Impact Report 2025

Our intentions and progress to date

We are a family business that’s proud to say we’re cut from a different cloth.

Simon Spinks, Group Chairman

We are a family business that’s proud to continue leading the way in our industry. Our commitment to doing things differently, and always responsibly, remains at the heart of everything we do.

This year has been one of real milestones. I was deeply honoured to be awarded an OBE for services to the bed industry. An award I accepted not for myself, but on behalf of everyone at Harrison Spinks. Just as when I accepted the King’s Award for Sustainability, this recognition belongs to the entire team whose passion and hard work continue to set us apart. A Royal visit to our business was a moment of pride, not just for our colleagues but for Yorkshire too.

We’ve also secured a sustainable future for the business with Harrison Spinks Beds becoming an Employee Ownership Trust. This is a fundamental shift in the way we operate, ensuring that the business belongs to the people who make it what it is, and safeguarding our values for generations to come.

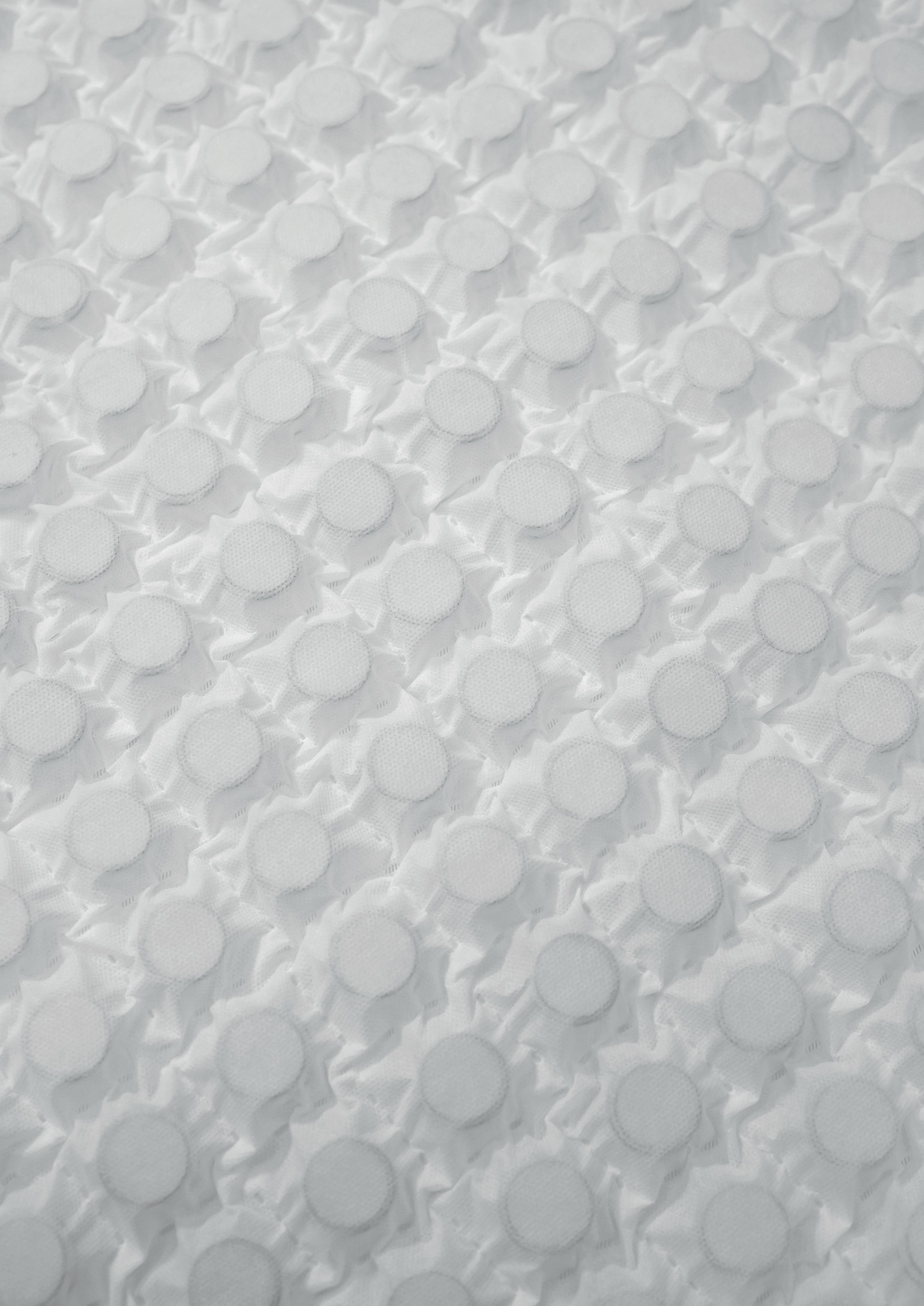

On the ground, we continue to make progress across all areas of our sustainability roadmap. At our farms, we are advancing towards full organic certification. In our weaving operations, we’ve expanded to include warping, strengthening our unique capability to produce fire-retardant chemicalfree fabrics in-house, an achievement no other UK bedmaker can claim

Our spring technology continues to deliver significant efficiencies, proving that innovation and responsibility go hand in hand. And our upgrade investment at our hemp processing line means we can now begin working towards reprocessing post-production waste into clean fillings, taking another bold step towards true circularity, and keeping our purpose of creating a happier, healthier world firmly in focus.

Our connection to community remains just as important. We are proud to support local charities such as Zarach, who remind us that a good night’s sleep is a basic right, not a privilege. We’ve also deepened our commitment to the Wild Ingleborough project, with colleagues volunteering their time to help restore landscapes and encourage biodiversity right here in Yorkshire.

As I look back, I’m proud of all we’ve achieved. As I look forward, I’m excited about where we’re heading. Together, as colleagues, partners, and communities, we’re showing that industry can lead in sustainability, create real social value, and inspire positive change. That’s what drives us each and every day.

