options: Not Allowed, Allowed Def: Allowed

Enable or disable canopy float function.

••SideSeal Functions

Enable or disable sideseal functions.

••Main SideSeal Fcts

Enable or disable main sideseal functions.

••Backflush Functions

Enable or disable backflush functions.

••Conveyor Push Function

Options: Not Allowed, Allowed Def: Allowed

Enable or disable conveyor push function.

••CurtainSpray Function

Options: Not Allowed, Allowed Def: Allowed

Enable or disable curtain spray function.

Options: Not Allowed, Allowed

Options: Not Allowed, Allowed

Options: Not Allowed, Allowed Def: Allowed

Def: Allowed

Def: Allowed

•:Sensor Status:

Section for parameters to enable or disable individual sensors on this shield only.

••Leg Pressure >>

Options: OFF, ON Def: ON

Enable or disable leg pressure sensor >>.

••<< Leg Pressure

Options: OFF, ON Def: ON

Enable or disable leg pressure sensor <<.

••Ram Position

Options: OFF, ON Def: ON

••Main Pressure

Options: OFF, ON

Enable or disable mainline pressure sensor.

••Return Pressure

Options: OFF, ON

Enable or disable return line pressure sensor.

Def: OFF

Def: OFF

•:Service:

Section for service related actions

••clear errors facewide

•• (P)

Clear errors facewide by pressing P key. ••boot pgm to neighbor

•• << >>

Use N or P to send program from this PMC-R to the neighbor PMC-R. This unit will reset and send the program. ••boot program facewide

•• (P)

Use P key to send program to all other PMC-Rs. This unit will reset and send the program. ••PMC reset

•• (P)

Use P key to reset this PMC-R. ••destroy program

•• (P)

Use P key to destroy program in this PMC-R. It will then try to pick up program from a neighbor. Never necessary on face unless PMC-R reports that it has a different program! ••Send global parameters

•• (P)

Transmit all global parameters from this PMC-R to all other PMC-Rs. Should never be necessary since program will keep all global parameters identical across face. ••Display Brightness

•• - +

Use N and P keys to decrease or increase display brightness in this PMC-R. ••Calibrate Beeper

••-only this shield (P)

Use P key to calibrate this beeper. Beeper will activate continuously for several seconds and will cycle through various pitches to find the loudest one. ••FACE CONVEYOR (AFC)

••To start, press Start.

This display appears after pressing external green button and will start the conveyor after pressing Start key.

•:Configuration:

Section for configuration parameters. ••:Conveyor Push:

Section for Conveyor Push configuration parameters.

•••Push Protection

Options: NONE , PARTIAL, FULL Def: FULL

Toggle level of conveyor push protection: full (assumes invalid ram cannot push), partial (assumes invalid ram can push), none (doesn't care - just pushes). FULL is recommended.

•••Delta Protection

Options: OFF, ON Def: ON

Enable or disable delta protection which doesn't allow any shield to push too much farther than another. This reduces stress in conveyor connections. ON is recommended. •••Conv Push Delta

Range: 5-25 Def: 16

Conveyor push will pause when the stroke gets this far ahead of a neighbor. •••Conv Push Delta(hys)

Range: 2-20 Def: 5

Conveyor push will resume after pausing when the neighbor push that was behind catches up by this much. •••Abort Dist

Range: 1-5 Def: 2

Conveyor push is not allowed within this distance from a shield that is not advanced. Must be at least one less than Push Dist Behind Prime.

•••Max Time

Range: 2000-18000 Def: 6000

Sets max time allowed for conveyor push to finish. If it does not finish within this time, it

posts a timeout error. •••Bankpush Start Group

Range: 1-10 Def: 3

Number of shields that are triggered immediately at beginning of Bankpush. Others activate one at a time after a delay.

•••Locking Push Key

Options: For Time, For Stk Def: For Stk

Select whether the Locking Push Key (3 key) operates for time or pushes to a specific target stroke. •••Locking Push Tgt Stk

Range: 1-100 Def: 100

The target stroke for the Locking Push Key (3 key). •••Headgate Push Ctl

Range: 1-10 Def: 8

Num of HG shlds that push evenly at same time; pressing 6-6-Start in headgate triggers this number of HG shields to push. Ex: if set to 5 then #5 controls the HG push. •••Headgate Push Group

Range: 1-20 Def: 20

Num of HG shlds that are not allowed to push farther than the 'HG Push Control' shield. •••Tailgate Push Ctl

Range: 1-10 Def: 5

Num of TG shlds that push evenly at the same time; pressing 6-6-Start in tailgate triggers this number of tailgate shields to push. Ex: if set to 5 then 5th shield from TG controls the TG push. •••Tailgate Push Group

Range: 1-20 Def: 15

Num of TG shlds that are not allowed to push farther than the shield that is 'TG Push Control' from the TG.

•••Next Push Target Stk

Range: 0-100 Def: 100

Overrides normal target stroke on next conveyor push (Bankpush or SRB Push); usually 100 - it gets set to calculated number when a Tapered Push is programmed.

