1 minute read

RADIATOR AND OIL COOLER

If any one of the above conditions 1, 2 or 3 is not fulfilled, then the assembly has not been carried out correctly. -Remove the plate (10). -Deflate the tyre. -Remove the safety-type retaining ring (1) and the shoulder (2). -Repeat Steps 9 to 15. If any one of the above conditions 1 or 2 is still not fulfilled, then the rim is not to specifications. Replace the rim with a new one.

STEP 16

Installing wheels on the machine

STEP 1

12 13 16

11

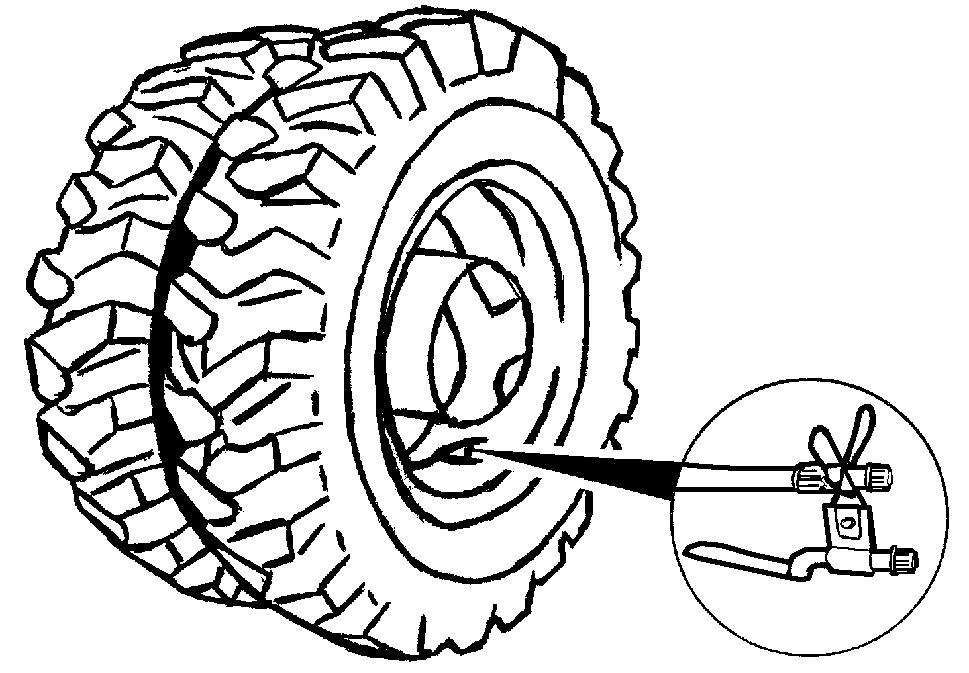

CS99F513 Lock the safety-type retaining ring firmly into place with the safety pin (11).

STEP 17

Inflate the tyre to the pressure specified by CASE. See “Tyre pressures” .

STEP 18

Check that the retaining ring is correctly mounted in its groove (it is imperative that the ring be fully seated in the groove, all the way round the wheel). Any gaps appearing between the ring and the edge of the groove or the shoulder are totally unacceptable. If gaps are detected, leave the wheel in the inflating cage, deflate the tyre completely and repeat Steps 9 to 18. If no gaps are detected, remove the wheel from the inflating cage.

14

CS99C625 Install the inner wheel (12), the rubber twinning ring (14) and the outer wheel (13), making sure the valve extension (16) is properly positioned in its housing. Secure the valve extension in its clip. TRIM THIS EDGE

265

TRIM THIS EDGE RIGHT PAGE