Thisprocedurecoversthereconditionofthefrontand rearaxleassemblieswithoutdifferentiallock.SeeSM KeysheetArea01---002forreconditionofaxleswithdifferentiallock.Forfrontaxleremovalandinstallation procedure,seeSMKeysheetArea01---004.Forrear axleremovalandinstallationprocedure,seeSMKeysheetArea01---029.

Readandunderstandthefollowingsafety instructionsbeforeattemptingtoperformany ofthetasks.Thesubassembliesareheavy. Removalfromtheaxlehousingcausesthe unittobecomeunstable.Potentialforsevere injuryispresentifallsafetyinstructionsare notstrictlyfollowed.

Note:Eachaxleassemblyweighsapproximately3,000lb(1360kg).Eachaxleassembly includingsteercylindersweighsapproximately 3,140lb(1425kg).

1.Mountaxleassemblyonsupportswiththedifferentialcarrierassemblyfacingup.Securetosupports withC---clampsorsimilarmeans.

2.Whenhandlingsubassemblies,alwayskeepthe loadwellbalanced,andaslevelaspossible.Move slowlyandkeeptheloadundercontrol.Donotattempttohandlesubassemblieswithoutassistance.

3.Whenliftingsubassemblies,useonlyaliftingdevicewhichhasthepropercapacitytohandlethe load.Allriggingusedmustbeingood,sound conditionandbethepropersizeforthejobtobe performed.

4.Failuretofollowtheseinstructionsduringrigging operationsmayresultindamagetoequipmentor injurytopersonnel.

Duringthedisassemblyprocess,inspectbothcupand coneofalltaperedrollerbearings.Ifeithercomponent isdamaged,theymustbereplacedasaset.Labeland tagassemblylocationwheneverabearingistoberemoved.

Followallmanufacturersrecommendations concerningsolventsandcleaningsolutions. Seriouspersonalinjurymayresultfrom misuseoftheseproducts.

1.Thebreatherandallotheropeningsshouldbe tightlycoveredorclosedtopreventthepossibility ofsolventfromenteringtheassembly.Thoroughly cleantheexterioroftheaxlewithanapproved cleaningsolvent.Allowtoairdry.

Note:Thedisassemblyandassemblyproceduresofbothrightandlefthandwheelend planetaryassembliesareidentical.

2.Ifrequired,removerearsteerindicator. Rearaxle only.

3.Ifrequired,removesteeringcylinders.RefertoSM KeysheetArea01---007forcorrectprocedure. RefertoFigure1.

4.Removecotterpins(45)andcastlenuts(44)from tierodend(48).

5.Usingatierodflaretool,separatetierodend(48) fromsteeringknucklehousing(26)andremovetie rod(46)assembly.

Note:Twotypesoftierodendsareavailable.In eithercasetoaidtheassemblyprocess,count andrecordthenumberofrevolutionsthatare requiredtoremovetierodend(48)fromtierod (46).

6.Removetherodendusingoneofthefollowing stepsasrequired:

a.Loosenlocknut(47)andremovetierodend (48).

b.Loosennut(54)andremovetierodend(48) fromtierod(46).Ifrequired,removenut(54), lockwasher(55),capscrewandwasher(57), andtierodclamp(56)fromtierod(46).

Note:Axlehousing(42)anddifferentialcarrierhousing(109)oilcapacityis40pt(19L). Planetaryhubhousing(36)oilcapacityis8pt (3.75L)each.

7.Removeplugs(20,35,62,65)andbreather(63). Usingasuitablecontainer,drainaxlehousing(42), differentialcarrierhousing(109),andplanetary hubhousing(36)thoroughlybeforedisassembly. Properlystoreordisposeofusedoil.

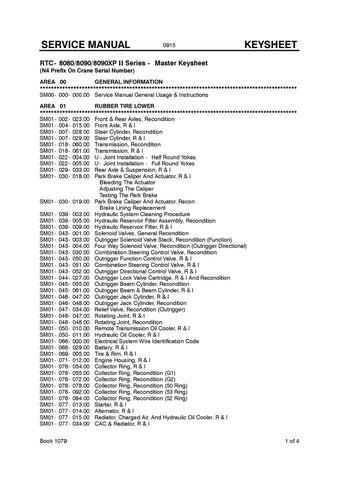

1.O---rings 2.Shafts 3.ThrustWashers

4.PlanetaryGears

5.ThrustWashers

6.ThrustButton

7.JamNut

8.Locktab

9.AdjustmentNut

10.WheelStuds

11.PlanetaryHub

12.PlanetaryRingGear

13.ThrustWasher

14.SunGear

15.SnapRing

16.ThrustButton

17.Setscrews

18.PlanetaryCarrierHousing 19.Capscrews&Lockwashers 20.Plug 21.Nuts&Lockwashers 22.Spindle 23.Studs 24.Bushing 25.Seal