•••Overload Alert Enable

Options: OFF, ON Def: ON

Enable or disable the conveyor overload alert. •••Overload Alert %

Range: 0-140 Def: 125

When the PLC reports a conveyor load percentage equal to or higher than this parameter, a facewide Conveyor Overload alert will be triggered. •••Overload Alert Delay

Range: 0-3000 Def: 500

Time to wait when conveyor load goes over max %% load before tripping alert.

•••AutoDrag

Options: Not Allowed, Allowed Def: Allowed

Enable or disable AutoDrag feature facewide. •••AutoDrag Lowering Time

Range: 300-1500 Def: 600

Length of time that AutoDrag will lower a shield that is back prior to allowing nearby shields to push.

••:Conveyor Pullback:

Section for Conveyor Pullback configuration parameters. •••Abort Dist

Range: 3-5 Def: 3

Distance on each side that will abort if a shield is already up. •••Max Time

Range: 2000-9000 Def: 3000

Max time for pullback to complete. If not complete within this time, a timeout error is posted. •••Start Group

Range: 0-5 Def: 2

Number of shields that will activate at the same time at the start of the conveyor pullback. •••Delay Time

Range: 0-1000 Def: 75

Delay between each of the shields activating in the conveyor pullback after pullback start group is active.

•••HG Pullback

Options: Not Allowed, Allowed Def: Not Allowed

Enable or disable conveyor pullback on the first 10 shields at the headgate.

•••TG Pullback

Options: Not Allowed, Allowed Def: Not Allowed

Enable or disable conveyor pullback on the last 10 shields at the tailgate.

••:Network:

Section for Network configuration parameters.

•••Server Connected

Options: NO, YES Def: YES

Toggle option for a PMC-R server connection. If set ton ON, the server should have a 10k coding plug. If set to OFF, shield #1 must have a 10k coding plug in order to number shields.

•••Filter Station

Options: NO, YES Def: YES

Toggle option for a PMC-R filter station unit between the server and #1

•••Face Direction

Options: LEFT, RIGHT Def: RIGHT

Toggle face direction. This will be set automatically if there is a server. •••Number of Shields

Range: 1-310 Def: 211

Set # of shields on face.

•••Shield Group 1 Type

Options: Gate Shield, Face Shield Def: Gate Shield

Toggle shield type for 1st shield group.

•••Shield Group 2 Type

Options: Gate Shield, Face Shield Def: Face Shield

Toggle shield type for 2nd shield group.

•••Shield Group 3 Type

Options: Gate Shield, Face Shield Def: Gate Shield

Toggle shield type for 3rd shield group. •••Shield Group 2 Begin

Range: 2-310 Def: 5

Beginning shield # of the 2nd shield group on the face. •••Shield Group 3 Begin

Range: 3-310 Def: 209

Beginning shield # of the 3rd shield group on the face. •••Max Allowed Data Loss

Range: 1-200 Def: 20

Max # of messages that can be lost in neighbor comms before posting error message System Error - Data Lost.

•••HG Comms Thru PMC-P

Options: OFF, ON Def: ON

Communicate to VCU through PMC-P (On) or through direct connection to VCU computer (Off).

•••PMC-P Comms Data Rate

Options: 57600, 115200 Def: 115200

Toggle data rate to PMC-P.

