Leading the Way: Continuous Inkjet Printing Solutions by

Hanuja Technologies

Bangalore has emerged as a technology and manufacturing hub in India, and among its many industrial offerings, continuous inkjet printing technology stands out. The demand for high-speed, reliable, and efficient printing has made continuous inkjet printers essential for manufacturers across sectors such as packaging, pharmaceuticals, food & beverages, and electronics. This growing demand has fueled the rise of expert continuous inkjet printer manufacturers in Bangalore, offering cutting-edge equipment designed for consistent performance.

The Power of Industrial Inkjet Printing in Modern Manufacturing

Today’s manufacturing environment demands more than just speed—it calls for precision, reliability, and seamless integration. This is where industrial inkjet printer manufacturers in Bangalore are making a difference. By developing printers that support continuous production cycles and deliver precise outputs under harsh conditions, they are enabling businesses to meet strict regulatory and branding requirements efficiently.

Industrial inkjet printers, particularly continuous inkjet (CIJ) systems, are ideal for high-volume applications. They work non-stop, ejecting tiny ink droplets at high speed without ever touching the substrate. This allows them to mark curved, flat, or uneven surfaces without causing product damage or delay. Bangalore-based manufacturers are producing machines that handle metals, plastics, glass, paper, and more, without compromising on print quality or speed. Manufacturers are also embedding smart technology and connectivity features into their printers. Touchscreen interfaces, remote monitoring capabilities, and error diagnostics are now standard in many models. These advancements reduce downtime and enable faster troubleshooting, making the production process more streamlined and cost-effective. Local manufacturers are prioritizing these upgrades to ensure their solutions stay competitive.

Key Features Enabling Efficiency:

• Non-stop operation for maximum throughput.

• Precision marking on diverse materials and shapes.

• High-speed ink ejection for rapid coding.

• Robust design for challenging industrial environments.

Another key advantage is the focus on sustainable and eco-friendly printing. Many continuous inkjet printer manufacturers in Bangalore are introducing low-volatile inks and energy-efficient machinery. This shift toward greener production methods not only helps companies reduce their environmental impact but also improves workplace safety and operational efficiency.

Why Businesses Choose Bangalore for Inkjet Printer Manufacturing?

Bangalore’s rise as a preferred destination for industrial inkjet printer manufacturing is no accident. The city combines technical expertise, innovation, and industrial maturity. For decades, Bangalore has been at the forefront of India’s engineering and technological revolutions, making it an ideal breeding ground for advanced printing technologies like continuous inkjet systems.

