1 minute read

Shimming the differential..............................................................................................................................................D1

Crown wheel and pinion and differential

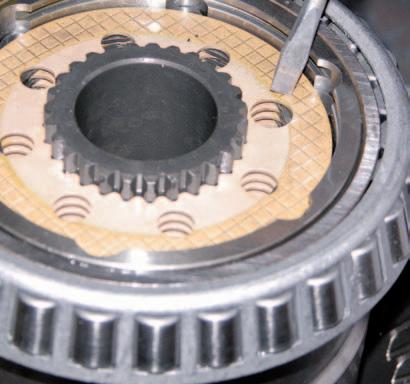

– Refit the disks while aligning the holes of the larger diameters (D). The first and last discs are in steel. – Clamp the assembly using the retainer ring. – Place the crown gear on the differential casing, then smear the screws with Loctite(270) and tighten at 12 ± 1 daN·m. – Heat the bearings, then refit them. – On the piston side, when not replacing the tapered roller bearing, refit the original adjustment shims, then the outer bearing cage. – When replacing the tapered roller bearing, refit with a 1,5 mm shim.

D

Shimming the differential

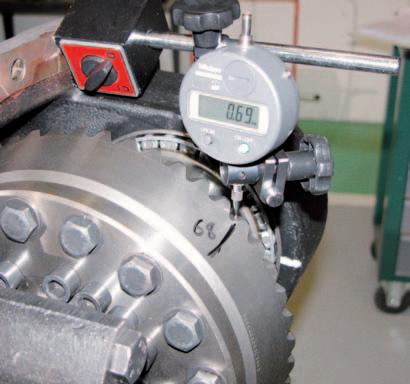

– Refit the differential assembly. – Pretighten the bracket screw and the nut. – Check clearance between the teeth of the crown gear and tapered pinion. There must be between 0,18 and 0,23 mm of play. – Adjust the 1,5 mm shim located behind the bearing on the piston side according to the clearance found. If clearance between the teeth is too high, reduce the adjustment shim, and conversely. – Refit the differential assembly. – Check the torque with a dial wrench fitted with tool n°0011360200. The value must be 0,42 ± 0,1 daN·m.

455hsm47 Fig. 96

455hsm48 Fig. 97