PORTFOLIO

Harry Waudby

Part II Architectural Assistant - Sheppard Robson

Artist Studio

Hill Holt Wood

January 2019 - August 2021

An artist in residency programme within the ancient woodland at Hill Holt Wood (HHW), Lincolnshire. Comprised of a treehouse for accommodation, a shower/sauna and toilet block, and a workshop to facilitate local craft. In keeping with HHWʼs exemplary demonstration of green construction and innovative exploration of responsible and sustainable development, the buildings are autonomous in terms of energy generation and other services. It also served as a demonstration of building techniques and is used to teach natural building workshops to the local community during construction.

Sketch Concept Development

Early sketch development explores design massing concepts, each serving a different function. Each building will demonstrate a different sustainable construction technique, including the treehouse made from timber sourced on-site, pre-fabricated straw panels in the workshop, and Hempcrete insulation in the toilet block.

Concept

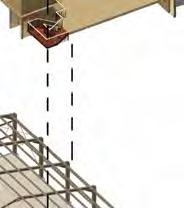

The toilet block and sauna were later split into two elements, utilising the opportunity to show two different sustainable methods of construction. The first is a timber framed Hempcrete toilet block, with both cubicles having accessible facilities and a robust composting system. Second, is a nordic-style log cabin building. Scotts Pine in the round, sourced from the on-site ancient woodland, is notched together, sitting atop gabion foundations. The wood burning sauna heater provides a more sustainable, off-grid alternative to heating. A raised decking platform between both buildings connect the two and provide views out towards the surrounding ancient woodland, and the retained hazel and oak trees within the immediate vicinity.

See Roof Junc$on Detail

See Roof Junc$on Detail

Roof Junc$on Detail 1:10 @ A2

Roof Junc$on Detail 1:10 @ A2

KEY

A - Ecoslates (Recycled Plas$c Tiles)

B - Breather Membrane

C - 18mm OSB3 Board

D - 112mm Half Round Gu^er Black

A - Ecoslates (Recycled Plas$c Tiles)

E - 150mm x 50mm Scots Pine Sub-Ra`ers

B - Breather Membrane

C - 18mm OSB3 Board

F - Oak Fascia Board 150 x 25mm

D - 112mm Half Round Gu^er Black

G - 2 no. 150 x 50mm Timber Lintels

E - 150mm x 50mm Scots Pine Sub-Ra`ers

H - 38 x 25mm Treated Timber Ba^en Over Window to Support Wall infill

F - Oak Fascia Board 150 x 25mm

I - 100 x 50mm Scots Pine Studwork

G - 2 no. 150 x 50mm Timber Lintels

J - 38 x 25mm Treated Timber Ba^ens fixed to Studwork

H - 38 x 25mm Treated Timber Ba^en Over Window to Support Wall infill

I - 100 x 50mm Scots Pine Studwork

K - Hempcrete or alterna$ve Infill

J - 38 x 25mm Treated Timber Ba^ens fixed to Studwork

L - 12.5mm Lime Render Finish

K - Hempcrete or alterna$ve Infill

L - 12.5mm Lime Render Finish

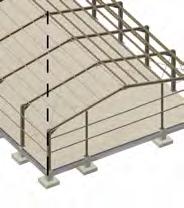

Chamber Detail 1:10 @ A2

Chamber Detail 1:10 @ A2

See Chamber Detail

See Chamber Detail

Artist Studio

Hempcrete Toilet Block

KEY

A - 22mm OSB3 Board Finished with Waterproof Vinyl Finish

KEY

B - 50 x 50mm Treated Timber Studwork

C - TGV Pine Matchboard 100 x 19mm

D - 400mm Diameter PVC Pipe

E - 100 x 50mm Scots Pine Studwork

Ground Floor Plan 1:50 @ A2

Timber framed construction with Hempcrete infill, based on thermalite blockwork to house the composting toilet chambers. Hempcrete was mixed on site, then hand placed by staff and community volunteers. This was also taught as part of the construction course within the onsite education provision. Finishes included clay interior render, and a lime external render, with ecoslate roof tiles.

A - 22mm OSB3 Board Finished with Waterproof Vinyl Finish

F - 22mm OSB3 Board Finished with Waterproof Vinyl Finish

B - 50 x 50mm Treated Timber Studwork

C - TGV Pine Matchboard 100 x 19mm

G - 150 x 50mm Treated Timber Floor Panels

D - 400mm Diameter PVC Pipe

H - M12 x 200mm Bolt (DIN 975)with Wing Nut

E - 100 x 50mm Scots Pine Studwork

Hands on involvement with the design and construction of the building throughout all aspects, including project management.