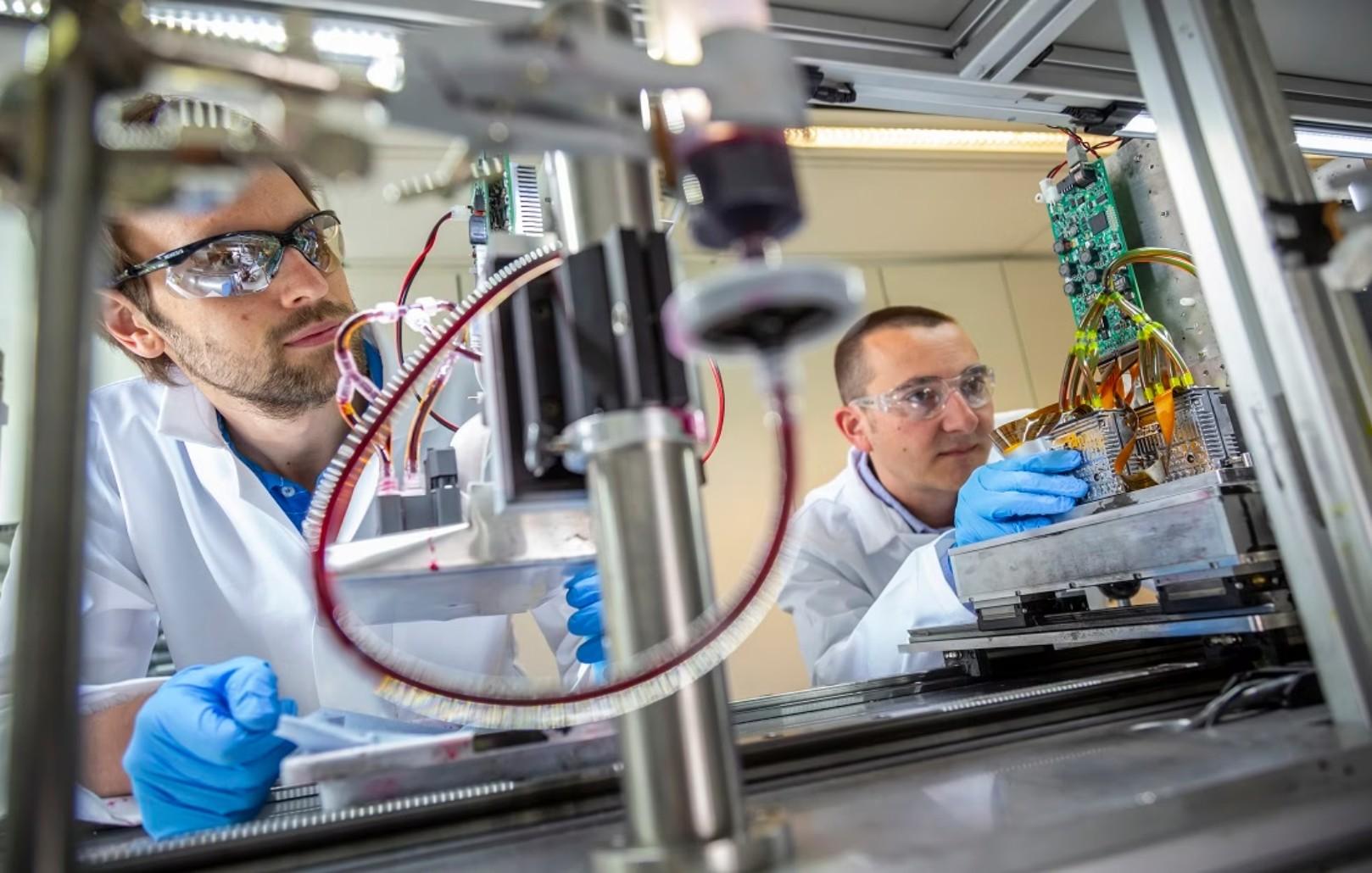

Many local manufacturers have access to world-class research and development facilities. These R&D centers are focused on enhancing printhead design, ink chemistry, machine durability, and software controls. Through rigorous testing and prototyping, they create products that meet global quality benchmarks while remaining cost-effective for Indian industries.

Additionally, the talent pool in Bangalore is unmatched. Engineers, designers, and production experts collaborate to deliver solutions that meet evolving client expectations. These teams understand the unique challenges of industries ranging from pharmaceuticals to automotive, and they develop printers accordingly—with customization and scalability in mind.

The city’s robust supply chain and transportation infrastructure also play a pivotal role. Whether sourcing components or delivering final products, manufacturers in Bangalore benefit from seamless logistics and proximity to industrial corridors. This efficiency translates into quicker deliveries, better service, and reduced overheads for clients sourcing printers locally.

Advanced CIJ Printing Technology for Industrial Efficiency

One of the standout innovations in Bangalore’s manufacturing scene is the rapid development of continuous inkjet (CIJ) printer technology. These machines are redefining productivity for industries that require high-speed, uninterrupted marking. CIJ printers use a high-pressure pump to force ink through a nozzle, creating a continuous stream of droplets that are precisely directed onto surfaces.

The versatility of CIJ printers is a major reason behind their popularity. From date coding on beverage cans to lot numbers on pharmaceutical labels, these printers deliver consistent, clear markings even in dusty, humid, or high-temperature environments. Manufacturers in Bangalore are fine-tuning these systems to withstand harsh industrial conditions without any drop in performance.

Precision Ink Delivery

High-pressure pump creates a continuous stream of precisely directed ink droplets for consistent marking.

Robust Environmental Tolerance

Versatility Across Substrates

Designed to operate flawlessly in dusty, humid, or high-temperature industrial settings, ensuring continuous output.

Capable of printing on diverse materials like metal, plastic, and glass, adapting to various industry needs.

Ink Formulation: Tailored for Every Application

Another critical focus area is ink formulation. Ink plays a vital role in printing adhesion, drying time, and contrast. Local manufacturers are formulating specialized inks that cater to unique substrates and regulatory requirements. Whether UV-resistant ink for outdoor applications or food-grade ink for consumable packaging, these options ensure optimal compatibility and safety.

Furthermore, manufacturers are enhancing user experience by introducing plug-and-play printer designs. With simplified maintenance, quick-change ink cartridges, and user-friendly interfaces, CIJ printers made in Bangalore offer great ease of operation. This reduces downtime and training needs while increasing productivity for the end user.

Specialised Inks

Formulated for various substrates, ensuring optimal adhesion and legibility.

Regulatory

Compliance

Includes food-grade and UV-resistant options to meet industry-specific standards.

User-Friendly Design

Plug-and-play functionality, quickchange cartridges, and intuitive interfaces simplify operation and maintenance.

Unmatched Support and Custom Solutions from Local Manufacturers

One of the major advantages of choosing industrial inkjet printer manufacturers in Bangalore is the personalized service and support they offer. These companies often work closely with clients to understand their specific printing challenges and design solutions that integrate seamlessly into existing production lines.

