ELECT RICIAN &INSTALL ER

at

How to record the details of protective devices on the

What sort of RCD circuit protection should be associated with Mode 4 charging equipment?

17 How to fix PV arrays to on-roof solar photovoltaics systems

20 Some essential pointers when working with DC circuits

22 Why is the arc flash boundary so important?

41 Considerations that should be made for the selection and erection of electrical accessories in locations that are subject to mechanical impact

42 How have loop tests evolved over the last 40 years?

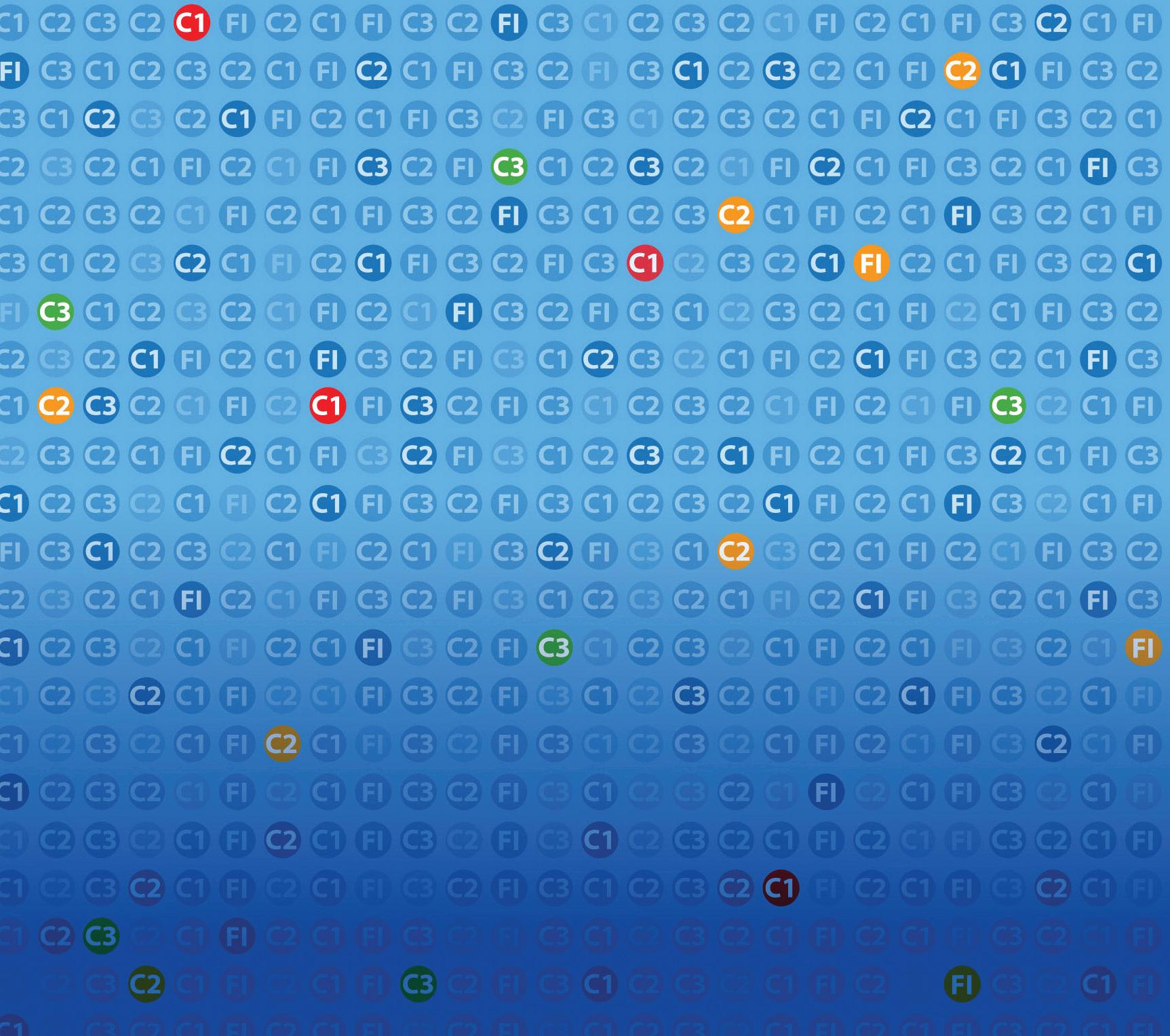

44 The team at NAPIT give our reader submissions the ‘Codebreakers’ treatment

46 Dr Zzeus, Tom Brookes, answers another fire safety-related question from the field

48 The ultimate guide to Surge Protective Devices (SPDs)

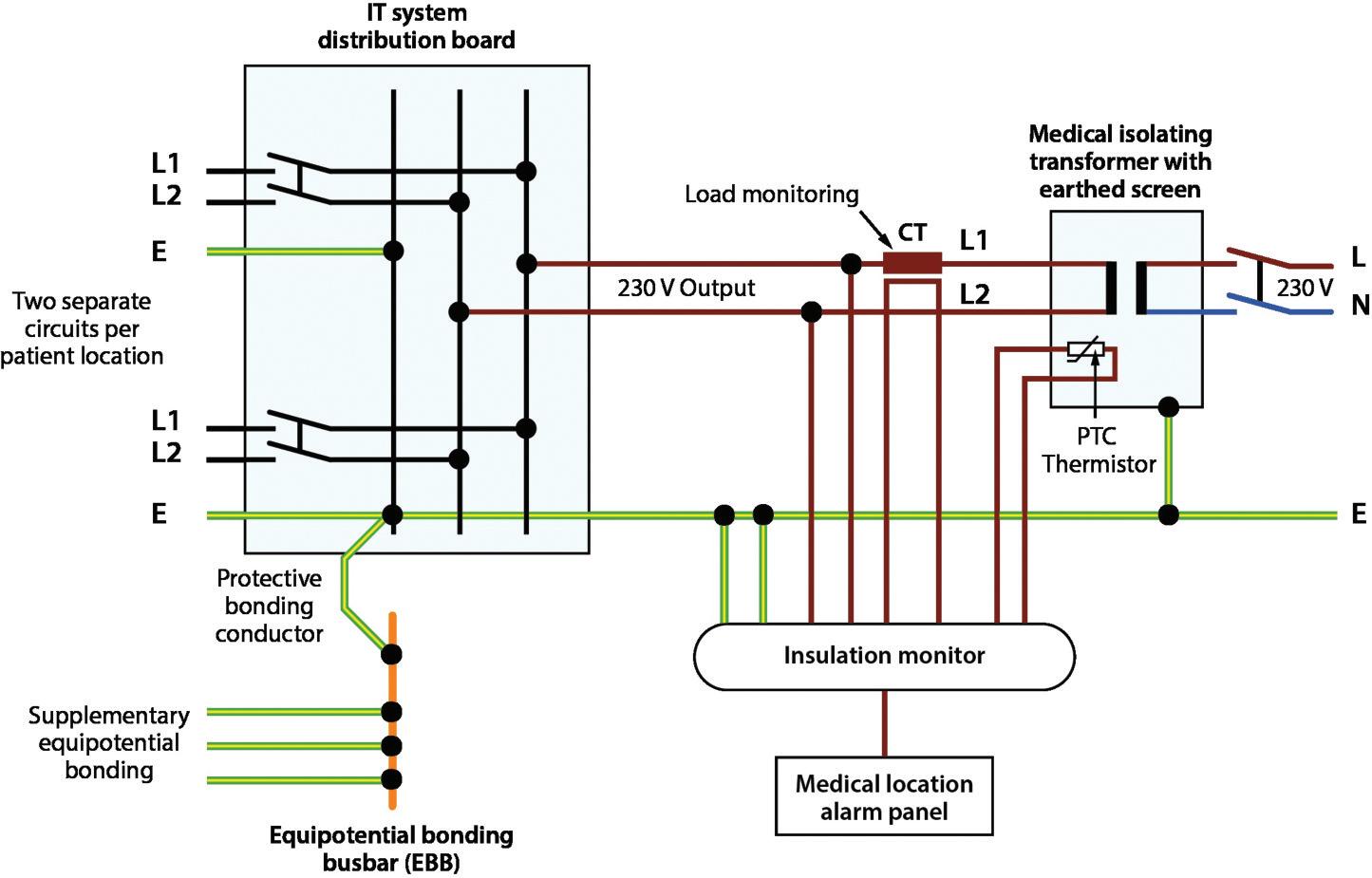

51 Considering the requirements for the use of medical IT systems within a Group 2 location

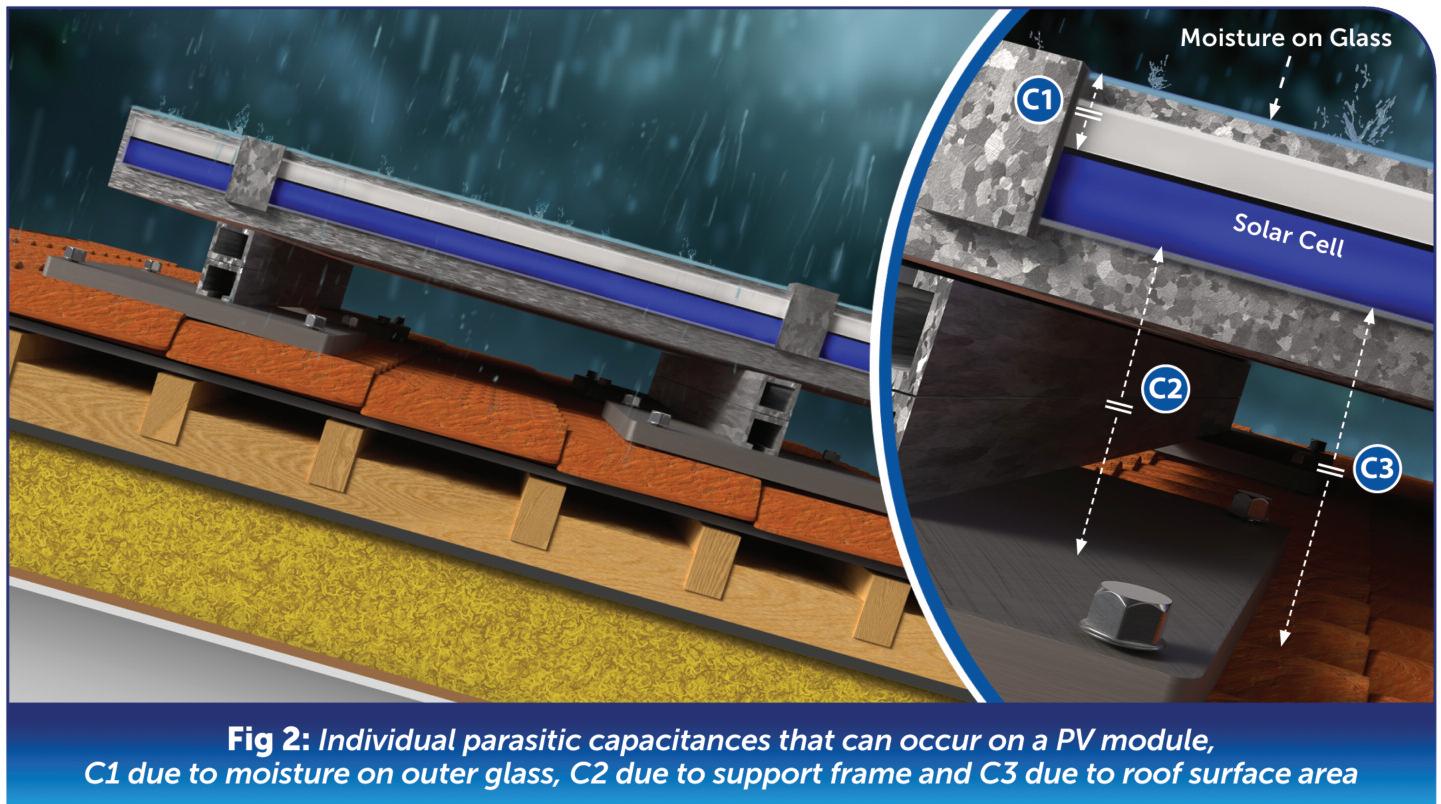

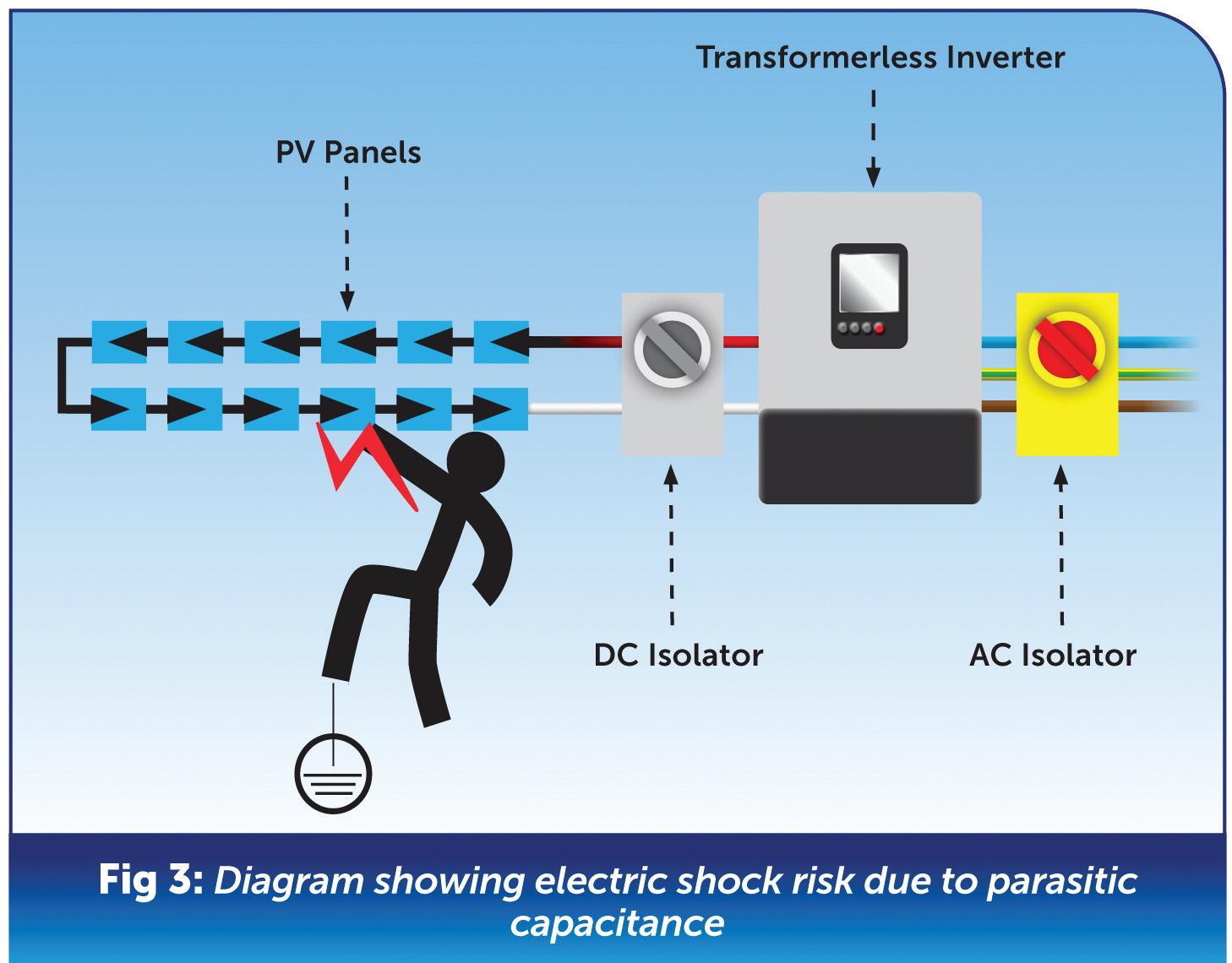

55 Discussing the concept of parasitic capacitance in solar PV installations

58 NICEIC’s team of expert, technical engineers answer key questions from the industry

60 How to ensure you are carrying out Portable Appliance Testing correctly

62 The team at NAPIT give our readers submission the ‘Codebreakers’ treatment

65 The factors to be considered when providing protection against overvoltage in a domestic premises having a service fuse of rating not exceeding 100 A per phase

68 The considerations professionals need to make when sourcing appropriate ventilation equipment for the application/environment in question

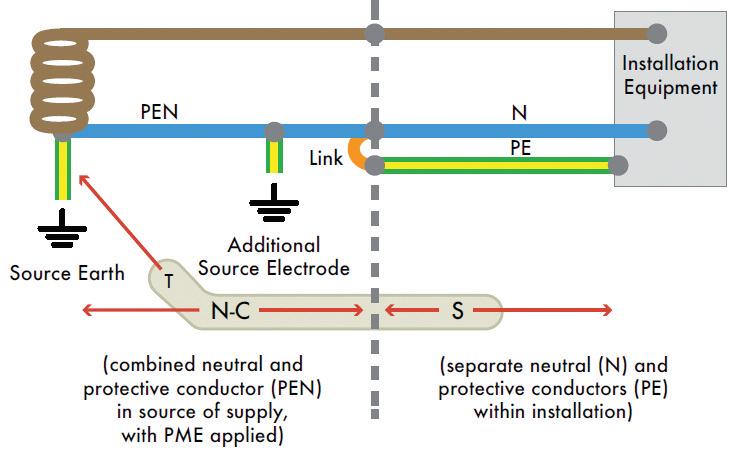

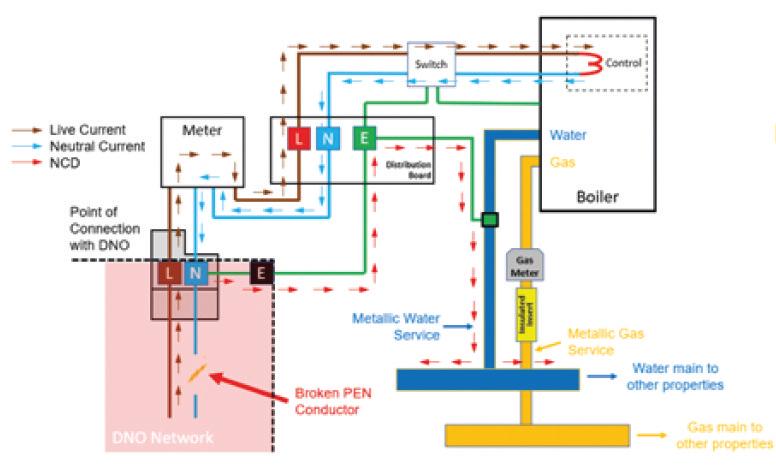

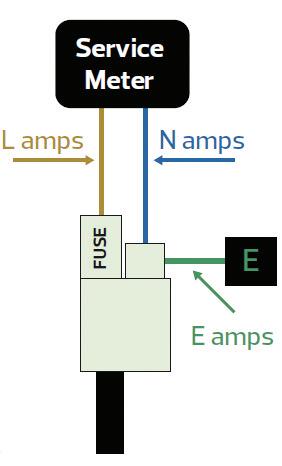

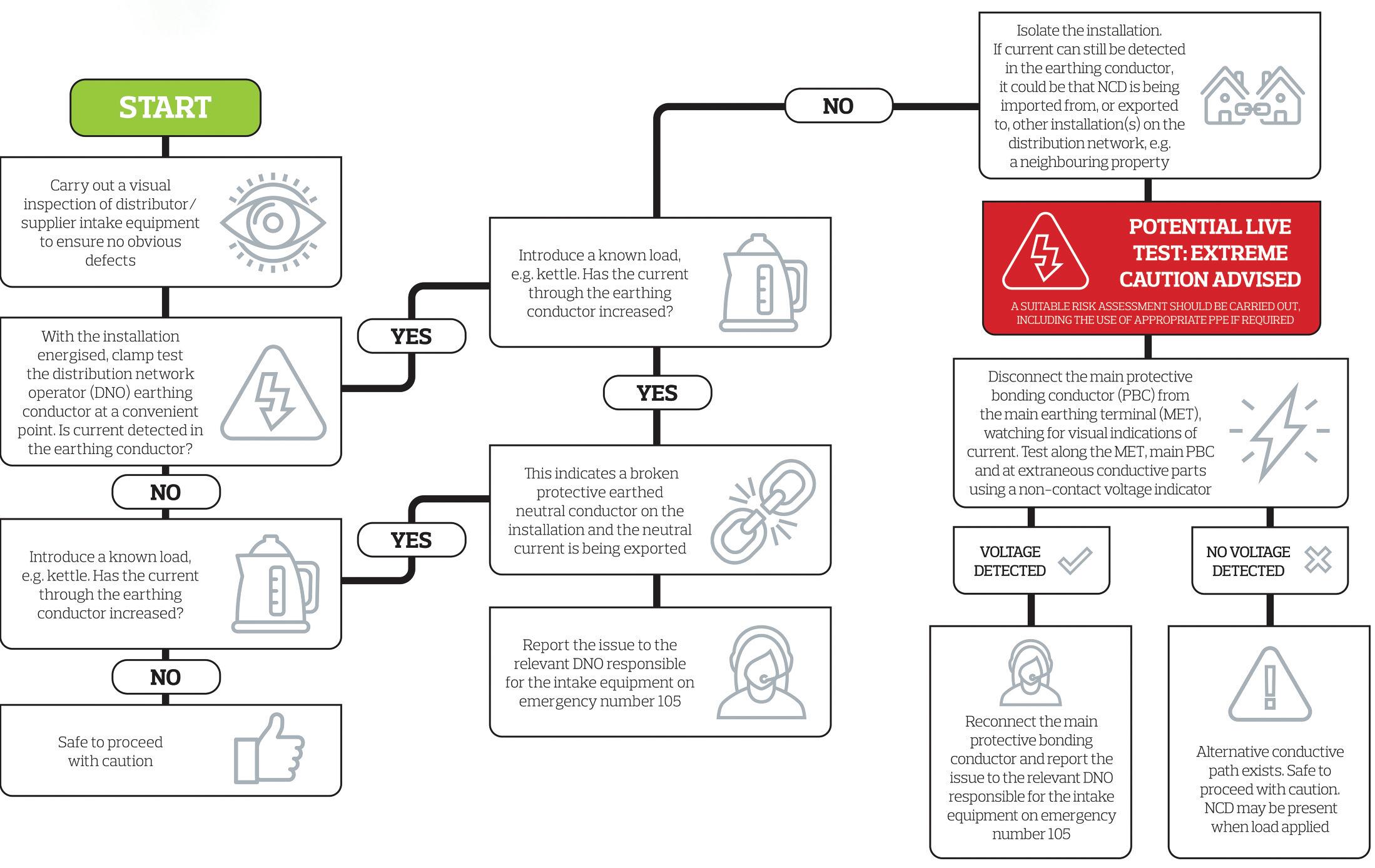

70 What is neutral current diversion (NCD) and where is it most likely to occur?

72 The team at NAPIT give our reader submissions the ‘Codebreakers’ treatment

74 Dr Zzeus, Tom Brookes, answers another fire safety-related question from the field

75 The requirements for the protection against electric shock in medical locations

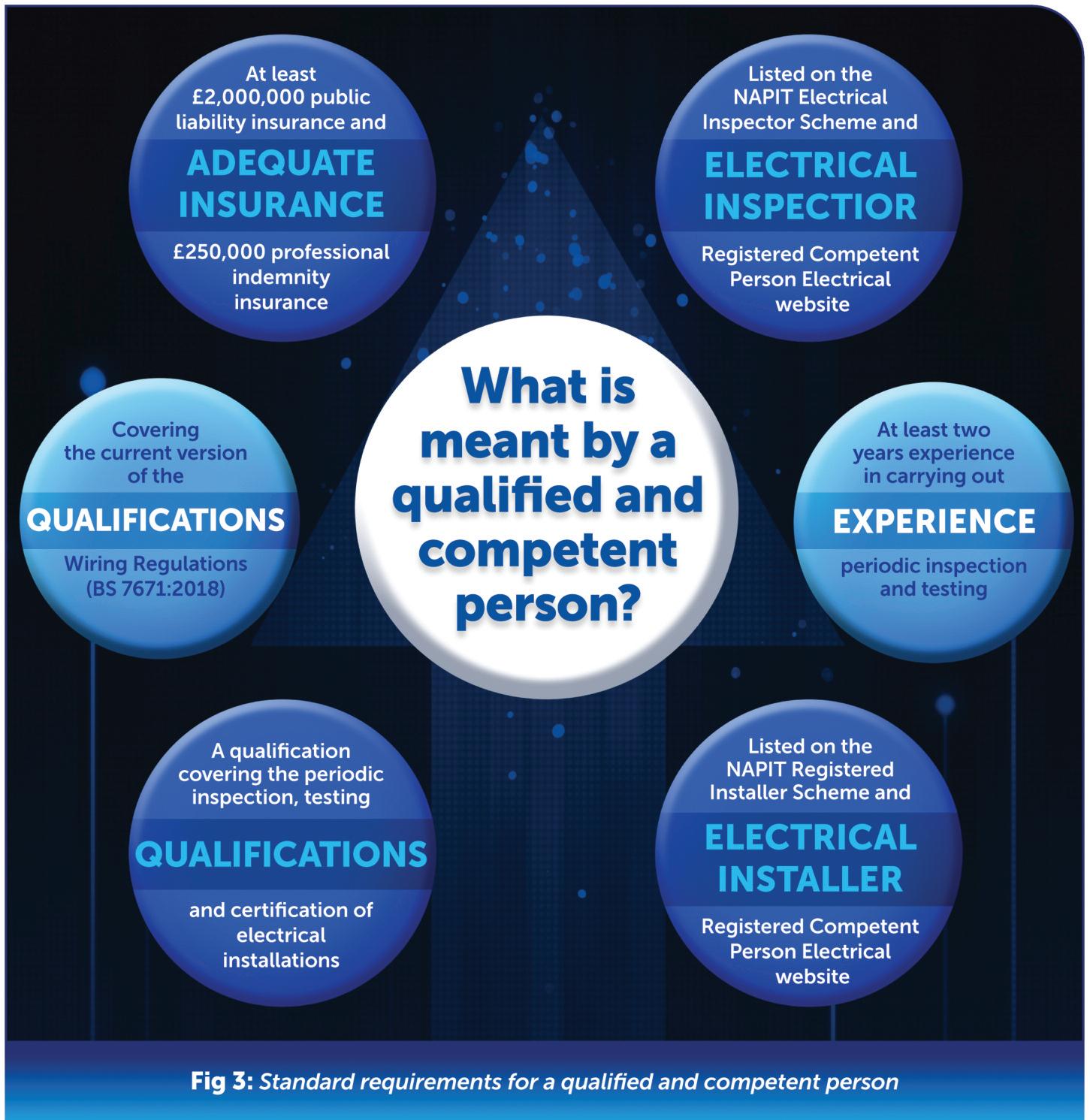

78 The key responsibilities that will ensure tenant safety and legal adherence with the PRS electrical safety check requirements