26.SteeringKnuckleHousing

27.ShimPack

28.Seal

29.UpperKingpinCap 30.Capscrews

31.GreaseFitting

46.TieRod 47.Locknut

48.TieRodEnd

49.GreaseFitting

50.LowerKingpinCap 51.Seal

52.ShimPack

53.Capscrews 54.Nut

55.Lockwasher

56.TieRodClamp

57.Capscrew&Washer

58.Locktab 59.Capscrews

60.ExpansionPlugs

61.Bushings

62.Plug

63.Breather

64.Studs

65.Plug

66.Bushing

67.Seal

68.Capscrews

69.Lockwashers

70.BearingCaps

71.DowelPins

72.Capscrews&Lockwashers

73.DifferentialCasePlainHalf

74.ThrustWasher

75.DifferentialSideGear

76.DifferentialSpider

77.Capscrews

78.Nuts&Lockwashers

79.BearingAdjuster

80.BearingCup

81.BearingCone

82.DifferentialCaseFlangeHalf

83.RingGear

84.ThrustWasher

85.DifferentialSideGear

86.DifferentialPinionGears

87.ThrustWashers

88.ThrustStop

89.Locknut

90.SnapRing

91.Bearing

92.ShimPack

93.Pinion

94.BearingCone

95.BearingSpacer

96.Capscrews&Lockwashers

97.BearingCone

98.InputFlange

99.O---ring

100.Washer

101.Locknut

102.Deflector

103.Seal

104.BearingCup

105.PinionHousing

106.Gasket

107.BearingCup

108.Nuts&Lockwashers

109.DifferentialCarrierHousing

110.BearingAdjuster

111.BearingCup

112.BearingCone 113.CotterPins FrontandRearAxleAssembly,Continued

Usecarewhiledisassemblingwheelends. Brakeliningscontaminatedwithexcessive amountsofgrease/lubricantscannotbe salvagedorcleaned.

Note:Matchmarktheplanetarycarrierhousing (18)toplanetaryhubhousing(36)forassembly purposes.

8.Removeallbuttwo,sidebysidecapscrewsand lockwashers(19)retainingplanetarycarrierhousing(18)assemblytoplanetaryhubhousing(36).

9.Rotateplanetaryhubhousing(36)assemblyuntil thelasttwocapscrewsandlockwashers(19)are locatedatthetop.Loosenbutdonotremove,the lasttwocapscrewsandlockwashers(19).

10.Installthreecapscrewsandlockwashers(19)into jackholesprovidedinplanetarycarrierhousing (18)andinstalluntilbondisbrokenonjointbetweenplanetarycarrierhousing(18)andtoplanetaryhubhousing(36).Removecapscrewsand lockwashers(19)usedasjacks.

11.Properlysecureanappropriateliftingdevicetothe planetarycarrierhousing(18)assemblyandremovealltheslack.

12.Removeremainingtwocapscrewsand lockwashers(19).

Planetaryringgear(12)isnotsecuredtothe planetaryhub(11).Careshouldbetakento preventthisgearfromaccidentallyfallingout whenplanetarycarrierhousing(18)assembly isremoved.Potentialforsevereinjuryis presentifsafetyprecautionsarenot observed.

13.Removeplanetarycarrierhousing(18)subassembly.

14.Removeplanetaryringgear(12).

15. Ifrequired,disassembleplanetarycarrierhousingsubassembly:

a.Removesetscrews(17).

b.Forassemblypurposes,matchmarkshafts(2) toplanetarycarrierhousing(18).

c.Usingashoppress,removeshafts(2)from planetarycarrierhousing(18).

d.Removeo---rings(1)fromshafts(2).

Note:Forassemblypurposes,recordthe positionoftangslocatedonthrustwashers (3,5)toindentsinplanetarycarrierhousing (18).

e.Removethrustwashers(3,5)andplanetary gears(4).

16.Removethrustbuttons(6,16),snapring(15),sun gear(14),andthrustwasher(13).

Note:Someaxleassemblieshaveajamnutand somehavealocktab(58)securedby capscrews(59)usedforsecuringadjustment nut(9).

Olderbrakeliningsmaycontainasbestos fibers,acancerandlungdiseasehazard. Brakeliningsmanufacturedtodaycontain non--asbestosfibers,whoselong--term effectstohealthareunknown.Usecaution whenhandlingeitherasbestosor non--asbestosmaterialsusedinbrake linings.RefertoOSHAregulationsforproper handlingofthesematerials.MaterialSafety DataSheets(MSDS)regardingbrakelining materialscanbeobtainedfromyourlocal distributor.