I - Operable Door for 'Podging'

F - 22mm OSB3 Board Finished with

J - Timber Door Backed with Galvanized Steel Sheet

K - Ibstock Laybrook Mixed Commons 102.5 x 215 x 65mm

L - Filter Layer System - GF40 Grid 40mm

Filled with Clean Limestone, Woven Geotex$le Membrane, Perforated Galvanized Steel Sheet

M - Trench Rebated 112mm in C20 Concrete Founda$on

N - 150 mm C20 Concrete Pad

0 - 150 x 22mm Treated Timber Form-Work

P - 150 mm Compacted Aggregate Base

Artist Studio

Log Cabin Sauna

Nordic-style log cabin sauna and shower block. Using traditional construction methods, this is an exemplary project showing the possibility of using timber in the round and heritage craft. On-site timber logs are felled, stripped using draw knives, then notched creating a tight seal when stacked. The building is set on gabion foundations, a more environmentally conscious alternative to more conventional systems.

Taught Level 2 Log-cabin building workshops during the construction process to local community groups.

Dissertation

MArch Y5 September - January 2022

Graded: 78% + Tarn Dissertation Prize Winner

To what extent can Hempcrete retrofit assist in achieving the UKs net-zero targets by 2050? A comparative study using cradle-to-grave Life Cycle Assessments and the EnerPHit Standard in a UK case study.

Abstract

The UK has set ambitious targets to reach net zero greenhouse gas emissions by 2050. The construction industry plays a fundamental role in achieving this, with the current UK housing stock one of the most substantive contributors. Whilst recent emphasis has been primarily on reducing carbon in operation, there will soon be a transition to reducing embodied carbon in national policy. Finding more environmentally, socially, and economically sustainable material alternatives is growing increasingly crucial, alongside the need to justify these by using robust life cycle assessments.

By applying high standard energy benchmarks, such as EnerPHit, case studies have demonstrated significant reductions in operational energy demand. However, studies have shown a correlation between decreasing operational demand and increasing embodied consumption, primarily because of improved fabric efficiencies and renewable technologies.

This dissertation investigates the use of biobased material build-ups, focusing primarily on Hempcrete, in reducing embodied carbon whilst maintaining EnerPHit standards. A comparative study using whole-life, cradle-to-grave assessments in OneClick LCA is carried out, comparing these biobased materials to a petrochemical material building assembly.

Results show that whilst switching to biobased materials can help to mitigate the effects of climate change, this is solely reliant on the inclusion of biogenic carbon storage in life cycle calculations. When breaking these down into stages, the biobased scenario emits significantly more CO2 from A1-C4, than the petrochemical alternative with the exception of B1-B5. These are evaluated individually to assess where these materials could improve, and how current industry-standard life cycle assessments may impact the results.

Additionally, qualitative research is carried out to assess the practicality, performance and applicability of a Hempcrete material option, considering various types of Hempcrete application to retrofit an existing dwelling.

Further studies are recommended to assess the validity of results across different life cycle assessment tools, as well as testing other biobased material options such as Hemp batt to substantiate the research. It is strongly encouraged to develop the material testing to better integrate biobased material alternatives within standard construction, and life cycle assessment methodology.

Figure 24 - All Data obtained from OneClick LCA EPD Database (OneClick LCA 2022a)

Figure 24 - All Data obtained from OneClick LCA EPD Database (OneClick LCA 2022a)

Masonry blocks, with the highest achieving thermal conductivity, and the lowest global warming potential, also achieving similar biogenic CO2 storage, were adopted in this study. Following manufacturer guidelines from the EPD supplier, IsoHemp, it is recommended that when applying to existing masonry walls there is a layer of loose-fill Hempcrete between, binding the two (IsoHemp 2021). Therefore, the option for this was to use sprayapplied hempcrete instead of hand-placing to keep overall carbon emissions down.

Masonry blocks, with the highest achieving thermal conductivity, and the lowest global warming potential, also achieving similar biogenic CO2 storage, were adopted in this study. Following manufacturer guidelines from the EPD supplier, IsoHemp, it is recommended that when applying to existing masonry walls there is a layer of loose-fill Hempcrete between, binding the two (IsoHemp 2021). Therefore, the option for this was to use sprayapplied hempcrete instead of hand-placing to keep overall carbon emissions down.