Simon Spinks OBE Group Chairman

Business update

In 2024 we made some strategic operational changes to our businesses which will affect how we report on our sustainability goals next year.

In October the Spinks family placed 51% of our beds business into an employee ownership trust (EOT), ensuring the company will always stay true to its core beliefs, its Yorkshire heritage and close to its employees. Our components business will remain wholly owned by the Spinks family, and will continue to focus on new product development and global sales growth.

In October 2024, we took the first steps towards securing the long‑term strategic direction for our beds business by placing 51% of it into an employee ownership trust (EOT).

Securing the 184‑year history and ensuring it stays true to its core beliefs, its Yorkshire heritage and close to its employees.

This will therefore be the last joint report. Moving forward each business will record and communicate it’s impact separately in line with the new structure. But rest assured, our commitment to being one of the UK’s most responsible manufacturers will not change.

Our Businesses

We are two distinct businesses with the same purpose and values. Spinks, our components division and Harrison Spinks, our bed-making division. Sharing the same values and location, we work seamlessly together.

Mattress and bed manufacturing

Makers of proudly different mattresses and beds, each one is built on a belief in doing things the right and most responsible way. For our customers, and for everyone.

Handcrafted in our Yorkshire factory, using only the finest and sustainable materials. With natural fillings, homegrown on the Harrison Spinks farms. Springs from our components division. Even fabrics woven in-house too.

We make mattresses for several markets, including retail partners in the UK and internationally. These include high-street retailers (often under their own brand) and the independent retail sector (under the Harrison Spinks and Somnus brands) as well as hospitality and high-end interior design industries.

Components division

We are the world’s leading manufacturer and supplier of award-winning pocket core and micro springs which are used predominantly within the bedding and upholstery markets.

We also transfer our technology and expertise to as many different applications as we can. Ranging from automotive, rail and bus seating, footwear and any markets where sustainable comfort is needed.

We believe that collaboration and sharing of knowledge are vital for delivering lasting change. It’s why we have made our spring-making equipment and intellectual property available to others, allowing them to benefit from the quality and efficiency of our products.

This reflects our belief in supporting a collaborative environment within our industry.

Our purpose

As a business, we continue to build on the things that matter to us. Staying true to our purpose.

Together, we are passionate about creating a happier and healthier world.

Proud of our Yorkshire values, we are the only UK bedmaker with our own farms. Which gives us a unique connection with the land around us. Yet we feel the most effective way to make a positive difference locally is by taking a global view.

It’s why we are proud members of the UN Global Compact.

As a signatory to the world’s largest corporate sustainability initiative, we annually monitor our progress and use the UN Sustainable Development Goals to help guide our sustainability strategy.

UN Sustainable Development Goals most relevant to us

Ensure healthy lives and promote wellbeing for all at all ages

Reduce inequality within and among countries

Strengthen the means of implementation and revitalize the global partnership for sustainable development

Achieve gender equality and empower all women and girls

Ensure sustainable consumption and production patterns

Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all

Take urgent action to combat climate change and its impacts

Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation

Protect, restore and promote sustainable use of terrestrial ecosystems, sustainably manage forests, combat desertification, and halt and reverse land degradation and halt biodiversity loss

As we look ahead and build for a better future, our key points of focus are:

• Address how we respond to the climate crisis through continuing climate change adaptation and reducing our energy and material consumption.

• Continue to develop our responsible sourcing model to ensure our supply chain is as ethical as possible and to further reduce reliance on virgin materials.

• Continue our innovation in mattress and spring development, including industry-first approaches to product and component circularity. Designing and manufacturing with the goal of making each material usable again and again.

• Provide ongoing support for our people and our community to help them thrive.

• Continue to be creative and innovative in our strategic shift away from overseas carbon offsetting and take real ownership of the lasting difference we can make locally.

In October 2024 Princess Anne visited us to personally present us with our latest Kings Award for Enterprise in Sustainable Development.

Simon Spinks, Group Chairman

HRH Princess Anne

Our sustainability efforts receive royal approval

Back in 2013, we were awarded our first Queen’s Award for Enterprise. Since then, we are proud to say we’ve won another seven.

“We were deeply honoured and grateful to welcome Her Royal Highness The Princess Royal to our farm and factory. She took the time to learn about our sustainable practices, meeting with our hard-working team, and presenting us with the Kings Award for Enterprise in Sustainable Development, which is an incredible privilege. This recognition reflects our team’s unwavering commitment to sustainability and innovation at every stage of production, from our farm to the final product. As a family business, we take so much pride in leading the industry towards a more responsible future, and we remain dedicated to making a positive impact on our local communities and the environment. Sustainability is at the core of everything we do, so The Princess Royal presenting us with this incredible award and taking the time to learn how we’re continuing to push the boundaries of what it means to be a sustainable business has been a special day for our entire team.”

Simon Spinks Group Chairman

Our year in numbers

With our business-wide commitment to sustainability, plus the support of our dedicated in-house sustainability team, we constantly push ourselves to understand where we can make the biggest difference.

In the last year, we have worked hard to reduce our impact and improve the environment and the community.

We’ve increased our flax crop – a more sustainable alternative to cotton BY 20%

We’ve reduced in the last financial year SCOPE 1 EMISSIONS BY 10%

We’ve planted over of native hedgerows 3km

We’ve increased mattress donations to children’s bed charity Zarach by 50%

We’ve permanently removed from our manufacturing process 75 TONNES OF HOT MELT GLUE

We’ve reduced in the last financial year SCOPE 2 EMISSIONS BY 37%

of all components in-house by weight We manufacture 95%

We have delivered of training OVER 200 HOURS

We harvested of hemp to create natural filling fibres 250 acres

We have employed our first colleague through the growing rooms programme ST GEORGE’S CRYPT

We have volunteered with the Wild Ingleborough programme OVER 160 HOURS

We donated to children in our local area 150 CHRISTMAS GIFTS

Environmental update

We continue our path to becoming an even more responsible manufacturer. In the last 12 months, we have taken steps to reduce waste across the business and to become nature net positive.