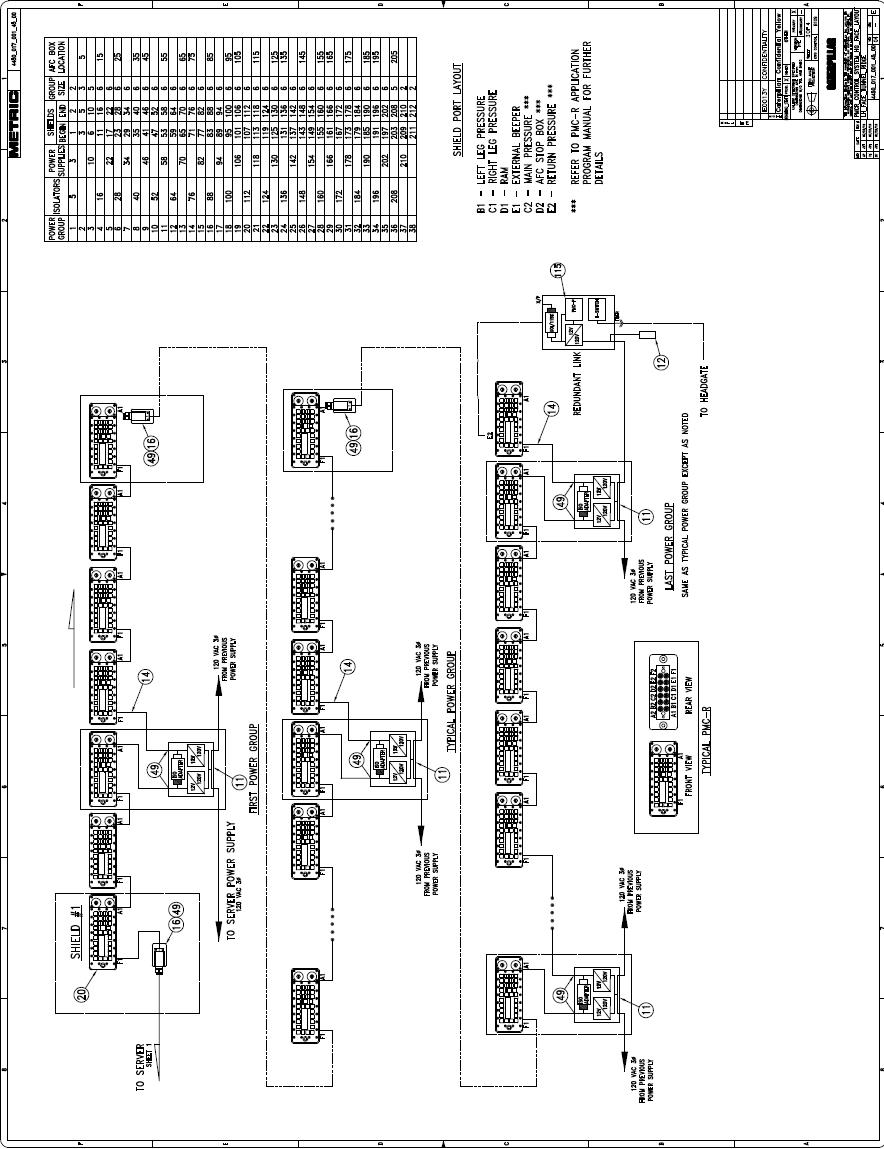

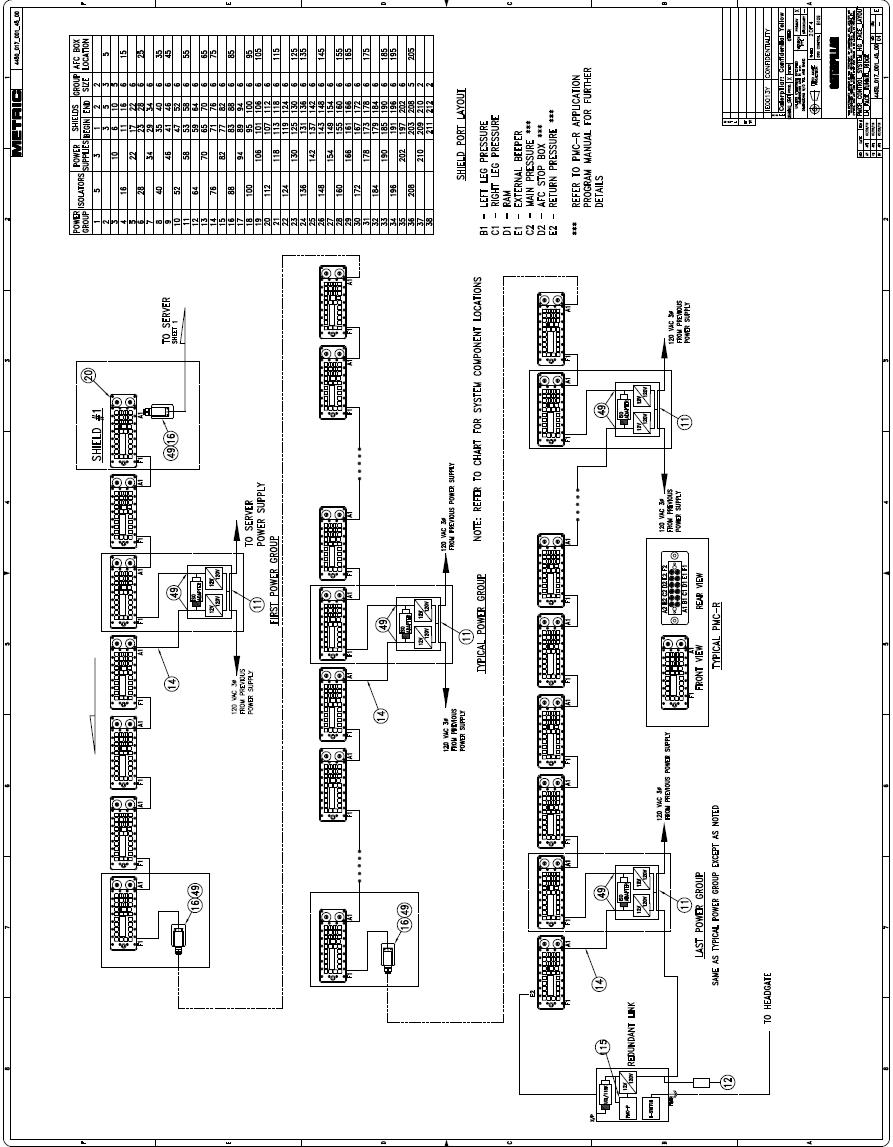

•••HG Red. Bus Shield #

Range: 1MAX_FACE Def: MAX_FACE

Shield number near headgate that has redundant bus connection to a shield near tailgate. •••TG Red. Bus Shield #

Range: 1-310 Def: 211

Shield number near tailgate that has redundant bus connection to a shield near headgate.