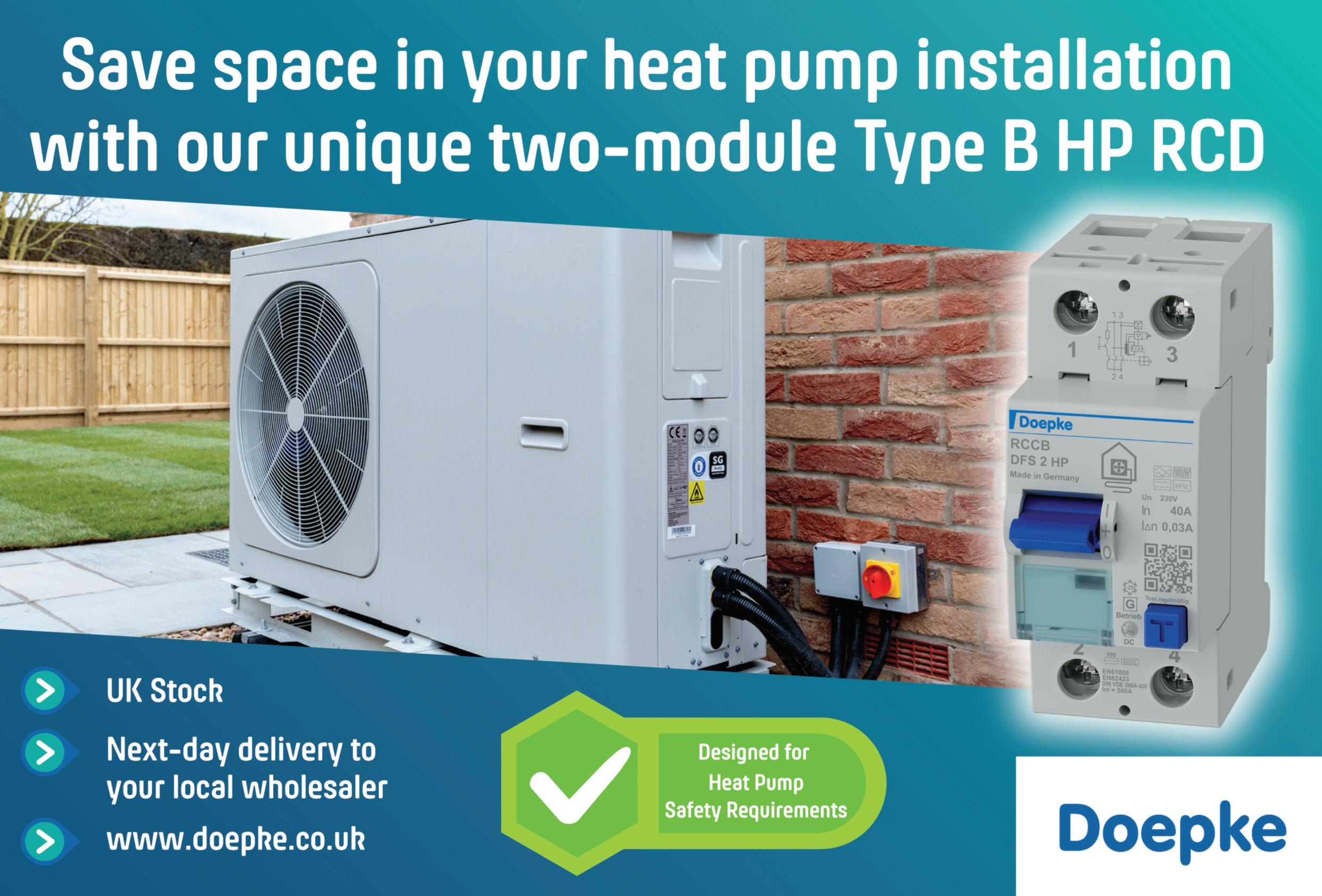

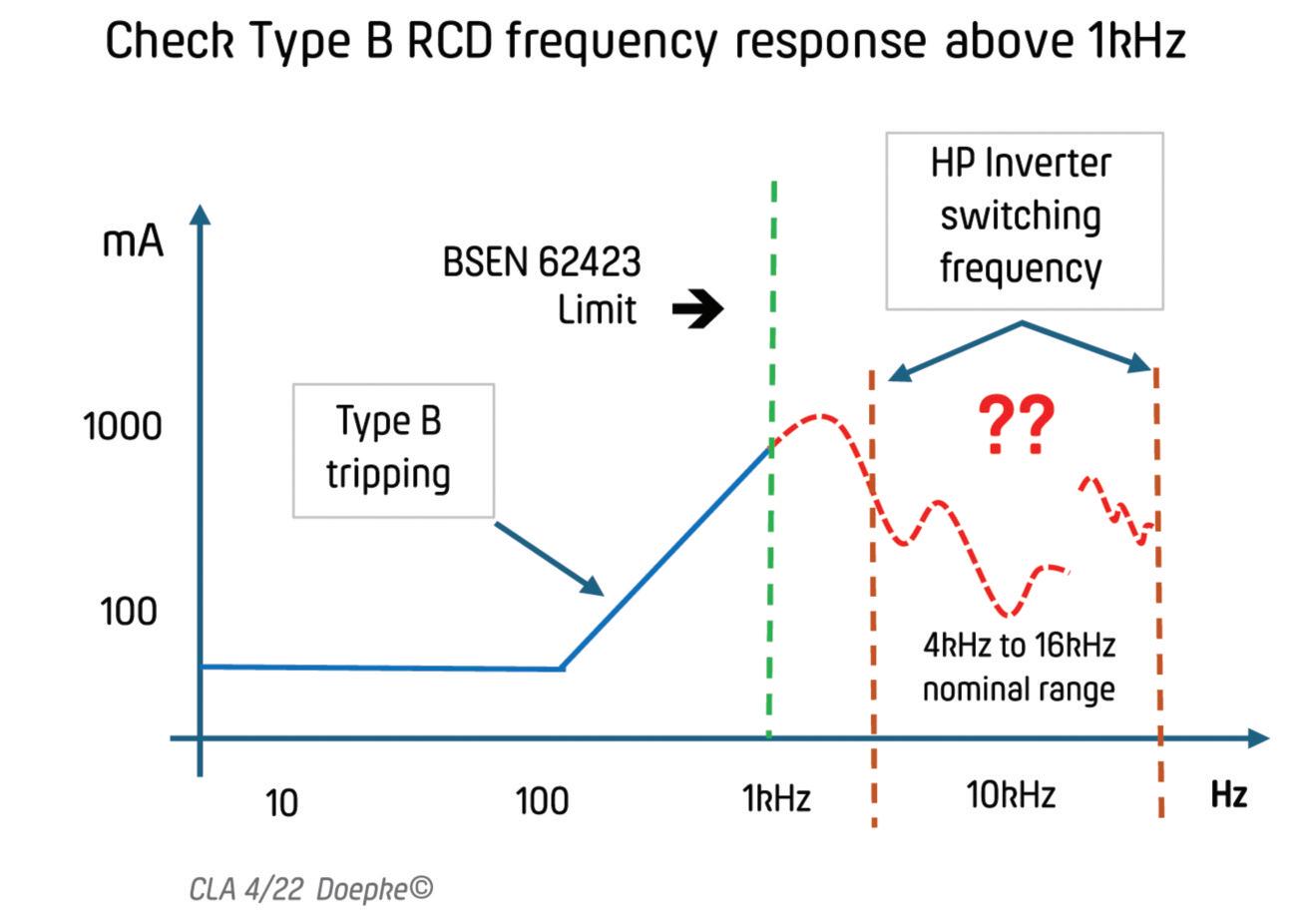

80 A look at the requirements for Type B RCD use in heat pump installations

82 The team at NAPIT give our reader submissions the ‘Codebreakers’ treatment

84 The experts at NICEIC answer more of your FAQs

85 A closer look at fault currents

86 What do you need to consider before installing EV charge points?

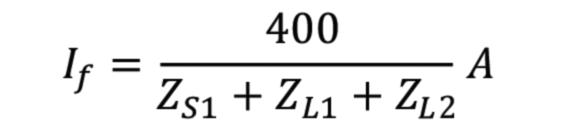

89 Analysing the installation of cables within containment systems

92 What must be taken into account when selecting protective devices for use in applications where bidirectional power flow is to be expected in normal operation?

Editor

RICHARD BOWLER

email: pe@hamerville co uk

Digital Manager

REBECCA MCGEOCH

email: rmcgeoch@hamerville co uk

Digital Assistant

ADAM ROBERTS

email: aroberts@hamerville co uk

Advertisement Manager

ANTHONY SCOTT

email: ascott@hamerville co uk

Assistant Advertisement Manager

IAN TURNER

email: ianturner@hamerville co uk

Design

GEMMA WATSON

Production Assistant

KERRI SMITH

Group Production Manager

CAROL PADGETT

Distribution Manager

KARL CLARK

Printed by:

PCP TELFORD

Published by:

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts, WD24 4YF

Tel: 01923 237799

Fax: 01923 246901

Email: pe@hamerville co uk

PROFESSIONAL ELECTRICIAN is the business journal for the electrical contracting industry It is available to the trade at leading electrical wholesalers throughout the UK © 2025

Subscriptions to PROFESSIONAL ELECTRICIAN are available Please contact us for rates

Image References (Adobe Stock):

Pg 6 CPD sign © TreenaBeena

Pg 20 AC DC © Watthana Tirahimonch

Pg 47 Fire service © Gorodenkoff

Pg 71 Electric current © Wasai

Pg 75 Medical location © People Images

The electrical industry has always been about more than wires, circuits and connections. At its heart, it’s about professionalism, safety, and a commitment to doing the job right

But as our sector continues to evolve –shaped by new technologies, regulatory changes and customer expectations – the skills and knowledge we rely on need to evolve too.

That’s why Continuing Professional Development (CPD) is no longer just a “nice to have” It’s rapidly becoming a nonnegotiable part of working life for electricians and contractors across the UK

The recent update to the Electrotechnical Assessment Specification (EAS) underlines this point For the first time, businesses looking to achieve recognition through a Certification or Registration Body are required to maintain appropriate records of staff qualifications, training (including CPD), and experience

In other words: it’s not enough to rely on past achievements or existing certificates

You must be able to demonstrate that you –and your team – are keeping your professional development alive and active

This is not a box-ticking exercise and this requirement is only likely the beginning We can expect future versions to set out even stricter conditions, with CPD forming a central plank of technical competence and compliance

Add to that the IET’s Rules of Conduct, which demand at least 30 hours of recorded CPD a year for active members (or 10 for those partially active), and it’s clear that CPD is becoming a defining benchmark for professionalism within our industry

So where does that leave you? For many,

it raises questions: Where do I find credible CPD opportunities? How do I fit this learning into my already busy schedule? And most importantly, how do I record it in a way that stands up to scrutiny from certifying bodies?

That’s where Professional Electrician & Installer is proud to step up We’ve listened carefully to these concerns, and the result is a 98 page publication which wraps up the content from PE’s monthly ‘CPD Zone’ section from the first six issues of 2025.

The six individual sections contain content that has been carefully developed to deepen your understanding of key areas –from changes in legislation and regulation to technical innovations and best practice

Every article is submitted to, and independently checked by, The CPD Group, a respected third-party accreditation body That stamp of legitimacy means you can use it with confidence

Best of all, by reading and engaging with each section of The CPD Book, you can download a bespoke certificate providing one CPD credit – equivalent to one hour of structured learning Work your way through this publication and you can earn up to 6 hours of CPD you can prove

This is a genuine first for our sector PE is the only independent UK-based electrical trade publication to have every issue CPD accredited, and to produce a special edition publication like this It’s an achievement we’re proud of – but more importantly, it’s a service designed to make your professional journey simpler, more transparent, and more rewarding.

In an industry where standing still is not an option, CPD’s importance grows every day Thanks to publications like this one, that edge is now within everyone’s reach

W O R K T H R O U G H E A C H S E C T I O N A N D E A R N 6

C P D C R E D I T s ( o r 6 h o u r s o f l e a r n i n g ) T O WA R D S YO U R P R O F E S S I O N A L R E C O R D !

continuing professional development (CPD) can be broadly defined as any type of learning you undertake which increases your knowledge, understanding and experiences of a subject area or role

To help professionals to better document and prove this process, the CPD Book contains content and articles that have been checked, verified and accredited by a third-party specialist organisation

Collectively, the content within this specially designed publication has been deemed worthy of 6 CPD credits, or 6 hours’ worth of CPD, with each individual section providing 1 credit, or 1 hours’ worth of CPD.

Once this content has been consumed, readers will have the

opportunity to scan a QR code which will provide a bespoke, downloadable certificate that can be used as part of a professional’s ongoing CPD record

DO NOT SCAN THE

QR

CODE UNLESS YOU HAVE READ ALL OF THE CONTENT WITHIN EACH SECTION!

A large element of CPD involves self-certification and relies on professionals being honest about what they have actually read, consumed and digested A QR code has been placed with the final article in each of the five learning sections within this publication and ONLY once you have read ALL of the articles within each section, should you then scan the code to receive your bespoke certificate

By skipping any of these steps, you’re not just cheating the system, but yourself and your fellow professionals at the same time!

NEW USERS – ACCESS YOUR BESPOKE CPD CERTIFICATE IN FIVE STEPS

1. Read ALL of the content and articles included within the five sections

2. Find the QR code with the last article in each section and scan

3 Enter your email address

4. Fill out your details on the contact form

5. Download your certificate for use as part of your annual CPD record

PREVIOUS USERS – ACCESS YOUR CPD CERTIFICATE IN FOUR STEPS

1. Read ALL of the content and articles included within the five sections

2. Find the QR code with the last article in each section and scan

3. Enter your name and email address.

4. Download your certificate for use as part of your annual CPD record

All certificates are valid for one year from the issue date If you’re having any issues with downloading your certificate or using the system, please email us at: pe@hamerville.co.uk