We want to show that making beds in the UK can be responsible, sustainable and ethical. We have already made big changes and are committed to doing even more to ensure we will leave the environment richer than how we found it. This includes:

1. Protecting valuable materials through waste mitigation.

2. Expanding our circular manufacturing philosophy by designing for disassembly and material recovery.

3. Sourcing materials, products and services locally where possible, and that meet our environmental policy.

WE’RE MAKING GOOD PROGRESS!

Science Based Targets

COMMITMENT: WE WILL BE NET ZERO BY 2050, SETTING A CLIMATE PATHWAY IN LINE WITH THE SCIENCE BASED TARGETS INITIATIVE

SBTi net zero update

This year we have continued our work on our carbon footprint, ensuring it is aligned with the SBTi guidance and ready for validation. Unfortunately, we have had to delay getting our reduction plan approved due to the business structure changes. Moving forward, we will be recommitting our reduction plan as Harrison Spinks Beds, and Spinks will support us with our reductions as a key supplier. Our goal is to get our new plan approved by the SBTi in the 2025/26 financial year, and we will share this once completed.

WE HAVE THE PROCESSES IN PLACE TO MEASURE THIS ON AN ANNUAL BASIS.

COMMITMENT: WE WILL CONTINUE TO MEASURE OUR SCOPE 1, 2 AND 3 EMISSIONS TO HELP US UNDERSTAND AND REDUCE OUR IMPACT

Since 2021, we have been measuring our Scope 1, 2 and 3 emissions in line with international greenhouse gas (GHG) guidance. This has helped us understand our impact and highlighted where we need to improve in order to reach our end goal of net zero.

The chart below shows that the majority (94%) of our emissions sit within Scope 3 of our carbon footprint; this is due to the quantity of emissions associated with raw materials and is very typical for a manufacturing business.

Scope 1 - 3%

Scope 2 (Location based) - 3%

Scope 3 - 94%

In the chart above, we can see that our total carbon footprint increased slightly in 23–24 compared to the previous year. While we achieved reductions in our Scope 1 and 2 emissions, this overall increase is driven by growth in our Scope 3 emissions. Importantly, we have still recorded a relative reduction in carbon intensity when measured against turnover. The rise in emissions is mainly due to factors such as improved data capture, greater use of British wool within our product ranges, and increased production output. We are currently reviewing our highest-emitting products and services to identify where we can make measurable improvements, both in the short and long term.

We will be looking to reduce our emissions by introducing more regenerated materials, driving efficiencies in our processes and designing products with lower carbon materials.

Scope 1 Emissions

Our Scope 1 emissions are direct emissions from our fleet of vehicles, gas consumption from our facilities, and methane produced by livestock on our farm.

We continue to reduce our Scope 1 emissions by:

• Replacing diesel vehicles with hybrids and electric vehicles (EVs), and installing EV charging points at our Leeds factory and offices.

• Improving the heating efficiencies of our factory and office buildings, and reducing the volume of natural gas consumed to heat our facilities.

• Moving our mattress production and divan & headboard production shifts from a five-day week to a condensed four-day week. We now have one less day a week to heat our facilities.

As a result of these measures, we have reduced Scope 1 emissions by 28% from our base year.

Scope 2 Emissions

Our Scope 2 emissions are indirect emissions that relate to the energy we purchase.

• Our procurement team continues to work hard to identify the most cost-effective and optimal energy contracts for our facilities.

• We’ve achieved a 70% reduction in Scope 2 emissions since 2021-22.

• In November 2022, we moved four of our eight Leeds site factory facilities to renewable biomass contracts, which became Renewable Energy Guarantee of Origin (REGO) in April 2023.

• In December 2023 we moved our remaining four facilities over to zero-carbon energy contracts. These are REGO-backed, 100% renewable contracts.

Scope 3 Emissions

Our Scope 3 emissions are from purchased raw materials, services, packaging and business travel, which contribute to more than 90% of our total emissions.

We continue to focus on our Scope 3 emissions. Building on the great progress made in 2022‑23, our goal is to see our Scope 3 emissions fall, even when production volumes rise.

Energy efficiency strategy

Energy consumption

At the core of driving down our emissions in scope 1 & 2 is reduction in energy consumption, that’s why we’ve developed a comprehensive energy efficiency strategy. This not only helps us deliver crucial savings across the business but also enables us to meet other key commitments for energy reduction.

Our Strategy is comprised of three key areas of focus:

1. Staff Training & Awareness -driving a culture of sustainability.

2. Automated Monitoring and Targeting- Using digitisation to monitor our machines and processes for efficiency losses.

3. Site & Machine maintenance and upgrades-investing in more efficient technologies. So far, we have saved at least 55,000 kWh through lighting upgrades, motion sensors and thorough shutdown procedure training, with this number anticipated to rise as we continue our programme of improvements and upgrades.

We have also invested

in renewable

energy

for our

farm site by installing 590 solar panels across five of the site buildings. They are projected to generate around 230,000kWh of renewable energy annually *

*Based on a 260kWp system. Using a rough estimate for sunlight hours, weather patterns, orientation etc. the estimated annual output is 230,000kWh

Energy

consumption by production department

The chart below shows energy usage. While we have been able to make significant savings in many departments, increased production has led to increased energy use in others. Our goal is to reduce energy use across all departments, and that is something we continue to work towards.

Goods In Wire Drawing**

Divans & Headboards

Microsprings Core Units

Fillings***

Innovation Centre The Farm***

**Wire drawing (16%) – We introduced in-line heat treatment and two more wire-drawing lines at a wire-drawing plant in Scunthorpe, as well as a higher volume output.

***Fillings & The Farm (18 & 28%) – The increase in farm and fillings energy use is due to an increase in fillings processing. Here we installed a tearing line at the farm to reprocess production offcuts.