••:Current Reservation:

Section for Current Reservation parameters. Current Reservation is part of the MSHA IS approval; it regulates the amount of current drawn by solenoids to prevent possibility of ignition. •••HG Group 2 Begins

Range: 1-17 Def: 3

Shield number where second power group begins on headgate end of face. •••HG Group 3 Begins

Range: 1-17 Def: 6

Shield number where third power group begins on headgate end of face. •••Standard Groups Begin

Range: 1-33 Def: 11

Shield number where next (fourth) groups begins. This group and all groups across the face must have the same number of shields.

•••Standard Group Size

Range: 4-16 Def: 6

Size of standard power group across the face. Headgate and tailgate can have special sizes but normal groups across the face must be same size. •••TG Group 1 Begins

Range: 30-310 Def: 203

Shield that begins first nonstandard size group in tailgate. •••TG Group 2 Begins

Range: 30-310 Def: 209

Shield that beigins second nonstandard size group in tailgate. •••TG Group 3 Begins

Range: 30-310 Def: 211

Shield that beigins third nonstandard size group in tailgate (this is start of last power group on face).

Section for setting up locations of AFC control boxes. •••Maintenance Mode (OFF)

•••OFF ON

Maintenance Mode - For set-up only! Only requires server AFC box to be present to allow for face set-up. Toggles maintenance mode On or Off for the whole face. •••AFC Box at Server

Is there an AFC control box on the server?

•••AFC Box at Filter Sta.

Is there an AFC control box on the filter station?

•••HG Location

Shield location of first AFC control box.

•••Standard Spacing Begin Shield location of second AFC control box.

•••Standard Spacing Standard distance between AFC control boxes.

•••TG Location

Shield location of last AFC control box.

••:Pressure Monitoring:

Section for Pressure Monitoring parameters. •••Main Pr. Min (bar)

Range: 100-250 Def: 150

Min pressure acceptable for main pressure. If lower than this then Pressure Pause feature will pause all face automation if Low-Pressure Pause is set to ON. •••Return Pr. Max (bar)

Range: 20-50 Def: 30

Max pressure accetable for return pressure. If higher than this, face will be QuickStopped if High-Ret. Press. Trip is set to ON.

••:Dust Supp Spray:

Section for dust suppression spray parameters

•••Dust Supp Spray

Options: OFF, ON Def: OFF

Enable or disable the dust suppression spray feature. Designated shields will activate the curtain spray function when the shearer is far enough away on the HG side of the shield. (See next parameter.) •••Dust Shearer Distance

Range: 5-30 Def: 20

No dust suppression sprays will activate within this distance of the shearer position. Decreasing this value allows the shearer to get closer to the shield before the spray is deactivated. Increasing this number keeps the active sprays farther away from the shearer.

•••Dust Supp Spray Local

Options: OFF, ON Def: OFF

Local parameter to determine which shields spray for dust suppression. •••Dust Supp Spry Spacing

Range: 1-310 Def: 10

How far between the shields that spray for dust suppression? •••# of HG shlds w/ light

Range: 1-10 Def: 6

Number of HG shields that all have a light. Only matters if the light installation parameter is set to EVEN or ODD.

•••# of TG shlds w/ light

Range: 1-10 Def: 4

Number of TG shields that all have a light. Only matters if the light installation parameter is set to EVEN or ODD.

••Umbrella Lock Distance

Range: 5-15 Def: 10

Umbrella lock covers this number of shields on each side of initiating shield. ••Stop Key Group

Range: 10-310 Def: 10

Distance in shields that the Stop key will affect on each side of the shield where it is pressed ••First AuxFct Display

Range: 1-30 Def: 1

Sets which line is shown when a neighbor shield is selected. This is set according to the number at the beginning of the desired line. Scroll up or down to see other lines.

••Baselift with B/D key

Options: OFF, ON Def: ON

Toggle option to have baselift activate whenever the B or D key is being used to advance a shield.

••Belt Tailpiece Station

Options: NO, YES Def: YES

Global parameter to toggle option for Belt Tailpiece station connected to Server to control HG push.

••PMC-R Vltg Rpt to VCU

Options: Ext Voltage, Min Ext Voltage, Bidi Comm Voltage Def: Ext Voltage

Determines how PMC-R reports voltages to VShield. ••Coal Height (inches) Coal height in inches.

Range: 20-240 Def: 84

••Coal Dens. .01 lb/cuft

Coal density in 0.01 lbs/cu.ft.

Range: 2000-60000 Def: 8700

••Lite Set

Options: OFF, ON Def: OFF

Lite Set prevents the ASQ and PSA functions from setting the shield to high pressures. Setting pressure is limited to the Lite Set Pressure parameter which follows. Lite Set is a local parameter that is enabled or disabled on individual shields. C-key hotkey provides a shortcut to this parameter. ••Lite Set Pressure

See description above.

