5 minute read

HYDRAULIC SYSTEM

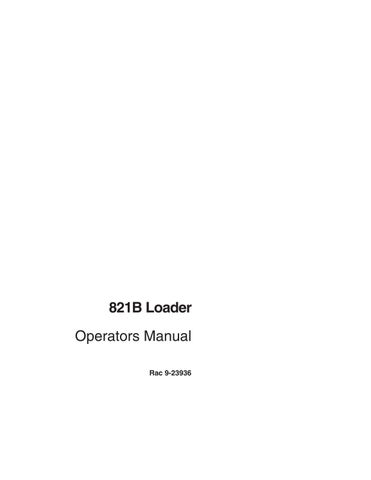

Coolant Reservoir Fluid Level

Check the coolant reservoir fluid level when the coolant is cold and the engine is stopped. Do not remove the radiator cap during this check. The coolant level must be between the FULL and ADD marks on the reservoir. Add coolant as required to raise the coolant level to the FULL mark.

Radiator Fluid Level

Check the radiator coolant level when the coolant is cold and the engine is stopped. Open the rear access door and remove the radiator cap. The coolant level must be up to the radiator cap opening.

NOTE: If the radiator coolant level is low and the coolant reservoir level as at the FULL mark, check for air leaks in the hose between the radiator and coolant reservoir.

IMPORTANT: Only add the correct mixture of ethylene glycol and water to the radiator. A17846

RADIATOR CAP

A17912 TRIM THIS EDGE

95

TRIM THIS EDGE

RIGHT PAGE

Template Name: OM_1_colTemplate Date: 1994_04_29

Template Date: 1994_04_29Template Name: OM_1_col

TRIM THIS EDGE

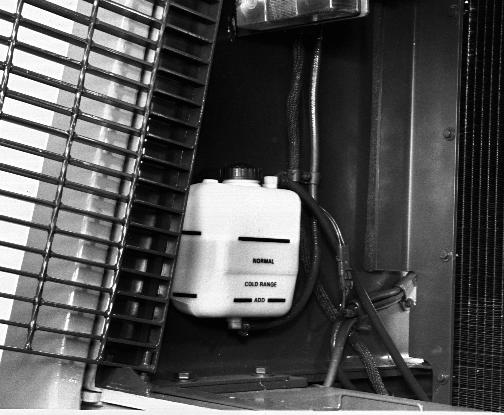

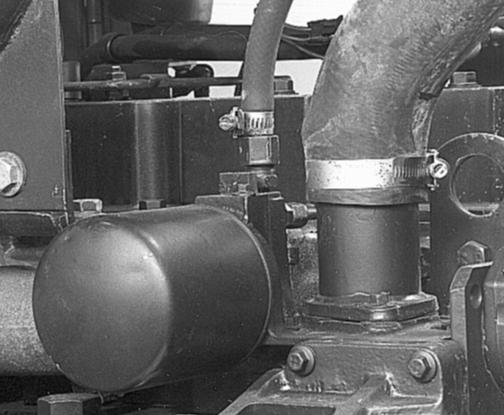

Replacing the Cooling System Filter

1.Rotate the filter shutoff valve 1/4 turn to the OFF position.

2.Cover the alternator with a plastic bag to keep coolant out of the alternator.

3.Use a strap wrench and turn counterclockwise to remove the old filter.

Discard the old filter.

4.Use a clean cloth and clean the filter mounting area on the filter head.

5.Apply a thin layer of clean grease or oil to the gasket of the new filter. 6.Turn the new filter clockwise onto the base until the gasket makes contact with the base. Continue to tighten the filter for 1/2 to 3/4 turn with you hand.

OFF POSITION

COOLING SYSTEM FILTER

IMPORTANT: Do not use a filter strap wrench to install the new filter. A leak can occur if the filter is dented by the filter wrench.

7.Rotate the filter shutoff valve 1/4 turn to the ON position.

RP95K171

ON POSITION

RP95K170

96

TRIM THIS EDGE

LEFT PAGE

Cleaning the Cooling System

WARNING: Hot coolant can spray out if radiator cap is removed. To remove radiator cap: Let system cool, turn to first notch, then wait until all pressure is released. Scalding can result from fast removal of radiator cap. Check and service engine cooling system according to maintenance instructions. SA023

Drain, flush and replace the engine coolant every 2000 hours of operation or each year, whichever occurs first. Clean the system and replace the coolant if the coolant becomes dirty or has the color of rust.

