2 minute read

Control of hydraulic system and hitch attachment without draft control unit - Specific character of tractor operation with machines that require driving from rear PTO

Control of tractor hydraulic system and hitch attachment

Hitch attachment on tractors is controlled with extreme right-hand handle of distributor. When operating with mounted machines, use only “lift” and “floating” positions of handle.

It is prohibited to set the handle into “lowering” position, when operating with mounted tilling machines!

Use “lowering” position only when operating external cylinders, installed on the machine and intended to adjust positions of working devices (reel, header, ploughshares. etc.) of harvesting, seeding and other machines. If distributor handle doesn’t return automatically to “neutral” after termination of cylinder travel, take it out manually. And vice versa, in case of premature return of the handle hold it by hand until operation is fully completed.

Special character of tractor operation with machines that require driving from rear PTO

General recommendations: a) Make sure that rear PTO control is properly adjusted before connecting machine to tractor; b) Install and fasten securely required (6, 8- or 21-splined) PTO drive end and actuate drive of rate speed corresponding to it. Set 540 rpm for 6, 8-splined drive end, and 1000 rpm for 21-splined drive end.

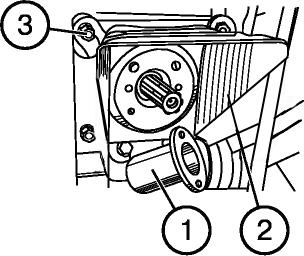

To replace PTO drive end, fulfill the following operations: 1. Screw out two bolts and remove a cap (1). 2. Unscrew four nuts (3) and remove guard (2). 3. Screw out six bolts (4), remove plate (6) and dismount the drive end (5). 4. Install another drive end into spline opening and install the plate (6). 5. Assemble remaining details in the reverse sequence.

c) Lubricate the shaft and tube of cardan drive telescopic joint with solid oil.

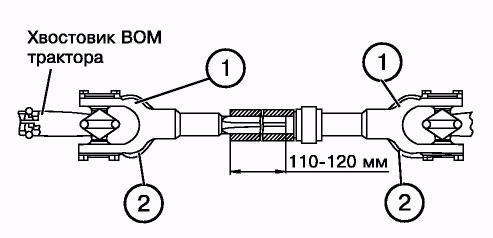

Install cardan drive joint on PTO drive end, fasten it securely in fixation groove. Make sure that eyes (2) of joint forks (1) of intermediate (telescopic) shaft lie in one plane. Failure to satisfy mentioned requirement causes cardan drive and PTO overloading; d) Install cardan shaft guard of agricultural machine; e) After cardan drive installation make sure that there is no thrusting of telescopic connection elements of cardan drive, when machine is in its extreme positions towards the tractor; minimum overlapping of cardan drive telescopic part should be 110-120 mm, as drive discoupling is possible if overlapping length is less.

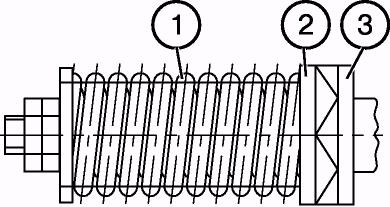

Safety clutch spring length (1) of agricultural machine should be adjusted in such a manner to provide turnover of cam clutches (2 and 3) against each other in case of overloading. Excessive spring tightening leads to clutch malfunction and cardan drive and PTO overloading. Actuate separate PTO drive at minimum engine speed or when the engine is shut down. Actuate synchronous PTO drive with running engine, while smoothly engaging clutch coupling. When operating tractor without use of PTO be sure to set PTO control lever into “PTO-off” position, set shifting clutch of two-speed PTO drive into position 1 (540 rpm), and set selector lever of separate-synchronous PTO drive into middle (neutral) position.