3 minute read

E) Power cell disassembly

E) Power cell disassembly

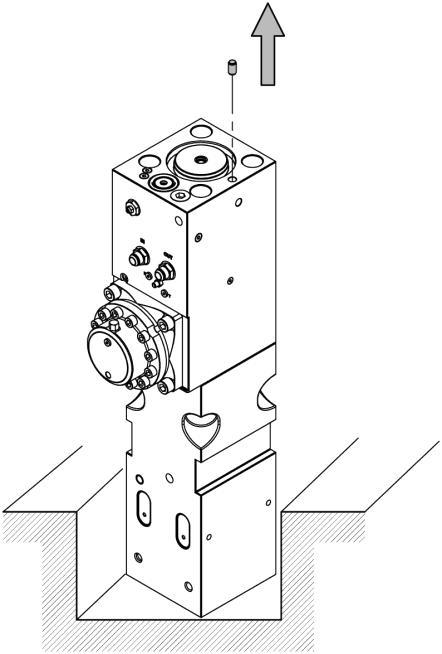

WARNING!

Ensure holding pipe is available to avoid power cell falling down. Disassembling without proper lifting devices and holding pipe is very dangerous and may cause injury or fatal accident.

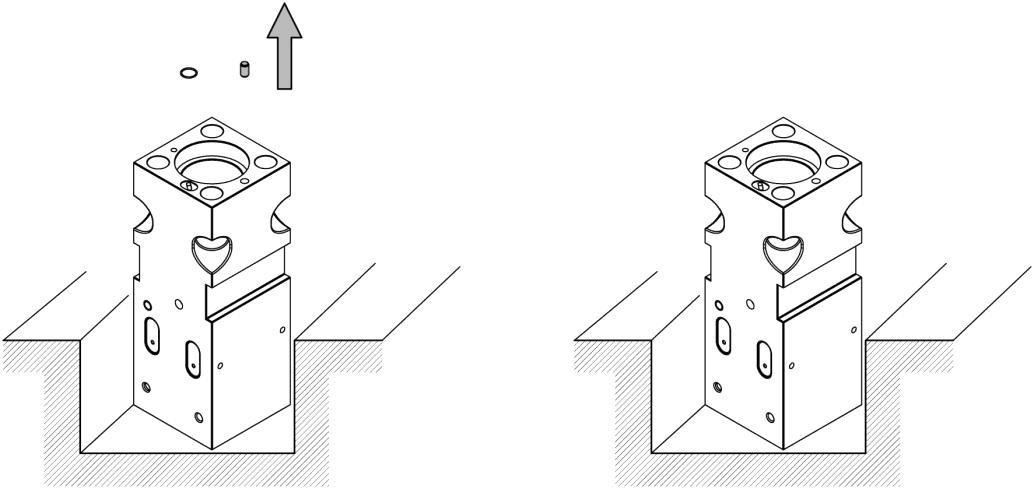

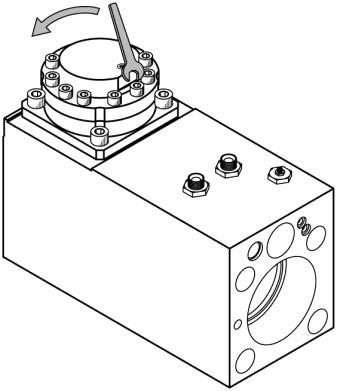

a. Place power cell on the pipe.

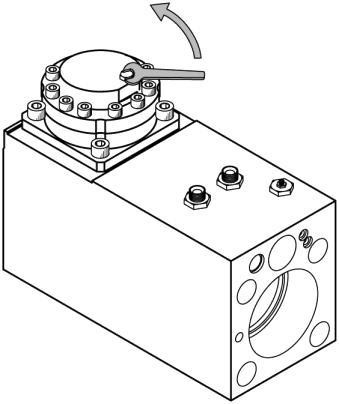

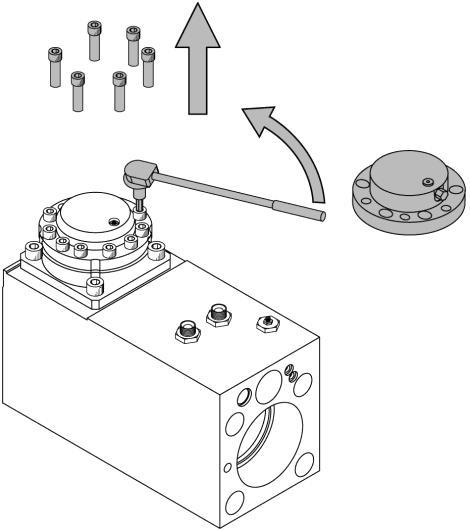

b. Loosen through bolt nuts, remove through bolts, top and bottom nuts and washers.