02ud - Petrochemical:

02ud - Petrochemical:

U-Value: 0.118 Thickness: 415mm

Petrochemical: U-Value: 0.118

02ud - Hempcrete:

02ud - Hempcrete:

U-Value: 0.118

415mm

Thickness: 415mm

1. 10mm – Silicone Render 2. 100mm – Kingspan K5 EWI 3. 110mm – Victorian Facing Brick 4. 30mm – Finger Cavity 5. 110mm – Victorian Facing Brick 6. 53mm – Kingspan K118 Insulated Plasterboard 7. 1mm – Gypsum Plaster Skim 8. 1mm – Paint

1. 10mm – Silicone Render 2. 100mm – Kingspan K5 EWI 3. 110mm – Victorian Facing Brick 4. 30mm – Finger Cavity 5. 110mm – Victorian Facing Brick 6. 53mm – Kingspan K118 Insulated Plasterboard 7. 1mm – Gypsum Plaster Skim 8. 1mm – Paint

U-Value: 0.117 Thickness: 832mm

U-Value: 0.117 Thickness: 832mm

1. 1mm – Graphenstone Biosphere Premium Paint

1. 1mm – Graphenstone Biosphere Premium Paint

2. 10mm – Thermalime Render

2. 10mm – Thermalime Render

3. 150mm – IsoHemp Masonry

4. 360mm – IsoHemp Masonry

5. 50mm – Hempcrete (Spray applied)

6. 110mm – Victorian Facing Brick

3. 150mm – Masonry 4. 360mm – Masonry 5. 50mm – Hempcrete (Spray applied) 6. 110mm – Victorian Facing Brick

7. 30mm – Finger Cavity

7. 30mm – Finger Cavity

8. 110mm – Victorian Facing Brick

9. 10mm – Thermalime Plaster

10. 1mm – Graphenstone Biosphere Premium Paint

8. 110mm – Victorian Facing Brick 9. 10mm – Thermalime Plaster 10. 1mm – Graphenstone Biosphere Premium Paint

Figure 25 – 02ud Wall Sections

Figure 25 – 02ud Wall Sections

Petrochemical Elements Reference: (Mohammadpourkarbasi, 2023)

Petrochemical Elements Reference: (Mohammadpourkarbasi, 2023)

Dissertation Softwares

Passivhaus Planning Package + OneClick LCA

Post-Failure Remediation by the Sea - Redcar

MArch Y5 | Group Project September 2022 - May 2023

Challenging the Anthropocene of Redcar, and other coastal industrial settlements: critiquing successive regeneration failures by re-introducing a balancing of nature and human developments. The ownership and development model of the Anthropocene has led to degradation of landscape, deprivation, and continued failures of regeneration.

The proposal is for three key stages of remediation, looking to heal the industry, landscape, and community through rewilding, biobased material manufacturing, and a central catalyst to facilitate all three processes. The architecture will provide functions in support of Hemp processing and manufacturing, communal spaces to facilitate discussion, and a protest building for ecological management.

Thesis Portfolio Scan for full project overview

Regional Remediation Strategy AutoCAD + Photoshop

Regional Remediation Strategy

Within the thesis, the project aims to answer the following:

• What form has the failure of regeneration taken in Redcar?

• Can the agency of rural, nature-based regeneration be adapted to the post-failure coastal condition?

• What strategies and interventions should be implemented in the short, medium and long term in a new form of architectural agency?

The three strands of remediation, tackling the Landscape, Industry and Community, are considered in the wide scale strategy to restore natural processes and return the site to nature. Warrenby is utilised as a catalyst incorporating contemporary green-industry, whilst further improvements to Housing (using a Retrofit-First strategy) and the surrounding landscape are also strongly considered.

Contaminant Hotspot

New Nature Reserve

Low Quality Housing

Dormanstown - Housing Case Study

New Build Housing Allocation

Agroforestry - Area 1

Agroforestry - Area 2

Warrenby - Masterplan Area I H G F E D C B A

Aforestry

South Tees Development

Corporation Boundary

Existing Nature Reserves and Green Space

Contaminated Ground and Slag Heaps

Housing Areas (Existing and Proposed)

Proposed Connections to Break Down Boundaries

Rewilded Corridors to Connect Reserves

Hemp Growing Areas (Soil Remediation)

Areas with High Demand for Retrofit

Housing Retrofit and Biobased Industry

Underpinning the project is the necessity to address the existing UK housing stocks poor operational performance (represented right), and the impact of this on the 2050 net zero targets. Dormanstown, a local industrial town South of the Warrenby site, is used as a case study to experiment with biobased materials in retrofits. The proposal introduces a hemp production facility within Warrenby, acting as a catalyst to start the three strands of remediation (Industry, Landscape, Community). This will also expand the regional biobased supply chain network, with Redcar well-positioned to become the epicentre of the scheme.

