1 minute read

Loader Main Relief Valve Pressure Check

VACUUM PUMP BELT ADJUSTMENT

The effectiveness of which the Hydrovac brake system operates depends upon the condition and tension of the belt that drives the vacuum pump and should be checked every 60 hours of operation.

When the belt tension is too tight, the belt will wear and also cause side loading of the vacuum pump shaft causingdamage to the pump. When the belt tension is to loose it will cause belt wear, slippage and reduce the effectiveness of the Hydrovac brake system.

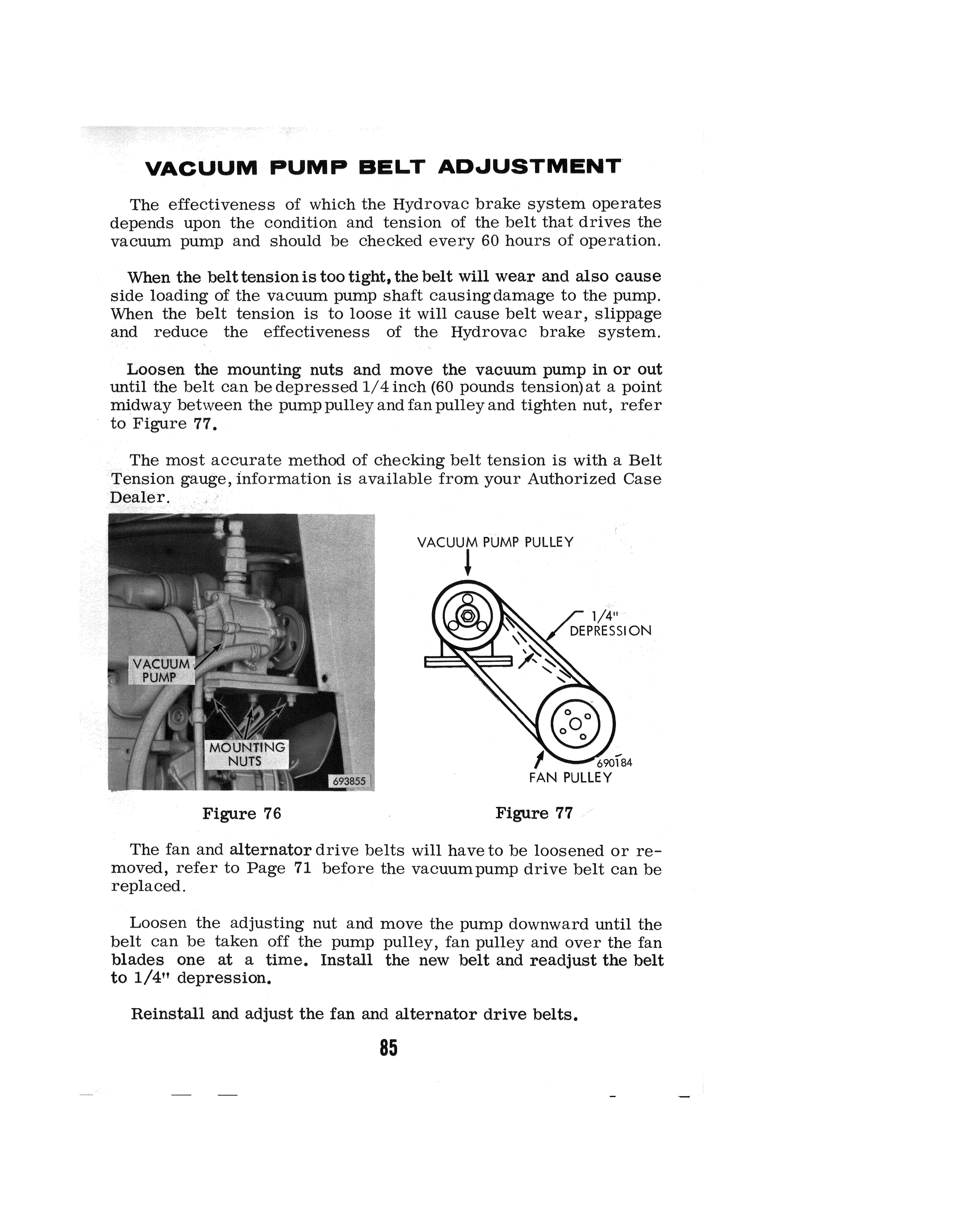

Loosen the mounting nuts and move the vacuum pump in or out until the belt can be depressed 1/ 4 inch (60 pounds tension) at a point midway between the pump pulley and fan pulley and tighten nut, refer to Figure 77.

The most accurate method of checking belt tension is with a Belt Tension gauge, information is available from your Authorized Case Dealer.

Figure 76 Figure 77

The fan and alternator drive belts will have to be loosened or removed, refer to Page 71 before the vacuumpump drive belt can be replaced.

Loosen the adjusting nut and move the pump downward until the belt can be taken off the pump pulley, fan pulley and over the fan blades one at a time. Install the new belt and readjust the belt to 1/411 depression.

Reinstall and adjust the fan and alternator drive belts. 85