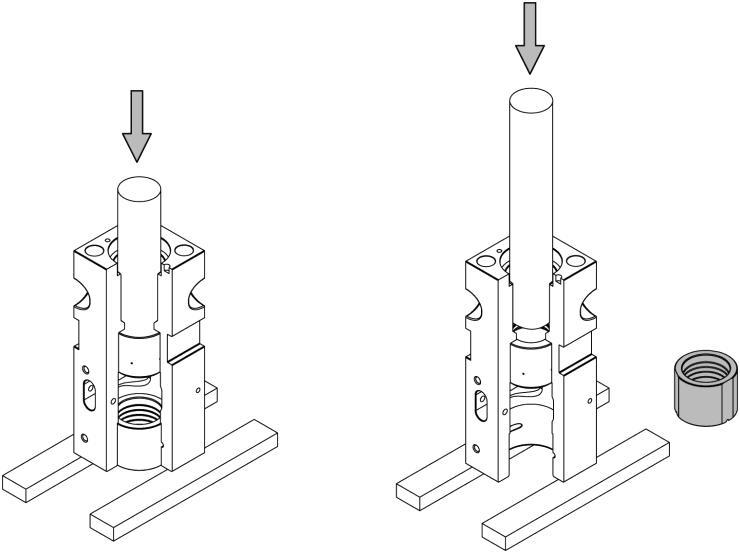

c. Remove back head.

Put the back head down on wood blocks and remove O-ring from the back head.

d. Take rock pin (holding pin) and piston out of the cylinder.

e. Disassemble cylinder bush from the piston. Remove seals on the cylinder bush.

CAUTION Use wood or plastic hammer only when removing cylinder bush. Removed seals shall never be recycled.

f. Remove cylinder block.

g. Remove rock pin (holding pin) and O-ring from the front head block.

h. Disassembly of lower bush and upper bush

• Remove stopper pins and rubber plug. • Put front head block upside down on wood block. • Insert a round steel bar into front head hole. • Remove lower bush from the front head block by pushing the bar down with hydraulic press. • Take upper bush out of front head block by the same way

Lower bush Upper bush

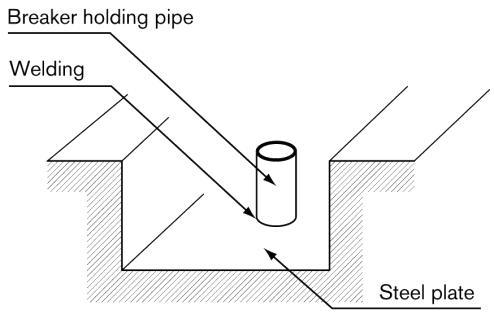

NOTE! In case hydraulic press is unavailable, bushes can be removed by welding torch.

Model Bead layer

Bead size mm inch

CB62 4 7×7 0.28×0.28

i. Disassembly of cylinder block

1. Remove seals

NOTE! Cylinder is a very sensitive part to contamination. Ensure cylinder block disassembly is carried out on a completely clean pad.

1. Removing Ro plugs is not required for breaker overhauling. DO NOT remove any Ro plugs at all if not agreed with the breaker supplier for a specific purpose.