Zonal

Strategy Revit + Photoshop

Proposed is a process of remediation in three key stages; aiming to heal the community, landscape, and industry. This is facilitated through the retrofit of Warrenby, and achieved through rewilding, a retrofitting strategy in response to the UK climate and housing crisis, and the introduction of hemp manufacturing. Hemp is key to the scheme as its ability to phytoremediate contaminated ground enables rewilding and construction on post-industrial sites. This hemp is then used as the insulation material in the retrofit of Redcar’s housing.

A phased masterplan consists of: the community gateway and visitor centre, to the Hemp growing and processing facility, then a knowledge quarter including Research and Development and a forum for community engagement, finally arriving to an observatory built on rewilded South Tees Development Corporation land to stand in opposition to current developer plans.

Operational Masterplan AutoCAD + Photoshop

Demolished Housing

The old terraced footprints have been used as reference for creating zoning strategies and building orientations.

Allotment

Demolished Terraced Housing

Key Monument Route

Using the remaining historical buildings, and footprints of those lost, to weave a route and narrative across the site.

Existing

Destroyed Heritage

Retrofit of Warehouses

Existing warehouses are retained where possible. For those which are not, the materials are inventoried and reused.

Maintained

Recycled

Nature Corridors

Open Water

Rewilded

Rewilded Grassland

Hemp Field

New Building

Retrofit of Existing Building

Central Stitching Walkway

The visitor centre and warehouse food court begin the site, demonstrating newbuild and retrofit construction with hemp.

The key design driver was to use a retrofit-first strategy and environmentally conscious design principles to achieve net-zero. Key concepts behind the massing (left) and reinterpretations of the existing framing system (right) reinforce the response to the localised site strategy.

Using OneClick LCA as a Design tool to calculate the Embodied Carbon of various design iterations, the buildings successfully achieved Net Zero in both Embodied and Operational Carbon.

- Manual Hemp Processing -

Retrofitting an existing warehouse, the Hemp interventions frame a ‘model’ hemp field within the historic allotments. Here, the hemp is retted, decorticated and packaged.

The forum building reinstates a 1770’s Inn as a gathering space by mirroring the form and creating a bridge between the old and new. The Inn house becomes a space for informal gathering while the new build hosts a larger, more formal discussion space.

Research and Development Reception Area

An urban square formed around the historic Marsh House provides community engagement, employment and research facilities. It functions as a resting, educational, and pivot point where users can follow the Dormanstown Line to the Ridge Observatory.

industrial land. Designed as three wings with different functions and a central bird observation tower.

MArch4

February - May 2022

Located in Budapest’s District 8, the project aimed to fill the void in community resources through reclaiming lost space as a “third space”, allowing different communities to reclaim ownership.

The project aimed to explore design through the lens of detail, showing technical development in tandem with the wider concepts of the project.

Isometric Section

Revit + Illustrator + Photoshop

Masterplan Development

The site consists of 4 abandoned, dilapidated buildings with an opportunity to reclaim an unused area of land for the community. These are stitched together with a series of community functions, book-ended by two key street frontages; opening the existing facade to the West, and a new build to the East.

The existing structures are connected together by a steel truss forming an arcade typology inspired by 18th century arcades. The addition of balconies and stairs creates a dynamic social space.

Detailed Perspective Section Revit + AutoCAD + Illustrator + Photoshop

Section Detail - East-Facing Facade AutoCAD + Photoshop

1 - Wall

Nexus Brick-faced Soffit Support

65mm Flemish Bond Brickwork

50mm Cavity (inc. Brick Tie Track)

DPM

150mm PIR Rigid Insulation

13.5mm OSB Sheathing

120mm Metsec Infill Walling

100mm Woodfibre Batt Insulation

12.5mm Fire Board

12.5mm Plasterboard

2 - Cantilevered Floor

22mm Hardwood Flooring

30mm Dry Mix of Sand and Cement

IHS Standard Pipe 16x2mm

25mm Polystyrene Insulation

57x45mm Battens

DPM

50mm Self-levelling Concrete Screed

297mm Deep Dish Slim Floor Metal

Decking with Concrete Infill

406x178x85 UKB

100mm PIR Rigid Insulation

Aluminium Z Purlin

Carrier Track

Suspended Metal Soffit Panel

3 - Foundation

50mm Self-levelling Concrete Screed

150mm PIR Rigid Insulation

DPM

160mm Concrete

240mm Drainage Aggregate

Concrete Strip Foundation

4 - Foundation Wall

Triple Glazed Aluminium Window Cavity Closer DPM

65mm Engineering Brickwork

100mm Cavity Fill

Thermalite Blockwork