Mattress Line

Creating efficiencies through digitisation

We’ve partnered with the Manufacturing Technology Centre (MTC), pioneers in manufacturing innovation, to help create a better future of sustainable manufacturing in the UK.

With the support of the MTC and Innovate UK, we’ve developed a deeper understanding of our wire-drawing processes. This has allowed us to reduce our carbon emissions in a way that benefits product quality.

The results have huge implications for the whole of the UK industry too, helping promote high-quality manufacturing and meet net zero targets.

Our partnership with the MTC delivered insights way beyond our expectations and we intend to expand what we have learned and, where possible, continue further collaboration.

Digitisation has given us better visibility of energy consumption and machine maintenance scheduling, allowing us to be more proactive. We’re trialling it in pocket spring production, and we aim to roll out what we have learnt across the business. Better data visibility allows us to monitor efficiencies as we move forward on our carbon reduction strategy.

WE’VE MET OUR TARGET.

Waste and circularity

COMMITMENT: ZERO PRODUCTION WASTE TO LANDFILL BY THE END OF 2025

Our materials are made to last, using only high-quality, premium products. However, that does not stop us from planning for their end of life. That’s why our mattresses are carefully constructed from 100% recyclable or biodegradable raw materials.

We continue to work with our partners to help drive the circular economy of mattress manufacturing. Currently, we rely on downstream infrastructure and a recycling partner to disassemble and recycle our end-of-life mattresses. Looking much further ahead, our vision is to recover our post-consumer mattresses for reprocessing.

Did you know that over 5 million mattresses end up in landfill or are incinerated each year? Being a responsible bed manufacturer, this doesn’t sit well with us.

To support the drive for product circularity, we continue to refine our processes to ease disassembly, repairability and prioritise locally sourced materials.

Despite great successes, we know we still have work to do.

Effective waste separation means we can maximise the chance to reuse and recycle where possible. Where reuse or recycling is not possible, waste is converted to energy. We have achieved our commitment to send zero production waste to landfill by the end of 2025, and now we aim to minimise the incineration of waste.

Currently, it’s very difficult to repurpose mixed-composition textiles, and so much of our textile waste finds its way to an incinerator for energy recovery. We know this isn’t the ideal route for our waste, which is why we are always innovating, looking for alternative uses and doing our best to be circular.

Our 2023‑24 Waste Footprint

Metals

Wood

Recycled: Melted down to go back into manufacturing.

Recycled: Chipped to go back into manufacturing.

Textiles 74,000 Incinerated: Energy from waste.

Polypropylene 47,000 Recycled: Reprocessed to go back into manufacturing.

LDPE 6,700 Recycled: Reprocessed to go back into manufacturing.

Cardboard 66,000 Recycled: Pulped to go back into manufacturing.

General waste 183,000 Processed at a material recovery facility. Residual waste goes to waste for energy.

Total 636,700

60% of waste was recycled and 40% was waste to energy. We have set ourselves the target to recycle or reuse 80% of our waste by 2030, which would require us to find alternative purposes for our textile waste.

Our future plans

Over the next three years, we have big plans to invest in new equipment to help us reprocess a variety of materials, including production waste, filling pads, mattress fabric and borders. Starting this summer, we will be making crucial upgrades to our tearing line at our hemp production site; these upgrades will allow us to process a wider variety of materials and increase their luxuriousness by making them finer and softer.

Resource efficiency

Waste Reduction

We are on a journey to improve our impact on the environment, not just by supporting specific environmental projects but also by improving the material efficiency of our production processes. This means we can purchase less and generate less waste.

Our business wide waste strategy has reshaped the way we operate, reducing waste and improving material efficiency. We now have three clear objectives:

1. Separate waste effectively (to maximise reuse or recycling)

2. Reduce waste by improving operational efficiencies

3. Continue to explore opportunities for reuse/recycling of our waste

We believe the key to achieving these is fostering a culture of ownership and accountability.

Our new morning management meetings have provided the perfect opportunity to review each department’s waste targets on a weekly basis. It gives us a much better understanding of how efficient we are with our raw materials. With the company being vertically integrated, we can react quickly to resolve internal issues, as well as collaborate to increase its chances of internal production waste being reused or recycled.

“We now have an accurate database that tracks and targets waste generated in each production facility. Accurate data and weekly waste KPI meetings are driving projects for improvement, and we have seen a positive culture change. Everyone is responsible for the waste they generate, and everyone shares the same goal: to reduce our impact on the environment.”

Chris Townsley – Operations Director

Supply Chain

We continue to work hard on our supply chain (both existing and new suppliers) to ensure they have policies and procedures in place that meet our standards.

Our focus this year has included:

• Only sourcing materials, products and services that meet our environmental and health and safety policies.

• Where possible, procuring locally with a view to boosting and supporting the local economy.

• Ensuring that fair contract terms are applied and respected, including fair opportunities for small and medium enterprises.

• Ensuring human rights, respect for the rule of law and decent work standards are met in line with our modern slavery policy.

Raw Materials

We have carried on our work reviewing our materials and finding alternatives that better align with our values.

Some of our key new products this year are:

• BCI-accredited cotton fibre and yarn

• Coir fibre as an alternative to horsehair

• British Wool yarn for our mattress ticking

• Traceable British alpaca fibre

We also continue to work with Scottish luxury accessory maker Alex Begg to upcycle their clean, high-quality cashmere production offcuts. We use these in our luxury filling pads, replacing the need to source virgin cashmere. By making this switch we have been able to save approximately 2 tonnes of CO2 e in transport emissions and have given another life to a material that otherwise would have been incinerated. Responsible sourcing

WE’RE ON TRACK TO MEET OUR TARGET!

Land and biodiversity

COMMITMENT: TO BE NATURE NET POSITIVE ACROSS ALL OUR OPERATIONS

Farming update

Our Hornington Manor and Ryther farms are on track to achieve the Soil Association organic certification in September 2026.