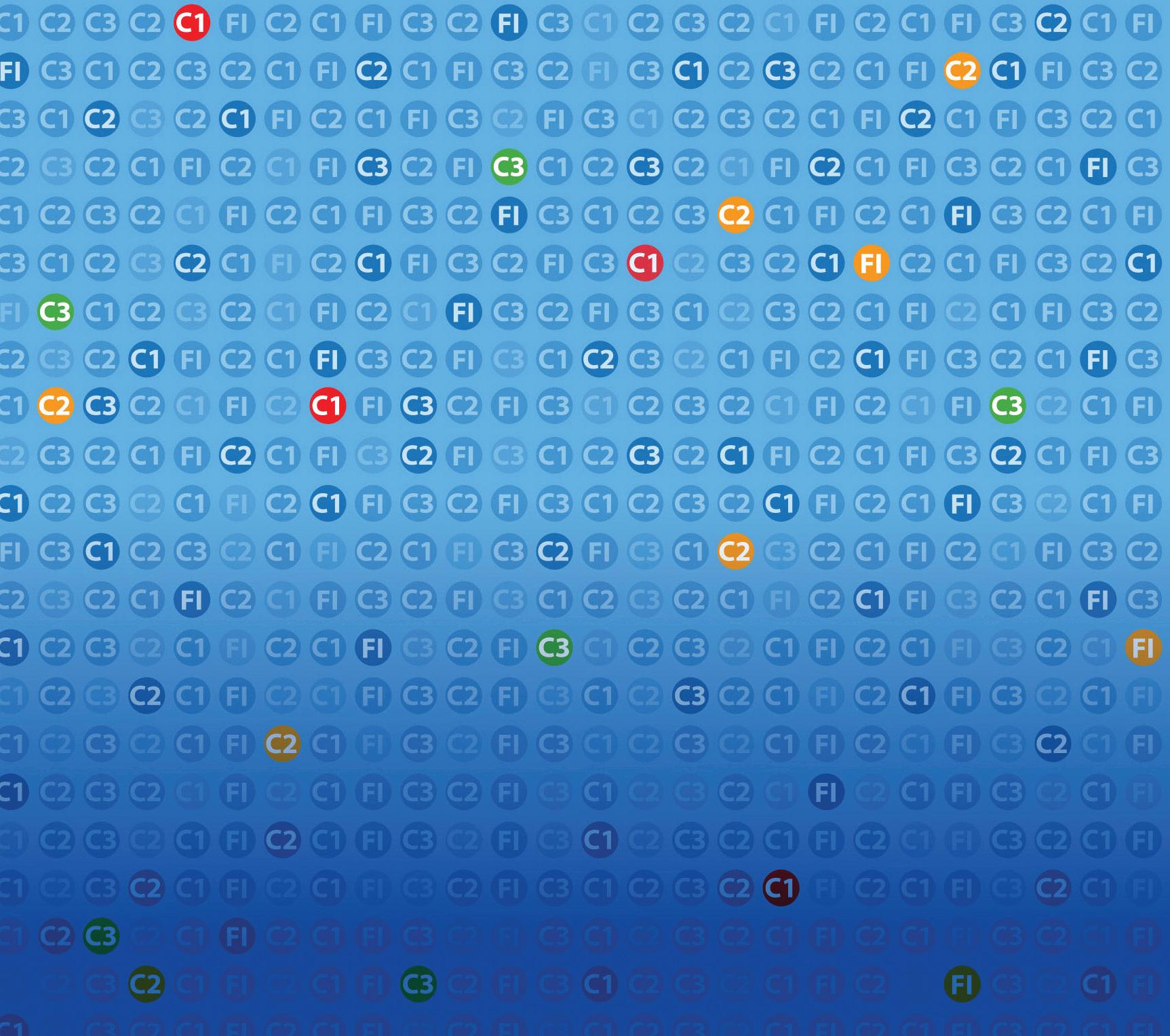

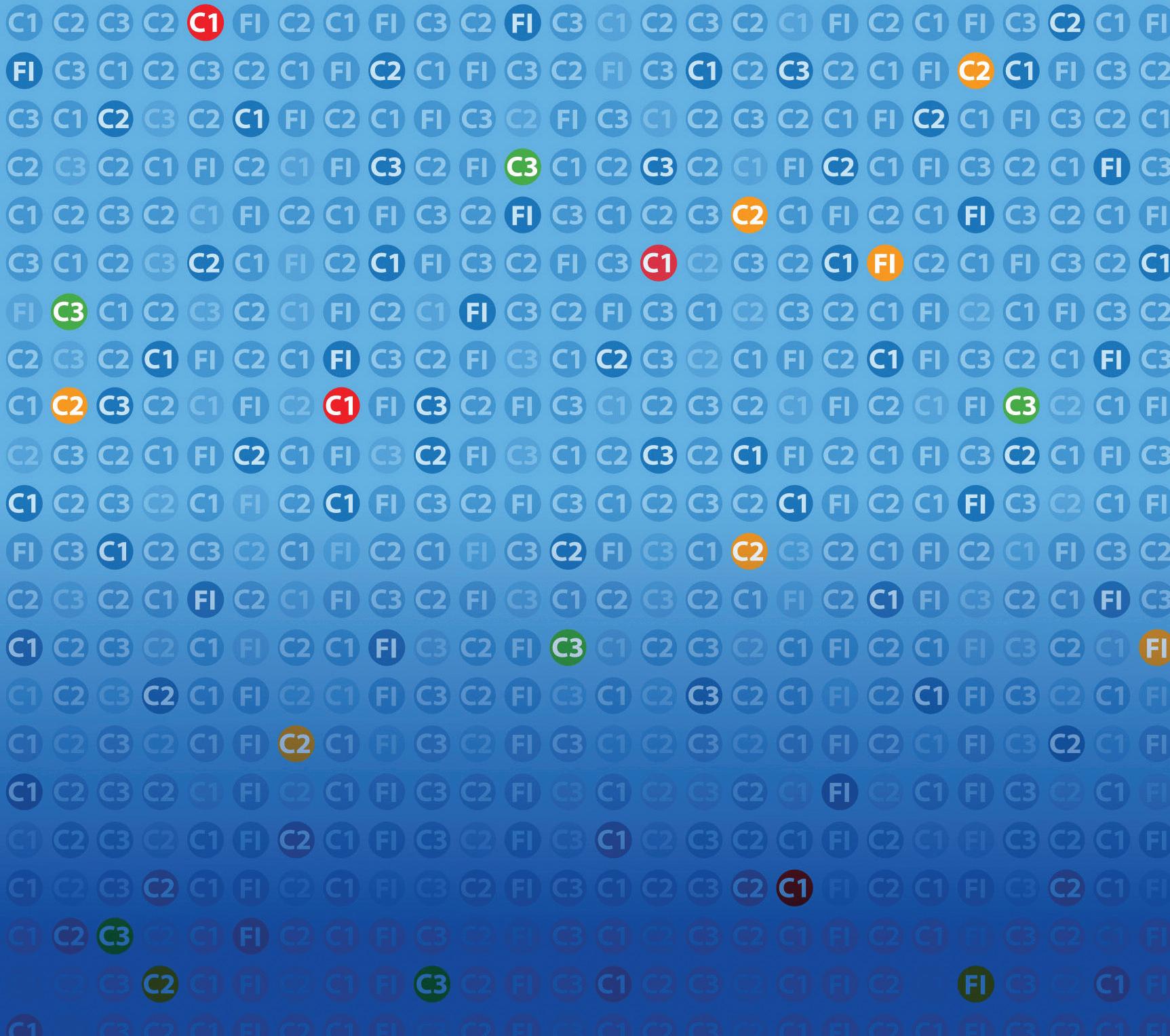

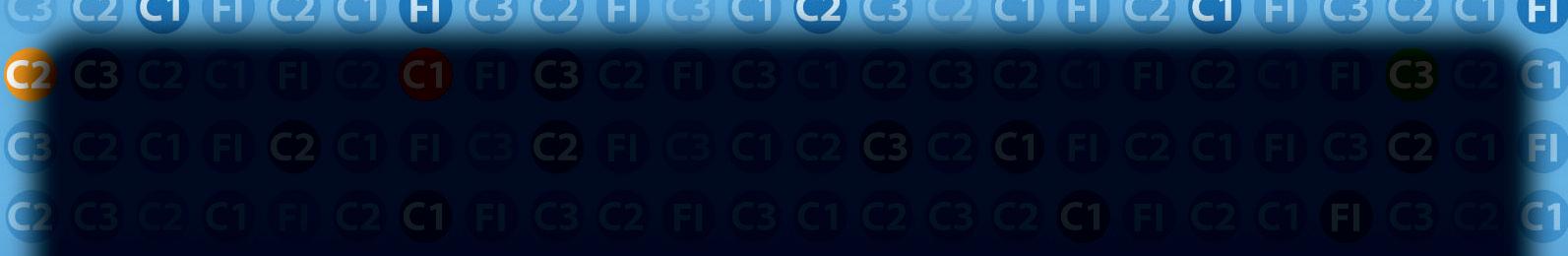

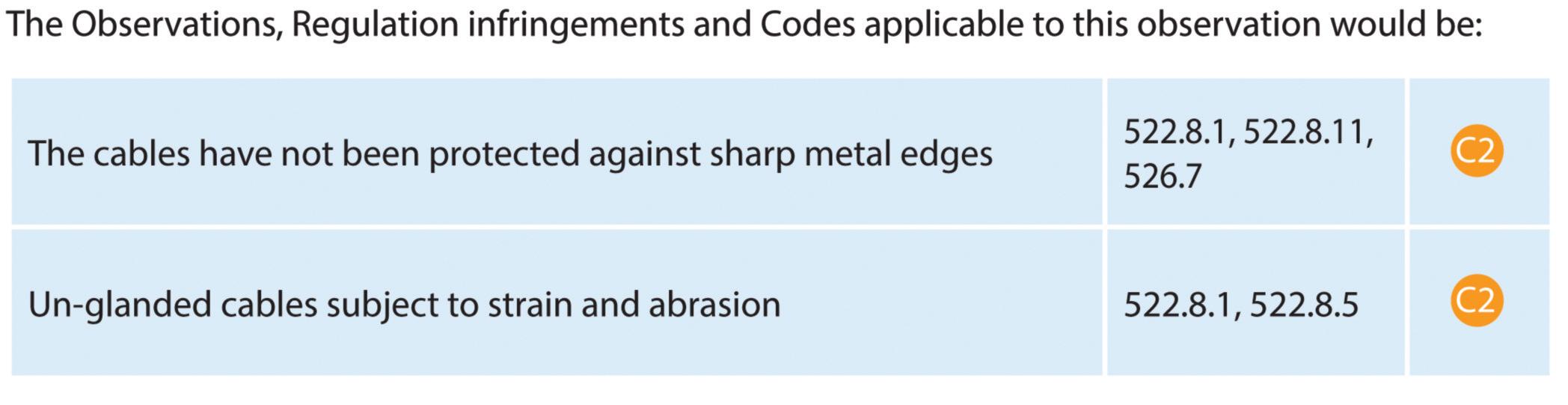

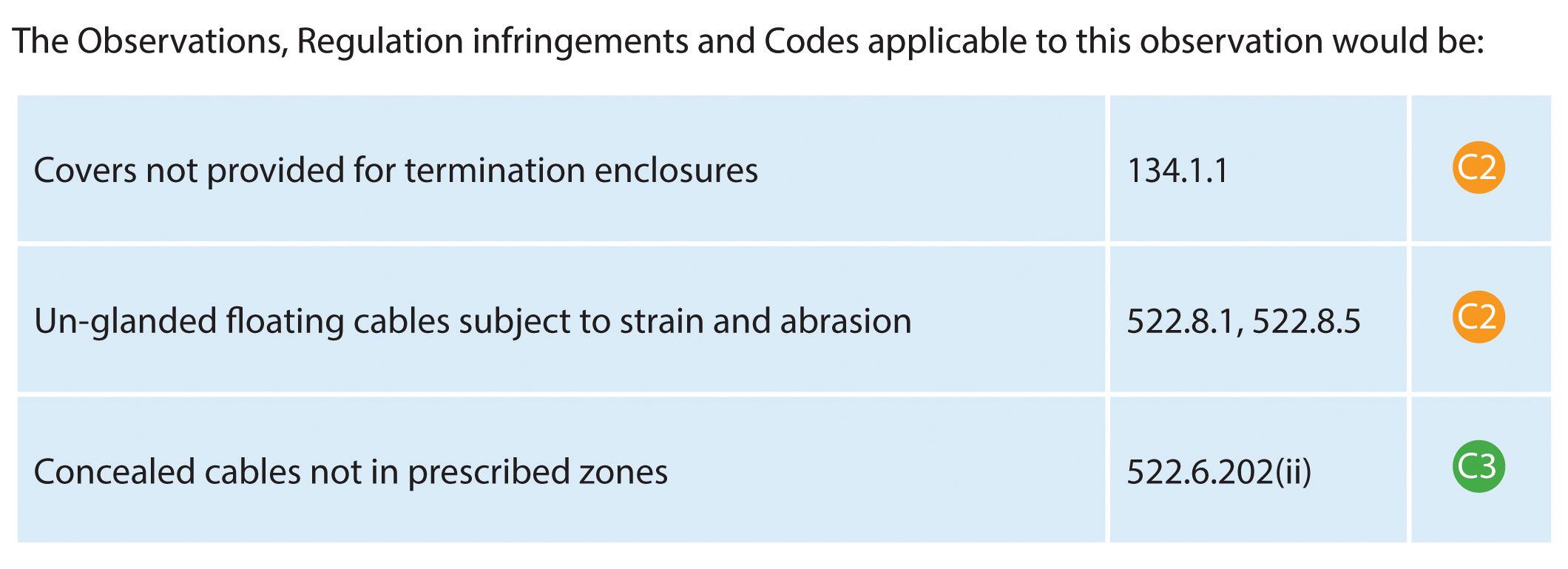

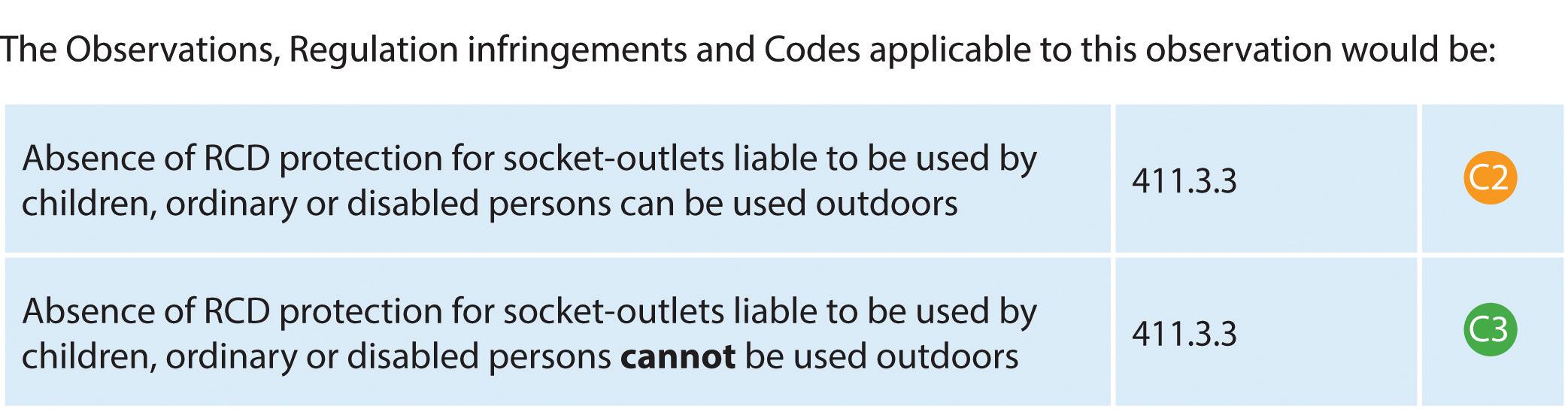

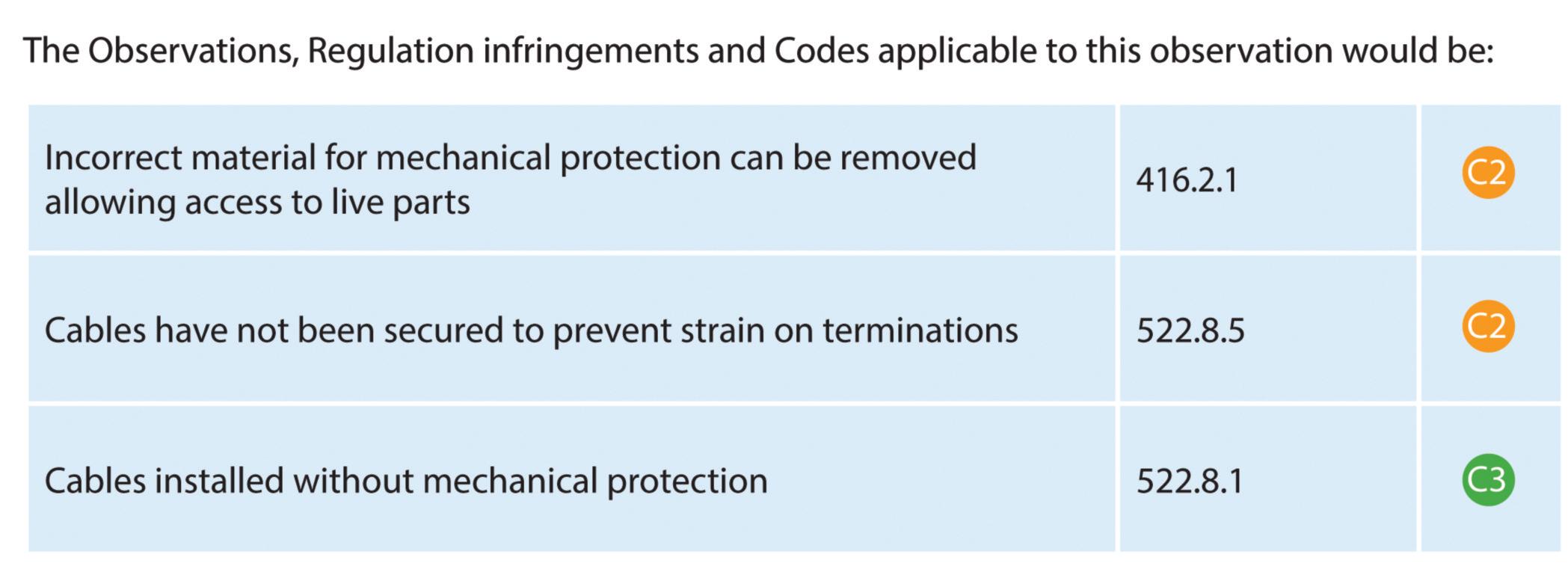

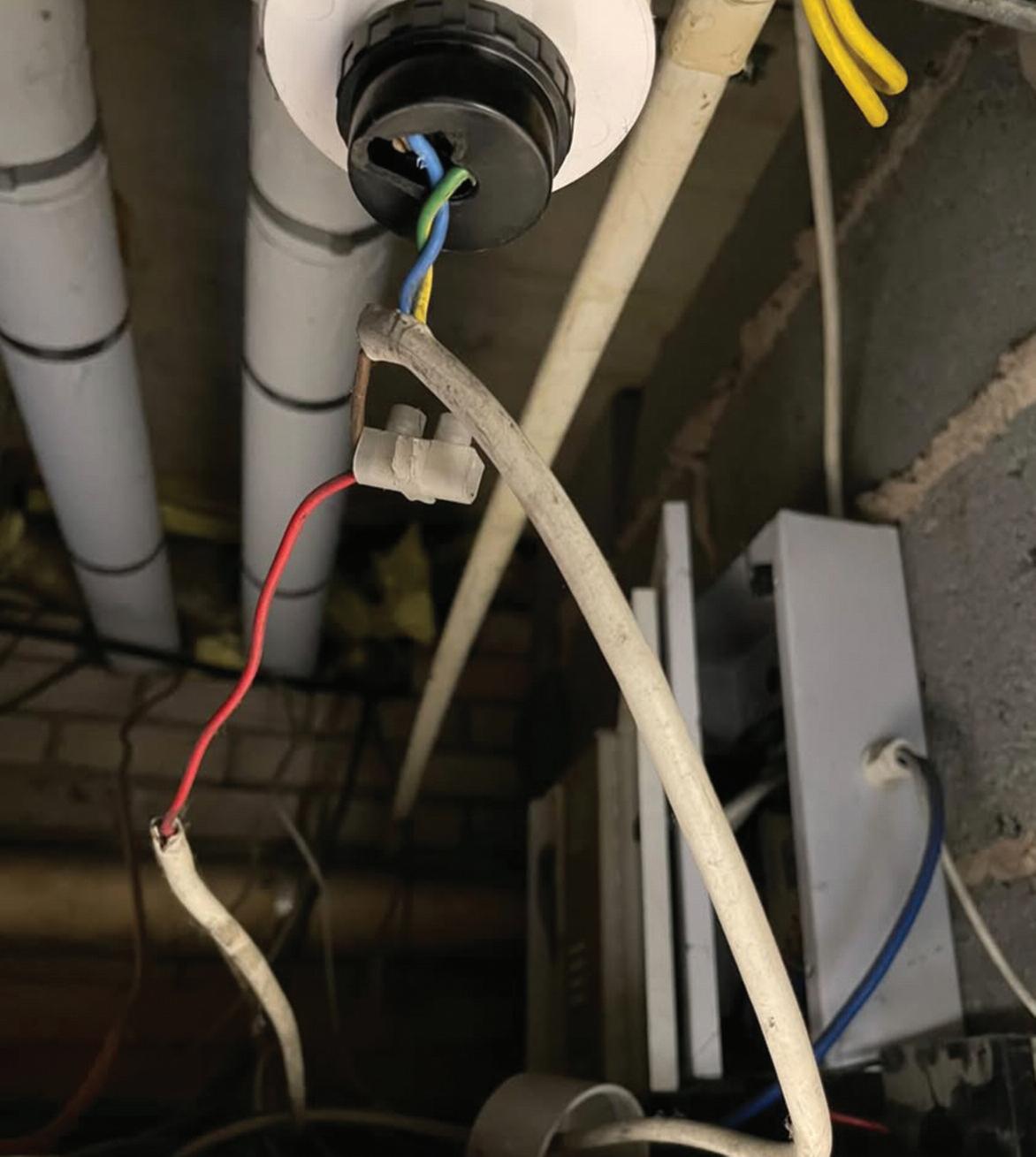

At times, it can seem to be the case that the electricians are seen as invisible to other trades, especially with our electrical accessories that could potentially be in their way

In this example, the plumber has changed or installed a new boiler or water system and has not considered the elec trical installation With the installation of the new pipework , the socket- outlet needed to be installed into a new accessible position, but now we have a situation where the socket- outlet can no longer be used

This could also cause a fur ther issue when conducting periodic inspection and testing, where this socket- outlet could not be inspected, or any form of testing be per formed

Therefore, the classification code would be a C3, Improvement required, due to the lack of access to the socket- outlet.

Updated for BS 7671:2018+A2:2022, NAPIT ’s EICR Codebreakers publication is purpose -written to aid contractors, inspectors and clients, and now includes updates to align with Amendment 2 of the IE T 18th Edition Wiring Regulations The book is the per fect technical aid for electrical professionals and their customers.

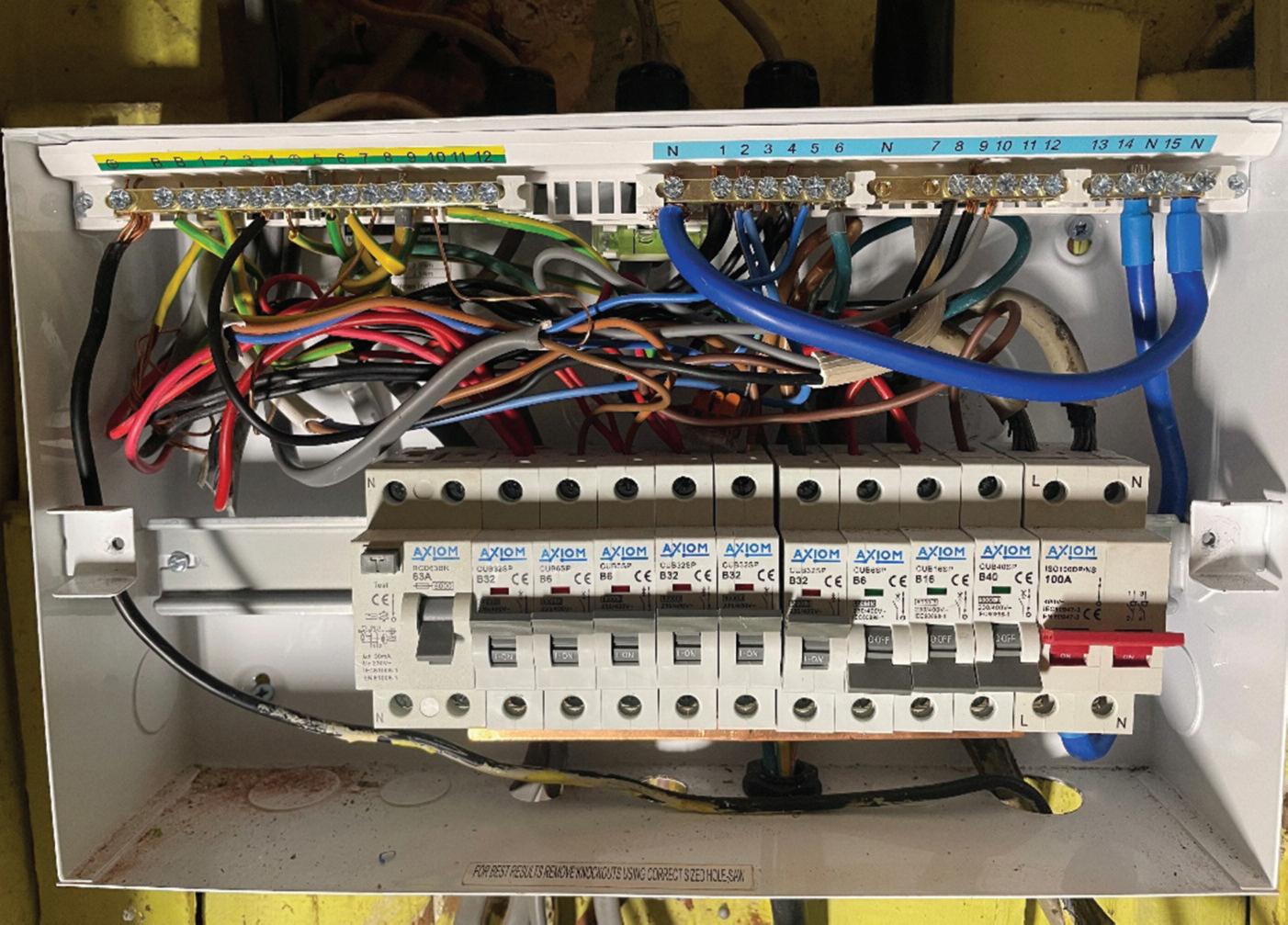

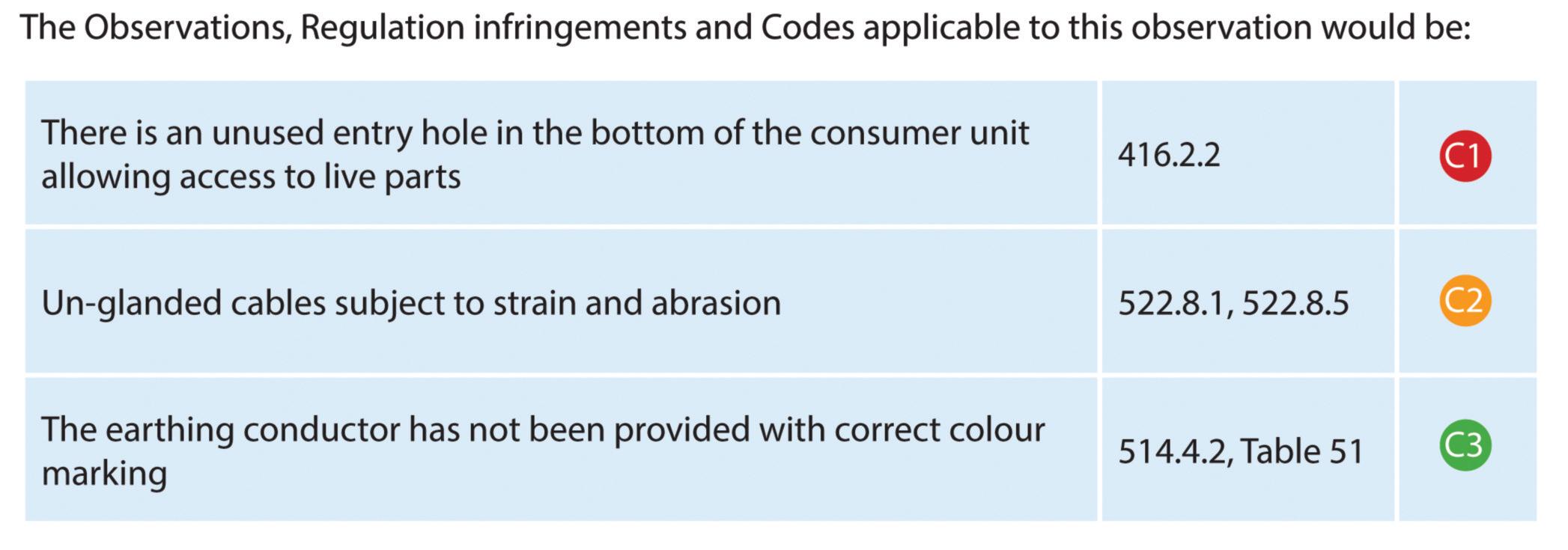

Need help with cracking those all-impor tant EICR codes? Ever y month the technical team at NAPIT will be studying your latest ‘Caught on Camera’ photos and offering advice on the next steps, should you find a similar installation. If you want the team at NAPIT to help crack your codes then send your pic tures through to us at: pe@hamer ville.co.uk

When accessories are installed as par t of the electrical installation, they become an integral par t of the wiring system and must comply with all aspects of BS 7671 and Building Regulations.

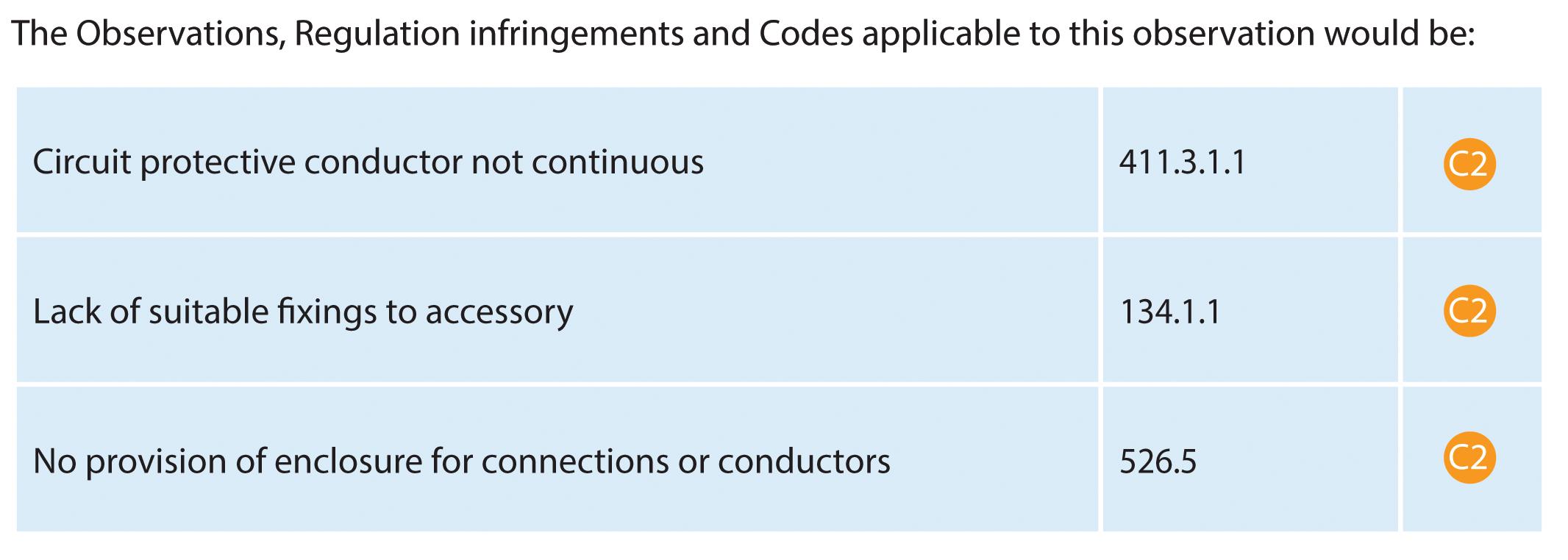

In this instance there has been no provision of a back box to enclose the live par ts or conductors and the circuit protective conductor (cpc) continuity has not been maintained throughout the circuit

I t is often overlooked that the cpc is required to be installed and terminated to each point of the wiring and each accessor y. The only exception is for a lamp holder

Although this device is marked as a double insulated and does not require ear thing, the requirement is to terminate the cpc at this point

Failure to terminate the cpc ’s does not provide the continuity of protective conductor or any exposed- conductive -par ts that are par t of the circuit

The lack of an enclosure for an accessor y does not provide containment of live par ts and for any protection against potential spread of fire The lack of secure fixings for the accessor y also places strain on the connections with the potential to allow the live connections to become exposed

Therefore, the classification code would be a C2, Potentially Danger present – urgent remedial action required, due to the lack of cpc continuity

The A2:2022 18th Edition Codebreakers publication is priced at £22.00 (members) and £24.00 (non-members). It is available in both hard copy and digital versions * Price is VAT exempt and excludes postage and packaging.