Usecarewhiledisassemblingbrakes.Brake liningscontaminatedwithexcessiveamounts ofgrease/lubricantscannotbesalvagedor cleaned.

RefertoFigure2.

17. Removebrakecaliper:

a.Removecapscrews(10),washers(11),andremovebrakecaliperassembly.

18. Disassemblyofbrakecaliper:

Note:Ifshoeandliningassemblies(12)aregoingtobereused,protectthemfrombeingcontaminatedbylubricants,brakefluid,orother contaminants.

a.Removecapscrews(13),plates(14),andshoe andliningassemblies(12).

b.Removeplug(9),cap(8),andpiston(4)from housing(1).

c.Removedustseal(3),backupring(5),ando--rings(6,7).

d.Ifrequired,removebleederscrew(2). RefertoFigure1.

19. Ifrequired,disassembleplanetarycarrierhousingandbrakerotor:

a.Removejamnut(7)andlocktab(8)thatsecure adjustmentnut(9).

b.Properlysecureanappropriateliftingdeviceto theplanetaryhubhousing(36)andbrakerotor (40)assemblyandremovealltheslack.

c.Removeadjustmentnut(9).

d.Installtheappropriatecapscrewsintojack holesprovidedinplanetaryhub(11).Screwin untilbearingcone(33)andplanetaryhub(11) assemblycanberemovedfromplanetaryhub housing(36).Taglocationofbearingcone(33) forassemblypurposes.Removecapscrews usedasjacks.

e.Ifrequired,removebearingcone(33)from planetaryhub(11).

f.Removeplanetaryhubhousing(36)andbrake rotor(40)assembly.

20. Ifrequired,disassembleplanetaryhub housingandbrakerotorsubassembly:

a.Removecapscrewsandlockwashers(41)and brakerotor(40).

b.Taglocationofbearingcone(38)forassembly purposes.Removeseal(39)andbearingcone (38).

c.Iftheymustberemoved,taglocationofbearingcups(34,37)forassemblypurposes.Removebearingcups(34,37)andwheelstuds (10)fromplanetaryhubhousing(36).

21. Ifrequired,removeanddisassemble spindleandsteeringknucklehousing subassemblies:

a.Removenutsandlockwashers(21)and spindle(22)subassemblyfromsteering knucklehousing(26).

b.Removeseal(25).

c.Inspectbushing(24)forwearand/ordamage. Ifitmustberemoved,useashoppressandthe correctsizedrivertoremovebushing(24).

22.Removeaxleshaftassembly(43).

23.Recordmeasurementandlabellocationofshim pack(27).Removecapscrews(30),upperkingpin cap(29),andshimpack(27).Ifrequired,remove greasefitting(31)fromupperkingpincap(29).

24.Properlysecureanappropriateliftingdevicetothe steeringknucklehousing(26)assemblyandremovealltheslack.

25.Recordmeasurementandlabellocationofshim pack(52).Removecapscrews(53),lowerkingpin cap(50),andshimpack(52).Ifrequired,remove greasefitting(49)fromlowerkingpincap(50).

26.Removesteeringknucklehousing(26)fromaxle housing(42).

27.Ifrequired,removestuds(23),capscrewandnut (32),andseals(28,51).

28.Removeseal(67)fromaxlehousing(42).

29.Inspectbushings(61,66)forwearand/ordamage. Replaceifrequired.Useashoppressandthecorrectsizedrivertoremovebushings(61,66)andexpansionplugs(60).

30.Properlysecureanappropriateliftingdevicetothe differentialcarrierhousing(109)subassemblyand removealltheslack.

31.Removenutsandlockwashers(108)securingdifferentialcarrierhousing(109)subassemblytoaxle housing(42).

32.Removedifferentialcarrierhousing(109)subassembly.

33.Ifrequired,removestuds(64)fromaxlehousing (42).

34.Ifdifferentialcarrierhousing(109)subassemblyis tobedisassembled,mountinastandsimilarto standillustratedinFigure3.

35. Ifrequired,disassembledifferential carrierhousingsubassembly:

a.Usingadialindicator,measureandrecordring gear(83)topinion(93)backlashandtotalendplayofdifferentialbearings.

Ifbearingcaps(70)arenotinstalledinthe correctlocations,theboresandthreadswill notmatchthedifferentialcarrierhousing (109).Itwillbedifficulttoassemblethe bearingcaps(70)onthedifferentialcarrier housing(109)anddamagetocomponents mayoccur.Donotforcethebearingcaps(70) intoposition.

b.Forassemblypurposes,matchmarkbearing caps(70)anddifferentialcarrierhousing(109). c.Removecotterpins(113)andloosen capscrews(68)andbearingadjusters (79,110).