This year we grew 120 acres of flax – an increase of 20 acres from the previous year.

We grew last year’s flax crop using our new organic methods, and it was a record yield. Flax is a comparable material to cotton in mattress manufacturing, but it doesn’t need secondary pesticides, it requires a fraction of the water and has a significantly lower carbon footprint.

This year we and our partners grew 250 acres of hemp for our production process.

As with any organic farming pathway, we are learning as we go. We are currently experimenting with 30 acres of legume mix cover crops to naturally improve soil health. These have been left to grow in the fields for two years to improve drainage and soil structure, and retain nitrogen. We’ve also added 14 tonnes of manure per acre. Adding green manure also improves biodiversity and gives the worms something to eat.

We have a four-year crop rotation to maintain good soil.

The sheep love our winter crops too. And once they’ve been on the pasture, it only needs a light plough to be ready for hemp sewing.

Herbicide‑free weed eradication

Some of our land needs treatment for weed eradication before we can drill our crops. Farming organically, without herbicides, we use a machine to pull the weeds out and slice them off at their roots.

Wildlife and biodiversity

We have around 47 acres of Ings grassland on the farm. These are grazed throughout the winter and left unstocked from around March until July to allow ground-nesting birds to fledge. We only cut the grass to make hay once a year to allow the flowers to bloom and to protect the local wildlife.

This year we have planted over 3,000m of native hedgerows to encourage even more wildlife to our farm.

In addition to planting new hedgerows, we continually manage our existing hedgerows, coppicing unmanaged areas, as well as removing perches for predators to make it safer for ground-nesting birds.

To improve biodiversity, especially bird life, we have been restoring the historic orchard at Hornington Manor, including hedge planting and plans to introduce in-hedge trees next winter. We also use approximately 1 tonne of bird feed in the winter months to feed our songbirds.

We keep track of the impact this is having with regular bird surveys, and, because of our farming practices, we have reintroduced several rare bird species back to the farm.

The KUHN Group PROLANDER 500R removes the weeds without spoiling the integrity of the soil structure

“Harrison Spinks’ support has enabled Wild Ingleborough to really focus on our montane plant recovery project. Using this funding we have been able to invest in a new watering system as well as other essential equipment needed for the collection of seeds, spores and cuttings of our rarest species. This has been so successful that we now have over 10,000 plants waiting to be put back out into the wilds of Ingleborough this autumn.

In addition to this investment, we have seen Harrison Spinks contribution of time and resources to help with drystone walling, potting seedlings and tree planting. The Wild Ingleborough team are very impressed with Harrison Spink's efforts!”

Dr. Tim Thom – Wild Ingleborough Programme Manager

Want to get involved?

Anyone can become a volunteer and make a difference in this stunning and important landscape. Scan to find out more.

Wild Ingleborough

Last year, due to the lack of transparency around offshore carbon offsetting, we made the important move to focus efforts closer to home – switching from offsetting to rewilding.

The Wild Ingleborough programme in the Yorkshire Dales, led by Yorkshire Wildlife Trust with partners like WWF and The Woodland Trust, is a long-term effort to tackle climate change and restore habitats. Together, they’re boosting biodiversity by creating new wildlife habitats and reintroducing rare native species.

This year, we continued our support by funding alpine plant nurseries and providing volunteers.

To give colleagues hands-on experience, we ran successful volunteering days, including drystone walling and tree planting to create wildlife shelter.

One of our teams even broke the record for the most trees planted in one day –an impressive 2,365!

We remain committed and will continue organising volunteering days and exploring new ways to support Wild Ingleborough.

Social update

We continue our commitment to play our part in creating happier and healthier communities. Making a difference by improving social mobility, promoting wellbeing and active lifestyles, and, importantly, creating a business and community that is open and inclusive.

We’ve already seen the positive impact our commitments are making. We plan to build on these to ensure our team and the community have the best opportunities in the years ahead.

Our ongoing commitments include:

1. Investing in our colleagues to give them the skills and confidence, as well as the health and wellbeing opportunities they need to succeed.

2. Put into action programmes to increase diversity across all areas of the business.

3. Strengthen our charitable partnerships to make sure we are making the biggest difference to the people who need it most.

WE ARE MAKING GOOD PROGRESS, BUT THERE’S MORE WE CAN DO

COMMITMENT: WE WILL

WORK WITH THOSE AROUND US TO IMPROVE SOCIAL MOBILITY AND SUPPORT HEALTHY AND INCLUSIVE COMMUNITIES.

For us as a business, social mobility plays a vital role in both our and the community’s success.

Creating a lasting sense of inclusion and belonging, for us, is the most sustainable way to run our business.

Community Engagement and Social Mobility

As a business, social mobility is key to our success and that of our community.

Through outreach, training, and internal opportunities, we develop local talent, reduce staff turnover, and build a loyal, skilled team; boosting productivity, innovation, and our reputation as a local employer.

We’re improving social mobility through careers fairs, school engagement, and partnerships with local charities.

Women in Manufacturing careers event, Leeds Manufacturing Festival

Designed to encourage more women into a very male-dominated industry, we were delighted to take part in this event.

We contributed to a panel where students from around Leeds could ask questions about getting into manufacturing roles.

To help bring the opportunities for women in our industry to life, a couple of colleagues with different careers within the company also attended. They provided very real examples of the career pathways available to women in this space.

We’re committed to expanding this work in line with our equality, diversity, and inclusion (ED&I) goals.

Champions Community Sport & Health CIC

We proudly support Champions Community Support and Health CIC, which uses sport to educate and empower young people, especially in diverse and marginalised areas of Leeds with poor health outcomes.

Over the past three years, we've contributed to their Christmas gifting, donating 150 gifts last year to children from low‑income families.

We also assist with printing, promotion, and spreading awareness to boost youth participation in their sports programmes.

