2 minute read

FUEL SYSTEM

FUEL SYSTEM Service specification

Draining water and sediment from the fuel tank..............................Every 50 hours Draining water from the water separator.........................................Every 50 hours Cleaning of water separator filter..................................................Every 500 hours Fuel filter replacement...................................................................Every 500 hours Cleaning the priming pump screen.............................................Every 1000 hours Fuel hoses replacement....................................................................Every 2 years or every 4000 hours (whichever comes first) Fuel tank capacity.....................................................................................611 litres Type of fuel...................................................................See "Fluids and lubricants"

Draining water and sediment from the fuel tank

Draining water from the water separator

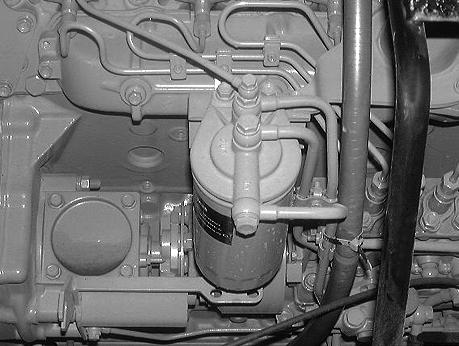

The water separator is located in the rear compartment of the machine.

2 A

1

CD01K077 Position a drain pan under the drain plug. Open the drain valve located at the bottom of the tank and drain the accumulated sediment and water. After draining, close the drain valve.

CD01K078

When the float reaches the level line (A)

Loosen the drain plug (1) and drain the water and sediment. When the float (2) settles on the bottom, tighten the drain plug (1). Verify that there are no fuel leaks.

WARNING: Completely wipe off any spilt fuel. It may cause a fire.

Fuel system (continued)

IMPORTANT: Always protect your face before using compressed air.

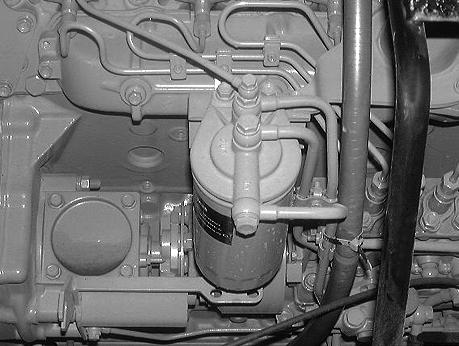

Cleaning of water separator filter

1

CD01K078 Remove the socket head screw (1), take out the filter and clean it using compressed air. Check the condition of the filter and replace it if necessary. Install the filter and the socket head screw (1).

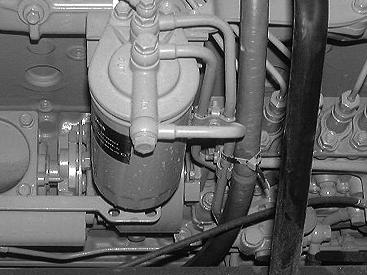

Replacing the fuel filter

CD01N034 Clean the area around the filter head. Place a receptacle of a suitable capacity under the filter and remove the filter, using a filter wrench. Apply a fine film of oil or grease to the contact face of the new filter. NOTE: Do not fill the new filter with fuel before installing. Install the new filter. Turn the filter until the seal comes into contact with the filter head and turn an extra half turn by hand. IMPORTANT: Do not use a filter wrench to install the filter. Overtightening the filter can damage the seal and filter. NOTE: If the engine does not regain full power after replacing the filter, bleed the system.

Bleeding the system

It is necessary to bleed the fuel system when: -The tank has been completely emptied. -The fuel filter has been replaced. -Parts of the fuel system have been removed for servicing or repair work. -The machine has been in storage for a fairly long period.

1

2

CD01N034 WARNING: Completely wipe off any spilt fuel after replacing a filter element or bleeding the system.

IMPORTANT: Always protect your face before using compressed air.

Cleaning the priming pump screen

CS98M578 Loosen the knob of the priming pump (2). Loosen the air bleed screw (1). Move the handle of the priming pump (2) up and down until no bubbles come out of the air bleed screw (1). When bubbles no longer come out, tighten the air bleed screw (1) and tighten the knob of the priming pump (2). Completely wipe off any spilt fuel. Start the engine and check for fuel leakage.

1

CD01N034 The screen is placed in the socket-head screw (1). Remove the screen, clean it with compressed air, then rinse it in fuel.