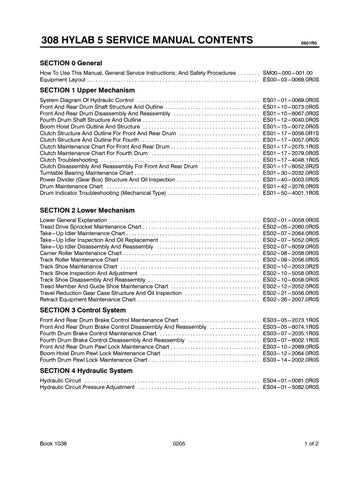

SECTION0General

HowToUseThisManual,GeneralServiceInstructions,AndSafetyProceduresSM00---000---001.00 ........ EquipmentLayoutES00---03---0068.0R0S

SECTION1UpperMechanism

SystemDiagramOfHydraulicControlES01---01---0069.0R0S FrontAndRearDrumShaftStructureAndOutlineES01---10---0073.0R0S FrontAndRearDrumDisassemblyAndReassemblyES01---10---6067.0R0S FourthDrumShaftStructureAndOutlineES01---12---0040.0R0S .......................................... BoomHoistDrumOutlineAndStructureES01---15---0072.0R0S .......................................... ClutchStructureAndOutlineForFrontAndRearDrumES01---17---0056.0R1S ClutchStructureAndOutlineForFourthES01---17---0057.0R0S ClutchMaintenanceChartForFrontAndRearDrumES01---17---2075.1R0S ClutchMaintenanceChartForFourthDrumES01---17---2079.0R0S ClutchTroubleshootingES01---17---4048.1R0S ClutchDisassemblyAndReassemblyForFrontAndRearDrumES01---17---6052.0R2S TurntableBearingMaintenanceChartES01---30---2032.0R0S PowerDivider(GearBox)StructureAndOilInspectionES01---40---0003.0R0S DrumMaintenanceChartES01---42---2076.0R0S DrumIndicatorTroubleshooting(MechanicalType)ES01---50---4001.1R0S .................................

SECTION2LowerMechanism

LowerGeneralExplanationES02---01---0058.0R0S TreadDriveSprocketMaintenanceChartES02---05---2060.0R0S Take---UpIdlerMaintenanceChartES02---07---2064.0R0S Take---UpIdlerInspectionAndOilReplacementES02---07---5052.0R0S Take---UpIdlerDisassemblyAndReassemblyES02---07---6059.0R0S CarrierRollerMaintenanceChartES02---08---2058.0R0S TrackRollerMaintenanceChartES02---09---2056.0R0S TrackShoeMaintenanceChartES02---10---2053.0R2S TrackShoeInspectionAndAdjustmentES02---10---5058.0R0S TrackShoeDisassemblyAndReassemblyES02---10---6058.0R0S ........................................ TreadMemberAndGuideShoeMaintenanceChartES02---12---2052.0R0S ................................ TravelReductionGearCaseStructureAndOilInspectionES02---21---5056.0R0S ........................... RetractEquipmentMaintenanceChartES02---26---2007.0R0S

SECTION3ControlSystem

FrontAndRearDrumBrakeControlMaintenanceChartES03---05---2073.1R0S FrontAndRearDrumBrakeControlDisassemblyAndReassemblyES03---05---6074.1R0S FourthDrumBrakeControlMaintenanceChartES03---07---2035.1R0S FourthDrumBrakeControlDisassemblyAndReassemblyES03---07---6002.1R0S .......................... FrontAndRearDrumPawlLockMaintenanceChartES03---10---2069.0R0S BoomHoistDrumPawlLockMaintenanceChartES03---12---2064.0R0S FourthDrumPawlLockMaintenanceChartES03---14---2002.0R0S

SECTION4HydraulicSystem

HydraulicCircuit ES04---01---0081.0R0S HydraulicCircuitPressureAdjustmentES04---01---5082.0R0S

SECTION5HydraulicUnit

HydraulicUnitEquipmentLayoutES05---01---0015.0R0S .................................................