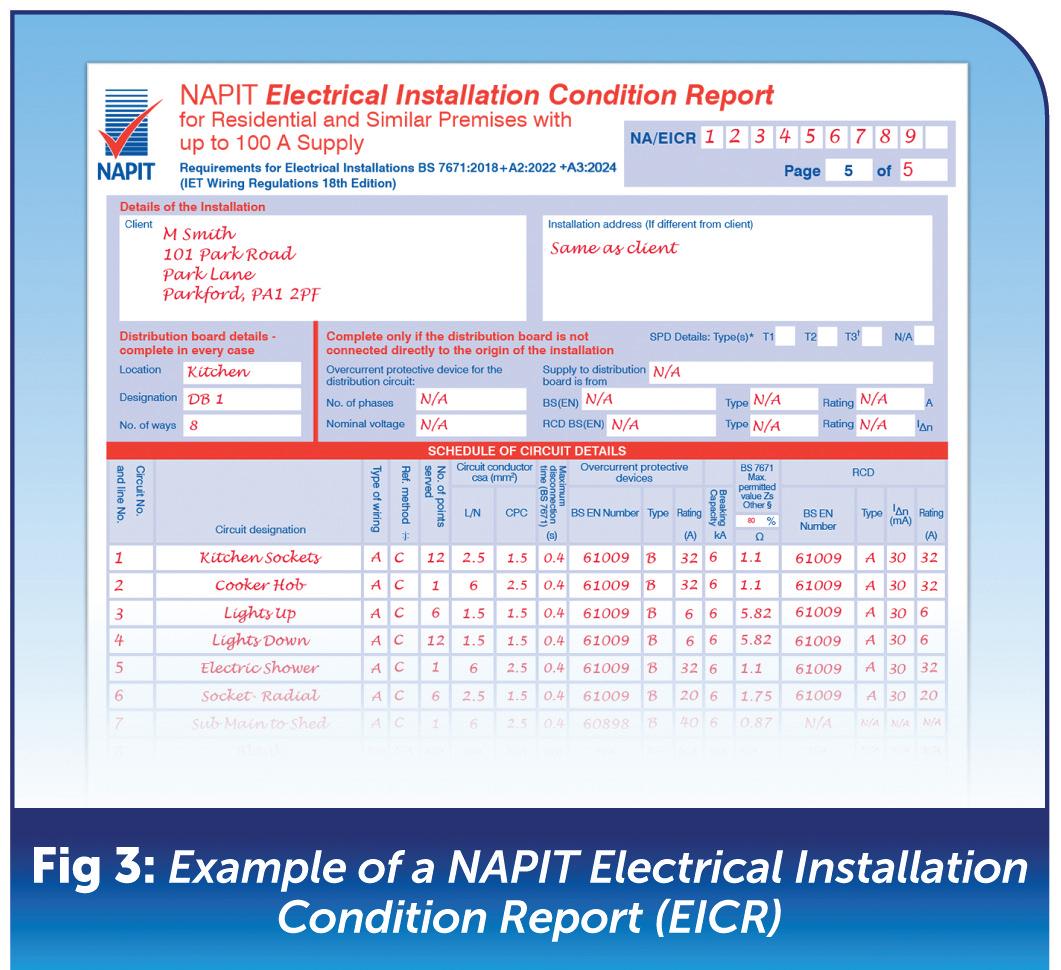

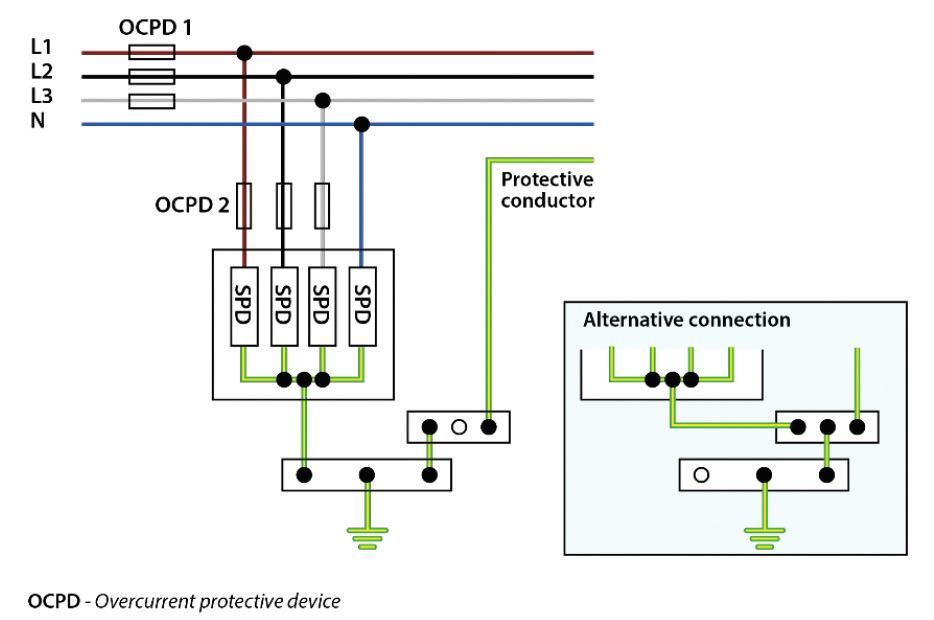

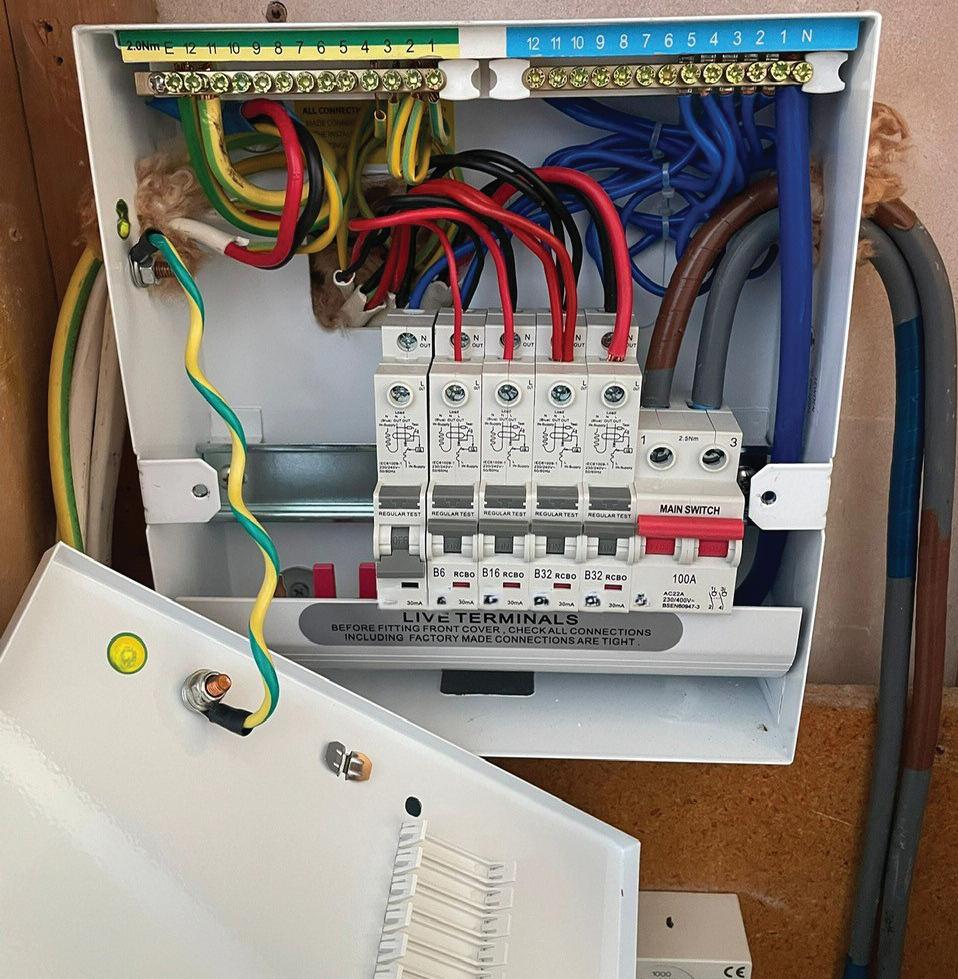

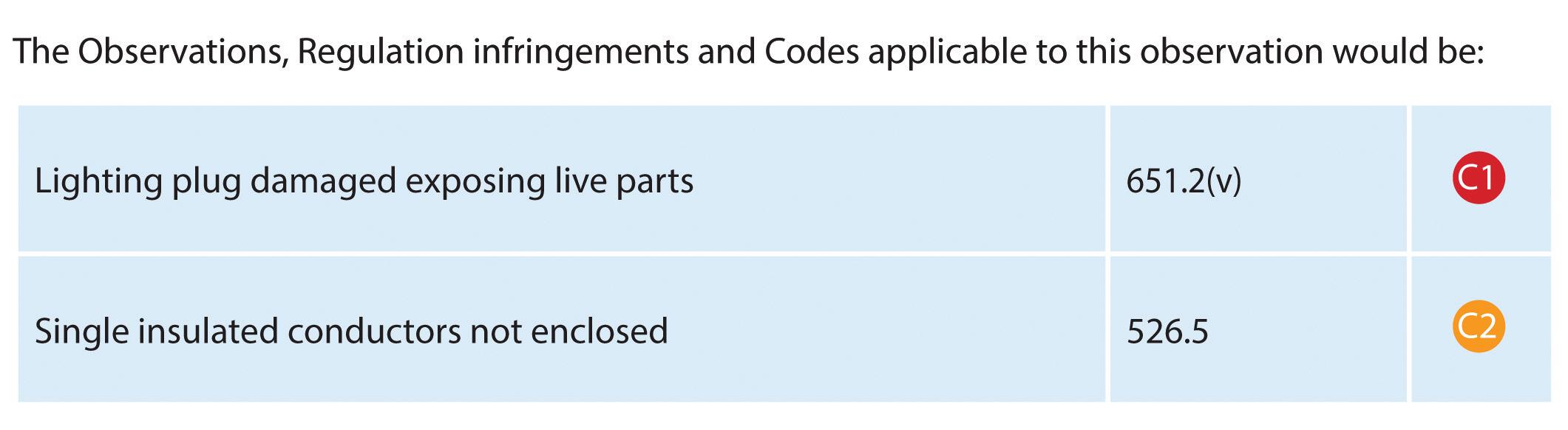

A number of protective devices are now available which perform more than one function, such as Residual Current operated Circuit-Breakers with integral Overcurrent protection (RCBO), and combination RCBO and Arc Fault Detection Devices (AFDD). The model ‘Schedule of circuit details’ in Appendix 6 of BS 7671 asks for a number of key functional characteristics of the various elements within the device to recorded. This article from the experts at NICEIC describes how these details can be recorded.

Switchgear manufacturers have developed several protective device products for use in distribution boards and consumer units which contain multiple functionalities, including those of a:

● Circuit-breaker

● Residual Current Device (RCD)

● Arc fault detection device (AFDD).

Combining multiple functions into a single device provides a benefit that smaller distribution boards having fewer ‘ways’ may be installed than would be the case if devices providing only a single function were installed. It also allows the required or desired protection to be more easily applied to the circuit(s) the designer intended However, enquiries received by the

NICEIC field and helpline teams indicate that the use of such combination protective devices is causing some confusion in respect of the information that must be recorded on the Schedule of Circuit Details which form part of both an Electrical Installation Certificate (EIC) and Electrical Installation Condition Report (EICR).

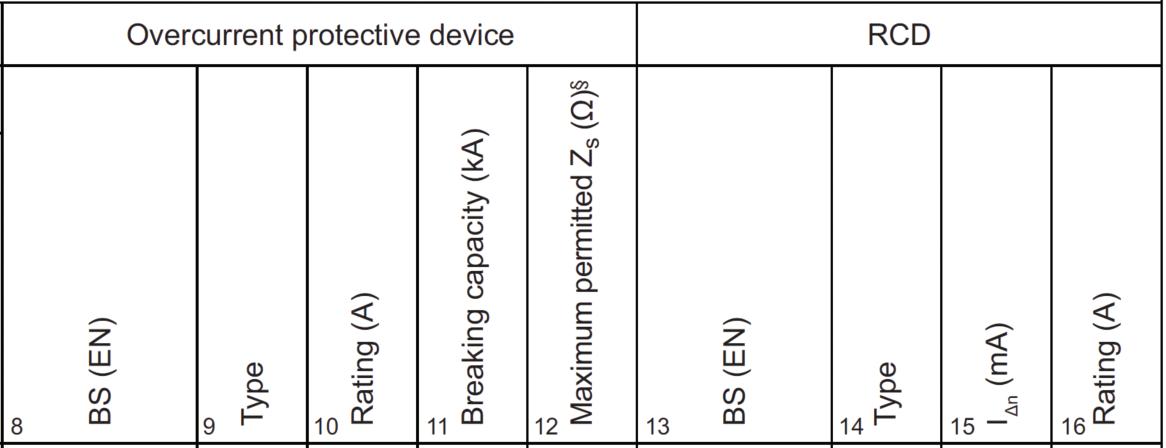

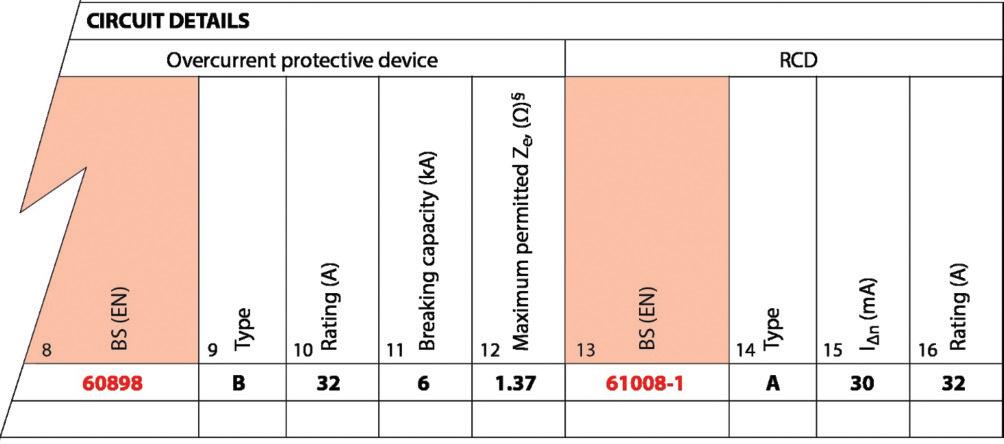

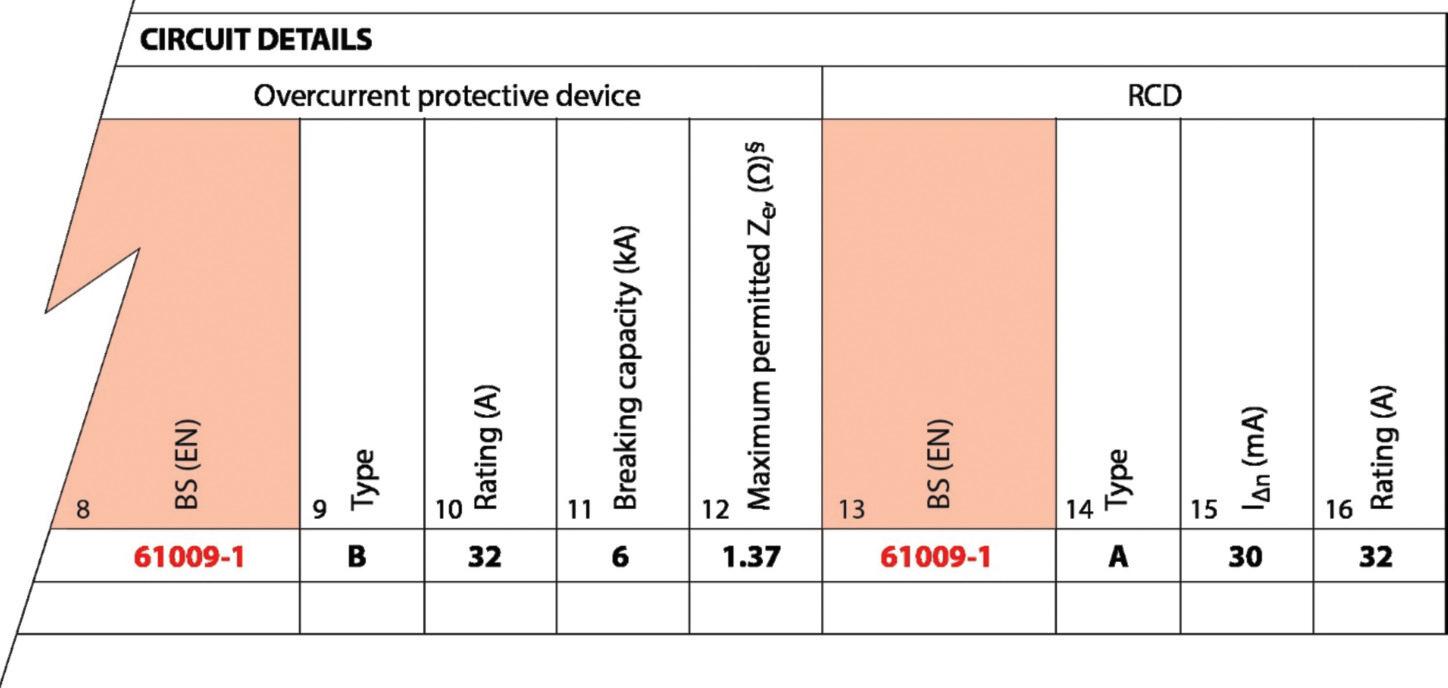

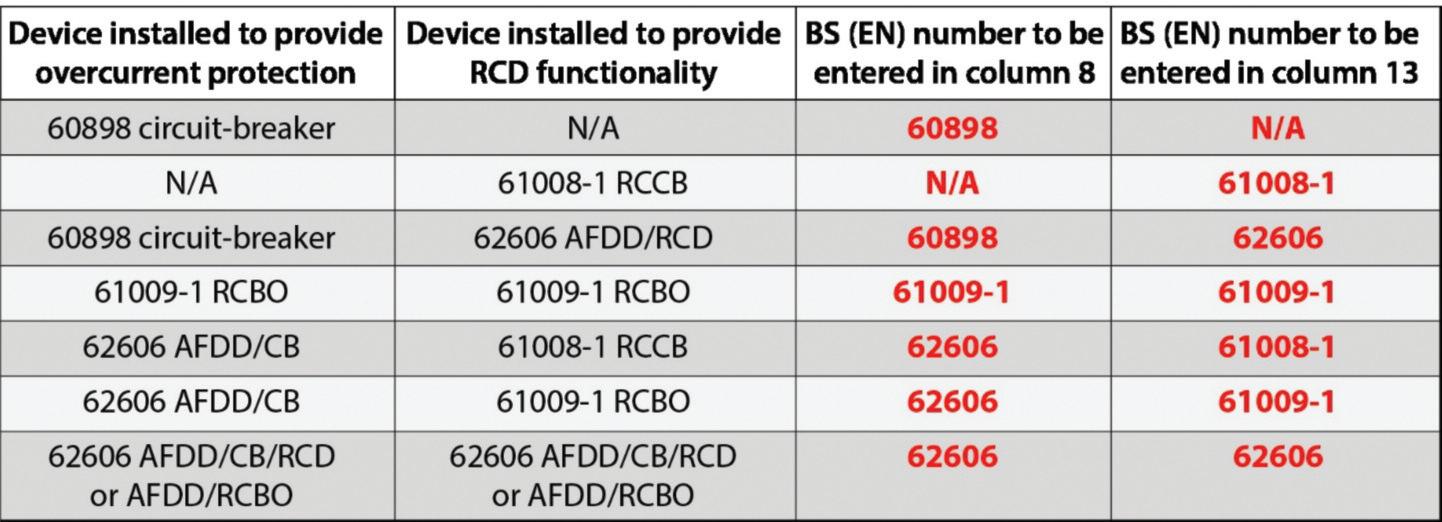

As can be seen in the extract reproduced in Fig 1, the new Schedule of Circuit Details introduced in Amendment 2 (AMD2) published in 2022 requires information relating to both the overcurrent protective device and any installed RCD to be recorded.

Completing the ‘BS (EN)’ columns (numbered 8 and 13 respectively in the BS 7671 model form) is a straightforward

matter where the overcurrent protective device and RCD are separate, standalone devices

However, what’s less clear is how these fields should be completed where the circuit-breaker and RCD elements are combined in an RCBO or even more so when such functionality is integrated in an AFDD.

Where separate overcurrent protective device and RCD are installed

Where a circuit is protected by a separate circuit-breaker and RCD, it is clear that ‘60898’ should be entered in column 8 to identify the circuit-breaker and ‘61008-1’ should be entered in column 13 to identify the RCCB (an RCCB being the specific form of RCD used in this instance) (Fig 2)

Where an RCBO is installed

Clause 1 (Scope) of BS EN 61009-1 states that ‘This standard applies to devices performing simultaneously the function of detection of the residual current, of comparison of the value of this current with the residual operating value and of opening of the protected circuit when the residual current exceeds this value, and also of performing the function of making, carrying and breaking overcurrents under specified conditions ’

Note 1 to this clause clarifies that content of the standard relating to residual current conditions is based on IEC 61008-1 while the content relating to protection against overcurrents is based on IEC 60898-1

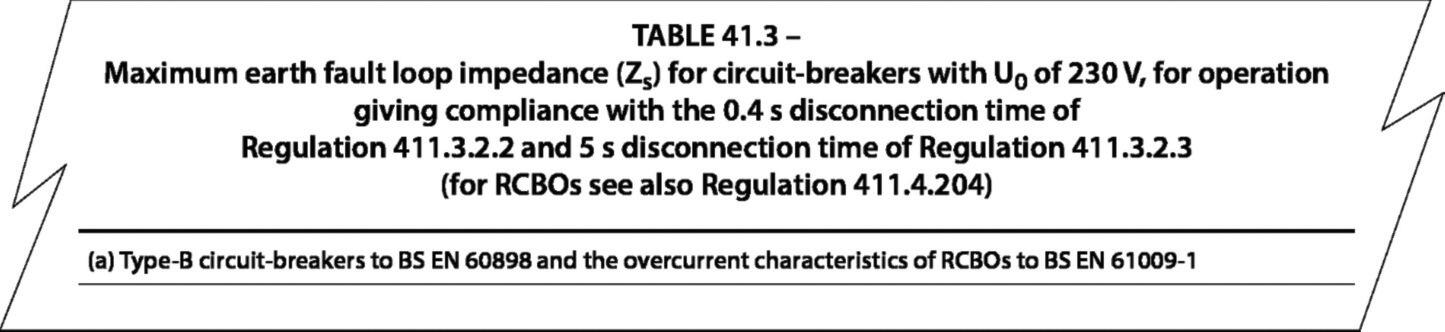

Table 41 3 of BS 7671 (Maximum earth fault loop impedance (Zs) for circuit-breakers with U0 of 230 V, for operation giving compliance with the 0 4 s disconnection time of Regulation 411 3 2 2 and 5 s disconnection time of Regulation 411 3 2 3) specifically references in the descriptors to Parts (a), (b) and (c) thereof that the data within the table is applicable to both circuit-breakers to BS EN 60898 and to the overcurrent characteristics of RCBOs to BS EN 61009-1 (Fig 3)

This clarifies that the device providing the overcurrent protection is the

BS EN 61009-1 RCBO and not a circuit-breaker to BS EN 60898

It would therefore be incorrect, and confusing, to those inspecting the installation at a later date if ‘60898’ was recorded in column 8, as there is not a BS EN 60898 circuit-breaker protecting the circuit; the installed device is an RCBO to BS EN 61009-1

Where the circuit is protected by an RCBO, ‘61009-1’ should be recorded in both column 8 and column 13 (Fig 4)

Where an AFDD with integral overcurrent device and/or RCD functionality is installed

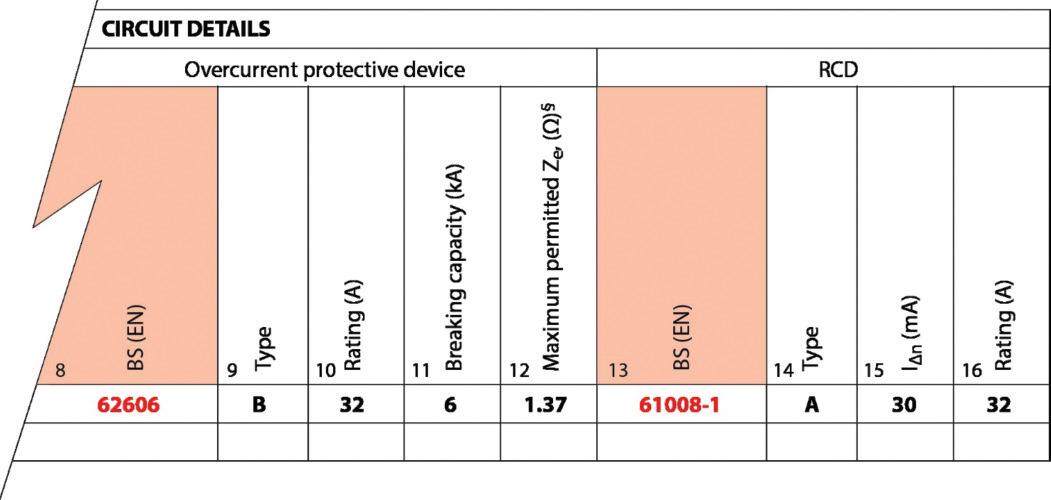

The same logic should also be applied when considering an AFDD to BS EN 62606 incorporating an overcurrent protective device and/or an RCD.

Clause 1 (Scope) of BS EN 62606 General requirements for arc fault detection devices states that ‘The integrated protection device is either a circuit-breaker in accordance with IEC 60898-1 or an RCD in accordance with IEC 61008-1, IEC 61009-1 or IEC 62423. ’ In order to determine which of these standards is applicable to a particular device reference should be made to the manufacturer’s data for the AFDD being installed

Where an AFDD incorporating overcurrent protective device and a separate RCD are installed

The device providing the overcurrent protection is the BS EN 62606 AFDD and not a circuit-breaker to BS EN 60898

As was the case where an RCBO is installed, it would be incorrect, and confusing, to those inspecting the installation at a later date if ‘60898’ was recorded in column 8, as there is not a BS EN 60898 circuit-breaker protecting the circuit; the installed device is an AFDD to BS EN 62606 (Fig 5)

As there is a separate RCD installed, the following should be recorded in column 13:

● ‘61008-1’ for an RCCB

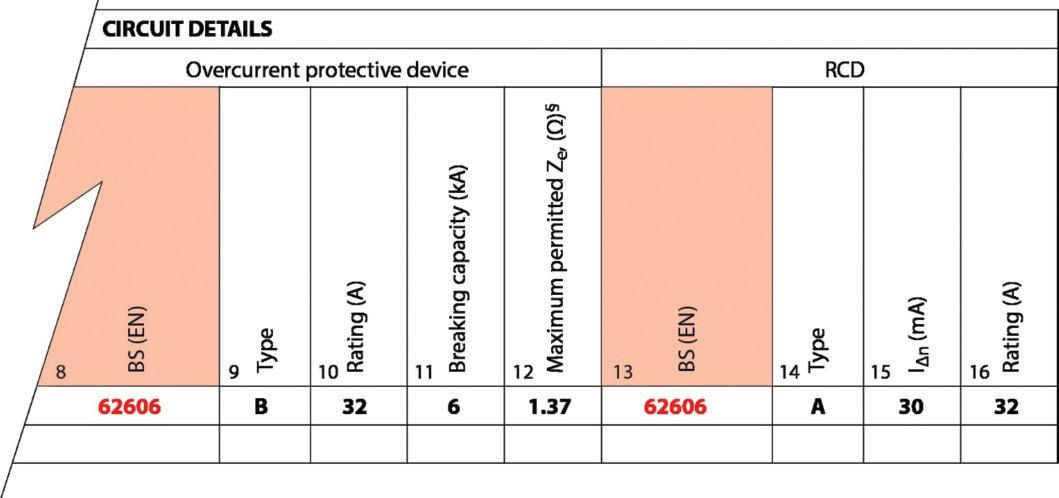

Where an AFDD incorporating both overcurrent protection and RCD functionality is installed

Where this type of device is installed:

● The overcurrent protection is provided by the BS EN 62606 AFDD and not a circuit-breaker to BS EN 60898 It would be incorrect, and confusing, to those inspecting the installation at a later date if ‘60898’ was recorded in column 8.

● The RCD functionality is provided by the BS EN 62606 AFDD and not an RCD in accordance with IEC 61008-1, IEC 61009-1 or IEC 62423 Again, it would be incorrect, and confusing, to those inspecting the installation at a later date if ‘61008-1’ was recorded in column 13 (Fig 6)

In order to provide the correct information required for the identification of the functional characteristics of protective devices providing more than one type of protection, whether overcurrent, residual current and/or arc fault current, it is necessary to refer to the relevant product standard to which the installed product conforms. A summary of this information is provided in Table 1

Providing the information in this manner is not only a correct reflection of the installed equipment but will also aid those carrying out alterations and/or additions or periodic inspection and testing at a later date to correctly identify the installed protective devices for the circuits of the installation.

