OVERHAULING THE ENGINE

DISMANTLING THE ENGINE

Cam Wheel Bushes With a two-diameter drift drive out the cam-wheel bushes. The metal cap in the timing cover must be pressed out before the bush behind it can be removed.

s. in fo

Note.— When unscrewing the oil-return pipe nut (top nut) at the crankcase end, take care that the spanner does not touch the feed pipe nut (lower nut) thus creating a levering action on the lower nut which can break the crankcase.

Timing-Side Bush

The crankcase can now be separated and the flywheels taken out.

Big-End Assembly

Support the crankcase with a short length of steel tube (1½-in. outside diameter, 1 ¼-in. internal diameter) placed in the timing chest around the bearing bore in the crankcase, and force out the bush. If a bush with two diameters is used, support the crankcase and force out the bush from inside the timing chest.

es

Tappet and Guides

The tappet and its guide can only be removed together. Some difficulty may be experienced as the guides are a very tight fit in the crankcase. Repair shops and the manufacturers use a special tool. These guides should only be removed when the tappet feet are worn, or when the six-slot guides are to be fitted. The valve-lifter shaft, if fitted, is removed and the two crankcase halves bolted together to prevent distortion. Without the special tool, heat the crankcase uniformly and drive out tappet and guide from inside the timing chest.

ch l

Thoroughly clean the exterior of the crankcase before it is placed on the bench, then remove the sump plug to drain the oil. Remove: (i) Both oil-pump end-caps, the pump guide pin, and take out the oil-pump plunger, before attempting to separate the crankcase. (ii) The small timing-pinion nut which has a left-hand thread. (iii) Both cam wheels. (iv) The timing pinion. (v) The bottom crankcase bolt if fitted. (vi) The cylinder barrel. If a compression plate is used it will come away with the cylinder. (vii) One circlip only, push out the gudgeon pin and take off the piston. If the gudgeon pin, which is a sliding fit, is difficult to extract, remove burrs round the circlip groove. Wrap the piston in clean rag and put it in a place of safety.

m

at

Squirt petrol through holes in the timing-side axle with the object of removing oil from the big-end bearing so that up-and-down movement between the connecting rod and bearing can be detected. Should there be no up-and-down movement but the connecting rod can be rocked sideways (this must not be confused with side clearance between the rod and flywheel), then attention is necessary.

s-

Separating the Flywheels

w.

Flywheel Shafts

aj

Remove both crankpin nuts; use a separating tool as shown in Fig. 6, or alternatively an Arbor press, to separate as the crankpin centre is a force fit in both flywheels. Check crankpin roller path and connecting-rod liner for wear or damage.

ww

Remove the nut retaining the driving-side axle which has a right-hand thread and push out the shaft, which is usually a tight fit, from inside the flywheel. Take out the grub screw alongside the nut retaining the timing-side axle (engines before 1954), unscrew the nut a few turns and tap the end of the shaft sharply to remove it as it is a taper fit. Take off the nut when the shaft is loose. Engines from 1954 onwards have a parallel shaft and must be pressed out.

Main Bearings

To remove the bearings, uniformly heat the crankcase and drop it face downwards on to a bench; the bearings with spacing washers will fall out. 11