Scan to follow

Champions Community Sport & Health CIC

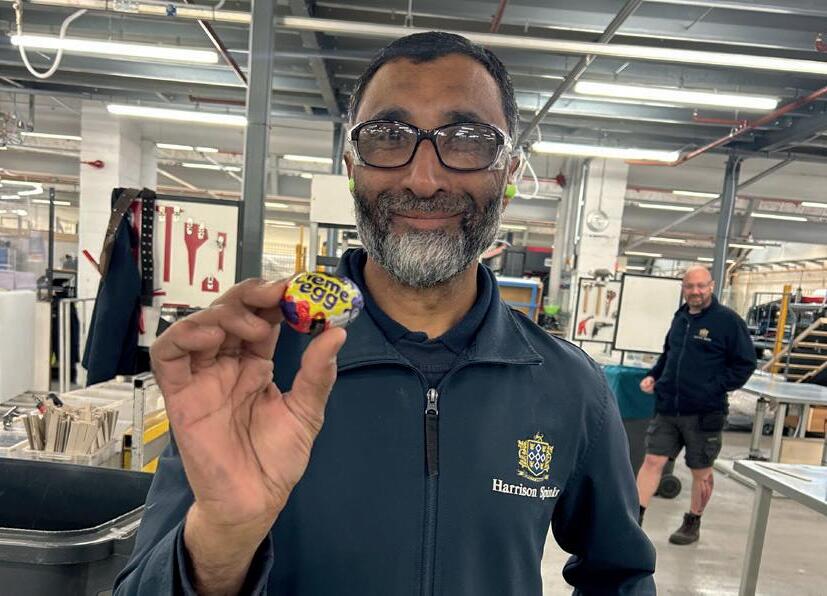

St. George's Crypt

Creating opportunities for all

We continue to work with St George’s Crypt, a Leeds-based charity supporting the homeless, vulnerable, and those recovering from addiction.

Through the Growing Rooms programme, we help individuals build skills, confidence, and readiness for employment. Key focus areas include:

• Skills development – training and transferable skills to boost employability

• Workplace integration – support in adapting to work environments

• Sustainability – helping individuals secure and maintain long-term jobs

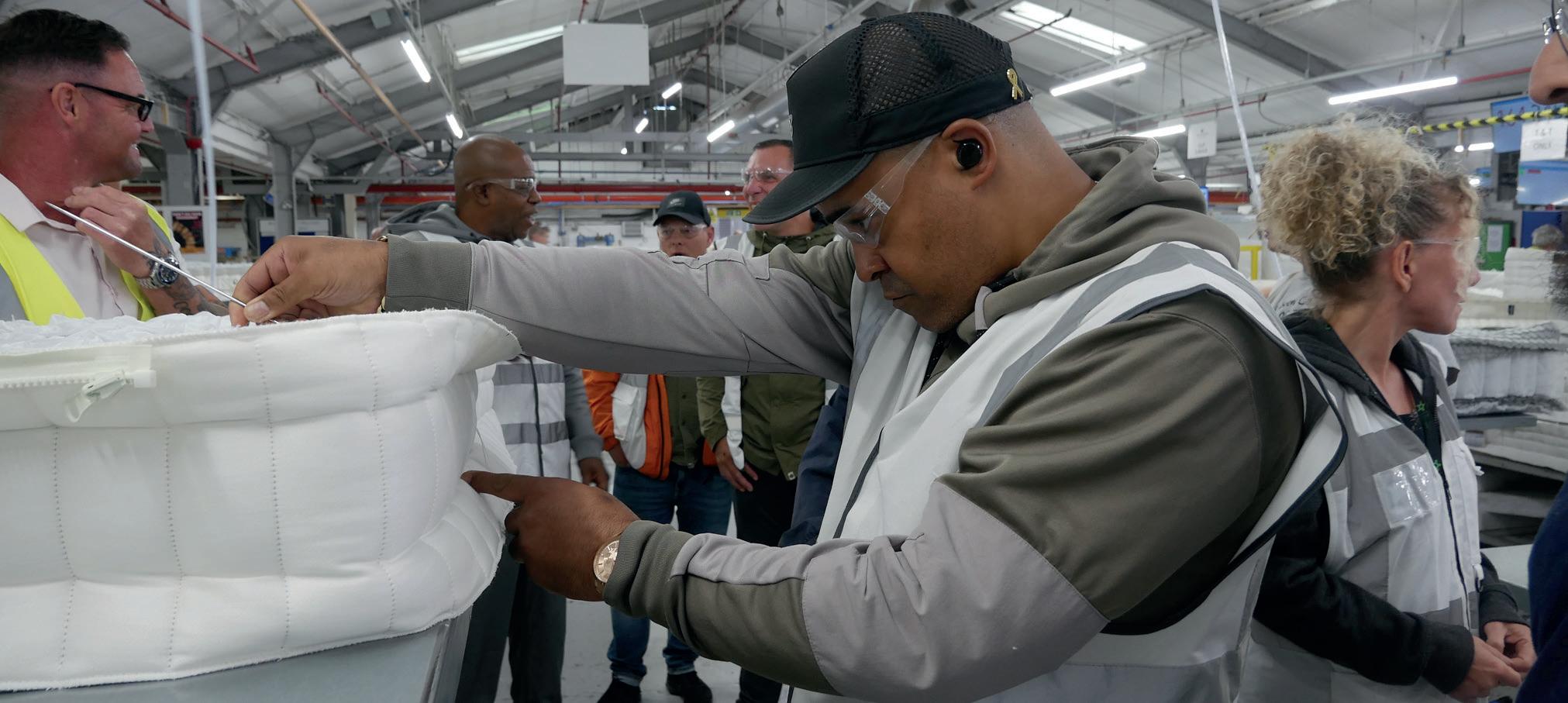

To support this, we’ve hosted on-site visits, facility tours, presentations, and CV workshops.