VariableDeliveryPumpOutlineAndStructure(ForHammer)ES05---02---0062.0R0S VariableDeliveryPumpOutlineAndStructure(P1,P2,P3)ES05---02---0063.0R0S VariableDeliveryPumpMaintenanceChart(P1,P2,P3,Hammer)ES05---02---2054.0R0S VariableDeliveryPumpTroubleshooting(P1,P2,P3,Hammer)ES05---02---4010.0R0S VariableDeliveryPumpDisassemblyAndReassembly(P1,P2,P3,Hammer)ES05---02---6038.0R0S ........... GearPump(SingleType---P6)ES05---03---0010.0R0S ................................................... GearPumpTroubleshooting(Singleand2---SeriesType)ES05---03---4051.0R0S GearPumpDisassemblyAndReassembly(2---SeriesType)ES05---03---6055.0R0S AccumulatorStructureES05---05---0035.1R1S AccumulatorInspectionES05---05---5032.1R1S ......................................................... AccumulatorDisassemblyAndReassemblyES05---05---6046.1R1S ....................................... AxialPistonMotorOutlineAndStructure(Front,Rear,4thDrum)ES05---09---0046.0R0S ......................

AxialPistonMotorMaintenanceChart(Front,Rear,4thDrum)ES05---09---2028.0R0S AxialPistonMotorTroubleshooting(Front,Rear,4thDrum)ES05---09---4027.0R0S AxialPistonDisassemblyAndReassembly(Front,Rear,4thDrum)ES05---09---6041.0R0S RotatingJointDisassemblyAndReassemblyES05---14---6029.2R4S ......................................

ClutchCylinderDisassemblyAndReassemblyForFrontAndRearDrumES05---18---6075.0R0S .............

ClutchCylinderDisassemblyAndReassemblyForFourthDrumES05---18---6076.0R0S HydraulicCylinderTroubleshootingES05---23---4001.1R0S SideFrameRetractCylinderDisassemblyAndReassemblyES05---23---6035.0R0S HydraulicCylinderTroubleshootingES05---23---4001.1R0S ...............................................

GantryCylinderDisassemblyAndReassemblyES05---24---6001.0R0S .................................... LineFilterStructureAndInspectionES05---30---0004.0R0S ............................................... ReturnFilter(ForHammer)ES05---32---0001.0R0S ReturnFilter ES05---32---0002.0R1S 8---WayRotatingJointDisassemblyAndReassemblyES05---34---6014.0R1S Take---UpCylinderDisassemblyAndReassemblyES05---57---6048.0R0S ..................................

SECTION6Gantry

GantryMaintenanceChartES06---01---2067.0R1S

SECTION7CraneAttachment

BoomFootMaintenanceChartES07---08---2061.0R1S

SECTION13ElectricalSystem

ElectricCircuitDiagramES13---01---0068.0R0S ElectricalSystemStandardizationES13---01---9033.0R0S StorageBatteryServicingAndInstallationES13---04---5004.0R0S ElectricalEquipmentLayout,WiringAndWireHarnessES13---10---0007.0R0S .............................

SECTION14TighteningTorqueTable

BoltTighteningTorquesES14---02---0004.0R0S .........................................................

2of20205Book1038

Top Boom

Pendant Rope

Bridle

Boom Raising/Lowering Wire Rope

Bail

Counterweight

Gantry Cylinder

Gantry (Mast) # Catwalk

Backstop

Main Hoisting Wire Rope

Operator's Cab

Bottom Boom

Main Hook

Grip Throttle Swing Control Lever

Engine Key

Front Drum Brake Pedal Throttle Pedal

Front Drum Lever

Rear Drum Lever

Boom Hoist Drum Lever

4th Drum Brake Pedal

Gate lock Leve

Rear Drum Brake Pedal

4th Drum Control Lever

Swing Lock Control Lever