Range: 20-200 Def: 110

••Datalogger Comms

Options: OFF, ON Def: OFF

Enable ZBus to Zbus comms between shield SCU and datalogger. Comms can only be confirmed on the datalogger. ••Conveyor Prestart Time

Range: 600-3000 Def: 800

Overall length of time for the conveyor prestart warning. During this time the beepers sound and lights alternated every second between 10, 20, 30 and 15,25, 35, etc. ••Shearer Pos Lum Dist

Range: 0-10 Def: 5

Distance in each direction from shearer position to illuminate amber luminaires during remote automation. Setting to zero results in one amber luminaire at shearer position.

•:Diagnostics:

Section for Diagnostic displays.

••:Static Info: ••:PMC-R Power Info:

Section for PMC-R Power Diagnostics. •••PMC-R Input Voltage

•••1210,1120,OKcV min:cV

Shows the input voltage being fed to the PMC-R Bidi port, and the minimum of this value. The voltage will be classified as 'OK' if it is between 11 and 12.5 volts, 'HIGH' if above 12.5 volts, and 'LOW' if below 11 volts. The min value can be reset by pressing the Enter key. Note: the value is shown in centivolts so 1220 means 12.20 volts. •••PMC-R Power Use

•••1390,1400,OKmW max:mW

Shows the power being used by the core PMC-R circuits and the max of that value. The power level will be classified as 'OK' if it is between 1360mW and 1460mW, 'LOW' if below 1360 mW, and 'HIGH' if above 1460mW. The max can be reset by pressing the Enter key. Note: the value is shown in milliwatts so 1360 means 1.36 watts. •••PMC-R Driver Current

•••10,120,OKmA max:mA

Shows the current draw of the solenoid driver and the max detected value. It includes the solenoid current and current for anything connected to E1 and E2 ports. 'LOW', 'HIGH', and 'OK' levels are calculated based on the sensors the program is configured to have and on the valves that are active at any given time. The max value can be reset by pressing the Enter key. Note: the value is shown in milliamps so 250 means 0.25A. •••PMC-R Sensor Current

•••13,14,LOWmA max:mA

Shows the current draw of the sensors connected to the B, C, and D ports; and the max of that value. The current draw is classified as 'OK', 'LOW', or 'HIGH' based on the number of sensors the program is configured to have. The max value can be reset by pressing the Enter key. Note: the value is shown in millliamps so 125 means 0.125A.

••:PMC-R Network Comms:

Section for PMC-R Network diagnostics. •••Current Active Network

•••

Shows this units number, the number of the beginning unit in the network, and the number of the end shield in the network. Number may also be designator SRV for Server or FLT for filter station.

•••Previous Network

••• begin:SRV,180 end:

Shows most recent broken net data; useful to find out where the network was broken after an intermittent break.

•••Status Buffers

•••>>6,15 <<

Shows the number of status buffer messages received in the previous 1s from the five shields on each side. Each shield sends a status message 3 times per second so normally this should be 15 +/- 1. If there are only two shields on one side then there would only be about 6 messages received every second. •••Bidi Comms Error Count

••• <<0,0 >>

Number of corrupted messages received on bidi communication ports since last poweron.

••:KH Luminaire:

Section for luminaire diagnostics. •••Model: 24,4Col+White,3

•••Status: Retest (P)

Shows the luminaire model that is attached and communicating with the PMC-R. Possible values are None, White, RedWhite, Signal, 4Col+White and Invalid. Status is ~~-invalid, 3-available, 4-unavailable, 5-blinking. This is checked every 30s. To re-check, press the P key. •••Lum Test

•••(P)

Press P to trigger a test of the available luminaire blink and color options.

••:Sensor Diagnostics:

Section for sensor related diagnostics. •••Face Shield,1

•••CodePlugValue is

Shows shield type and code plug value. •••Leg Pressure min/max

•••10,330,12,345/ /

Shows leg pressure min and max readings that have occurred since the last ASQ or since power-up or since being cleared by pressing Enter or using the 'Reset Min/Max Values facewide'.

•••Main Pressure 255,5,145 bar

•••src: min: bar

Shows the nearest available mainline pressure reading and the shield that is reporting the value; also shows the minimum pressure reading that has occurred. (The minimum value is reset if the pressure falls below 30 bar and then rises to 200 bar again. This prevents the minimum from always showing 0 because the pumps were off.) •••Return Press. 15,6,22 bar

•••src: max: bar

Shows the nearest available return-line pressure reading and the shield that is reporting the value; also shows the maximum pressure reading that has occurred.

•••#123,8,18,Below 24bar:100% Ret Avg/Max

•••

••:ASQ Cycle Times:

Section to view ASQ cycle times for this shield. •••Cycle Time 1

•••(most recent) 9

Cycle time of the most recent ASQ. Measured from the beginning of legs-lower until legsset causes leg pressure to reach 50bar. •••Cycle Time 2

•••10

Cycle time from previous ASQ. •••Cycle Time 3

•••18

Cycle time from 3rd ASQ in history. •••Cycle Time 4

•••7

Cycle time from 4th ASQ in history. •••Cycle Time 5

•••8

Cycle time from 5th ASQ in history.

