3 minute read

AIR CONDITIONING (optional

Template Date: 1994_04_29Template Name: OM_1_col

TRIM THIS EDGE

Dipper top/Bucket

(788 series)

2

Dipper cylinder top and bucket cylinder

Measure the play (J). If it is equal to or greater than 2 mm, insert washers to obtain a minimum play of 0.5 mm.

(788 series)

1 1

PDG0143 Measure the total play. If it is equal to or greater than 2 mm, insert washers (2) so as to obtain a minimum play of 0.5 mm.

(988 series)

3

PDG0147 Insert washers (1) for the dipper cylinder and bucket cylinder.

(988 series)

1 3 1 3

PDG0143 Measure the total play. If it is equal to or greater than 2 mm, insert washers (3) so as to obtain a minimum play of 0.5 mm. To remove the pin, see “Replacing a backhoe bucket”.

PDG0147 Insert washers (3) for the dipper cylinder and washers (1) for the bucket cylinder. To remove the pin, see “Replacing a backhoe bucket”.

290

TRIM THIS EDGE

LEFT PAGE

Dipper cylinder bottom and bucket cylinder

Measure the total play. If it is equal to or greater than 2 mm, insert washers to obtain a minimum play of 0.5 mm.

(788 series)

1 1

PDG0147 Insert washers (1) for the dipper cylinder and bucket cylinder.

(988 series)

Yoke/Connecting rod and yoke/dipper pins

PDF0054 Using the nut, bring the yokes into contact with the connecting rod and with the dipper and then loosen until it is possible to fit the split pin in the nut. Play (at J1) should be between: Minimum play: 0.5 mm. Maximum play: 0.7 mm.

1 3 1 3

PDG0147 Insert washers (3) for the dipper cylinder and washers (1) for the bucket cylinder. To remove the pin, see “Replacing a backhoe bucket”.

291

TRIM THIS EDGE

RIGHT PAGE TRIM THIS EDGE

Template Name: OM_1_colTemplate Date: 1994_04_29

Template Date: 1994_04_29Template Name: OM_1_col

TRIM THIS EDGE

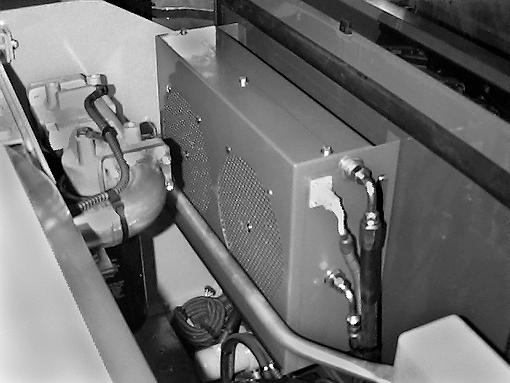

AIR CONDITIONING (optional)

The air conditioning system components require regular servicing. Respect these service intervals to ensure the correct operation and full effectiveness of the air conditioning system. The air conditioning system contains a gas which is subject to strict regulation. Any failures in the system must be repaired as quickly as possible.

WARNING: Never perform any service work on the refrigeration circuit. Consult an approved specialist for any service work required.

NOTE: Use the air conditioning at least once a week, if only for a short time. See “Air conditioning controls” in the “Controls/Instruments/Accessories” Section.

Service specifications

Compressor lubrication..........................................Once a week or every 50 hours Clean the condenser..............................................Once a week or every 50 hours Inspect the compressor belt..........................................................Every 200 hours Inspect and clean the dust filter............................................................Periodically Receiver/Dryer........................................To be checked every year by a specialist

Compressor lubrication Cleaning the condenser

To access the condenser, you must remove the front panel with the fans.

STEP 1

CD98D023 Using the air conditioning controls in the cab, start up the compressor to lubricate the inner seal. See “Air conditioning controls” in the “Controls/Instruments/Accessories” Section.

NOTE: In cold weather, run the engine for a few minutes before starting up the compressor. IMPORTANT: Never unscrew the plug located on top of the compressor, since this would discharge the system.

CD98D031 Remove the retaining screws and then dislodge the front panel.

292

TRIM THIS EDGE

LEFT PAGE