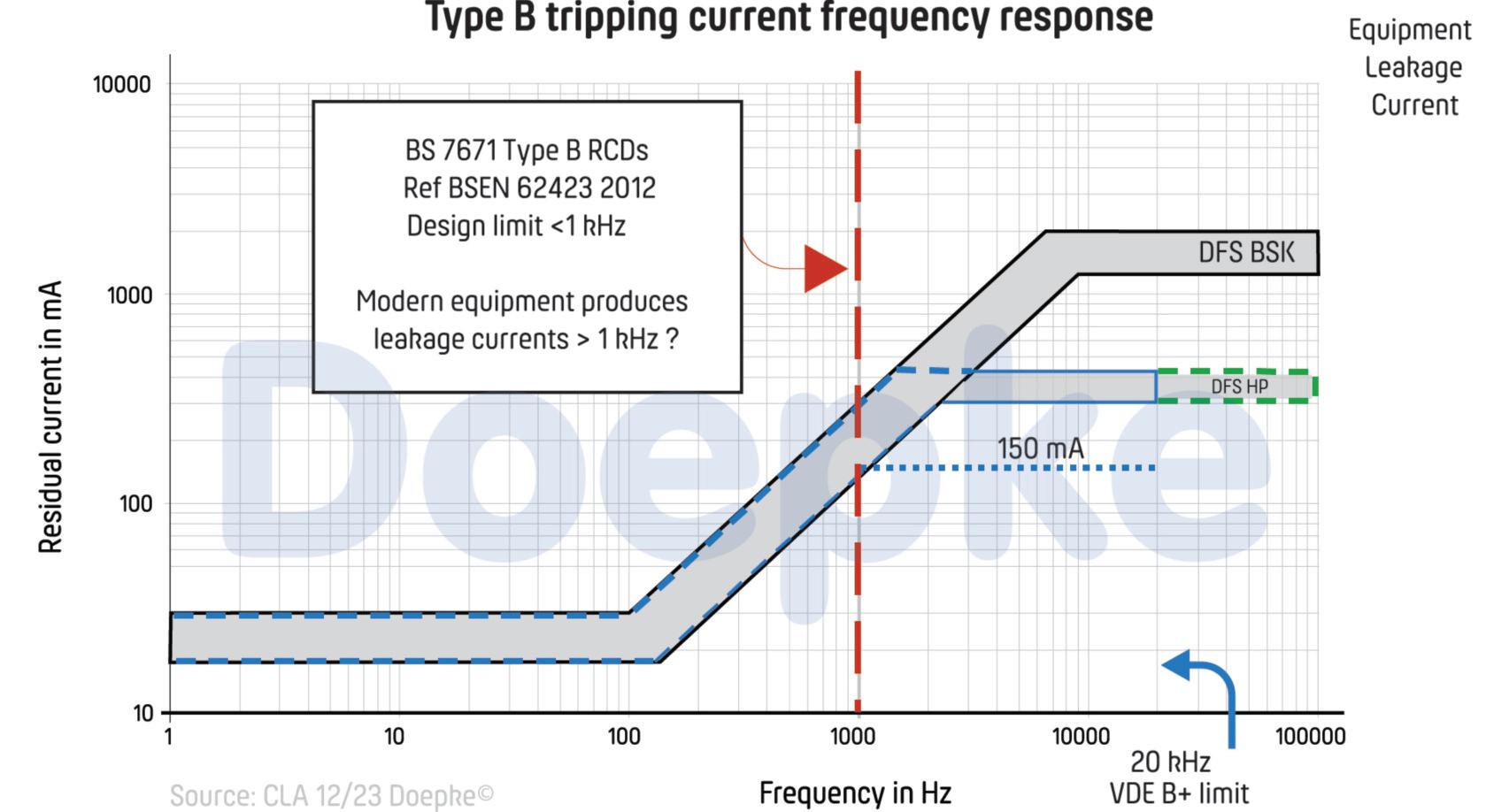

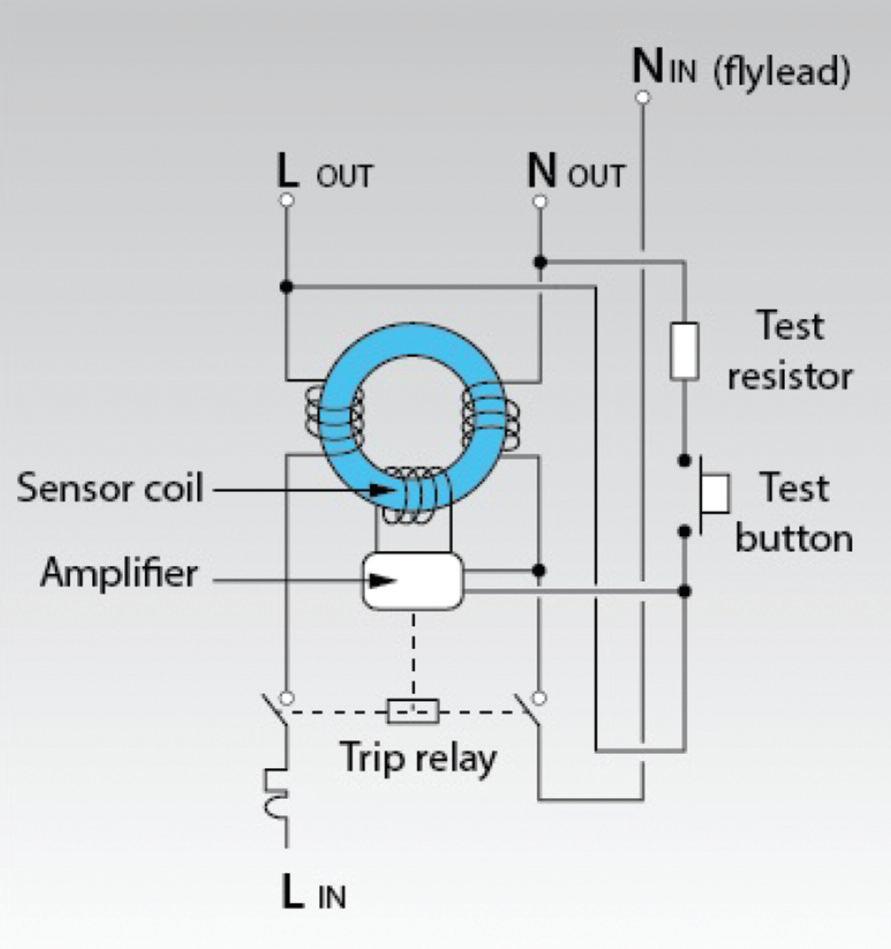

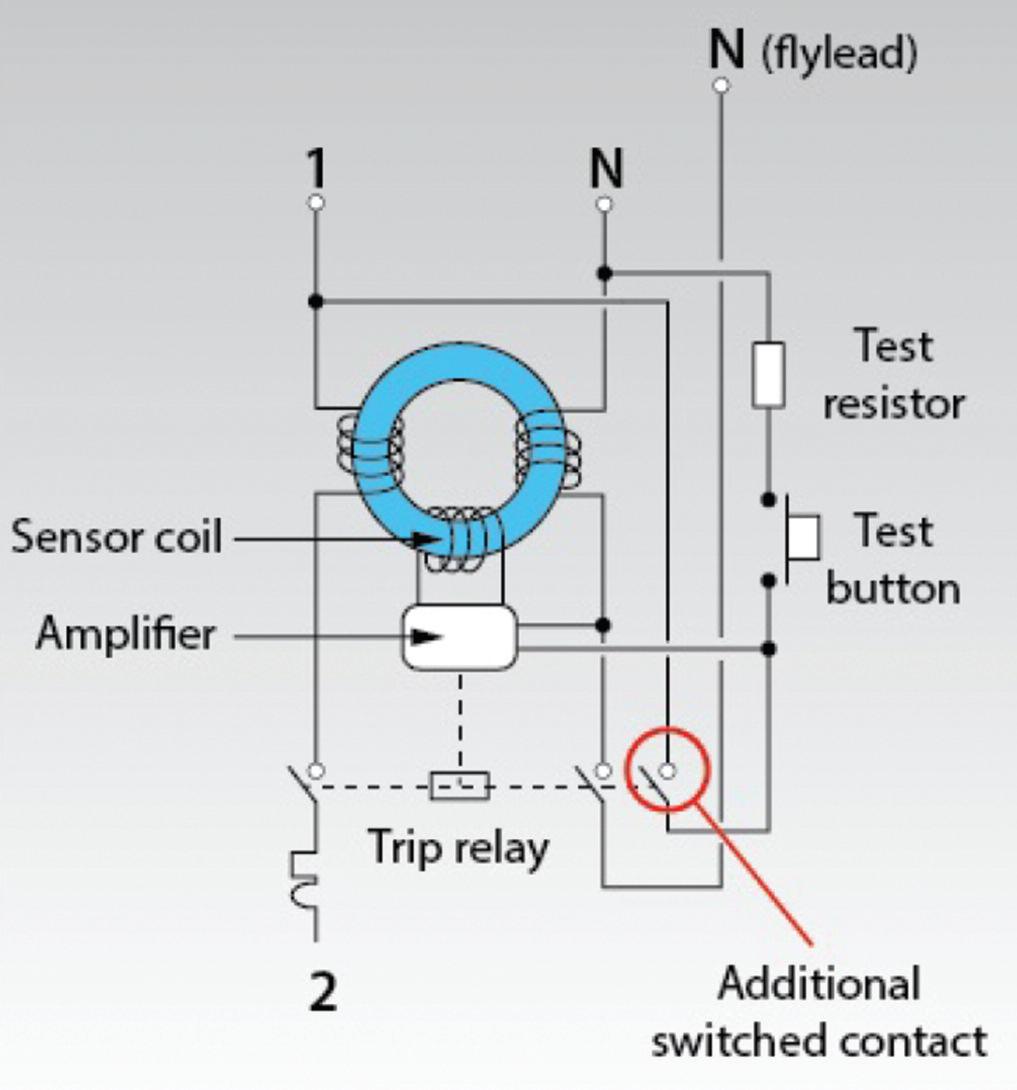

f you’re involved in regular installation of DC EV chargers, you’ll already be familiar with the significant differences between individual manufacturers’ performance characteristics and the impact on the supply-side equipment e.g. transient inrush current, harmonic distortion, leakage current, and associated RCD selection

Mode 4 guidance

It is not possible to give standardised recommendations for RCDs associated with Mode 4 chargers. But why?

Whilst there has been agreement for Mode 3 charging standards in Europe, with the publication of ENIEC 61851-1 2017, and the associated changes in section 722 BS 7671 2018, that is not the case with Mode 4 charging standards which are still coalescing.

DC charger design is far more complex due to the safety issues associated with high DC voltage/current This is reflected in the time taken to agree on a revision of BS ENIEC 61851-23 2014 – the current designated standard for DC charging, quoted in BS 7671.

For example, this early standard gives general design requirements but is light on standardised test methods for checking conformity This results in a wide variation in basic standardised performance characteristics between individual manufactures claiming compliance with a designated standard.

The current edition of BS 7671 (Oct 24) Clause 722 531 3 101 relating to RCD selection Note 2 states that: supplies using DC vehicle connectors to the BS EN 62196 series are under consideration.

Electrical safety design characteristics (the guts of the charger) may depend on the DC interface charging technology adopted by the vehicle manufacturer e g CHAdeMO (Japanese), GB/T (China), CCS 1 & 2 (North America & Europe), and Tesla (proprietary design NACS – based on North American standards).

Later versions of Tesla DC chargers were supplied with CCS 2 interface (compatibility with European EVs), but still NA electrical design standards

Use the basic principles of BS 6761 (clause 133.1, 134.1.1, and 531.3.3) to select appropriate RCDs, based on the individual chargepoint manufacturer’s characteristics and installation recommendations e g note minimum RCD characteristic requirements at the quotation stage *

* Clause 642 (Inspection): Refer to as an aid-memoire during installation planning/equipment verification.

Mode 4 chargers – general points

RCDs installed on the AC supply feeding the charger does not provide protection on the DC side of the charger. Electric shock and fault protection on the DC side is the responsibility of the chargepoint manufacturer: Conformity with the essential safety requirements is indicated by CE/UKCA Marking – see Clause 642 Refer to the chargepoint manufacturer’s installation instructions.

Inrush/transient currents

Depending on design and technology ed, equipment containing high ectifiers/inverters can produce ant transients during operation with the equipment manufacturer –may require transient resistant s, to prevent unwanted tripping necessary equipment downtime

This is the current that flows to earth during normal operation Leakage current values are specific to the manufacturer’s design and will vary as a function of the individual chargepoint harmonics, produced during various stages of charging and the supply quality (existing harmonic content)

The existing standard BS ENIEC 61851-23 sets minimum protective conductor requirements for Class 1 equipment, where touch currents exceed 3 5 mA Follow the manufacturer’s recommendations if they exceed the requirements of BS 7671 543 1 - 543 7

Unexplained RCD tripping may be the result of insufficient safety margin between the operational leakage current and the RCD sensitivity; note recommendations in 531 3 2 (ii)

Until recommendations are included in BS 7671-722, unless otherwise stated by the chargepoint manufacturer, only Type B RCDs (RCCB, RCBO, CBR) should be used upstream of Mode 4 chargepoints – see 531 3 3 (iv)

With any innovative technology the “state of the art” is an important concept to consider about the existing requirements of BS 7671 and installation advice provided by the equipment manufacturer Ask before acting and keep in mind the requirements of clause 133 1, 134 1 1 and 531 3 3

Steve Humphreys, Technical Commercial Manager

at

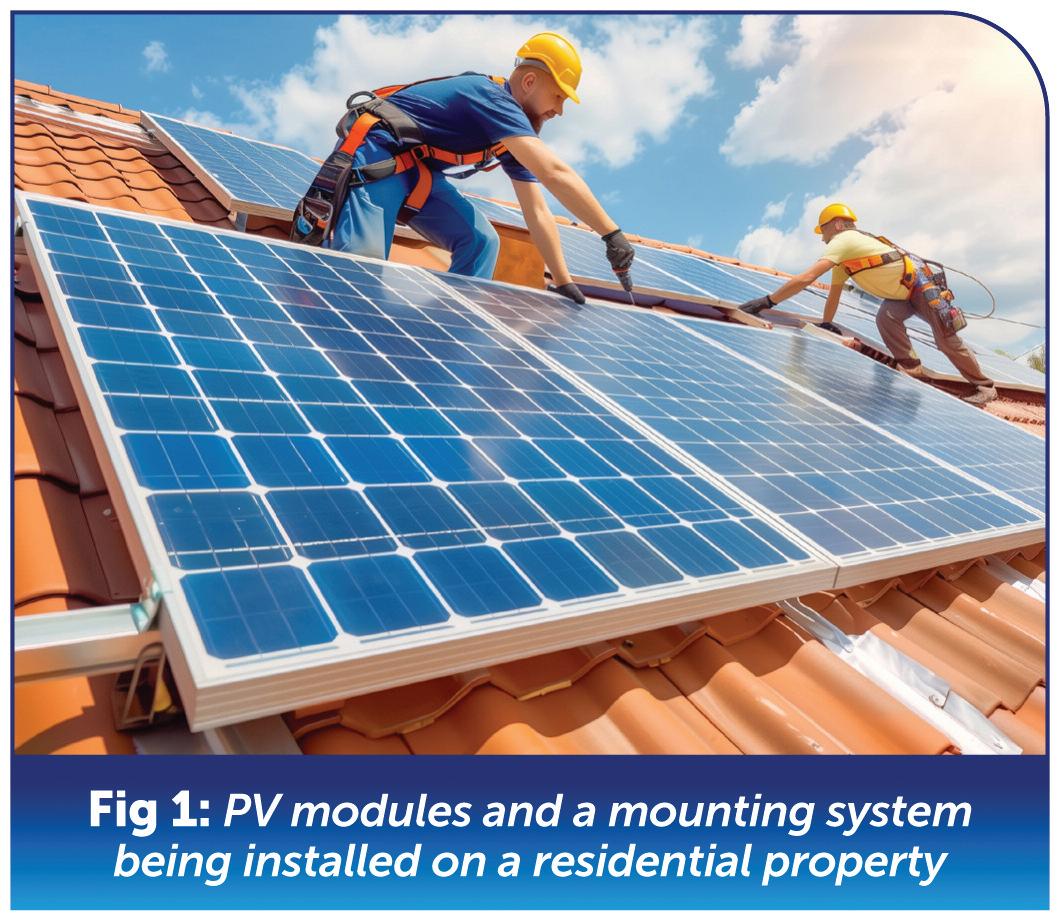

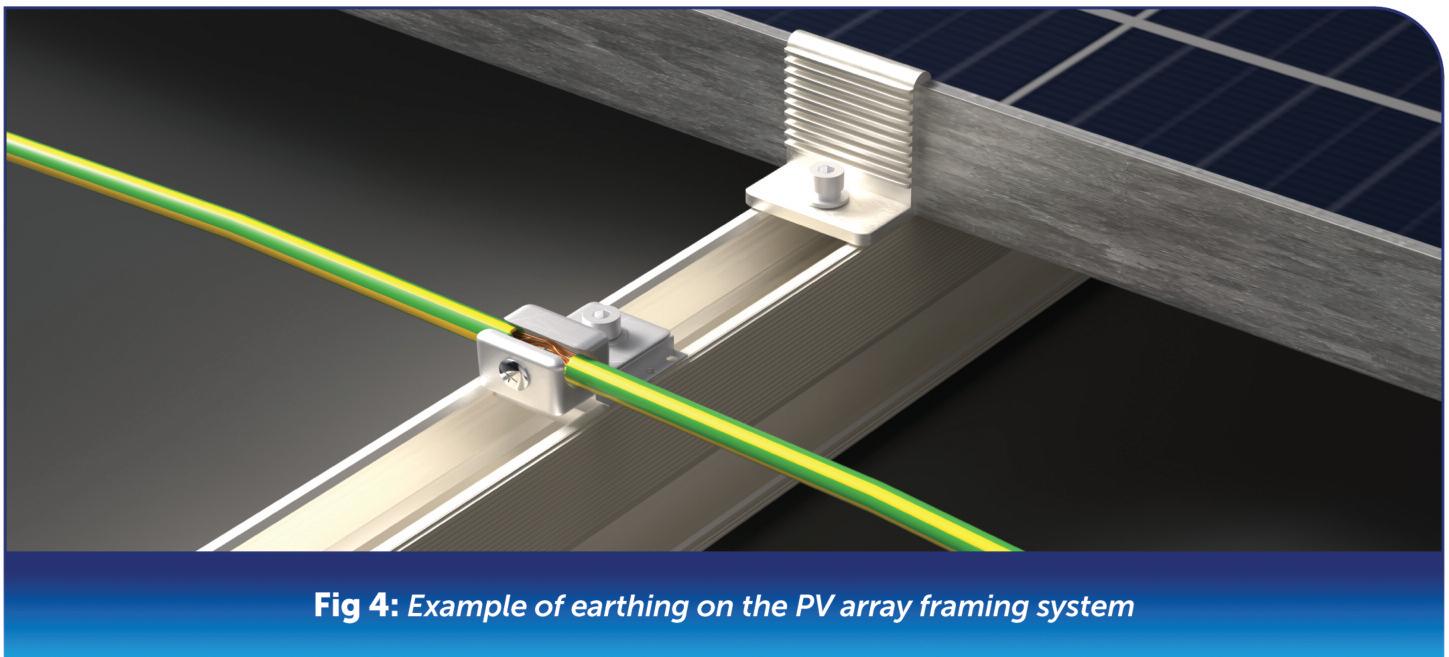

NAPIT, provides a guide on how to fix PV arrays to on-roof solar photovoltaics systems.

In this article, we will look at a simplified wind uplift calculation to determine how any fixings would be required for the array mounting system

One of the most important aspects of installing a solar photovoltaic (PV) system is the mounting of the PV array on the roof Fortunately, most modern domestic roofs can comfortably withstand the weight of a solar panel array The weight of a typical domestic array will be lower than the weight carrying capacity of the average roof

However, all roof structures should still be assessed by a professional If it can be seen that the roof components are in poor condition or that the property is very old, then guidance should be sought from a roofing professional or structural engineer

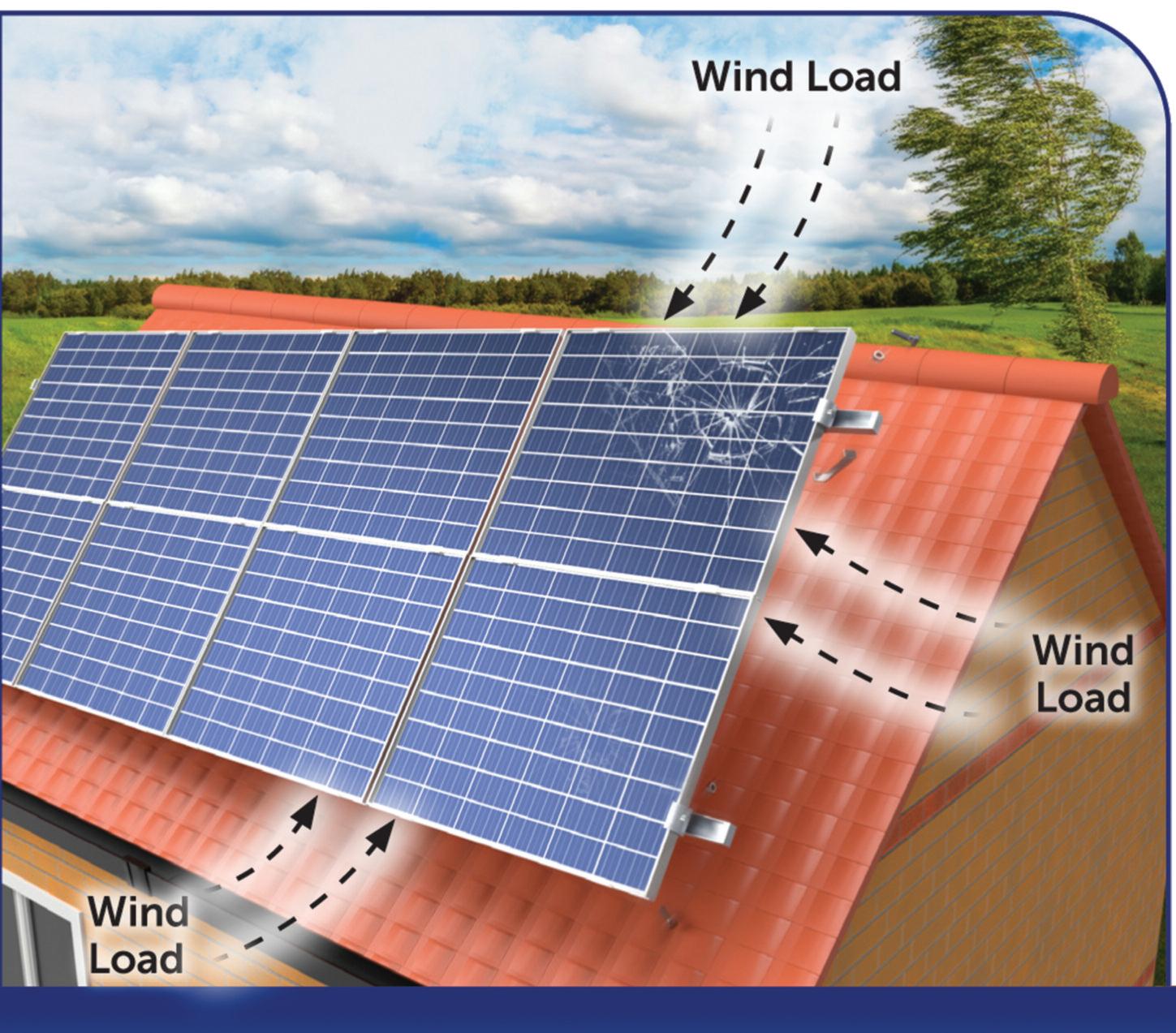

Wind load is more of a concern when mounting a PV array on a roof It can cause uplift when it makes its way between the roof and the solar panels, causing the panels to rise or break free, see Fig 1

Wind loads can vary significantly across the UK and is influenced by factors such as altitude, building height and local topography.

In areas where the panels are close to the roof edge, additional consideration should be given to the fixing points as the wind uplift will be greater there

There are various software applications available that can be

used to determine how many fixings are required, however, it’s important to understand the basis of wind uplift calculations

Wind Force (uplift) = Qp x A x Cp x SF

Where:

Qp is the peak velocity pressure

A is the area of module or array

Cp is the pressure coefficient

SF is the safety factor

Peak velocity pressure (Qp)

Peak velocity pressure is the maximum wind pressure that is to be expected at a particular location over a 50-year period.

