3 minute read

AIR CONDITIONING

Template Date: 1994_04_29Template Name: OM_1_col

TRIM THIS EDGE

CHECKING FOR CYLINDER LEAKAGE

A cylinder rod should be slightly oily. Check for leaks after a period of work, when the entire hydraulic system is at normal working temperature. 1. Wipe the rod and the bearing on the cylinder to be checked. 2. Operate normally for five to ten minutes. 3. Extend the cylinder rod. 4. Check for leaks.

ROD APPEARANCE TEST CONCLUSION

Dry Slight traces of oil when a piece of paper is wiped over 20 cm of the rod. Normal Slightly oily Paper remains stuck to the rod when wiped over the rod. Normal Oily Paper remains stuck when placed on the rod. Normal

Very oily orweeping

Each time the cylinder rod is extended, a ring of oil can be seen on the rod. Leakage Each time the cylinder rod retracts, excess oil drips from the bearing. Consult your CASE Dealer

302

TRIM THIS EDGE LEFT PAGE

SHIMMING OF ATTACHMENTS

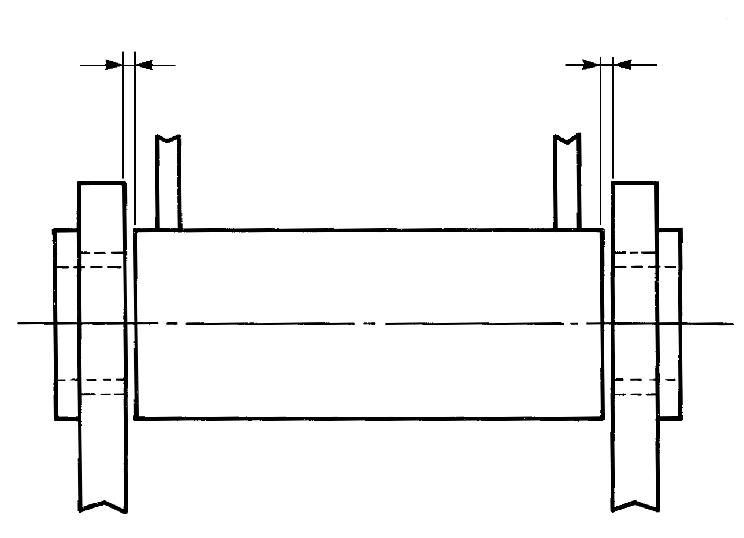

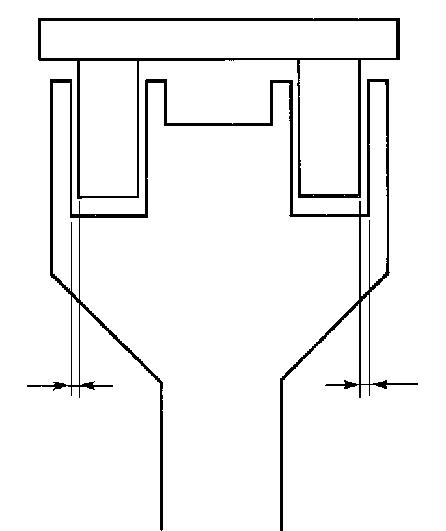

The purpose of shimming attachments is to reduce and spread lateral play in the linkages and to keep the various components correctly aligned. Play is defined as the extent of possible lateral movement between one component and another at their linkage point. Shimming is carried out using steel shimming washers. IMPORTANT: The minimum play for all linkage points should never be less than 0.5mm.

Shimming washers

Part No. (1) Part No. (2) Part No. (3) 1 mm.............................................N3145354.............P3145355...........Q3145356 2 mm..............................................D745341..............G3415325.............E745342 4 mm..............................................L745440.....................-...................M745441

Boom top/Dipper bottom Dipper top/Bucket

A

1 2

PDG0142 Measure the total play. If it is equal to or greater than 2 mm, insert washers (1) so as to obtain a minimum play of 0.5 mm. NOTE: Shimming must be symmetrical between the boom top and the dipper bottom. IMPORTANT: Do not insert washers on the inner side of the dipper bottom (A).

PDG0143 Measure the total play. If it is equal to or greater than 2 mm, insert washers (2) so as to obtain a minimum play of 0.5 mm. To remove the pin, see “Replacing a backhoe bucket” . NOTE: Shimming should be symmetrical between the dipper top and the bucket lugs. TRIM THIS EDGE

303

TRIM THIS EDGE RIGHT PAGE

Template Name: OM_1_colTemplate Date: 1994_04_29

Template Date: 1994_04_29Template Name: OM_1_col

TRIM THIS EDGE

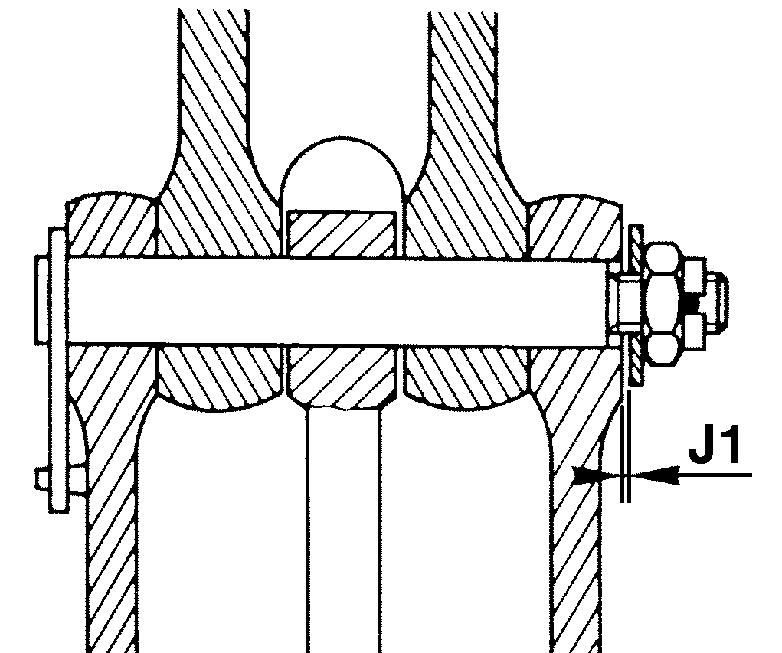

Dipper cylinder and bucket cylinder top

Measure play at (J). If it is equal to or greater than 2 mm, insert washers (1) until a minimum play of 0.5 mm is obtained.

1 3 1 3

PDG0147 Washers (3) for the dipper cylinder and washers (1) for the bucket cylinder. To remove the pin, see “Replacing a backhoe bucket” .

Dipper cylinder and bucket cylinder bottom

Measure the total play. If it is equal to or greater than 2 mm, insert washers (1) until a minimum play of 0.5 mm is obtained. 1 3 1 3

PDG0147 Washers (3) for the dipper cylinder and washers (1) for the bucket cylinder. To remove the pin, see “Replacing a backhoe bucket” . NOTE: Shimming should be symmetrical between the cylinder bottom and the lugs.

Yoke/connecting rod and yoke/dipper pins

PDF0054 Using the nut, bring the yokes into contact with the connecting rod and with the dipper and then loosen until it is possible to fit the retaining pin in the nut. Play at (J1) should be between: Minimum play: 0.5 mm. Maximum play: 0.7 mm.

304

TRIM THIS EDGE LEFT PAGE