We’re proud to have achieved our goal of getting people back into work, after volunteering, we’ve now hired our fi rst candidate from St George’s Crypt!

"Everyone at St George’s Crypt Growing Rooms is delighted with our partnership with Harrison Spinks. Together, we’ve developed a programme offering employment opportunities to clients completing their recovery.

During a site visit, our clients toured the facilities, attended CV workshops, and learned about potential roles. It was an incredibly informative experience for all involved.

We’ve since launched a phased employment programme, starting with one day a week of volunteering, progressing to paid work for successful candidates. We’re thrilled to have already seen our first success.

We’re grateful to the Harrison Spinks team for their generosity and ongoing support."

John Davis - Growing Room Manager

Scan to support St. Georges Crypt

Zarach

Giving Every Head a Bed

We are proud to continue our partnership with Leeds-based charity Zarach. With the aim of giving ‘every head a bed’, they are dedicated to helping children in poverty get a good night’s sleep.

We have seen how powerful the gift of a quality mattress can be. That’s why this year we have increased our donation by 50%, delivering 360 mattresses for children in need of a good night’s sleep.

95% of schools have said that receiving a bed from Zarach has had a positive impact on the lives of the children they have referred. That’s why we are proud to increase our commitment to Zarach. We are also looking at ways to inspire children from lower socio-economic backgrounds with factory tours to give them an insight into our business and the opportunities available to them.

“In the UK, 900,000 children lack a proper place to sleep. Zarach’s mission is to end child bed poverty, giving every child a bed to sleep on and the opportunity to engage at school, breaking the cycle of poverty. They partner with local schools to identify children in need of a good night’s sleep. Each child referred receives a bed bundle that includes a bed frame, mattress and bedding.”

Amy

Green - Funding and Communications Manager, Zarach

Scan to support Zarach

WE ARE MAKING GOOD PROGRESS, BUT THERE’S MORE WE CAN DO

COMMITMENT: WE WILL BE RECOGNISED AS AN INCLUSIVE EMPLOYER WHO MAKES A POSITIVE DIFFERENCE TO PEOPLE’S LIVES.

Health and wellbeing

Our most valuable asset is our people. So, looking after our people is looking after our business.

In the past year, we have developed several ways we can improve the physical and mental health and wellbeing of everyone within the business. And now, with 51% of our bed-making business placed into an EOT, this is now even more important.

New healthcare plan introduced

This year we have introduced a healthcare plan for all employees. Fulfilled by Westfield Health, this gives our colleagues access to a GP 24/7, money towards dental, therapy treatments, optical care and much more. It also includes a rewards app for discounts in retail stores and restaurants.

We have chosen Westfield Health as it supports our colleagues with all aspects of their wellbeing.

“The Westfield Health service has been very beneficial. After running lots of races last year, I ended up with a leg injury and I had to attend multiple physio appointments to fix the problem. I cannot recommend the service enough. It’s excellent for paying for those things that pop up unexpectedly and for those yearly check-ups you don’t think about until they happen.”

Scarlett McAndrew – Marketing Executive

Wellbeing Day

We continue to support our employees with a wellbeing day. This is an additional day added to everyone’s holiday allowance. We encourage colleagues to use this day to take time for themselves to support their health and wellbeing.

Mental health and wellbeing support

As part of our wellbeing programme this year we have launched a new mental health and wellbeing support app for our employees. These are both designed to help with mental health and getting more active.

The Myles app encourages physical activity to support with improving your mental health. In addition, the more you are active, the more rewards you receive, and these rewards are converted into vouchers. You can earn up to £50-worth of vouchers a year.

“The app has got me out walking more and focusing on what is good for my health, and the vouchers are an extra little bonus which is always encouraging!!! This has been a good initiative by the business.”

Laurence Borrows – Sales Manager

Volunteering

We continue to see the positive effects volunteering has on the health and wellbeing of our colleagues.

Our involvement with the Wild Ingleborough programme, in the Yorkshire Dales, has provided many opportunities for our colleagues to not only enjoy a day in the great outdoors but also make a real and lasting contribution to the rewilding of this ecologically important landscape.

"I enjoyed learning about the landscape-scale conservation project in the Yorkshire Dales, focusing on climate change, habitat restoration, and improving woodlands for wildlife movement. I also gained knowledge about native trees and how to plant them.

I enjoyed collaborating with people from different parts of the business and appreciated the rare chance to understand their roles.

Overall, I’m grateful for the experience—and as someone who loves the outdoors, it was a great day out."

Emma Towers – Customer Service Executive

Equality, diversity and inclusion

Our commitment to inclusivity starts with us understanding our workforce. For us to make meaningful changes we must be informed by data so we can create a culture that encourages diversity and inclusivity in all areas. That’s why we’ve focused on gathering and monitoring this information, so that we can start to build effective strategies that encourage building a more diverse workforce.

This year we have gathered employee data for a variety of characteristics including disability, ethnicity and gender. This has highlighted to us a few key takeaways that we will be addressing moving forward.

7.5% of employees stated they were from an ethnically diverse background Including African, Black African, Indian, Asian and Pakistani.

21% of employees stated they are female, 79% male 0% identified as non-binary.

3 out of 14

members of our leadership team come from ethnically diverse backgrounds

4% of employees identified as having a disability.

77% of the workforce responded as White or White British.

Nearly 30% of our leadership team identifies as female.

Although we know that the diversity data of our workforce is not unusual for the manufacturing industry, we know that we can make improvements, particularly in the areas of ethnicity and gender. However, there are some positive takeaways from the data we’ve gathered.

The proportion of women in leadership roles is higher than the company average, giving us a positive indication of gender representation in decisionmaking roles. We also see that we have a good start in terms of ethnic diversity within strategic leadership, showing we have diverse perspectives contributing to our business goals.

We will seek to increase diverse representation throughout the business and ensure we create opportunities for all our employees.

We are doing several things to work on this, including:

• Reviewing our recruitment process to remove unconscious bias.