The procedure for calculating peak velocity pressure is contained within BS EN 1991 Eurocode 1: Actions on structures, Parts 1-4: General actions - Wind Actions In order to determine the peak velocity pressure, we need to consider the following site-specific factors:

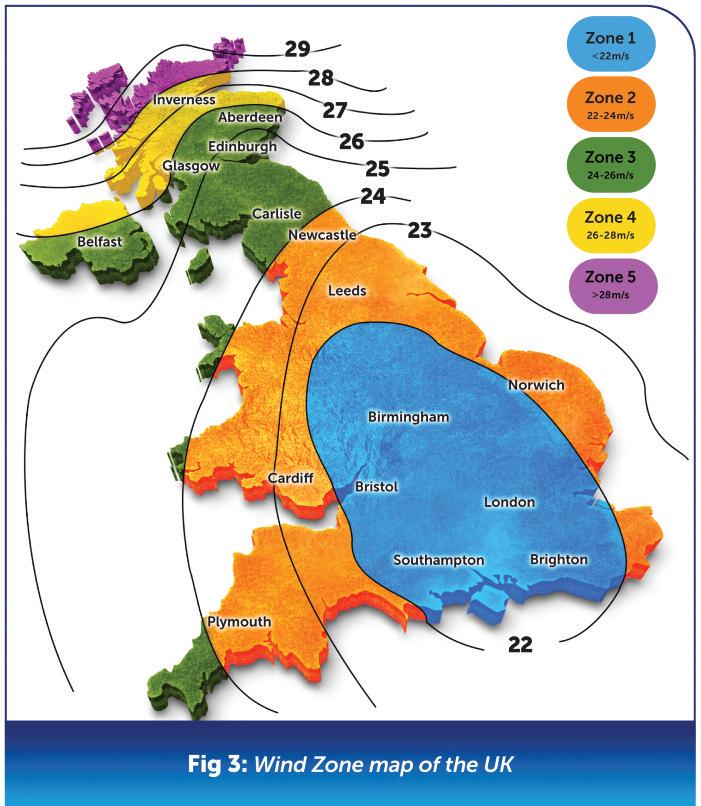

● Basic mean wind velocity (this can vary according to location and is taken from a map of the UK)

● Altitude correction factor (this accounts for the height above sea level)

● Reference height (the height of structure above ground level)

● Local terrain (the terrain type i e sea, town or country)

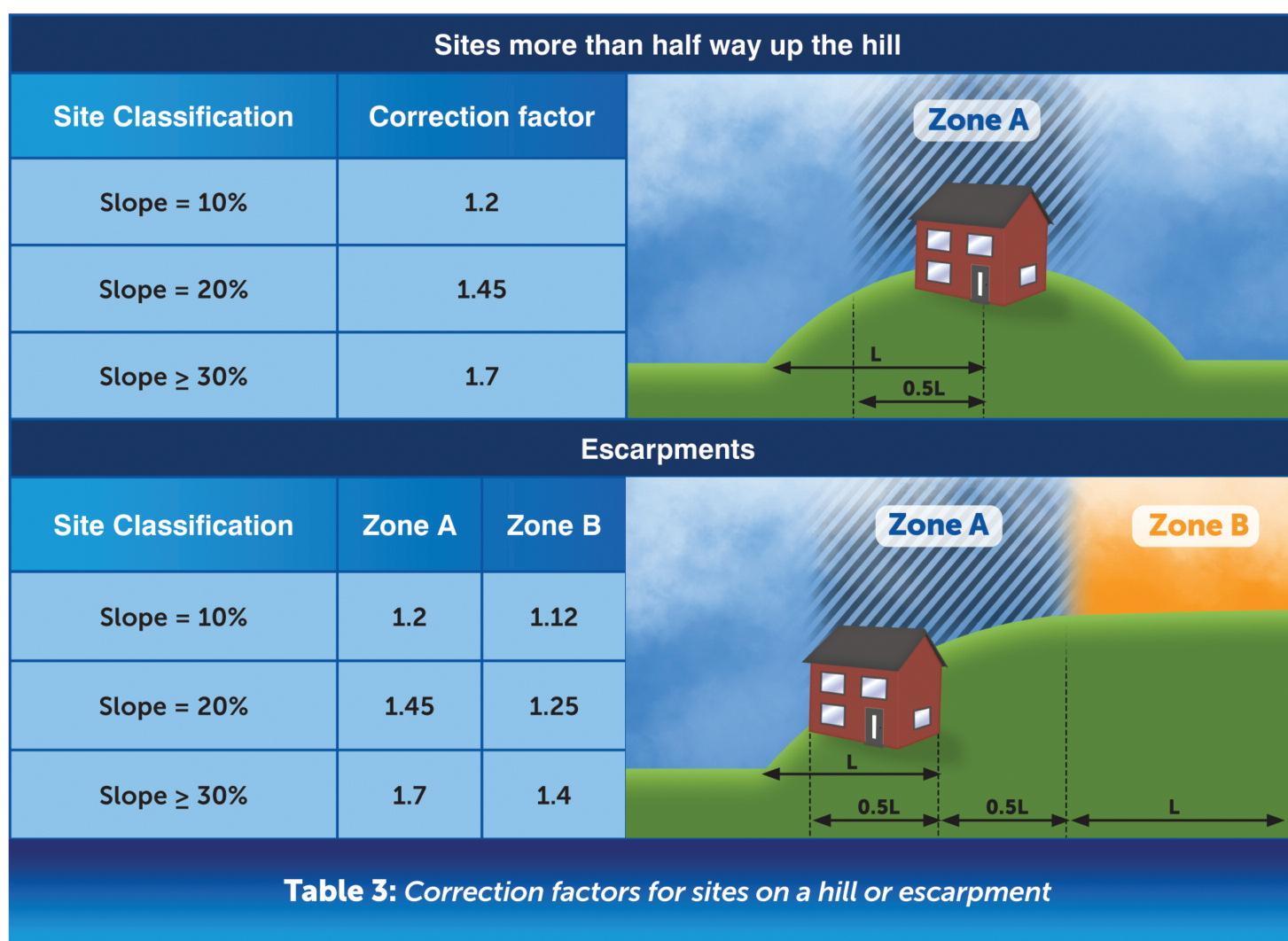

● Topography (this adds a correction factor where the site is on a hill or escarpment)

● Distance from the sea

Area of module or array (A)

This is quite simple to work out as the array size will be the metre square (m2) of one panel times the number of panels

Pressure coefficient (Cp)

The pressure coefficient is the external wind-induced pressure acting on the outside of the building, including the PV array.

“The pressure coefficient is the external wind-induced pressure acting on the outside of the building, including the PV array.”

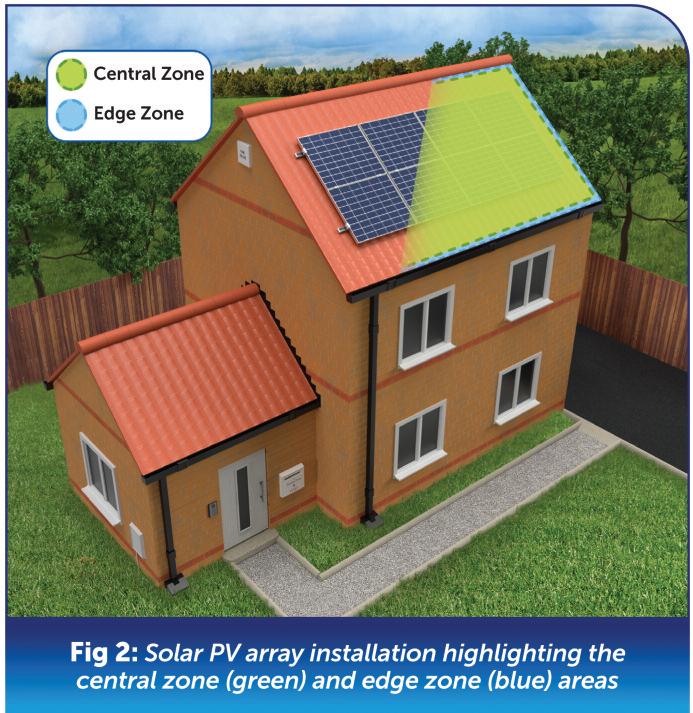

In general terms, for PV arrays that are installed in the ‘central zone’ of a Duopitch roof at an angle of 30˚ and has a gap of less than 200 mm from the underside of the array to the roof surface, a pressure coefficient of -0.5 can be used In contrast, for PV arrays installed in the ‘edge zone’ of a similar roof, a pressure coefficient of -0 6 is used, as displayed in Fig 2

Safety Factor (SF)

A safety factor should be applied to all

wind load calculations For PV systems mounted on roofs, a safety factor of 1 35 can be used

Let us now look at a worked example assuming the following scenario:

● An on-roof PV array installed in the ‘central zone’ of the roof

● The area of the array is 20 m2

● The array mounting is a rail and fixing bracket system with each fixing bracket having a rated capacity of 500 N

● The site is located in Birmingham, not on a hill, in urban terrain and is more than 20 km from the sea

● The altitude of the site (height above sea level) is 100 m

● The height of the building (from ground level to ridge height) is 10 m

First, we must determine the peak velocity pressure using a wind zone map for the UK, shown in Fig 3 Birmingham is located in Wind Zone 1, which has a value of 22 metres per second (m/s).

Our next step will be to determine the peak velocity pressure in the PV array by using the information provided in Table 1, along with the assumptions for the PV array

Peak velocity pressure (Qp) = 763 pascal (Pa)

The site altitude is not applicable to this e x a m p l e a s t h e s i t e i s 1 0 0 m e t r e s a b o v e sea level

In the case of sites located over 100 metres above sea level, the formula shown in Table 2 should be used to calculate the correction factor

To p o g r a p h y i s a l s o n o t a p p l i c a b l e i n t h i s example

If the site is on a hill or escarpment, the correction factor derived is shown in Table 3.

Let us now add all our values to the original formula:

Wind force (uplift) = Qp x A x Cp x SF

Qp is 763 Pa

A is 20 m2

Cp is -0 5 SF is 1.35

Therefore:

763 x 20 x -0.5 x 1.35 = 10,300.5 N or 10.30 kN

Finally, we need to establish the number of fixing brackets needed for the imposed total wind uplift force

● Total wind (uplift) force acting on array = 10,300.5 N

“Manufacturer’s instructions will give a maximum spacing between fixings and a maximum cantilever for the end fixings.”

● Each fixing brackets rated capacity = 500 N

Total wind (uplift) force acting on array/each fixing bracket having a rated capacity

10,300.5/500 = 20.6 so therefore at least 21 fixing brackets would be required

Conclusion

You can see from the wind uplift calculation, determining how many fixing brackets are needed for an on-roof mounted PV array can be complex. As mentioned earlier, software applications may be suitable when designing the PV array and mounting system

It’s also worth pointing out that the roof structure and the distance between the rafters will often dictate the location and number of fixing brackets used.

Manufacturer’s instructions will also play a large part in the spacing of fixing brackets

Manufacturer’s instructions will give a maximum spacing between fixings and a maximum cantilever for the end fixings Whatever method is used, it’s essential that the correct amount of fixings are used to prevent panels, the whole array, or the mounting system from breaking free

All of this information and more is available from the latest NAPIT publication: Practical Guide: Solar Photovoltaic Systems, available for pre-order at NAPIT Direct

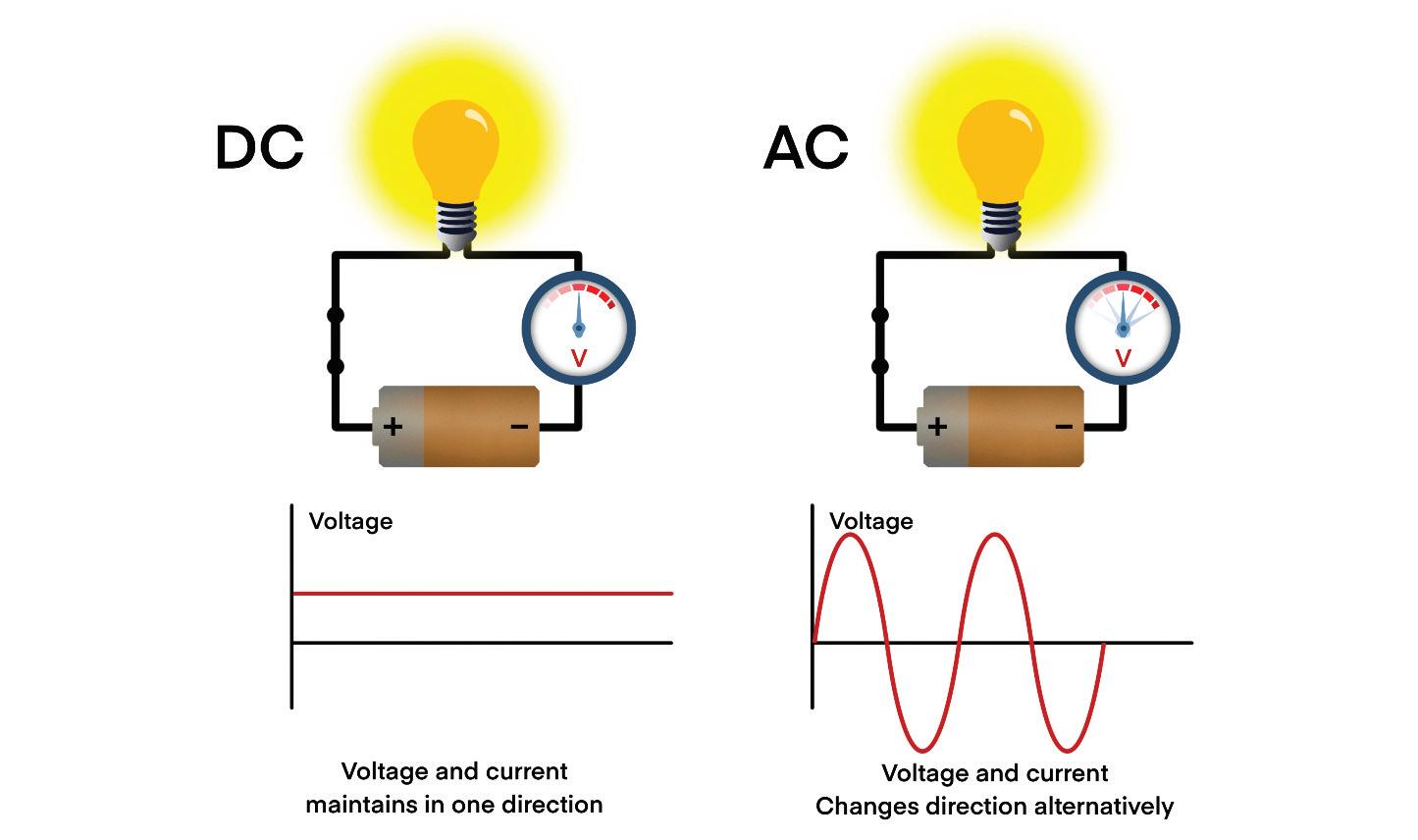

The majority of electricians, whilst familiar with the principles of direct current, are lacking in actual experience of working with DC circuits This is largely due to public low voltage supplies being 230/400 V AC

However, with the proliferation of photovoltaic systems, rectifiers, wind turbines, electrical energy storage systems and electric vehicle chargers, which utilise direct current, perhaps it’s time to brush up on your knowledge so that you can be safe at work and not fall foul of Regulation 16 of the Electricity at Work Regulations 1989 which states:

“No person shall be engaged in any work activity where technical knowledge or experience is necessary to prevent danger or, where appropriate, injury, unless he possesses such knowledge or experience, or is under such degree of supervision as may be appropriate having regard to the nature of the work ”

I hope this article will provide you with some food for thought and encourage you to explore the topic further

Isolation and earthing considerations DC supplies may or may not be earthed If you intend to operate an earthed DC system independent of the AC supply you must ensure the means of earthing continues to function by meeting the requirements of BS 7671 551 Low Voltage Generating Sets. Regardless of earthing, where DC supplies operate in the absence of an AC supply, steps must be taken to ensure that energised parts of the system can be isolated and that users, maintenance staff and emergency workers are able to safely isolate the DC system.

Alternating current rises and falls meaning that the current is zero Amps 100 times a second for a 50 Hz supply and subsequently arcs are more quickly extinguished. You can sometimes see an arc when switching a load (such as an immersion heater) as a faint flash of light through the side of the switch

Direct current does not pass through zero and can draw a significant arc for longer periods of time over larger distances than similar voltages of alternating current

When selecting switchgear it is essential that DC rated equipment is selected since the mechanisms are designed to operate more quickly and may have larger more robust parts. Often AC and DC switchgear appears to be the same product but closer

“Both AC and DC supplies have the capacity to kill, so it’s important to treat it with the respect it deserves.”

inspection will reveal that DC components are rated for lower voltages and current Switches are often linked-out too, effectively doubling the switch gap by utilising two switches in series

The removal of fuses and disconnection of plug and socket connectors can result in damage Loads should be removed and proved dead before attempting to disconnect.

A good DC clamp meter (preferably one with a flexible loop to permit access

in tight areas) will be useful With some equipment you may need to leave time for capacitors to become safe or discharge them in line with manufacturer instructions.

When selecting protective devices it’s important to confirm if the British Standard of the device selected covers DC and, where it can be utilised in AC and DC systems, take note of the voltage range which will be lower for DC than AC

Table 51 of BS 7671 provides a list of colours used in DC systems but it is recommended to label DC cables throughout their length and segregate them from AC cables when run in containment.

Electrolytic corrosion is a process which occurs when metals in building structures are in contact with the ground

When current flows in one direction it can cause the metal work to be oxidised (corroded) which may lead to premature failure It is often hidden, given that the reaction is in the ground

Electricians working in the rail sector will be all too familiar with this issue where large DC currents are present, but the rest of us might be less so.

Both AC and DC supplies have the capacity to kill so it’s important to treat it with the respect it deserves

If you’re unfamiliar with DC supplies a good starting point to help you with understanding more about the subject would be the IET’s Technical Briefing –Practical considerations for d c installations – available for free through the link below

LEARN MORE ABOUT ARENA TRAINING’S COURSES AT:

In this article the experts at Fluke discuss the importance of the arc flash boundary and the ways in which professionals can better ensure that arc flash incidents are kept to a minimum.

The arc flash boundary is the minimum “safe” distance from exposed energised conductors or circuit parts that has the potential for an arc flash.

Arc fault incidents happen daily around the world As such, you should take the proper steps to ensure your safety before taking any measurements, especially on energised equipment Knowing where the arc flash boundaries are is vitally important, so keep these top safety measures in mind

The National Fire Protection Association (NFPA) recommends defining three boundaries to minimise risk of electrical injuries Part of NFPA 70E highlights what each boundary is and how to determine where to place it. It breaks down to basically be, as you move closer to the exposed and live equipment, the more training and higher levels of personal protective equipment (PPE) you need

Arc flash boundary

The arc flash boundary, or restricted

approach boundary, changes depending on the potential arc flash hazard

The arc flash boundary is calculated to 1 2 calories/cm2 of incident energy That’s the distance where a worker without appropriate PPE would receive second-degree burns

Sometimes this boundary is the furthest one from the exposed equipment, other times the limited approach boundary is the furthest out When the arc flash boundary is the furthest away, it becomes the line no one should pass without training and PPE If the limited approach boundary is further out, then that should be treated as the line no one should pass without training and PPE

approach boundary

Moving toward the energised and exposed equipment, you’ll find the limited approach boundary Within this boundary, it is still possible to be exposed to a shock hazard Appropriate PPE should be worn by qualified workers in the limited space (space between the limited approach

boundary and the restricted boundary) Non-qualified workers should stay outside of this boundary unless wearing proper PPE and being escorted by a worker with specialised training.

Restricted boundary

The area closest to the live, exposed equipment is within the restricted boundary In order to pass this boundary, you must be a qualified worker with the proper training and PPE. If you need to perform work on the energised equipment, you may also need a work permit and documentation

Equipment considerations

Work on de-energised equipment

It’s the only way to eliminate hazards

Follow the lockout/tagout procedures and, whenever possible, take measurements while the system is de-energised Be sure to test for absence of voltage before conducting any tests without the necessary PPE. Until absence of voltage

testing proves the circuits are dead, they must be considered energised

Inspect equipment regularly

You can catch some wear and tear before it becomes a problem by regularly inspecting your equipment

Knowing the history of your equipment and what a normal reading looks like can help you identify abnormalities Gather baseline readings by inspecting critical components like electrical connections, insulation and circuit breakers

Checking the equipment regularly using condition monitoring tools or IR windows can also help you catch an issue before it’s too far down the road Knowing the machine’s health history means you can take any necessary corrective actions at the right time

Test instruments must go through standardised testing in order to meet safety requirements The CAT and voltage ratings listed on the test instrument and any accessories also need to match or exceed the electrical environment where you will use them

Look for tools that meet IEC standards with an independent lab testing verifying

it The lab’s symbol on the tool means an independent testing agency has checked the safety claims and CAT ratings and the test instrument passed

Test tool condition

Be sure you’re not using tools or accessories that are outdated or defective While your digital multimeter should last for a long time, it can still break or wear down eventually Accessories and smaller test instruments should be replaced more regularly Test leads, temperature probes and fuses, for example, won’t work accurately forever

Inspect any test instruments before you use them Look for any extra wear and tear, cracks, fraying or insulation showing. Make sure any connections are secure And, use the live-dead-live testing method to ensure your instruments are working properly before and after taking a measurement The live-dead-live testing method requires testing the functionality of your equipment on a known voltage source before and after taking a measurement

Stay out of the arc flash boundary

There’s no need to put yourself in an arc blast zone if you don’t need to be. Products like remote display, wireless and

non-contact tools can help put you further away from danger or let you take readings on an energised part without making contact They include:

● Non-contact voltage detectors or electrical testers

● Non-contact infrared thermometers

● Infrared cameras

● Remote display multimeters

Arc flash vs arc blast

Following these safety guidelines will help you stay safe in the event of an arc fault, but it’s important to also understand the ‘how’ and ‘what’ How is an arc fault caused and what is the difference between arc flash and arc blast?

Check out the link at the bottom of the page to get the full explanation

CLAIM YOUR CERTIFICATE!

SCAN THE QR CODE TO CLAIM YOUR CPD CREDIT FOR THIS SECTION OR VISIT: WWW.RDR.LINK/ EBJ015

VISIT THE ARC FLASH VS ARC BLAST EXPLANATION PAGE AT: WWW.RDR.LINK/EBJ016

GET MORE DETAILS ABOUT FLUKE’S RANGE OF TEST EQUIPMENT AT: WWW.RDR.LINK/EBJ017

While we need good outdoor lighting for safety, for work or to simply enjoy an outdoor meal on a warm summer’s evening, light pollution can be a problem As such, if you’re installing external lighting, you must ensure you get it right to meet most councils’ DarkSky initiatives

One thing you should always do is to take step back from the project that you’re lighting and consider the impact it will have on the surrounding areas and the darkness of the night sky The opening question you should always ask is whether your customer actually needs the lighting in the first place.

Direct the light

If the answer is “yes”, you should only light the area that needs it This means that the luminaire should have hoods or shielding so that you can target its direction to ensure there is no light spillage causing glare Think about the beam angle that you’re using and what you’re lighting

Where you can use wall lights, don’t mount them too high above the area you’re lighting as this will give a steep tilt angle that can cause unwanted light pollution If you do use uplights ensure that you direct the light and contain it to the area that you’re lighting Luminaires with asymmetric beams will focus the light in one direction, making it easier to achieve this.

Mitchell Waite, Product Manager at Collingwood Lighting, looks at how to nstall external lighting to avoid light pollution and meet many councils’ DarkSky policies.

Avoid upward light spill

The glow that we see at night from artificial lighting is due to unwanted light spilling upwards and away from its intended area

Where you’re using a wall light always

check its upward light output ratio (ULOR), which is the percentage of light that it emits above the horizontal plane For DarkSky approval it should have a ULOR of less than 0 5% or 50 lumens

Well-designed fittings will have high quality optics so that you can accurately direct the light where you need it, whether that’s downwards or focussed on the object that you’re lighting with minimal or no spillage

The DarkSky initiative also specifies that you should keep lux levels low where possible and to not use overly bright lights The illuminance needed will depend on what the lighting is for, and you will need to refer to appropriate standards for each situation.

In addition to controlling where the light goes, your customer should only have it on when they really need it And, on occasions when usage is low, it should be dimmed to reduce the light and save energy.

Implementing control scenarios is far simpler for LED lighting than, for example, metal halide lamps that are in many older installations While the former are easily dimmed, the latter can only dim down to 50% of their rated power. In addition, LED lighting will switch on and off immediately in response to timers, or PIR sensors, whereas metal halide sources are slow to turn on

The correlated colour temperature (CCT) also matters. DarkSky requirements are for a CCT of 3000K or warmer because this is less likely to scatter in the atmosphere than higher colour temperatures that have short-wavelength ‘blueish’ light

This is particularly important for nocturnal animals and insects. If, for example, bats are known or suspected to be in the area then the amount of upward light spillage, particularly the blue light content of higher CCT values, can affect their circadian rhythms

In general, you should assess how much

light the fitting produces relative to the amount needed for the task LED lighting produces more lumens per watt than other sources, so they’re more energy efficient Some are more efficient than others so it’s worth checking the lumen output of a fitting rather than just its wattage LED luminaires also have a long life, so they will not need replacing as often and some have replaceable parts so your customer will not always need to install a new fitting LED lighting provides a sustainable option and, if you pick the right fittings, they’ll enable you to meet the DarkSky commitments of many local councils

In conclusion, as the Institute of Lighting Professionals Guidance Note 1 for the reduction of obtrusive light states: make sure that you install ‘the right light in the right place at the right time, under the right control ’

The aim of this article from the experts at NICEIC is to look at overcurrent; and, in particular, short-circuit current, and how the requirements of BS 7671 are applied. The adiabatic equation given in regulations 434.5.2 and 543.1.3 will be introduced and used within a typical example to indicate its application within short-circuit current analysis.

The different types of current that can lead to an overcurrent occurring in a circuit are shown in the block diagram of Fig 1

Fault current

Fault-current consists of two types of fault, as shown in Fig 1 – earth faults and short-circuits

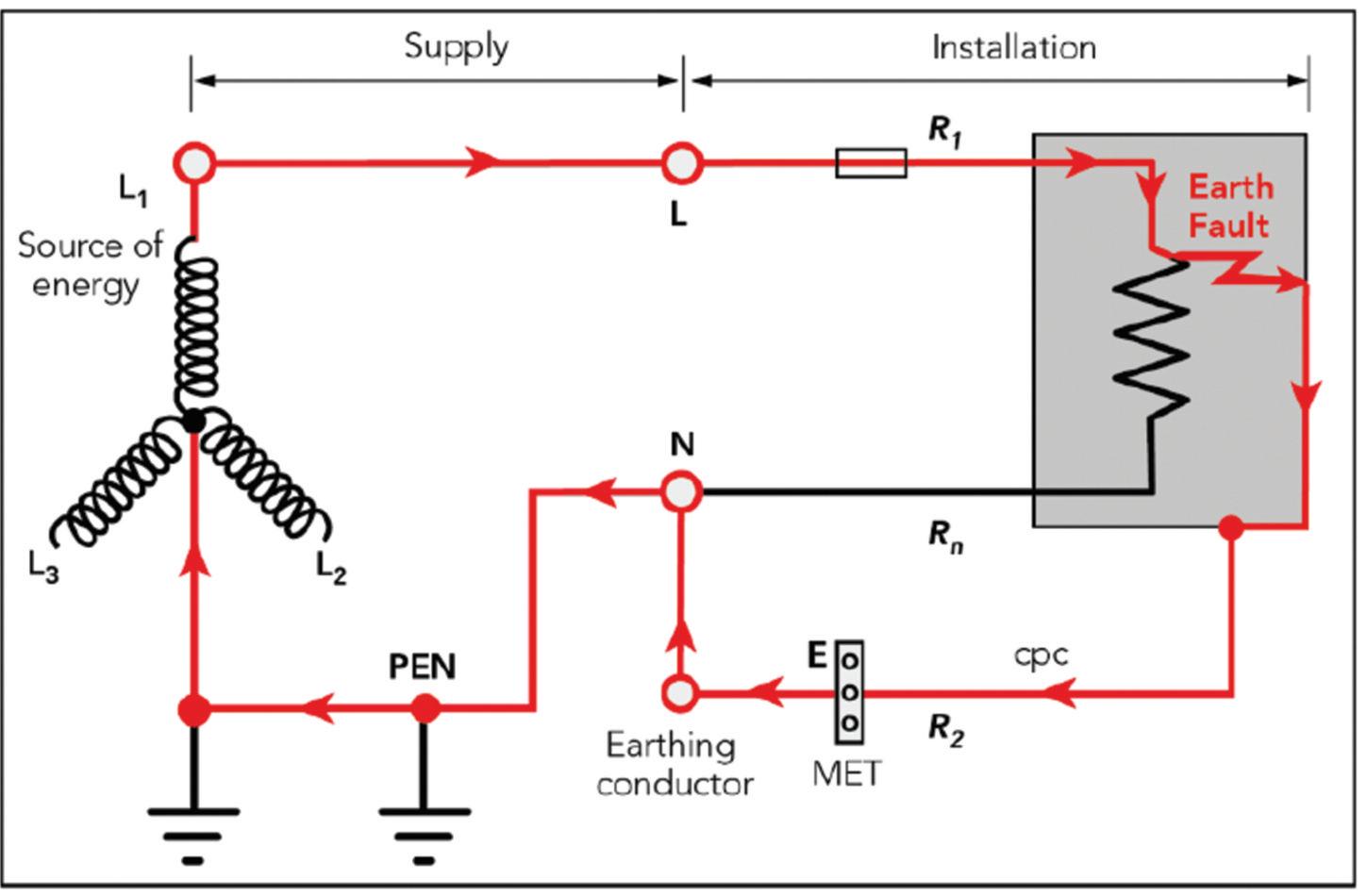

● Earth fault currents flow when there is fault between a live conductor and earth as shown in Fig 2a.