••:State Machines:

Section for State Machine diagnostics - mostly useful to programmers. The first number is the history position. Use N and P keys to change the history position. Pressing the P

key moves back in time, increasing the history position; pressing the N key moves forward in time, decreasing the history position. When the history position is 0, the next three numbers are the current state, the previous state, and the state before that. If the history position is 1, the next three numbers are the previous state and the two states before that.

•••Autosequence #0,0,40,35

•••

•••Bankpush #0,0,3,2

•••

•••Conveyor Push #0,0,9,2

•••

•••Conveyor Pullback #0,0,8,1

•••

•••Positive Set #0,3,2,1

•••

•••Luminaire Ctl #0,3,2,1

•••

•••AutoDrag #0,3,2,1

•••

••:Shearer Data:

Section for Shearer Data diagnostics. •••Shearer Pos

•••IR: 45>,45>, Ser:

Shearer position as detected by IR tracking and serial tracking (i.e., data comms with shearer). Measured in shields.

••:Lines:

Section to view line position in hex for conveyor line, shield line, etc. Mostly for programmers. •••Conveyor Position

•••0000,1AF4

•••Shield Position

•••0000,1676

Section for external communications diagnostics. •••Redundant Bus Status

•••OK

Redundant bus connection from near-tail shield to near-head shield is either OK or Down.

•••Server-Vshield Comms

•••OK

Comms between server and Vshield (VCU program) is either OK or Down. •••Server-Shearer Comms

•••OK

Comms between Server and CAT Shearer through the PMC-P is either OK or Down. If using another shearer brand, comms is only possible via PLC so this line always shows Down.

•••:PLC Communications:

Section for PLC communications diagnostics. ••••Data rec'd from PLC

••••YES

Indicates whether any kind of data was received from the PLC in previous 2s. ••••PLC Data Format OK

••••YES

Indicates that data with a valid CRC was received during previous 2s. ••••Reply to data-read

••••command received YES

Indicates that a reply to a data-read command was received during previous 2s. ••••Reply length is

••••correct YES

Indicates that a data-read reply with correct length was received during previous 2s. ••••Valid PLC Table

••••Version YES

Indicates that a data read reply with correct length, a changing shearer 'heartbeat' and with the correct table version was received during previous 2s. ••••Shearer activity

••••indicator OK YES

Indicates that a data read reply with correct length and indicating a changing shearer 'heartbeat' value was received during previous 2s. ••••Table ver in PLC:1

••••Table ver expected:1-7

Shows table version received from PLC and table version expected by PMC-R.

••:Last Auto Fcts:

All of the lines in this section report a previous function that was activated. The value for each will be one of the following: Batch Advance, Batch ASQ, SRB ASQ, SRB ASQ Restart, SRB ASQ Readvance, Manual ASQ, Manual Push, SRB Push, Bankpush, Endgate Push, Pullback, Pos. Flip Ret, Bank Spray, Positive Set, PSA Manual Set, Flipper Ret, Flipper Ext, BackFlush, Wedge ASQ. •••Last Auto Fct

•••1) PSA Manual Set

Shows the most recent automatic function triggered. •••Last Auto Fct

•••2) Pullback

Shows the 2nd most recent automatic function triggered. •••Last Auto Fct

•••3) Bankpush

Shows the 3rd most recent automatic function triggered. •••Last Auto Fct

•••4) Manual ASQ

Shows the 4th most recent automatic function triggered. •••Last Auto Fct

•••5) NONE

Shows the 5th most recent automatic function triggered.

••AFC Stop Bttns Pressed

••None

Shows list of shields with AFC Stop condition. Use N & P keys to scroll through list. ••:System Status:

The System Status section is only visible on the Server. Several lines are provided to display different status information about any shield on the face. The shield selection can be changed by entering the value or by using the N & P Keys to shift the selected shield © Caterpillar

•••# 27,psa+cvp+asq-bat+,CPU+bpu+srb+

•••

For the selected shield, shows which modules are Off, Ready, or Active in the selected shield. As shown, all modules are enabled but not active except asq which is disabled and conveyor pullback which is active. •••# 27,Prop L:310 R:280,Ram: 95

•••

For the selected shield, shows the leg pressures and the ram stroke. If there is a flipper sensor it is shown also.

•••# 27,0000,1AF4 Conv Position

•••

For the selected shield, shows the conveyor position value that is used to plot the position on the VCU. •••#27,0000,1676 Shield Position

•••

For the selected shield, shows the shield position value that is used to plot the position on the VCU.

•••AFC Box Status: SRVR, No Buttons Pressed

•••

Shows status of each AFC box on the face. Use N & P keys to scroll through list. An 'X' after the shield number indicates that the box is unregistered according to parameters.

