3 minute read

Stopping The Engine

If there are no shutdown events that are active or present, and after any pre-crank or start-aid activities have completed, the starter motor and fuel control will be activated. The EMCP 3 GSC will activate Relay Output #1 to activate the starter motor magnetic switch, and Relay Output #2 to activate the fuel enable circuit. On electronic engines with ADEM™ A3 or newer engine ECM, the start command and fuel enable signals will be sent from the EMCP 3 GSC to the engine ECM via the J1939 data link. After receiving the signals, the engine ECM will operate the fuel control relay and starter motor magnetic switch. Relay outputs #1 and #2 will not be used on those engines. Relay Output #1 will remain active until the programmed ENGINE CRANK TIME has been reached, or until the engine speed has reached the programmed CRANK TERMINATE SPEED setpoint value.

NOTE: the EMCP 3 GSC Crank setpoints: number of cranks, crank duration, and crank terminate speed are not used on engines using the ADEM™ A4 with the Common Engine Interface option or newer engine ECM. These values must be adjusted in the engine ECM.

CAUTION: To determine the exact starting sequence for your engine, consult your engine’s Operation and Maintenance Manual.

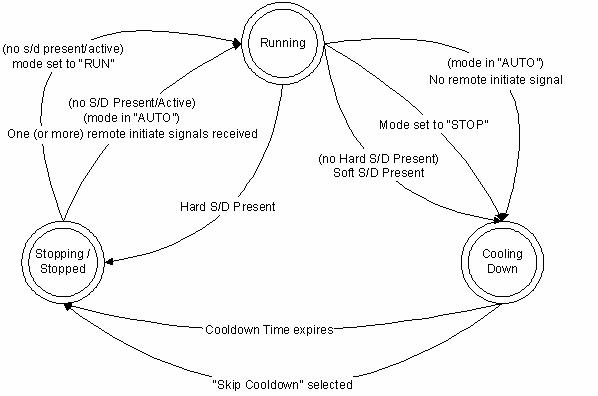

STOPPING THE ENGINE

Once the engine is started, the engine can be stopped by pressing the STOP KEY on the control panel. If the control is in AUTO, the engine can also be stopped by DEACTIVATING all of the remote initiate commands. There are three possible sources for this command: 1. The remote initiate input (digital input #2) 2. The remote initial command over the Modbus datalink (register number 1055) 3. The Programmable Cycle Timer Once the STOP command is issued, the control will go into COOLDOWN MODE. Cooldown mode will run for the duration of time that it is programmed in the COOLDOWN DURATION setpoint. If the cooldown time is set for zero minutes, the engine will stop immediately. On engines with ADEM™ A4 or newer engine ECM, the cooldown timer in the EMCP 3 GSC should be set to 0 (Zero) minutes because the cooldown time is controlled from the engine ECM (if this is not done, both cooldown timers will run in sequence). Also, the ENGINE OPERATING STATE INPUT CONFIGURATION parameter must be set to CAN INPUT.

The cooldown timer can be overridden by pressing and holding the STOP KEY for 5 seconds. The display will show a splash screen that will ask if you want to BYPASS COOLDOWN? or continue with the cooldown cycle.

If the ENTER KEY is pressed from the splash screen, the cooldown timer will be bypassed.

If the ESCAPE KEY is pressed from the splash screen, the cooldown cycle will continue until the programmed cooldown time has elapsed.

When the cooldown timer has elapsed or has been bypassed, Relay Output #2 will open. The STOP command will also be sent over the J1939 data link for those engines that require it. At that point, the fuel injection will be DISABLED and the engine will stop. Any time, while the engine is RUNNING: The EMCP 3 GSC detects a condition where an engine or generator parameter is ABOVE or BELOW programmed thresholds for a programmed amount of time or another SHUTDOWN EVENT occurs, then the EMCP 3 GSC will attempt to shut the engine down Depending on how a specific EVENT RESPONSE configuration is programmed, the EMCP 3 GSC will either put the engine in COOLDOWN, followed by a soft shutdown or shut the engine down immediately (a HARD SHUTDOWN).

FIGURE 15: STOPPING THE ENGINE

4.6 ENGINE SETPOINT VERIFICATION

The engine setpoint verification procedure verifies that the EMCP 3 GSC operates correctly

when OIL PRESSURE, HIGH COOLANT TEMPERATURE, LOW OR ENGINE OVERSPEED events occur. On an ENGINE OVERSPEED EVENT, the EMCP 3 GSC will shut the engine down.

LOW OIL PRESSURE and HIGH COOLANT TEMPERATURE each have two events, WARNING and SHUTDOWN. The EMCP 3 GSC will issue a WARNING whenever the warning threshold is reached and a SHUTDOWN whenever the shutdown threshold is reached. The configuration setpoints used in normal operation will be modified. During this procedure