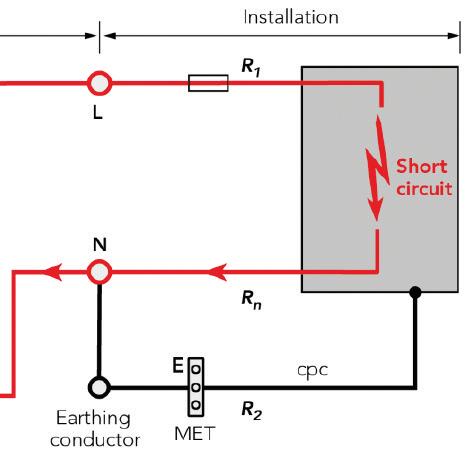

● A short-circuit current flows as a result of a fault between live conductors, for

example line-to-line or line-to-neutral, as shown in Fig 2b

The anticipated fault current in such a circuit is called the prospective fault current (Ipf).

This article will only consider short-circuit currents between live conductors

Short-circuit current

The short-circuit loop is indicated by the red line in Fig 2b. Because of the higher

values of current typically associated with short-circuit conditions, care must be taken when selecting appropriate switchgear and protective devices

Regulation 434 5 1 requires that the rated short-circuit breaking capacity of each circuit protective device shall normally not be less than the maximum prospective fault current at the point at which the device is installed

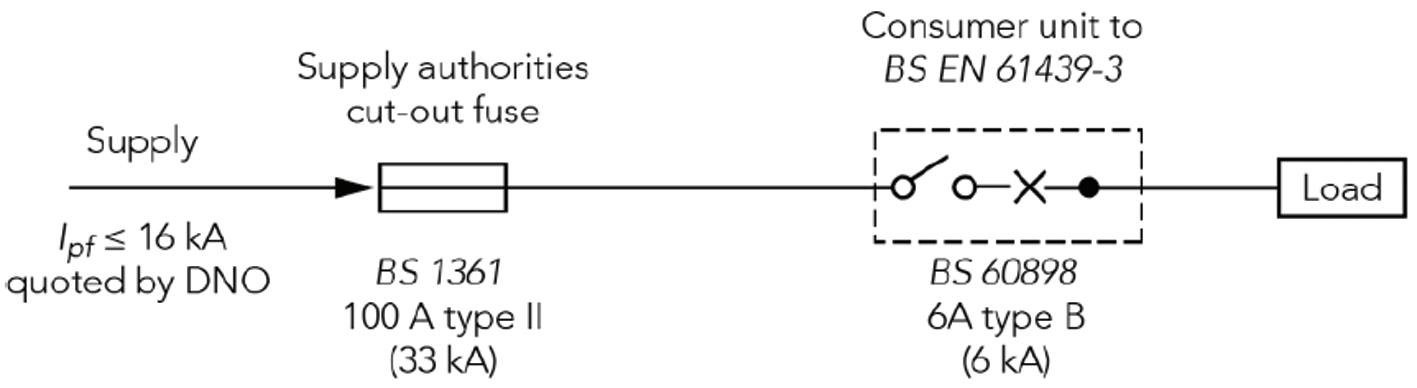

However, a protective device having a lower breaking capacity is permitted if another protective device having the necessary rated short-circuit breaking capacity is installed on the supply side, as shown in Fig 3.

In this situation, the characteristics of the devices shall be co-ordinated so that the energy let-through of these devices does not exceed that which can be withstood, without damage, by the device(s) on the load side

In domestic (household) or similar premises, where a consumer unit to BS EN 61439-3 is used and the maximum prospective fault current

“The thermal withstand of the cable must be greater than or equal to the let-through energy of the protective device.”

declared by the distributor is 16 kA, it is not necessary to measure or calculate prospective fault current at the origin of the supply

This specific conditional short-circuit rating applies when using an upstream BS 88-3 (formerly BS 1361 type II) fuse-link with a maximum 16 kA PSCC at the service cut-out and not at the consumer unit

The relationship between the protective device and the cable

While regulation 434 5 1 typically relates to a protective device and its ability to withstand the effects of the maximum prospective fault current, regulation 434 5 2 is concerned with limiting the heat that will be added to the current-carrying conductor while such a fault exists

For any applicable disconnection time the maximum energy withstand of the cable must be equal to or greater than the let-through energy of the protective device Where this is not the case, there is the risk that under fault conditions the insulation may suffer thermal damage

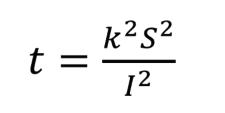

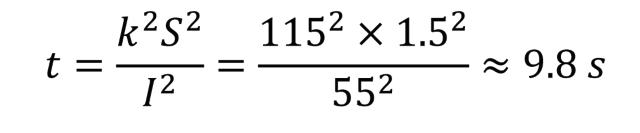

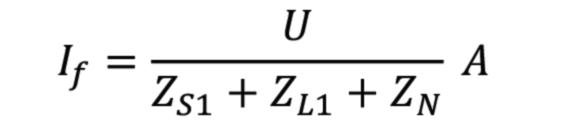

The time (t), in which a given fault current will raise the live conductors from the highest permissible temperature in normal duty to the limiting temperature, can, as an approximation, be calculated from the

adiabatic equation given in regulation 434.5.2:

It should be remembered that an earth fault has a maximum disconnection time of 5 s for TN systems (411 3 2 3) However, there is no such limitation on time given in regulation 434 5 2 for short-circuit currents Nevertheless, a check must be made to ensure that the protective device operates before the cable becomes damaged

Transposing the equation further to express the terms of the thermal relationship gives:

k2S2 = I2t

On one side is the thermal withstand of the cable k2S2 and on the other side is the let-through energy I2t of the protective device The maximum thermal withstand of the cable depends on its cross-sectional area S, and k, which is a factor that takes account of the material properties of conductors and insulation

As mentioned previously, the thermal withstand of the cable must be greater than or equal to the let-through energy of the protective device therefore, k2S2≥ I2t

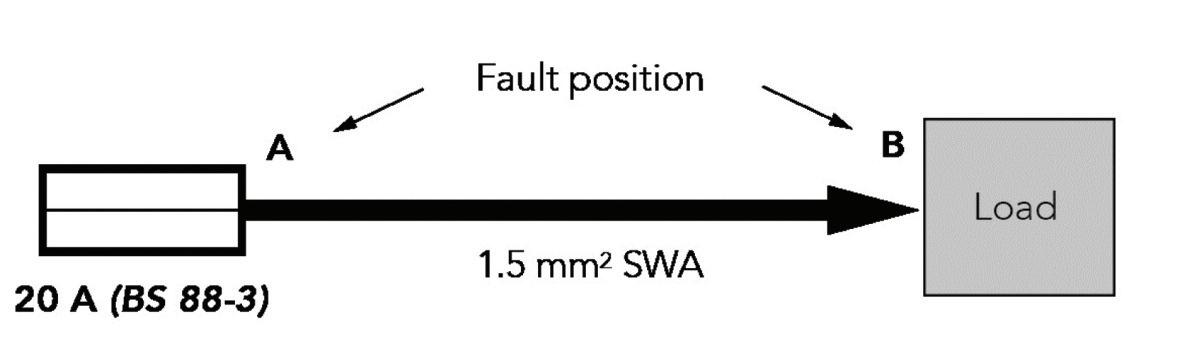

To illustrate the effects of a short-circuit occurring on a cable supplying a load, and referring to Fig 4, consider a fault occurring at position B, which due to a loose connection has some additional impedance If the total impedance of the line-neutral loop is 4 Ω, what effect will this have upon the circuit cable?

The circuit has been installed using a two-core 1.5 mm2 steel-wire armoured cable having copper conductors with 70°C thermoplastic insulation It is protected by a BS 88-3 fuse system C, rated at 20 A

“The two values of prospective fault current calculated highlight the condition that the most onerous situation arises when the short-circuit current is relatively low, such as at Position B.”

Under no-fault conditions, the line-neutral loop impedance values at the supply and load can be taken as 0 28 Ω and 0 62 Ω respectively The effects of voltage drop at the load have been ignored

The application of the regulations of Chapter 43 shall take into account both the minimum and maximum fault current conditions; so that the highest energy let-through is considered (533 3)

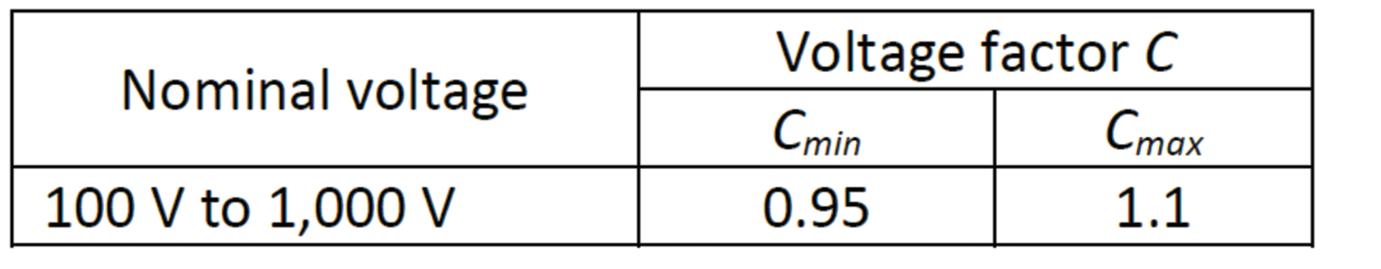

Regulations 411 4 4 and 411 5 4 incorporate a voltage factor into the equations given This voltage factor C takes account of voltage variations depending on time and place, changing of transformer taps and other considerations The voltage factor C is not intended to take into account any fault impedance

The values of C for a low voltage installation are given in Table 1, and are reproduced from Table 7 of

PD CLC/TR 50480: 20111 Determination of cross-sectional area of conductors and selection of protective devices.

The voltage factor used is dependent upon what is being considered For example, when estimating maximum fault currents, Cmax is applied When determining maximum disconnection times, Cmin is used.

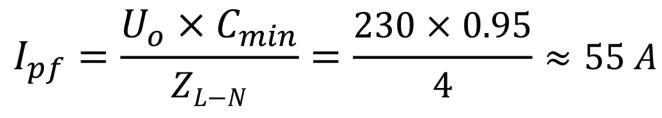

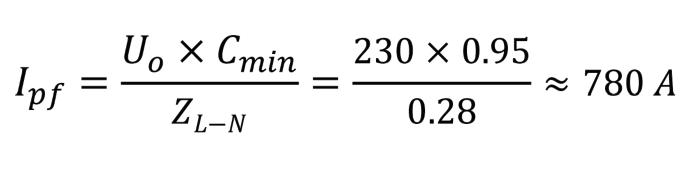

The prospective fault current at position B will be:

From Fig 3A1 of BS 7671, the disconnection time for the protective device is approximately 25 seconds What will be the maximum time the cable can withstand this level of fault current?

Using Table 43 1, the value of k for 70° thermoplastic insulated copper conductors is 115

The calculations show that the cable will certainly suffer some degradation as the disconnection time exceeds the time limit at which the cable can withstand the fault current

The prospective fault current at position A:

From Fig 3A1, the disconnection of the protective device occurs in a time less than 0.1 seconds, therefore the cable

will not be exposed to damage, and the fault current is within the rated breaking capacity of the device.

The two values of prospective fault current calculated highlight the condition that the most onerous situation arises when the short-circuit current is relatively low, such as at position B

Summary

This article has considered fault current and in particular focused on the effects of a short-circuit fault occurring between two live conductors

In the example given, the adiabatic equation was used to illustrate the effects and possible damage that may occur to a cable during a short-circuit fault

As such, for any relevant disconnection time, and to prevent thermal damage to the cable insulation during a fault, the maximum energy withstand of the cable must be equal to or greater than the let-through energy of the protective device

“The application of the regulations of Chapter 43 shall take into account both the minimum and maximum fault current conditions; so that the highest energy let-through is considered (533.3).”

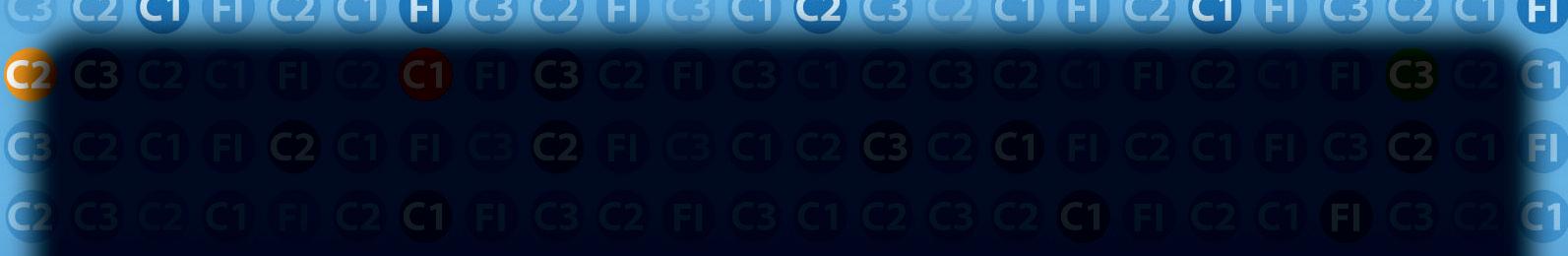

A periodic inspection and testing of an electrical installation is subject to limitations, within Section D of an EICR, where concealed cables in the fabric and containment have not been inspec ted

With this type of installation, it may not be obvious or may not be considered to investigate the external parts of the property to inspect any accessories or wiring systems This setup would appear to be for a ‘smar t ’ television installation where power, HDM i and data cables are needed at the rear of the T V, so the client would not appreciate internal room concealment or sur face containment.

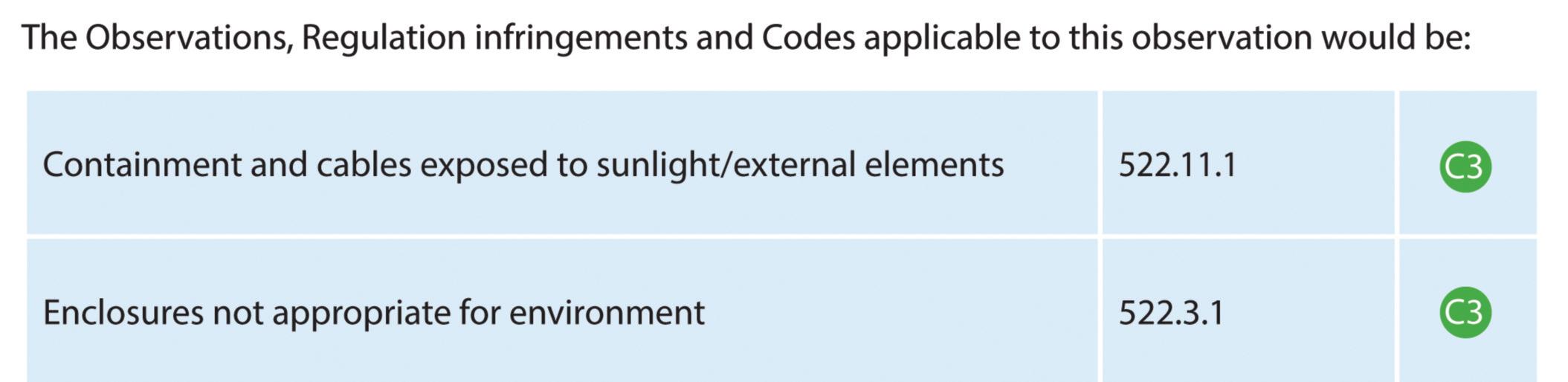

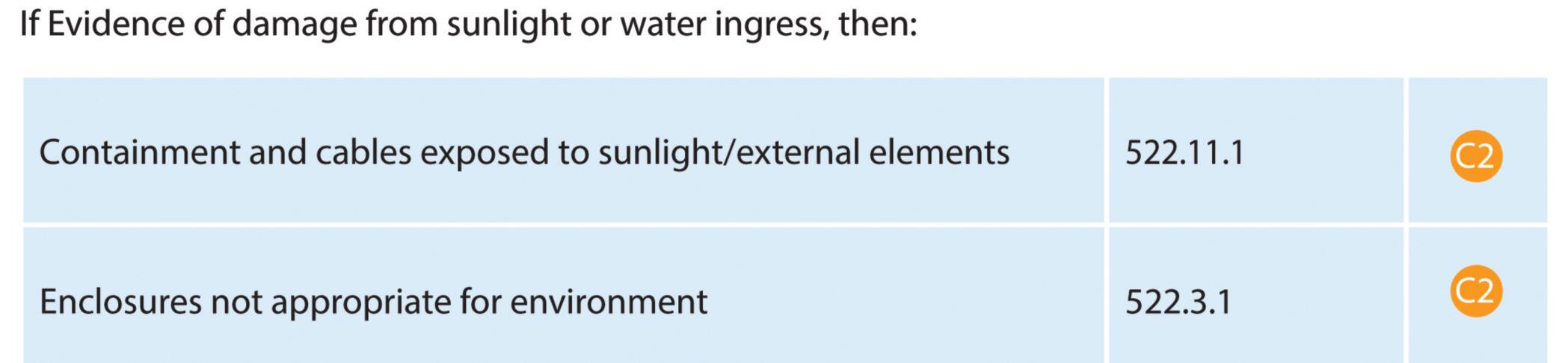

The solution installed has several issues:

● M ini trunk ing is not designed for ex terior installation with no IP, Ultraviolet protec tion

● The sur face pattress boxes with blank plate gain are not designed for this use

● There is a lack of mechanical protec tion especially with access to bins, and evidence of damage to the pattress boxes

● Potential clash with band I and II cables.

There’s also an additional cabling installation, in the top right of the image, for an upstairs room with lack of protection for the cables

There’s a risk of ingress of moisture into the internal elec trical accessories due to the incorrec t installation methods, and this would include cables passing through the cavity void which may include some form of insulation material which can affect the cable rating or the insulation Care must be taken when the periodic inspection is carried out, as in the summer the evidence of water ingress may not be present

Therefore, the classification code would be a C3, Improvement recommended unless there was evidence of moisture within the internal accessories or back boxes In the latter case it would attrac t a C2, Potentially dangerous urgent remedial action required

Updated for BS 7671:2018+A2:2022, NAPIT ’s EICR Codebreakers publication is purpose -written to aid contractors, inspectors and clients, and now includes updates to align with Amendment 2 of the IE T 18th Edition Wiring Regulations The book is the per fect technical aid for electrical professionals and their customers.

Need help with cracking those all-impor tant EICR codes? Ever y month the technical team at NAPIT will be studying your latest ‘Caught on Camera’ photos and offering advice on the next steps, should you find a similar installation. If you want the team at NAPIT to help crack your codes then send your pic tures through to us at: pe@hamer ville.co.uk

WILLIAM M CULLE TON:

T H

BS 7671 covers installations within the UK and some other jur isdic tions, unfor tunately D ublin does not fall under the requirements, therefore would not be subjec t to an Elec tr ical I nstallation Condition R epor t

The requirements in I reland fall under National Rules for Elec tr ical I nstallations E T101, where the ter m for the repor t remains as a Per iodic I nspec tion R epor t and has four obser vation numbers:

1. R equires urgent attention

2. R equires improvements

3. R equires some attention.

4. D oes not comply with the cur rent National Rules for Elec tr ical I nstallations

Although this installation would not be covered by an EICR, we will consider it as if it was

A socket- outlet has been installed at a high level, without any means of secur ing to the building struc ture This may not attrac t attention, although depending on what it has been installed for, it can present a danger to those using it

I t could be used for festive or celebration per iods for decorative lighting, which would involve staff plugging into an unsecured socket- outlet. This could place strain on the cables, ter minations and any equipment plugged into the socket- outlet

Therefore, the classification code would be a C 3, Im p rove me n t re com me n de d unless there was evidence of damage or loose connec tions to the socket- outlet or back box. I n that case it would attrac t a C2 , Po te ntia ll y d an g e ro u s urg en t re med ia l a c t io n req u i re d

The A2:2022 18th Edition Codebreakers publication is priced at £22.00 (members) and £24.00 (non-members). It is available in both hard copy and digital versions * Price is VAT exempt and excludes postage and packaging.

The Building Safety Act 2022 has introduced significant changes and responsibilities for the construction and maintenance industries. Clare Klug, Product Marketing Manager at Trimble Luckins, looks at how to manage product information for safer buildings.

The construction industry has long-since focused on health and safety practices on-site but the Building Safety Act 2022 shifts the mandate by stretching the responsibility to serve all those occupants of the building throughout its lifespan

A key focus of the Act is now the management of product information, which is deemed critical for ensuring safety and compliance throughout the lifecycle of a building The Act underscores the importance of accurate documentation, traceability, and accountability across the supply chain – from manufacturers to building owners As such, effective product information management is now essential for meeting these new regulatory standards.

With additional scrutiny on safety and information, one of the fundamental requirements of the Act is the need for precise documentation and thorough record-keeping The safety and compliance of a building depends on reliable and up-to-date information about the products used during construction and maintenance.

This is where the role of manufacturers becomes pivotal They’re responsible for providing accurate, regularly updated product data and making it easily accessible to contractors, sub-contractors, engineers, and building owners. To meet these demands, many in the industry turn to established datapools

that offer comprehensive, verified product information

These platforms remove the burden from contractors by maintaining a central database of product information, which is automatically updated via API As an example from the MEP industry, a unique TSI code assigned to each product ensures quick and easy reference to the relevant data

By using this identifier, contractors can seamlessly integrate product information into their internal systems and project documentation, ensuring compliance with the Building Safety Act

The Act introduces the concept of a “Golden Thread” of information, which

refers to a continuous digital record of all data related to a building’s design, construction, and ongoing maintenance

This is especially important for high-rise buildings, where safety is a top priority

The Golden Thread ensures that every product installed in the construction process is recorded, and that the information is kept up-to-date and easily accessible throughout the building’s lifecycle

The Act goes one step further and suggests that documentation be kept for a minimum of 15 years This certainly requires changes in working practices, with many UK contractors using industry established datapools to reference as part of their digital evidence This enables them to leverage resources from data experts that specialise in liaising with manufacturers and wholesalers to ensure the information is accurate.

Traceability is essential for ensuring that the products specified for a building are the same ones installed on-site Often, what is specified by the contractor can be replaced with other products due to availability or convenience However, this can pose risks to the building’s safety and compliance

Under the Act, maintaining the thread of information from specification through installation and into maintenance is crucial. Accurate product information allows for quick response times and safe replacements when components need to be changed during a building’s lifespan

Whether it’s 10 or 20 years later, having a complete record ensures that like-for-like replacements are made, preserving the safety and integrity of the structure. A verified product database ensures that all manufacturers, contractors, and building owners have access to the most current and accurate data at any time

Upon the completion of a construction project, it is now standard practice for contractors to provide a digital twin or as-built model of the building These digital representations contain detailed information about the building’s systems, including the materials and products installed.

This approach m building owners an teams to access th need for future rep integrating produc these models, stak reference the exac materials used. If an issue arise system years later, be consulted to ide involved and retrie or safety documen streamlined process saves time and ensures that any future work on the buildin high standards as g construction

Safety is at the core of the Act, and managing product information effectively is key to ensuring it Installation guides, maintenance manuals, and safety certifications must be readily accessible to everyone involved in the building’s lifecycle Housing this information in a central, verified database makes it easy for contractors, engineers, and building owners to retrieve the necessary documentation when needed Having accurate, accessible information instils confidence that the products being used meet regulatory standards and are safe for long-term use This not only helps ensure compliance with the Act but also provides peace of mind that the materials specified and installed will perform as intended without unforeseen safety issues arising down the line.

The Building Safety Act imposes new duties on every participant in the supply chain, from manufacturers and suppliers to building owners. Each party must collaborate to ensure the safety and compliance of the products used:

● Manufacturers must supply fully attributed product information and prove compliance with regulations They are responsible for ensuring that the information is provided in a format

that can be integrated into various systems used across the supply chain.

● Wholesalers are required to ensure that the products specified by contractors are supplied without substitutions based on stock availability or pricing preferences

● Contractors are now held accountable for assembling accurate documentation throughout the building’s lifecycle, ensuring that all records are robust and accessible

● Building owners must have access to this information for ongoing maintenance and regulatory compliance, ensuring that the building remains safe for occupants

The Building Safety Act 2022 sets new standards for product information management, with a strong emphasis on accuracy, traceability, accessibility, and safety By leveraging a robust database which provides stakeholders with what they need to uphold their responsibilities, the industry can meet these regulatory demands, ensuring safer buildings and better outcomes for everyone involved

In this article, Andrew Duffen, Technical Commercial Engineer at NAPIT, seeks to unravel the mysteries of unidirectional and bidirectional protective devices.

With the introduction of Amendment 3 of BS 7671, the requirement for the installation of bidirectional protective devices for all sources of supply, including grid connections, generating sets, i e battery storage, solar PV and electric vehicles, with the ability to power back to the charger (vehicle-to-grid), has been addressed

Amendment 3 is a standalone document and has to be included with the current version of BS 7671:2018+A2:2022 and Corrigendum (May 2023). It is a free-to download PDF and should be appended to your brown copy of BS 7671:2018

A key principle of this amendment is the safety and compliance of electrical installations as more users become prosumers in this modern world, the growth in the renewable energy market in the UK and the rising cost of energy

There are two definitions for BS 7671 in Amendment 3, describing both types of protective devices

What is a unidirectional protective device?