••Last Ringout Reason

••Invalid PP Thrown

Shows reason for the last facewide ring out that alerts when SRB has aborted for an internal error. Possible values are as follows: Shearer Zone Died, Invalid PP Rec'd, Invalid PP Thrown, Shear State Mismatch, SRB Restarts Killed, SRB Started, SRB Stopped, U-Lock Released, Umbrella Lock Set. ••Last Stop Key

••Pressed at #123

Tells the shield location where the Stop Key was most recently pressed. ••Last AFC Stop Reason

••Stop pressed # 15

Why did AFC stop? Stop button, shorted cable, broken cable, missing box, etc. ••Conveyor Loading

•• 97,OVERLOAD%

Shows conveyor loading value retrieved from PLC (in percent). ••Reset Min/Max

••Values Facewide (P)

Press P to reset all diagnostic min/max displays facewide.

•:Message Displays:

These are the messages that may be displayed on the SCU in certain conditions. These lines can not be found using the Menu Keys. ••Not Selectable!!!

••PMC in use

The shield is not selectable for the reason shown. The reasons possible are as follows: It's not a shield, QuickStop, It's Locked, No Solenoid Driver, Solenoid Driver Err, Locked Neighbor, maintenance lock. ••In Use! No manual ctl.

••Press Start for ASQ.

The shield is not selectable because it is currently in use (i.e., somebody pressed a key in the previous 4s). Pressing Start will queue as ASQ which can begin once key-time has expired and the SCU is in the idle mode again. ••SRB FACE AUTOMATION

••To start, press Start.

This display occurs during the 3-key process of starting SRB. When the SRB Key (9) is pressed (first key required), the operator is prompted to press the Start Key (second key required) with this display. ••SRB FACE AUTOMATION

••Confirm shearer dir

After pressing the SRB Key (9) and the Start Key, the operator is prompted to complete the process by confirming the shearer cutting direction using the F or G Key. ••SRB FACE AUTOMATION

••To stop, press Stop.

When SRB is running in either Serial or IR tracking mode, pressing the SRB Key (9) will prompt the operator to stop SRB by pressing the Stop Key (S). This is the recommended way of stopping SRB because it allows any active ASQs or pushes to finish and does not dump the dump valve. ••SRB : ** to chg pos,

••Stop Key to stop SRB.

When SRB is running in manual tracking mode, pressing the SRB Key (9) will prompt the operator Stop SRB by pressing the Stop Key (S) or to enter a new manual position by © Caterpillar

pressing the *-Key (0). This display is only seen if the operator is in the area where a new manual position is allowed, generally six shields ahead of the current position. ••#123

••WARNING! SRB STARTED!

This display is seen on all SCUs when SRB is started. ••#123

••SRB Cancelled

This display is seen on all SCUs when SRB is cancelled. ••SRB FACE AUTOMATION

••To restart, press (P).

If an SRB Restart can be done, this display will be seen when the operator presses the SRB Key (9). If the operator desires to do an SRB Newstart, instead of pressing the P key, press the Start Key. ••To set ULock hold 3s

••or press Enter

The Umbrella Lock feature creates a safe travel way to allow operators to move through areas where shields would normally be moving without altering the mining cycle. Pressing the Umbrella Key (5) for 3s activates the Umbrella Lock Zone; it extends on both sides of initiating shield. In this zone, shields can push but not advance. If a shield in the Umbrella Lock Zone is triggered to ASQ, the ASQ is paused; if the Umbrella Lock Zone is removed from the shield soon enough, the ASQ will then become active and advance the shield. This lets people move through areas where shields should be moving without danger and without screwing up the mining cycle. ••To clear ULock hold 3s

••or press Enter

When the Umbrella Lock Key (5) is pressed on the center shield of the Umbrella Lock Zone, this display prompts the operator to hold the key for 3s to cancel the zone. Removing the Umbrella Lock Zone may allow shields to complete a previously triggered advance. There is a notice beeper sound throughout the zone and a 3s delay before any ASQs will start, in addition to the normal ASQ prewarning. ••Umbrella activated.

••Not for maintenance!!

Umbrella lock is for travel only - not maintenance. For maintenance, the shield should be locked out using the PMC-R's black lockout button, and the maintenance lock should be used. Maintenance lock is setup by pressing 5 and then holding the 0 key. The shield should also be isolated hydraulically during maintenance. ••Umbrella activated.

••For travel only!!

Umbrella lock is for travel only - not maintenance. For maintenance, the shield should be locked out using the PMC-R's black lockout button, and the maintenance lock should be

used. Maintenance lock is setup by pressing 5 and then holding the 0 key. The shield should also be isolated hydraulically during maintenance. ••Umbrella overlapped

••with another!

This display is seen if the operator tries to start a new Umbrella Lock Zone at a shield that is immediately adjacent to an already existing Umbrella Lock Zone. ••Hold for 3s to set

••maintenance lock

After pressing the Umbrella Lock key momentarily, press and hold the 0 key (star) for 3s to set a Maintenance Lock. In the Mainentance Lock Zone, only adjacent deadman functions are allowed. The Maintenance Lock Zone cannot be moved like an Umbrella Lock Zone.

