products and services

ENSURING SAFE LIFTING OPERATIONS

PRODUCTS

• Lifting beams

• Lifting & transport frames

• Material lifting baskets

• Lifting & assembly work equipment

services

• Pilot studies & investigations

• Load weighing & 2D/3D scanning

• Design, calculations & regulations

• Certification of existing equipment

Standard equipment and bespoke solutions for any lifting operation! Hire us for a review, risk assessment, refurbishment and certification of existing lifting equipment.

www.lyftnord.se

bespoke lifting & transport frame

We have designed and delivered a large number of different bespoke lifting frames to ensure safe handling and servicing of machinery and machine parts.

The frames in the photos can easily be adapted to various lifting needs. We can also manufacture frames for other types of machine parts, for instance rollers and conveyor drums. Contact us so we can help you customise a solution to your particular lifting needs.

LIFTING FRAME FOR WET MAGNETIC SEPARATOR

We have designed a lifting frame to ensure safer and simpler handling of Metso’s WS1236 wet magnetic separator. The drum can be transported with or without using a gearbox.

LIFTING FRAME FOR DRY MAGNETIC SEPARATOR

We have designed a lifting frame to ensure safer and simpler handling of Metso’s DS 921-100 and DS 1224-100 dry magnetic separators. The drum can be transported with or without using a gearbox.

2 | Lyftnord

TRANSPORT FRAME FOR DRY MAGNETIC SEPARATOR

We have designed and delivered a transport frame to ensure safer, simpler handling and servicing, etc. of Metso’s DS 1224-100 dry magnetic separator.

LIFTING FRAME REGULATIONS

Lyftnord’s products naturally comply with all governing directives and provisions such as the Machinery Directive and the Swedish Work Environments Authority’s AFS 2006:6 relating to the use of lifting equipment.

3 Lyftnord |

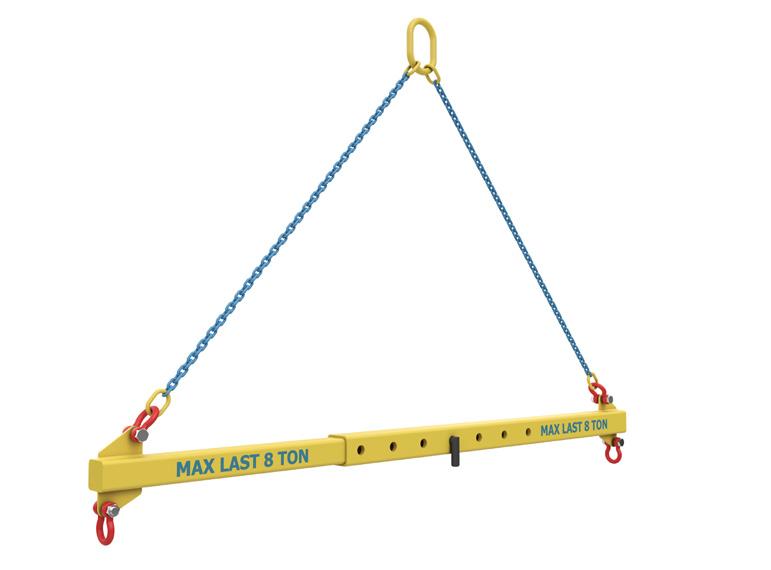

STANDARD LIFTING BEAM

Our lifting beams are designed and constructed in compliance with applicable provisions in SS‑EN 13155, and are tested and certified according to the 2006/42 EC machinery directive.

LIFTING BEAM

Lifting beams are used in low headroom situations and where the centre of gravity is well balanced.

ADJUSTABLE LIFTING BEAM

Adjustable lifting beams are ideal in situations with low headroom and where the centre of gravity is asymmetrical.

SPREADER LIFTING BEAM

A spreader beam offers good stability which makes it the ideal tool in situations requiring good lifting height.

ADJUSTABLE SPREADER LIFTING BEAM

Adjustable spreader beams provide both good stability and a high level of flexibility.

