2 minute read

CAB AIR FILTERS (IF EQUIPPED

Template Date: 1994_04_29Template Name: OM_1_col

TRIM THIS EDGE

Hydraulic/Brake System Oil Change

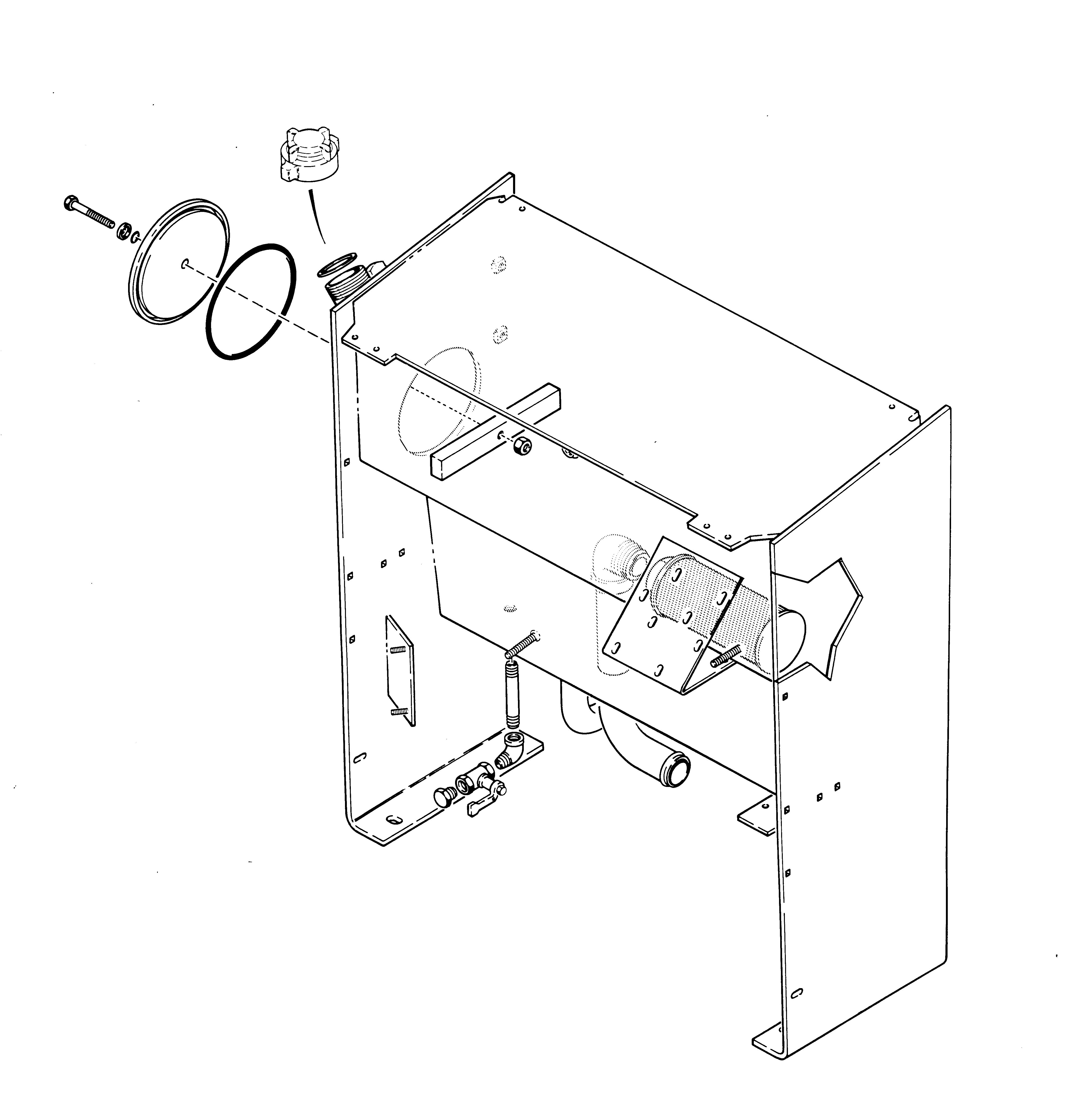

FILLER CAP

SEAL

SUCTION SCREEN

ACCESS COVER

SEAL

PLUG DRAIN VALVE

Change the hydraulic/brake oil every 2000 hours of operation or one time each year, or when ambient operating temperatures require, whichever occurs first. When changing the hydraulic oil also replace both hydraulic oil filters and clean the suction screen.

1.Make sure the hydraulic oil is at operating temperature. 2. Lower the loader bucket to the ground and apply the brake. Stop the engine. Put a DO NOT OPERATE tag on the steering wheel.

3.Make sure the accumulators are completely discharged. Push down and release one of the brake pedals a minimum of 30 times.

4.Clean the area around the filler cap and access cover. Slowly remove the filler cap of the reservoir. This will remove the air pressure from the reservoir.

911L92

106

TRIM THIS EDGE

LEFT PAGE

5.Remove the plug from the drain valve and install a hose on the drain valve.

6.Put the other end of the drain hose into a container that will hold 25 gallons (94.6 litres).

7.Open the drain valve.

8.Replace the hydraulic oil filters (see Page 105).

9.Remove the access cover from the hydraulic reservoir and remove the suction screen. Turn the suction screen counterclockwise to remove.

10.Clean the inside of the hydraulic reservoir with clean cloths.

11.Clean the suction screen in solvent and dry the suction screen with compressed air. Install the suction screen.

12.Turn the reservoir drain valve to OFF.

Remove the drain hose and install the plug in the drain valve (see Hydraulic

System in this manual for the correct type and quantity of hydraulic oil). Put new oil into the reservoir. 13.Install the access cover with a new seal and tighten the mounting bolt.

14.Install the reservoir filler cap.

15.Start the engine and run at 1000 rpm.

Check for oil leaks around the filters, access cover and the drain plug. When the balance pressure warning buzzer stops making noise, run the engine at 1500 rpm.

16.Bleed the brake system to remove old oil from the system. Remove a minimum of 1

Liter of oil from each bleed screw to make sure all old oil is removed from the system (See Bleeding the brake system in this manual)

17.Operate the loader controls several times to remove any air in the lines.

18.Lower the loader bucket to the ground and stop the engine. Check the hydraulic oil level.

19.Add oil as required. TRIM THIS EDGE

107

TRIM THIS EDGE

RIGHT PAGE