DO NOT remove the radiator cap if the coolant is hot.

1.Open the radiator drain valve and remove the radiator cap.

2.After all coolant is removed, close the drain valve.

3.Add cleaning solution to the cooling system and fill the cooling system with clean water. Follow the directions included with the cleaning solution.

4.After you drain the cleaning solution, flush with clean water and drain the water. A17879 5.Replace the cooling system filter.

6.Put one container (1 pint) of Part Number 331-509 cooling system additive into the radiator.

7.Turn the heater control valve to the ON position and fill the cooling system until the coolant level is 1 inch (25.4 mm) from the top of the radiator opening. DO NOT install the radiator cap at this time (see

Page 89 for the correct coolant mixture).

8.Fill the coolant reservoir to the FULL mark.

9.Start and run the engine at 1800 rpm (r/ min) for two (2) minutes).

10.Stop the engine. Fill the radiator to the top.

11.Install the radiator cap.

12.Check the coolant level in the coolant reservoir. Add coolant as required.

13.Check the coolant level daily. If the coolant reservoir is empty fill the radiator and the coolant reservoir as required.

97

TRIM THIS EDGE

RIGHT PAGE TRIM THIS EDGE

Template Name: OM_1_colTemplate Date: 1994_04_29

Template Date: 1994_04_29Template Name: OM_1_col

TRIM THIS EDGE

DIESEL FUEL SYSTEM Service Specifications

Fuel Tank Capacity.....................................................................72 U.S. Gallons (272.7 Litres) Interval for Draining Water from

Fuel Sediment Bowl (If Equipped)............................................Every 50 Hours of Operation Fuel Filter Replacement Interval.................................................Every 500 Hours of Operation In-Line Fuel Filter Replacement Interval (If Equipped)............Every 500 Hours of Operation or when Engine Power Decreases Fuel Tank Water Drain Interval...................................................Every 500 Hours of Operation

Fuel Conditioner

Diesel Fuel Conditioner is available from your dealer. Follow the instructions on the can. The conditioner will:

1.Clean the fuel injectors, valves and manifold for increased service life.

2.Disperse insoluble gummy deposits that can form in the fuel system.

3.Separate moisture from the fuel.

4.Stabilize the fuel in storage.

Fuel Filler Cap

RP95K147

98

TRIM THIS EDGE

LEFT PAGE

Diesel Fuel

Use No. 2 Diesel fuel in the engine of this machine. The use of other fuels can cause the loss of engine power and high fuel consumption. In very cold temperatures, a mixture of No. 1 and No. 2 diesel fuels is temporarily permitted. See the following note.

NOTE: See your fuel dealer for winter fuel requirements in your area. If the temperature of the fuel lowers below the cloud point (wax appearance point), wax crystals in the fuel will cause the engine to lose power or not to start.

The diesel fuel used in this machine must meet the specifications in the chart below or Specification D975-81 of the American Society for Testing and Materials.

Fuel Storage

If you keep fuel in storage for a period of time, you can get foreign material or water in the fuel storage tank. Many engine problems are caused by water in the fuel. Keep the fuel storage tank outside and keep the fuel as cool as possible. Remove water from the storage container at regular periods of time. Fill the fuel tank at the end of the daily operating period to prevent condensation in the fuel tank.

Specifications for Acceptable No. 2 Diesel Fuel

API gravity, minimum................................................................................................................................................34 Flash point, minimum...............................................................................................................................140˚F (60˚C) Cloud point (wax appearance point), maximum................................................................-5˚F (-20˚C) See Note above Pour point, maximum.....................................................................................................-15˚F (-26˚C) (See Note above Distillation temperature, 90% point....................................................................................540 to 640˚F (282 to 338˚C) Viscosity, at 100˚F (38˚C)

Centistokes................................................................................................................................................2.0 to 4.3

Saybolt Seconds Universal...........................................................................................................................32 to 40 Cetane number, minimum................................................................................43 (45 to 55 for winter or high altitudes) Water and sediment, by volume, maximum.....................................................................................................05 of 1% Sulfur, by weight, maximum............................................................................................................................50 of 1% Copper strip corrosion, maximum.........................................................................................................................No. 2 Ash, by weight, maximum...............................................................................................................................01 of 1%

WARNING: Engine fuel is flammable and can cause a fire or an explosion. Do not fill the fuel tank or service the fuel system near an open flame, welding, burning cigars, cigarettes, etc. SA022

99

TRIM THIS EDGE

RIGHT PAGE TRIM THIS EDGE