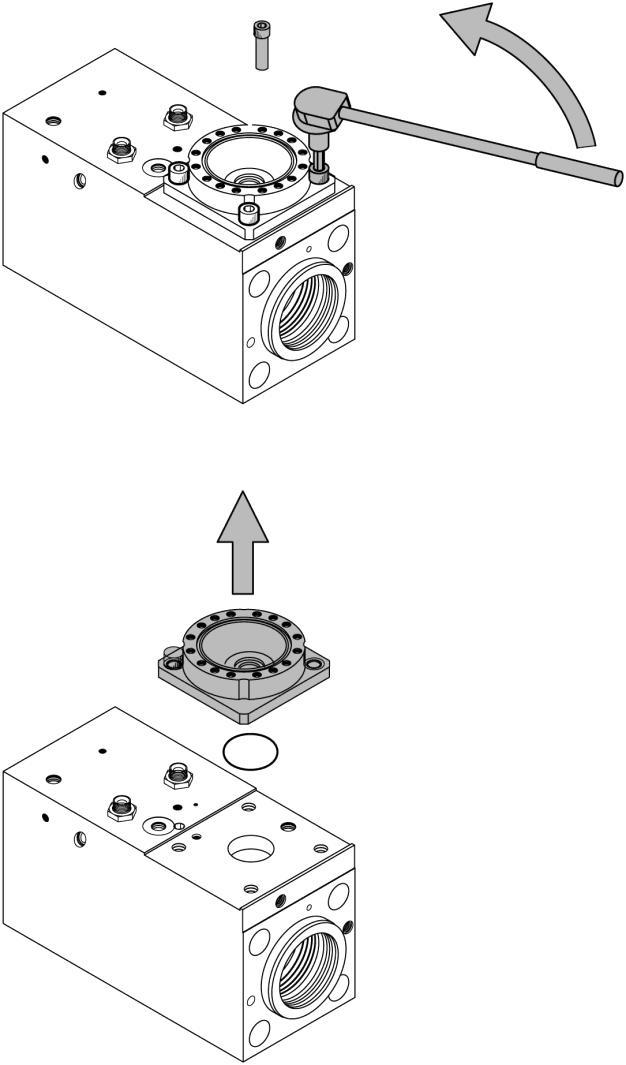

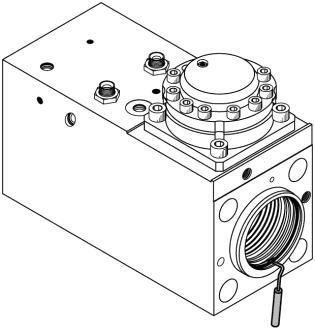

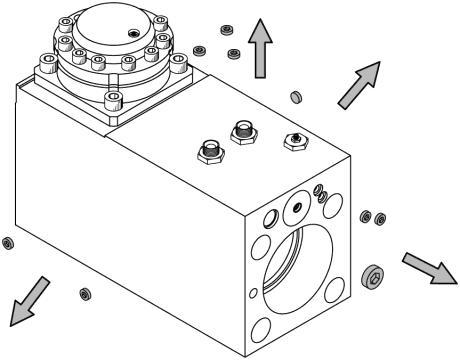

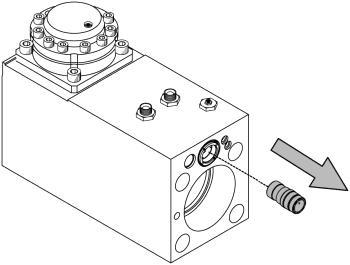

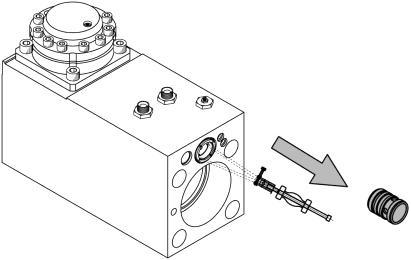

3. Remove valve cap with eye bolt, valve by hand and valve bush with valve puller.

4. Disassembly of accumulator 4-1. Discharge accumulator gas

WARNING!

Ensure accumulator gas is completely discharged before disassembly. Any remaining gas pressure may cause injury or fatal accident.

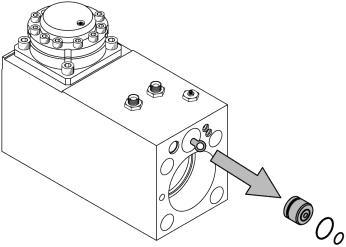

a. Open charging valve cap. b. Open needle valve cap

c. Open needle valve & release gas, you will hear nose of gas releasing. d. Check if gas releasing is done completely by opening needle valve a bit more.

4-2. Loosen accumulators cover bolts and disassemble accumulator cover.

4-3. Remove diaphragm

4-4. Loosen accumulator body bolt and remove accumulator body & face-seal.