1 minute read

C. Requirements of underwater application breaker maintenance

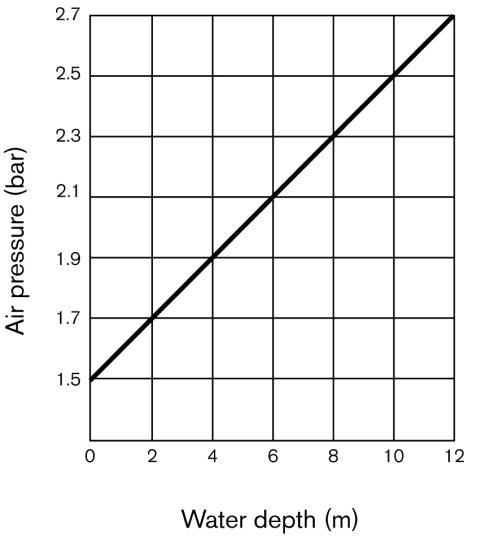

Air pressure = Water depth / 10 + 1.5 [bar] Water pressure gets 1 bar at every 10m water depth. You may calculate air pressure from the formulated on the left.

You may also get an idea of proper air pressure level from the chart on. the left

As soon as underwater breaker operating is finished, remove water that remains in percussion chamber 1. Operate the breaker at the ground over 10 times with air supply from the compressor. 2. Keep supplying compressed air to the breaker for minimum 10 minutes. 3. Apply hydraulic oil or anti-rust oil inside percussion chamber with air supply line. 4. Apply grease inside percussion chamber, repaint the breaker if necessary.

• Following is what you may refer to for maintain underwater application breaker.

Every 30 min. • Grease tool, tool pins, bushes • Check if tool moves up and down with no difficulty. • Check function range of air pressure switch. • Check air hoses and their fitting condition.

Daily (8 hours) • Remove tool pin and tool condition, remove burrs if any. • Check if tool was greased sufficiently, grease more frequently if needed. • Check if the breaker is rust or abnormally worn out, particularly piston face and percussion chamber.

When the job is over • Completely disassemble breaker and carry out overhauling including but not limited to seals. • Check if any breaker parts were damaged or rust, replace if any. • Check if all underwater kit parts are in good condition and work properly.