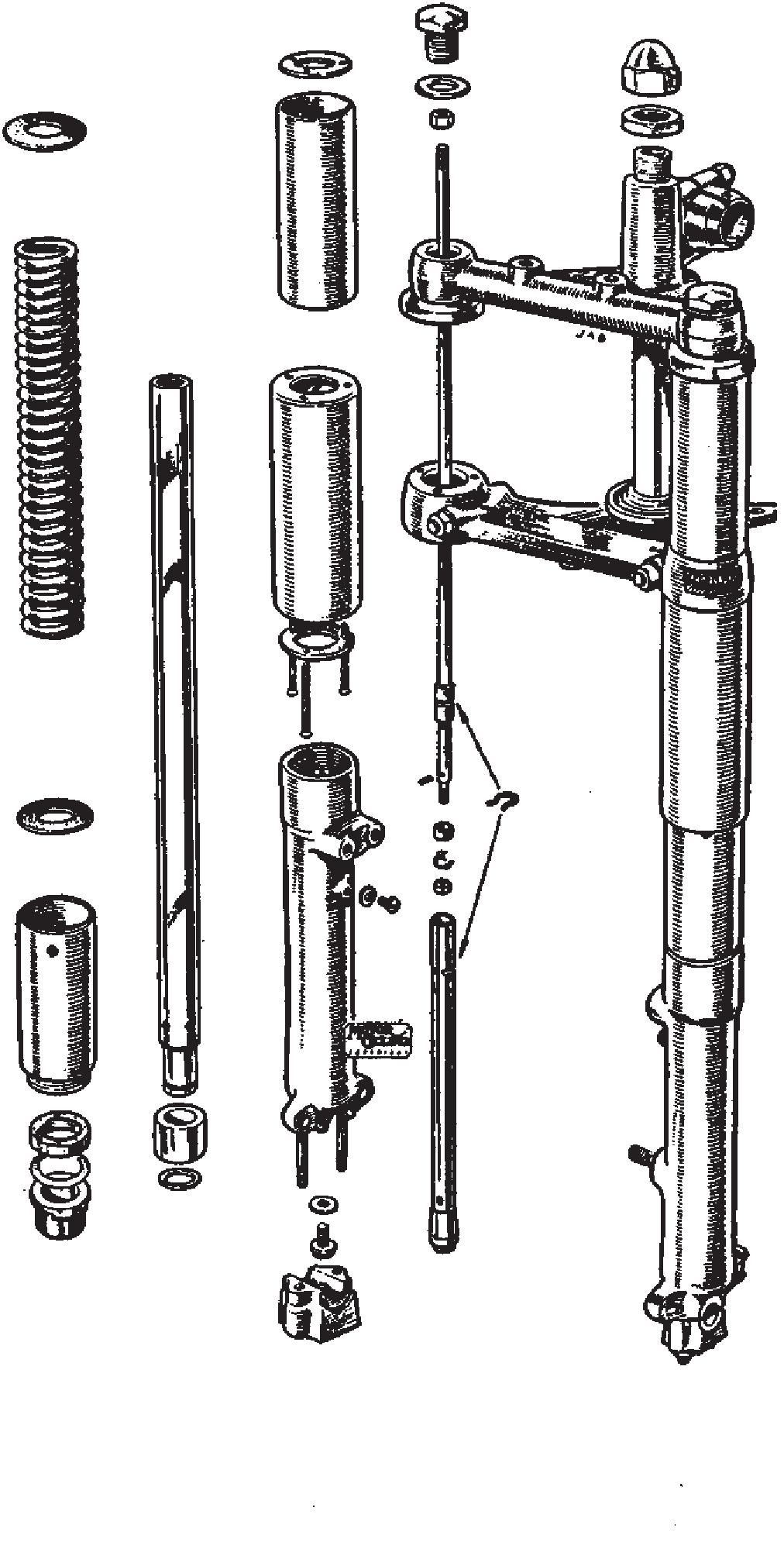

Rocker Box

To dismantle the rocker box completely, remove both rocker-axle nuts and washers securing the valve-end rockers. Tap out each axle or prise off the rocker. The axle with its loose steel sleeve and push-rod rocker attached can be withdrawn. The rocker-axle sleeve is mounted on two short bushes with a felt sealing ring between each bush. Heat the rocker box and press out the four bushes.

REASSEMBLING THE ENGINE Connecting Rod A detachable liner is fitted to the connecting rod. Liners sold as replacements are ground internally to allow for contraction when fitted; even so complete concentricity cannot he guaranteed as contraction is controlled by the interference fit of the liner in the rod. To ensure concentricity a lapping tool is used with grinding compound. If the big-end assembly is correct the rod should just fit over the rollers, with no appreciable side rock. MATCHLESS SINGLES 1939 -1955