• Creating new opportunities to join the business through careers fairs, connecting with charities, creating volunteering and mentorship opportunities.

• Continuing to promote and develop our talent within the business.

• Running listening groups where employees can share their experiences from their own cultures and backgrounds.

• Working to understand any barriers to progression that may exist within our business and work to remove these.

• Building a culture that celebrates diversity in all its forms and increases a sense of belonging for all.

• Continuing to build an environment where individuals feel supported and where their specific needs are met.

Training

Training and development has been a big focus for us this year. It plays a vital role in defining our culture, as well as giving everyone the skills and knowledge to help us become an even more responsible, fair and inclusive place to work.

We have delivered a variety of training sessions in key areas such as modern slavery, dignity at work and management development training. This has equated to over 200 hours of training delivered.

Dignity at work

At Harrison Spinks, we recognise every individual’s rights, self-worth and professional contributions.

To help us create an environment where employees feel valued, safe and supported, we delivered training workshops during November and December 2024, and January 2025 to team leaders and managers across the business. These emphasised the importance of dignity at work and how they can set the tone for the right workplace culture. The workshops have enabled them to be better equipped to deal with conflict resolution and foster an inclusive environment; preventing harassment, discrimination and other forms of mistreatment; ensuring all employees can perform to the best of their abilities without fear of intimidation or belittlement.

This training is to be shared company-wide as it is crucial that we provide a respectful environment where individuals can thrive and contribute to the organisation’s success.

Management training – creating great leaders

This year we have delivered two programmes of management training for 43 of our managers and supervisors from across the business. This has been a six-month programme that focuses on giving our people the tools to be great leaders.

The two programmes were aimed at different levels of the management team. The objective of both was to upskill managers, improve their leadership skills and management competency.

“I truly value the business offering this training; gaining this selfawareness and understanding of others’ perspectives will undoubtedly benefit both my individual contributions and our collective success.”

John Barnett – Technical & Specifications Business Partner

Modern slavery training

To increase the awareness and understanding of potential victims, signs to spot and high-risk sectors, we carried out a thorough programme of modern slavery training.

Carried out across HR, purchasing, operations, management and sustainability teams, the sessions were focused on understanding the principles of modern slavery and why these matter to Harrison Spinks. This included detailed sessions with key individuals across the business. Plus, sessions with the wider management team and further sessions delivered by team leaders and managers to their departments.

Investing in the next generation of our community workforce

We are proud to say we now have seven apprenticeships across the group. We have work to do, but this is a priority for us as it’s vital for bringing our social mobility, and in fact, our whole purpose to life.

Our strategy is to continue to make 5% of vacant roles apprenticeships.

We’re also investing in the future and will be launching a training academy to offer more apprenticeships in key areas.

Looking further ahead, the scope of The Harrison Spinks Training Academy is to train, educate and develop key roles in our business. It aims to provide skills development opportunities to advance learning and careers in a rapidly evolving field of engineering.

Phase one of the Academy will focus on multiskilling existing engineering apprentices, as well as recruiting more apprentices in key engineering disciplines across the business.

We are also currently working in partnership with UTC College Leeds with T-level placement students. UTC is a local college supporting 14 to 18-year-olds interested in careers within engineering.

Future intentions

We know we still have a huge amount of work to do. But we are 100% committed to continuing our path to becoming one of the most responsible UK manufacturers, as a result, creating a happier and healthier world for us all.

Environmental

• Set SBTi GHG emissions reduction targets in line with what is needed to keep global heating below catastrophic levels and reach net zero by 2050 at the latest.

• Review the first year of our ESOS Phase 4 action plan to reduce energy consumption.

• Establish a biodiversity baseline to work towards nature net positive.

• Gain organic status at the farm by the end of 2025 and produce our first organic crop by 2026.

• Implement our environmental management system (EMS) in line with the ISO 14001 international standard.

• Find alternative uses for production waste and establish new partnerships with local textile managers.

• Drive product innovation to look at circular materials and product building methods.

Social

• Begin a programme of work surrounding ED&I training, starting with cultural awareness training, and listening groups.

• Increase volunteering with local charity partners and organisations.

• Conduct a restructure of our Employee Consultative Forum to make it work better for our colleagues and the business.

• Continue with our commitment to improve employee benefits.

• Continue to commit to making 5% of vacant roles apprenticeships.

• Continue our work with St George’s Crypt and our other charity partners, helping to drive social mobility.

• Explore potential partners to extend our support to the LGBTQ+ community.

Feedback

We understand that to make the kind of difference we are aiming for takes a huge collaborative effort. And we’ll get to where we want to be quicker if we share ideas.

If you have any feedback on any of the ways in which we work, we’d love to hear from you.

Sustainability@harrisonspinks.co.uk

Sustainability awards to date:

The Queen's Award for Enterprise in Sustainable Development 2013

Insider Made in Yorkshire Green/Sustainable Manufacturing Awards, Winner 2018

The Queen's Award for Enterprise in Sustainable Development 2019

Furniture News Awards, Best for Sustainable Thinking Award 2022

Vet Partners Sustainable Farm Awards, Sheep Category Winner 2022

The Yorkshire's Business Excellence Awards, ESG Winner 2023

BFM Future of Furniture Awards, Sustainability Winner 2024

BFM Future of Furniture Awards, Sustainability Champion 2024

Yorkshire Sustainability Excellence Awards, Circular Economy Excellence Winner 2024

The King's Award for Enterprise in Sustainable Development 2024

National Bed Federation, Bed Manufacturer of the Year Award 2024/25

BFM Future of Furniture Awards, Sustainability Champion Winner 2025

Big Furniture News Awards Winner, Best Supplier for Sustainable Story 2025

Furniture News, Best for Sustainable Thinking 2025

Ideal Home Bedroom Awards, Best Sustainable Bedroom 2025

www.harrisonspinks.co.uk