4 minute read

PARKING BRAKE

D. TRANSMISSION OIL PRESSURE GAUGE The marker of the transmission oil pressure gauge must stay within the green area which indicates normal operating pressure. If the marker enters the red area, it is a signal that the oil pressure is too low. Do not operate the machine with low transmission oil pressure. Stop and check the cause of the problem. E. TRANSMISSION OIL TEMPERATURE

GAUGE The marker must register in the green area. Do not operate the machine when the gauge is in the red area. Stop the machine and determine the cause of high temperature.

6. MASTER SWITCH

The machine electrical functions can only be actuated if the rotary master switch is activated. The master switch is activated by the starting switch in the “ON” position.

7. AUXILIARY ELECTRICAL CURRENT RECEPTACLE

The machine is equipped with a 24V auxiliary electrical power supply.

8. IGNITION SWITCH

This switch is a rotary type and is activated with a key. It has four positions:

ACC OFF

RUN

START

ACC - Acessories In this position some circuits such as the wipers and lights, are energized for use. OFF In this position all key activated electrical circuits are off. The key can be removed. RUN In this position all key activated electrical circuits are “ON”. START In this position, the starting circuits are energized. The switch is spring controlled for start and will return to the “RUN” position when the key is released. CAUTION: Never leave the key in the “ON” position when the engine is not running.

46

AIR CONDITIONER

1- A/C OPERATION

The air conditioning control panel in the cab is on the right-hand side of the operator’s console. B3 - AIR CIRCULATION SWITCH ON/OFF push-button for start/stop system operation for air recirculation or outside ventilation.

B4 - AIR CONDITIONING SWITCH ON/OFF push-button for air conditioning compressor.

A - IGNITION SWITCH B1 - CAB FAN SWITCH It is a rotatory button switch, with four positions:

0 - OFF 1 - LOW SPEED 2 - MEDIUM SPEED 3 - HIGH SPEED B2 - CAB HEATER SWITCH The machine is equipped with a system that utilizes heat taken from the engine coolant.

This switch can be operated only if the engine coolant tap is open. The coolant flow through the cab heater motor is controled by a solenoid valve operated by the cab heater switch. ON/OFF push-button for start/stop heating system and front/rear windshield heater operation. To operate the air conditioning, air recirculation or heater systems, follow the sequence below: 1- Start the engine. This will energize the machine’s basic functions. 2- Turn the cab fan switch (1) to desired speed position (3). 3- Select either heat B2, fresh air B3, or cool air

B4.

2- A/C MAINTENANCE

The air conditioning/heating system maintenance is limited to three items. A- Air filter in evaporator case. B- Air compressor C- Condenser

1

1- THE AIR FILTER IN EVAPORATOR BOX MUST

BE CLEANED WHEN NEEDED OR EACH 250

HOURS.

47

1

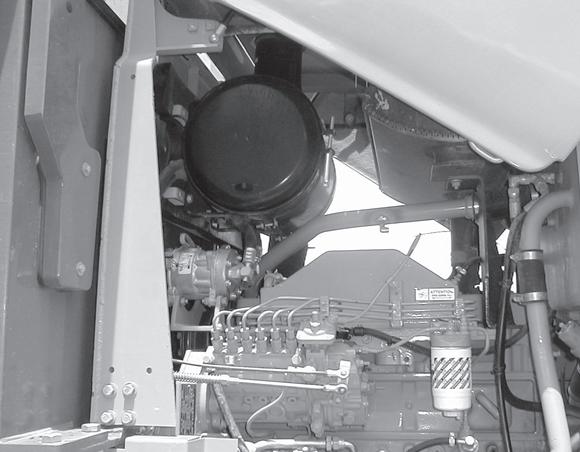

1- AIR CONDITIONER COMPRESSOR

2.1- A/C REFRIGERANT CHARGE

NOTE: A qualified technician is required to perform A/C system service. For leak test and/or gas charging use air compressor taps A and B only. 1. Add 50 grams R134a and allow system to build up 10 bar pressure (145Psig) by applying gaseous nitrogen. 2. Proceed with a gas leak test. Should a leak be CONFIRMED, evacuate the system and repair the leak. Repeat the test. 3. Connect he manifold hoses. 4. Connect vacuum pump to manifold center fitting. 5. Open the manifold valves and turn pump on. 6. Allow 20 minutes for pressure gages to indicate 26 inHg vacuum. 7. Close valves and disconnect vacuum. Close valves and disconnect vacuum pump. 8. Connect charging cylinder hose, open the manifold valve high side and apply 1200 grams of gas R134a. 9. Close the manifold valve, remove gas hose and repeat the test. 10.Disconnect manifold and install service valve covers.

2.2- RECOMMENDATIONS

1. Turn on A/C only when ventilation is turned on. 2. Make sure the evaporator inlet is not blocked. 3. Should the system performance fall below specification, inspect: • System refrigerant pressure; • Operation of fan unit. • Evaporator for obstructions. 4. Operate A/C at least 10 minutes per week. 5. When engine is at high speed operate fan at maximum speed. 6. Periodically check external cleaning of condenser (never operate condenser if it is 20% blocked or more). 7. Close all doors and windows when operating the A/C. 8. For fast cooling, use cabin internal air recirculation control.

2.3- SYSTEM MAINTENANCE

1. Clean condenser monthly or whenever the condenser air inlet shows 20% obstruction. 2. Check screw torque and belt tensioning yearly. 3. Clean air conditioning filter monthly or whenever air flow reduction is noticed.

48