H-BAR LIFTING BEAM

H-bar beams are used in low headroom situations and where there is a need for more lifting points.

ADJUSTABLE H-BAR LIFTING BEAM

Adjustable H-bar beams are ideal in low headroom situations and where there is a need for more lifting points at various positions.

4 | Lyftnord

BESPOKE LIFTING BEAMS

We customise lifting beams in line with client requests and requirements. We can deliver affordable bespoke solutions using well defined and standardised design, calculation and CE marking procedures.

LIFTING AND LOAD EYE OPTIONS

• LIFTING EYES: Selection of other lifting eye options to suit your lifting operation needs.

• ADDITIONAL LIFTING AND LOAD EYES: Is there a need for more lifting and load eyes? We can adapt the beam to suit your needs.

• ADJUSTABLE LIFTING EYE Does the load have an asymmetric centre of gravity? Select an adjustable lifting eye which can be moved laterally.

• LOADING POINTS FOR INSTANCE FOR SLINGS: Would you like to attach the slings directly to the beam? Then it is recommended to use bent iron rods to guarantee smooth edges.

STANDARD DELIVERY

• The lifting beam is delivered with CE certification in accordance with the Machinery Directive.

• The lifting beam is proof-load tested with 1.5 times the working load limit.

• The lifting beam is delivered with the beam profile shown in the product photo and resistant yellow finish.

• Lifting points are fitted with shackles.

ACCESSORIES

• HOOKS

• SHACKLES

• CHAINS, ETC.

WE DELIVER A TOTAL RANGE OF EQUIPMENT TO ENSURE SAFE LIFTING OPERATIONS!

5 Lyftnord |

Lifting and drop link options

Case studies

We design bespoke lifting and work equipment that makes your work easier and safer.

ROTATION EQUIPMENT FOR FLAT OBJECTS

We developed this CE certified rotation equipment for flat objects weighing up to 8 tonnes in accordance with the customer’s proposals. In other words, a great example of collaboration.

SCRAP HANDLING HOOK

Scrap from other processes can at times become lodged in LKAB’s crushers. The customer required a practical tool that could grab hold of the scrap and this led to the design of this simple and affordable hook.

6 | Lyftnord

ROCK BASKET FOR CRUSHERS

This robust lifting basket was designed to be lowered into stone crushers and filled by hand. It is then lifted out and emptied by hand or using a gantry crane.

LIFTING BEAM FOR ASSEMBLY OF HITCHES FOR IRON-ORE HOPPER WAGONS

Working closely with the customer, we designed a practical and simple lifting beam for the safe assembly of iron-ore hopper wagon hitches.

7 Lyftnord |

OUR SERVICES

Lyftnord delivers qualified products and services to industry and contractors. We boast extensive experience and unique expertise within all areas of your lifting project – from a site study, planning and design to completed delivery.

PILOT STUDY & EXAMINATION

Are there any uncertainties about the product’s appearance and design, what lifting standards are in force and what the final price will be?

We offer detailed pre-planning services where drawings, concept and calculations are created to establish functionality and target cost.

LOAD WEIGHING & 2D/3D SCANNING

Are you missing data and documentation about the object that has to be moved or transported? We have extensive experience of measuring and also identifying the centre of gravity through load weighing. We also offer a 2D/3D scanning service that is a very affordable method of scanning and inserting a point cloud in a CAD software file which then can be used in the design process.

DESIGN, CALCULATIONS & REGULATIONS

We offer design and calculation services, as well as consultation on laws and regulations, to meet all unique lifting needs. We strive at all times to make the most of customer and lift operator knowhow while ensuring that strength requirements and current regulations are met. Our services include refurbishment of equipment and the design of new ones. We also offer a review of existing equipment and conduct approval processes if required.

Lyftnord Föreningsgatan 7C 981 31 Kiruna, Sweden Tel: +46 (0)980 164 69 info@lyftnord.se www.lyftnord.se