Customization is a cornerstone of success in this domain. Whether it’s adapting a printer to handle a specific product shape or syncing it with conveyor belts, Bangalore-based manufacturers offer tailormade solutions. This flexibility ensures that clients don’t have to overhaul their systems to adopt new technology.

Post-sale support is another strength. Clients can expect regular maintenance, software updates, and spare parts availability directly from the manufacturer. Service teams are trained to provide on-site troubleshooting and remote diagnostics, minimizing disruptions and keeping operations on track.

In terms of compliance and safety, local manufacturers adhere to national and international standards. Their printers are often CE-certified and built with safety protocols that protect both the user and the product. With constant quality checks and stringent inspection systems, businesses can trust the durability and consistency of every unit shipped from Bangalore.

Driving Digital Transformation in Industrial Printing

The industry is rapidly shifting toward digital transformation, and continuous inkjet printer manufacturers in Bangalore are leading this evolution. These companies are embedding advanced technologies like IoT connectivity, predictive maintenance algorithms, and cloud-based printer management systems into their product lines.

Through remote monitoring tools, production managers can track real-time data such as ink levels, error logs, and usage metrics.

This not only ensures optimal printer performance but also enables predictive maintenance to avoid unexpected breakdowns. It reduces manual checks and improves operational planning across the factory floor.

Cloud integration also allows for firmware updates and feature enhancements to be rolled out instantly. This ensures that printers stay up to date without the need for expensive hardware replacements. Local manufacturers are investing heavily in these upgrades to make their machines future-proof and scalable for large enterprises.

Augmented reality (AR) is another frontier being explored. Some companies are testing AR-assisted maintenance, which allows technicians to receive step-by-step visual guidance during printer servicing. This drastically reduces downtime and training effort, especially for distributed manufacturing units operating across different locations.

These digital transformations make CIJ printers more intelligent, efficient, and aligned with modern manufacturing ecosystems. Bangalore’s tech-savvy environment makes it an ideal base for such innovations to be developed and deployed at scale.

Conclusion: Bangalore's Role in the CIJ Revolution

Bangalore has firmly established itself as a hub for continuous inkjet printer manufacturers in Bangalore and a reliable source of industrial inkjet printer manufacturers in Bangalore. With a blend of technology, innovation, engineering talent, and customercentric support, local manufacturers are helping businesses across India and beyond stay competitive in the fast-paced manufacturing landscape.

Whether it’s high-speed marking on production lines or durable printing in harsh environments, the city’s manufacturers are building machines that deliver on all fronts—efficiency, reliability, and customization. By choosing Bangalore-made CIJ printers, businesses not only gain access to world-class technology but also benefit from local support and quicker turnaround times.

Hanuja Technologies is one of the pioneers in this space, offering a comprehensive range of CIJ and industrial inkjet printers designed to meet the most demanding applications. As the demand for smarter, faster, and greener printing continues to grow, Bangalore remains at the heart of India’s industrial inkjet revolution.

FAQs: Your Questions Answered

What is a continuous inkjet printer used for in industrial applications? A continuous inkjet printer is primarily utilised to print crucial data such as batch codes, barcodes, corporate logos, and expiry dates directly onto products or their packaging within high-speed manufacturing environments. It excels in non-contact printing across a diverse range of materials, ensuring product integrity. Why should I choose a CIJ printer from a Bangalore manufacturer? Opting for a Bangalore-based manufacturer ensures access to advanced CIJ printers built with the latest technological innovations, customised features tailored to specific needs, dependable support, and significantly faster delivery times compared to imported units.

Can continuous inkjet printers work in harsh environments? Absolutely. CIJ printers are meticulously engineered for robust industrial use and consistently perform exceptionally well even in challenging conditions characterized by dust, high humidity, or elevated temperatures, all without compromising print quality or operational efficiency.

Do manufacturers in Bangalore provide custom CIJ printer solutions? Indeed. The majority of industrial inkjet printer manufacturers in Bangalore offer highly tailored solutions, which often include seamless integration with existing conveyor systems, the development of custom inks for specific applications, and variable printhead designs to accommodate unique product lines. What types of surfaces can CIJ printers print on? CIJ printers exhibit remarkable versatility, capable of printing on a wide array of surfaces including metal, glass, plastic, rubber, paper, and even intricately curved or uneven surfaces. This makes them eminently suitable for diverse industries such as food and beverage, pharmaceuticals, and electronics.

How do I maintain a continuous inkjet printer? Routine maintenance for CIJ printers typically involves regular ink replacement, thorough nozzle cleaning, and timely software updates. Bangalore manufacturers frequently offer comprehensive service contracts and advanced remote diagnostics capabilities to ensure the printer operates smoothly and efficiently with minimal disruption.