••Hold ** key for 3s to

••cancel maint lock

When the Umbrella Lock Key (5) is pressed on the center shield of a Maintenance Lock Zone, this display prompts the operator to hold the key for 3s to cancel the Maintenance Lock Zone. The Maintenance Lock can only be cancelled from the middle shield where it was initiated.

••Maint. Lock!! Must be

••at #35 to cancel.

Pressing the Umbrella Lock Key (5) on any shield of a Maintenance Lock Zone except for the middle shield will cause this display and inform the operator which shield is the middle shield where the zone can be cancelled.

••Cancelled from 35!!

When the Stop key is used to cancel actions on the face, all affected shields will show this display for several seconds indicating which shield sent the cancel command. ••BankPush GateEnd

•• ...press Start

Pressing the BankPush Key (6) twice in the endgate area causes this display to prompt the operator to press the Start Key to start the endgate push function. ••#100 SYSTEM TRIPPED!

••Reset System (P)

This display appears when the operator pressres the Start key from the default SYSTEM TRIPPED display. To reset the system and send an indication to the PLC, press the P key. A short beep will travel across the face; 3s later the server will reset the system and another short beep will travel across the face. ••FACE CONVEYOR (AFC)

••To start, press Start.

This display appears after pressing external green button and will start the conveyor after pressing Start key. ••FACE CONVEYOR (AFC)

••Start not allowed: BTP

This display appears after pressing external green button on the belt tailpiece unit which is not allowed to start the AFC due to being a distance from the PMC-R controller to which it is attached.

••FACE CONVEYOR (AFC)

••No start: Unregistered

This display appears after pressing external green button on a unit that is not registered according to parameters. ••FACE CONVEYOR (AFC)

••Can't start: AFC Stop

This display appears after pressing external green button or start key when there is an AFC stop on the face. ••FACE CONVEYOR (AFC)

••Can't start: split net

This display appears after pressing external green button or start key when there is a broken net.

••#123

••Allow Pump Loading (P)

This display appears when the operator presses the Start key from the default PUMPS UNLOADED display. To allow pumps to begin loading again, press the P key. A short beep will travel across the face; 3s later the server will command the headgate PLC to allow pumps to load and another short beep will travel across the face. ••Must now use Start and

••P to reset system.

You must now press Start and then P rather than Stop and P to reset system. You may now press the Start key and then P key to reset the system directly from this screen. ••SRB Not Started

••Too close to endgate!

This display occurs when the operator attempts to start SRB near the endgate with a cutting direction into the endgate. ••SRB Cancelled

••IR Position Jump!

The IR shearer position jumped too far so SRB was cancelled as a safety precaution. This is because several shields in a row did not 'see' the IR transmitter, probably due to dirty receivers or a dirty transmitter.

••SRB Not Allowed

••IR Position Jump!

If an SRB start is attempted while there is an IR Position Jump error posted, this display will occur to explain why SRB is refusing to start. ••SRB Readvance

••Select Direction

Holding the SRB Key (9) and pressing the R-Key (for Readvance) is the first step in setting an SRB Readvance Zone into the face. This display prompts the operator to press either the F or G Group Select Key to indicate to which side the SRB Readvance Zone is desired. When that is done, the next display will be seen. ••SRB Readvance

••Mark Beginning (P)

After completing the previous steps in setting an SRB Readvance Zone, this display prompts the operator to press the P Key to mark this shields as the beginning of the SRB Readvance Zone. The operator can then walk up to 10 shields in that direction and hold the SRB Key (9) and press the R-Key (for Readvance) to bring up the next display. ••SRB Readvance

••Cancel(N) Start(P)

At this display the operator can press the N-Key to abort the process of setting an SRB Readvance Zone or press the P-Key to finish the process: all shields in the zone will then be readvanced by SRB on the following number of passes set by parameter SRB Zone Readvance Ct.

••SRB Cancelled

••Serial Position Jump!

If the shearer position as received on the data link skips too many shields while SRB is active, this message will be seen to explain why SRB cancelled. ••SRB Not Allowed

••Serial Position Jump!

If an SRB start is attempted while there is a Serial Position Jump error posted, this display will occur to explain why SRB is refusing to start. Clear the error locally by pressing the E-Key (for Errors) and then clearing the Serial Position Jump error by pressing the Enter key when viewing the error. Then, when SRB is started, the error will be cleared across the face.

••SRB Not Started-HG Turn

••Pt not in Cleanup Zone

If an SRB start is attempted and the parameter HG Turn Pt is not inside the HG Cleanup Area, this message will occur to explain why SRB is refusing to start. The HG Turn Pt must be inside the HG Cleanup Area. ••SRB Not Started-TG Turn

••Pt not in Cleanup Zone

© Caterpillar

If an SRB start is attempted and the shield identified by parameter TG Turn Point from TG is not inside the TG Cleanup Area, this message will occur to explain why SRB is refusing to start. The turn point shield must be inside the TG Cleanup Area. ••SRB Not Started-Dbl Cut

••Pt in HG Cleanup Zone