For a unidirectional protective device, BS 7671 Amendment 3 states:

“A protective device where it is intended by the manufacturer that a source of supply is only connected to one defined set of connection terminals ”

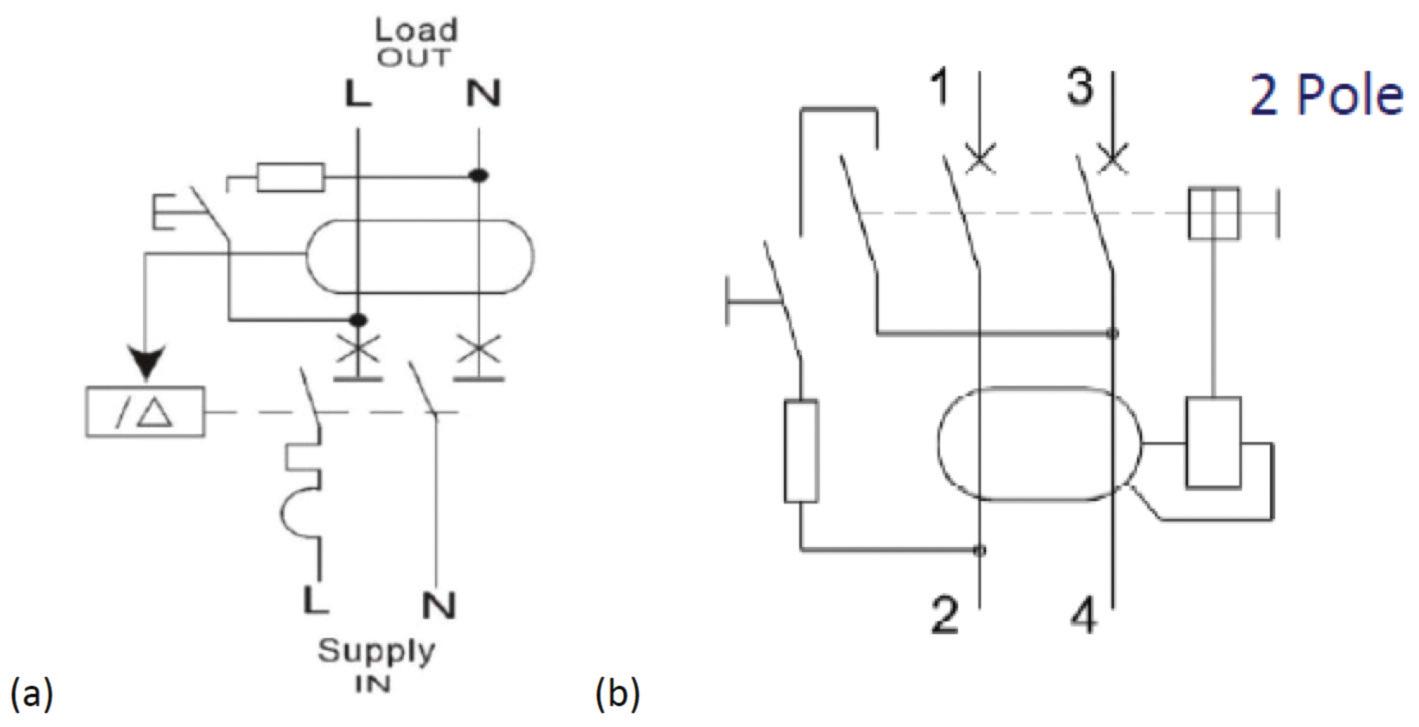

Unidirectional protective devices are labelled to show the line and load terminals and are intended to function when the source of supply connects solely in one direction, from the supply to the load It is essential to pay attention to the connection terminations as specified on the device, shown in Fig 1

An example of this type of device is a Residual Current Breaker with Overcurrent (RCBO) Not all RCBOs are unidirectional; some RCBOs now incorporate technology that prevents the RCBO from being damaged when the source of supply is derived from either direction, making them bidirectional protective devices

What is a bidirectional protective device?

The definition of a bidirectional protective device in Amendment 3 is defined as:

“A protective device where it is intended by the manufacturer that a source of supply is connected to either or both sets of connection terminals.”

“ ... a bidirectional protective device doesn’t have line and load terminal markings, which allows it to safely accommodate a source of supply from either direction without risk of damage.”

A n e x a m p l e o f t h i s t y p e o f d e v i c e w o u l d b e a R C C B , s e e F i g 2

G e n e r a l l y, R C C B s w i t h i n c o n s u m e r

u n i t s a r e i n t w o - m o d u l e - s i z e s , a n d d o

n o t u s u a l l y h a v e a n i n a n d o u t

i n d i c a t i o n ; t h e r e f o r e , t h e y a r e

c l a s s i f i e d a s b i d i r e c t i o n a l p r o t e c t i v e

d e v i c e s , t h o u g h t h e y c o u l d b e m a r k e d

t o d i s p l a y w h e r e t h e n e u t r a l o r l i n e

s h o u l d b e t e r m i n a t e d

RCCBs installed in split load consumer units are not suitable for the connection of solar PV or battery storage systems

How will Amendment 3 affect existing installations?

Careful consideration should be given to existing installations in regards to carrying out electrical installation condition reports (EICR) Inspectors carrying out these reports will need to give a classification code if a unidirectional protective device was installed with connections for more than one source of supply, such as a generating set

N A P I T a s p a r t o f t h e W i r i n g

Re g u l a t i o n A d v i s o r y G r o u p ( W R AG )

h a v e c r e a t e d a q u e s t i o n a n d a n s w e r

o n t h i s t o p i c w i t h i n d u s t r y c o n s e n s u s o n t h e i m p a c t o n e x i s t i n g i n s t a l l a t i o n s

To correctly assign classification codes when conducting EICRs, NAPIT and WRAG recommends checking with the manufacturer to establish if the

protective devices being installed are bidirectional or unidirectional protective devices and to receive a declaration of conformity which shall be appended to the EICR, as shown in Fig 3

I f a d e c l a r a t i o n o f c o n f o r m i t y i s p r o v i d e d , t h e n n o c l a s s i f i c a t i o n c o d e

s h o u l d b e r e c

After the release of Amendment 3, all sources of supply for connection to either set of terminals, including generation sets, must now be protected by a bidirectional protective device

Designers, installers and inspectors must be aware of Amendment 3, ensuring that all electrical installations that have sources of supply operating in either direction, such as generating sets, comply with the amendment Regulation 530 3 201 states:

“Selection and erection of equipment for protection shall take account of appropriate

use of either a unidirectional protective device or a bidirectional protective device ”

With rapid growth in the renewable energy industry, bidirectional protective devices will become the standard.

In regard to existing installations of generation sets, where it is unclear if the protective device is either unidirectional or bidirectional, inspectors must confirm the protective device type with the manufacturer, with either written or published confirmation of device type.

Once this information is gained, it will aid the inspector in determining any potential classification code required for an EICR

Further information on uni and bidirectional devices can be found in the On-site Solutions publication, available at NAPIT Direct.

The experts at ROBUS guide you through the basics of LED strip selection and installation.

LED strip has been a game-changer in recent times

While you’re probably familiar with the exceptional energy efficiency of LEDs, the advantages of mounting LED diodes on a flexible circuit board are still emerging Simply put, LED strip is essential to the electrician’s toolkit

The first step to an LED strip installation

You cannot choose LED strip without having a clear idea of what the result should look like Can you picture it? Having this defined vision to refer to will make the next steps easier

Consider the following:

● Where will you be installing your strip?

● Is the location outdoors or indoors?

● Is there potential for water or dampness in this space?

● What kind of ambience are you aiming for? Should it be vibrant and crisp, or soft and atmospheric?

● Will the LED strip be visible or concealed?

● Is there a preference for a continuous stream of light effect?

Once you’ve identified those factors, you’re ready to start the process of selecting your LED strip!

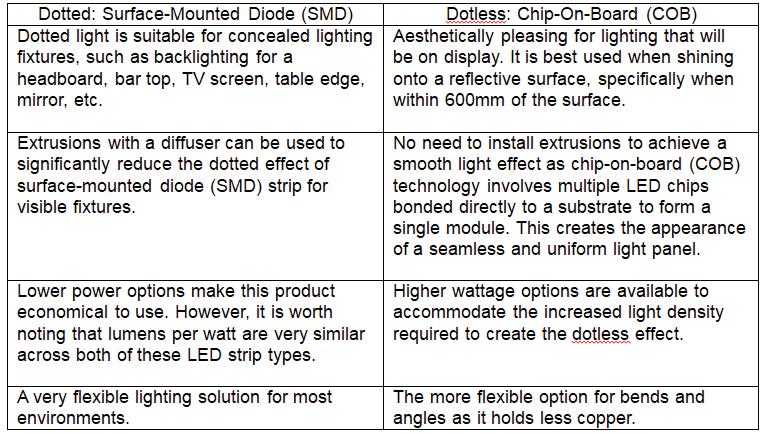

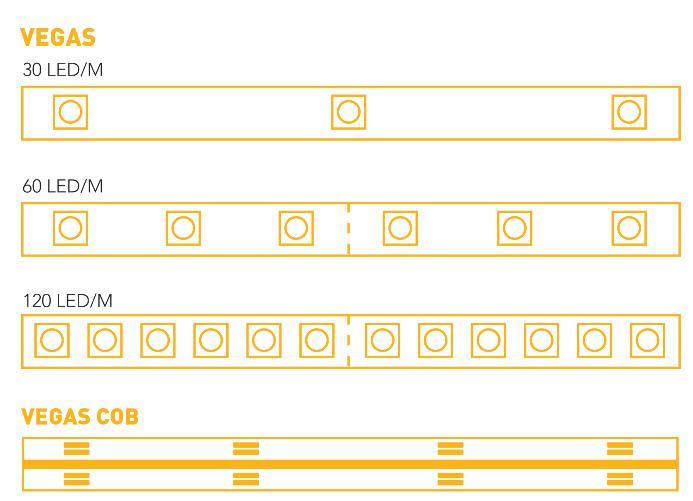

Light effect: dotted or dotless?

Why pick one lighting effect over the other? As a brand, ROBUS has a variety of dotted and dotless strip to choose from, so it’s helpful to understand the difference Take a look at the table in Fig 1 to understand the benefits of both

The key to deciding between these two options is understanding the location of the fitting and the preferred lighting effect

Once you make your choice, it is time to decide what colour lighting you require.

Colour: over 16 million options

One of the most appealing advantages of installing LED strip is the range of colour variations made possible by LED technology. RGB LEDs alone offer over 16 million possible colours, achieved by blending the primary colours of red, green, and blue – hence the name, RGB

Prefer a minimalist white aesthetic?

While RGB LEDs can approximate a white hue, you'll need a dedicated white LED chip if you want a pure white tone.

Ingress protection: how exposed is your light fixture?

Different types of LED strip come with different ingress protection ratings (IP ratings) to suit the diverse applications for which the lighting may be used. This is because electrical goods can deteriorate or malfunction when water or dust enters the fixture

Therefore, if the lighting is to be installed outdoors or in an area prone to water residue (such as a bathroom or bar), a higher-level IP rating is necessary.

Extrusions: one to match every application

Extrusions are solid, semi-hollow, or hollow aluminium casings that can be equipped with high-quality diffusers and mounting accessories. LED extrusions, also known as profiles, prevent damage and dissipate heat Additionally, they can enhance lighting by providing streamlined effects

Exposed LED chips are vulnerable to accidental knocks and scuffs from everyday occurrences, and these lightweight extrusions act as an attractive protective shield

Wattage: what wattage and why?

It’s all down to LED density! Lower wattages are generally more suitable for accent and background lighting purposes, whereas higher output is preferred for functional lighting in areas such as offices and corridors

When it comes to LED strip, the more LEDs on a strip the more light output is produced Equally true is that the more LEDs on the strip, the more seamless the light distribution

Driver: how to choose your power supply

The type of driver you require will depend on the specific LED strip selected, the necessary length, the IP rating and the dimming capabilities required. It’s important to choose the correct driver for your installation because if it has a lower voltage than your strip, there’s a potential risk of fire

To find out what driver you need you will require the following information:

1. The LED strip voltage

2 The wattage of the LED strip

3. The length of LED strip required

4. Multiplication of the wattage by the length (W/m)

Now you know what voltage driver you need and at what wattage per metre! You can safely pair a driver that has a higher capacity than the LED strip’s power draw

Please note: you should never use a driver that has a smaller capacity than the max power of your LED strip.

Want to keep learning? You can find out about connectors, controllers, and more in The ROBUS Guide: How to Land Your LED Strip

BROWSE OR DOWNLOAD THE ROBUS ‘HOW TO LAND YOUR LED STRIP’ GUIDE BY VISITING: WWW.RDR.LINK/EBK015

CLAIM YOUR CERTIFICATE! SCAN THE QR CODE TO CLAIM YOUR CPD CREDIT FOR THIS SECTION OR VISIT: WWW.RDR.LINK/ EBK016

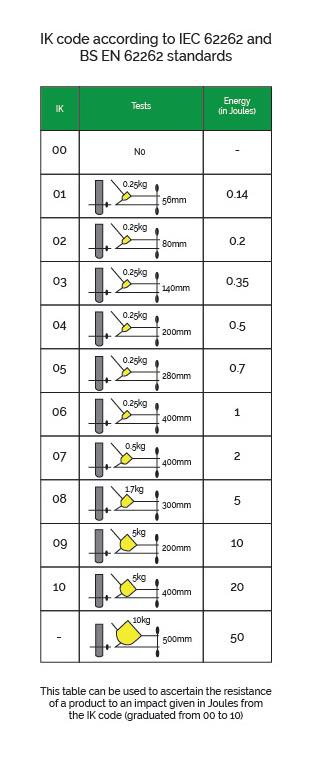

Click Scolmore looks at considerations to bear in mind for the selection and erection of electrical accessories in those locations that are subject to mechanical impact.

Asuitable for the location in which it is to be installed (132 5 1), and installed in accordance with the manufacturer’s instructions (134 1 1) and erected such that it is not compromised (134 1 2)

BS EN 62262: 2002+A1:2021 Degrees of protection provided by enclosures for electrical equipment against external mechanical impacts (IK code), is a standard which ‘ refers to the classification of the degrees of protection provided by enclosures against external mechanical impacts ’

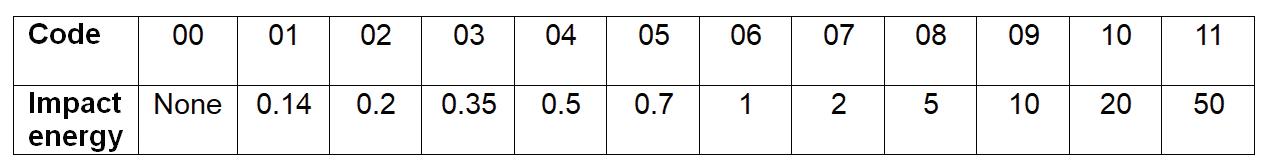

Table 1 in this standard details the codes for the impact energy (in joules) that the equipment is capable of withstanding Whilst Appendix 5 of BS 7671 doesn’t reference IK codes (it references ‘low’, ‘medium’ and ‘high’ severity of impact), there are a number of regulations within the standard which make specific references to BS EN 62262, including for example, Regulation 708 512 2 1 3, 709.512.2.1.4, and 712.512.

When designing an installation, it’s important that the designer gives careful thought to the nature of the activity and conditions likely to be found in the installation

Where there is a likelihood of a risk of impact designers, amongst other things, should select products capable of withstanding such impact Whilst there are only a few regulations detailing specific parts of an installation requiring a minimum energy withstand (IK code), there is a more general need to ensure that any installed equipment is suitable.

There is a duty on installers to ensure that they install any equipment in accordance with the guidance issued by the manufacturers of a product

More than this however, they should also ensure that their activities do not compromise the product itself, which can be caused by excessive force, incorrect location, poor fixing and the like

Consider the following cases:

a) A campsite has supplies available for various tent plots Regulation 708 512 2 1 3 is very clear, and because of the increased risks associated with persons being in contact with Earth, installed equipment

must have a minimum resistance to impact of IK08 (5 J)

b) A small industrial unit has a series of wall-mounted, surface wired accessories In this instance there is no minimum declared IK value, however the general principles apply; that is to take account of the environmental conditions which apply As such, a designer would likely select metallic outlets

It is important that both designers and installers take due account of the likelihood of impact when selecting and installing suitable products for those installations which have a harsher environment Additionally, certain special locations detail specific minimum impact requirements.

Scolmore’s comprehensive Metal Clad range is offered as part of Click’s Essentials wiring accessories and features electrophoretically coated plates and back boxes that provide a durable and long-lasting heavy-duty finish. All Metal Clad socket outlets and spurs are tested and approved to BS 1363

BROWSE THE CLICK SCOLMORE METAL CLAD RANGE OF PRODUCTS AT: WWW.RDR.LINK/EBL018

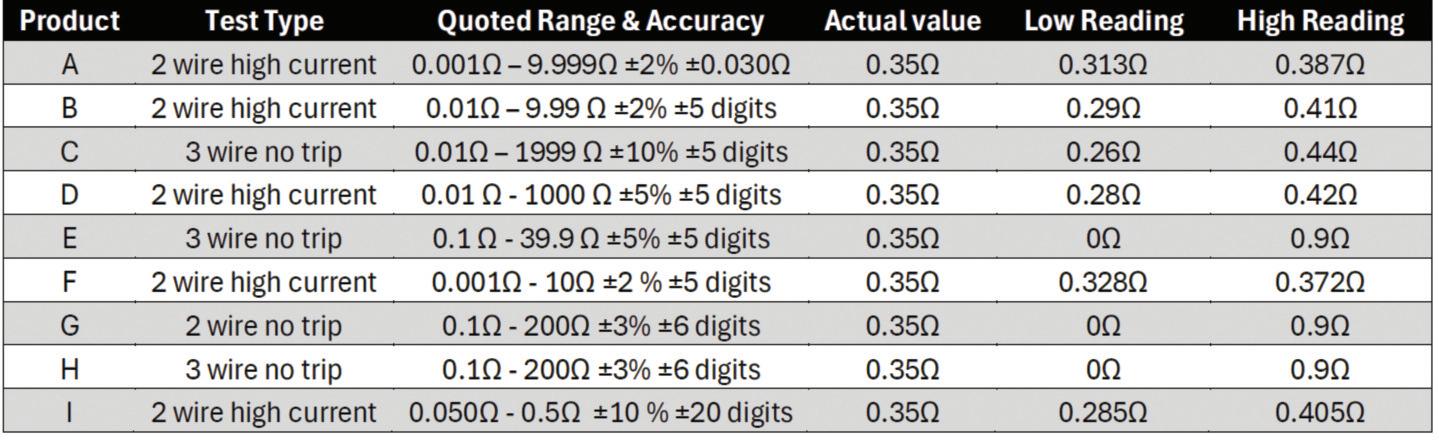

Most technical support questions received by manufacturers of test and measuring instruments generally concern issues related to Earth Loop Impedance test results

More specifically, the variations in readings obtained with successive measurements,

comparisons between different test instruments, or readings that are an issue, such as just outside of the permitted minimum value for a particular installation

Why is loop testing important?

For a protective device in an electrical installation to operate within the maximum permitted time detailed on

Julian Grant,

General Manager of Chauvin Arnoux UK,

recounts how loop tests have evolved over the last 40 years and explains the inherent measurement variability that has occurred along the way.

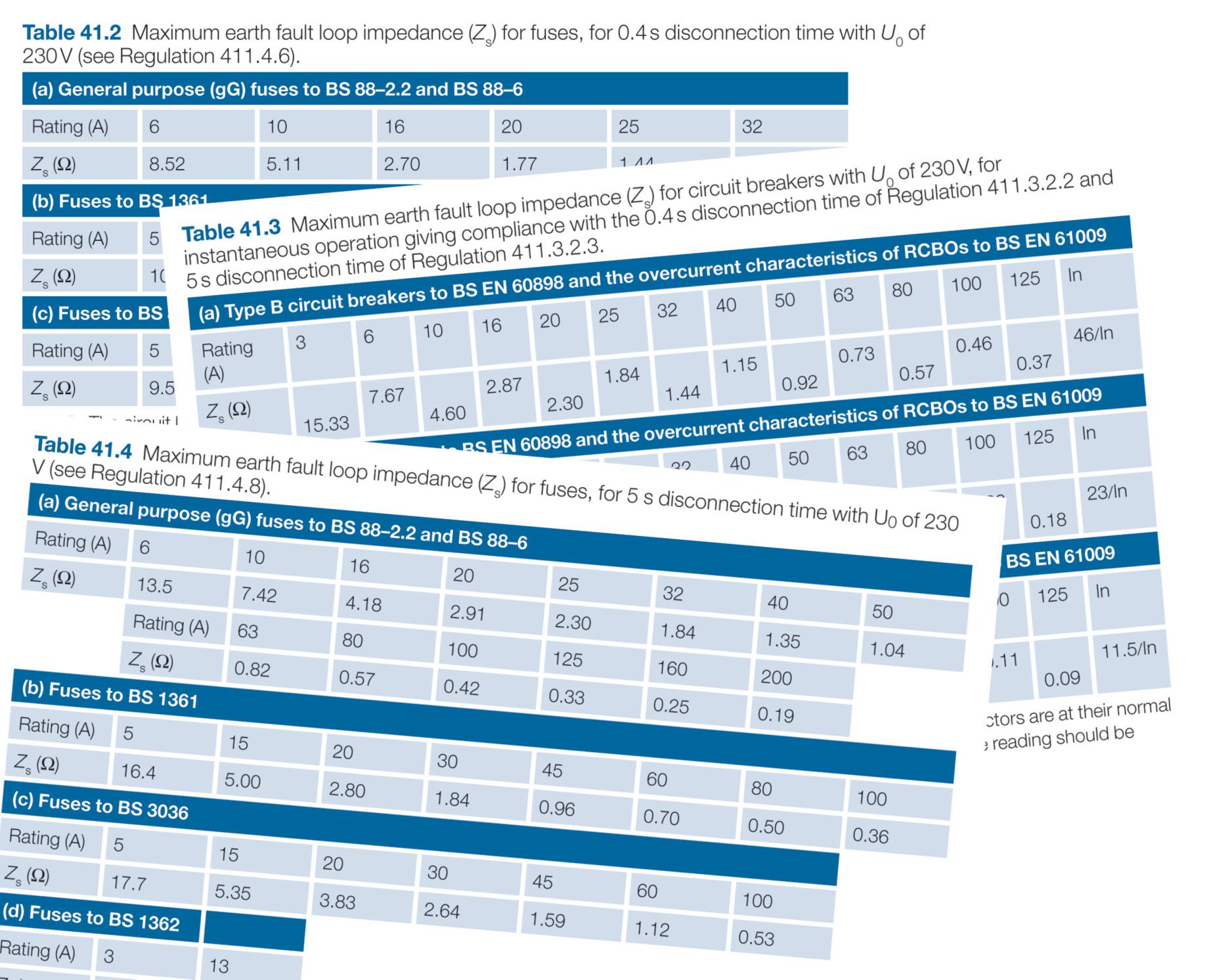

Table 41 1 of BS 7671, the earth fault loop impedance (Zs) for the circuit must not exceed the maximum earth fault loop impedance values for the protective device given in Tables 41.2 to 41.4.

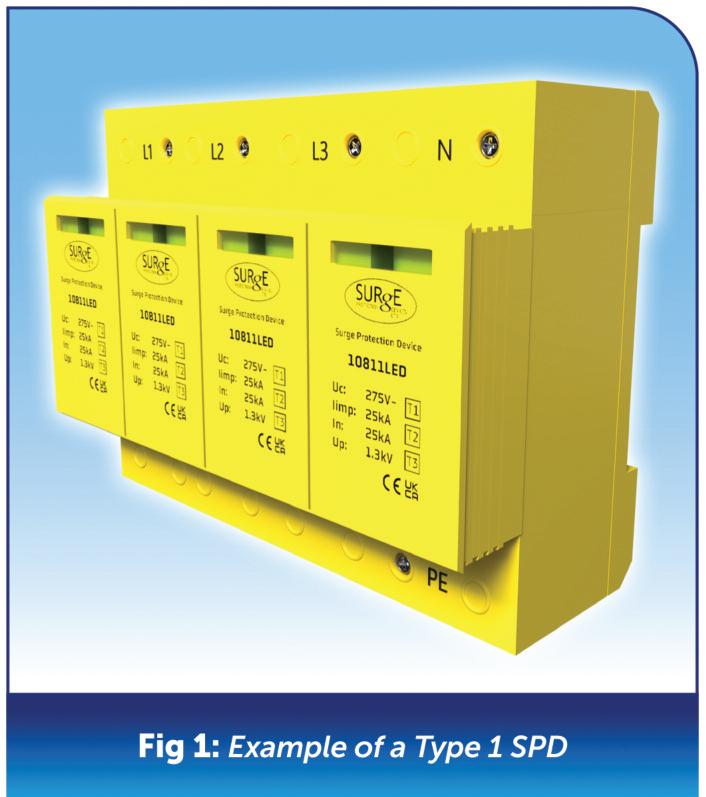

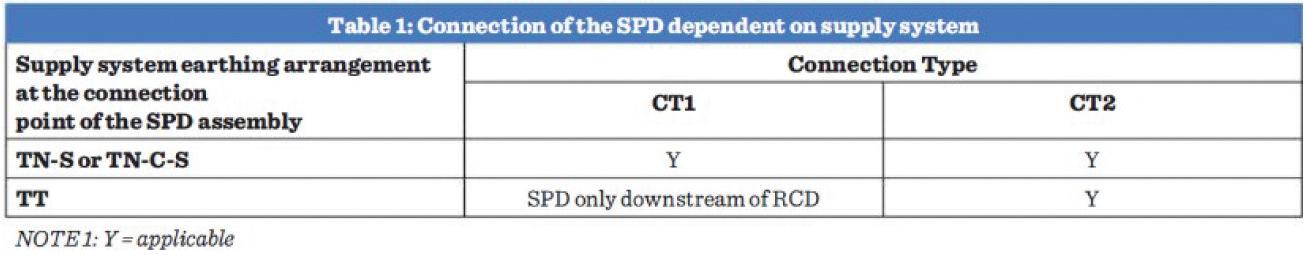

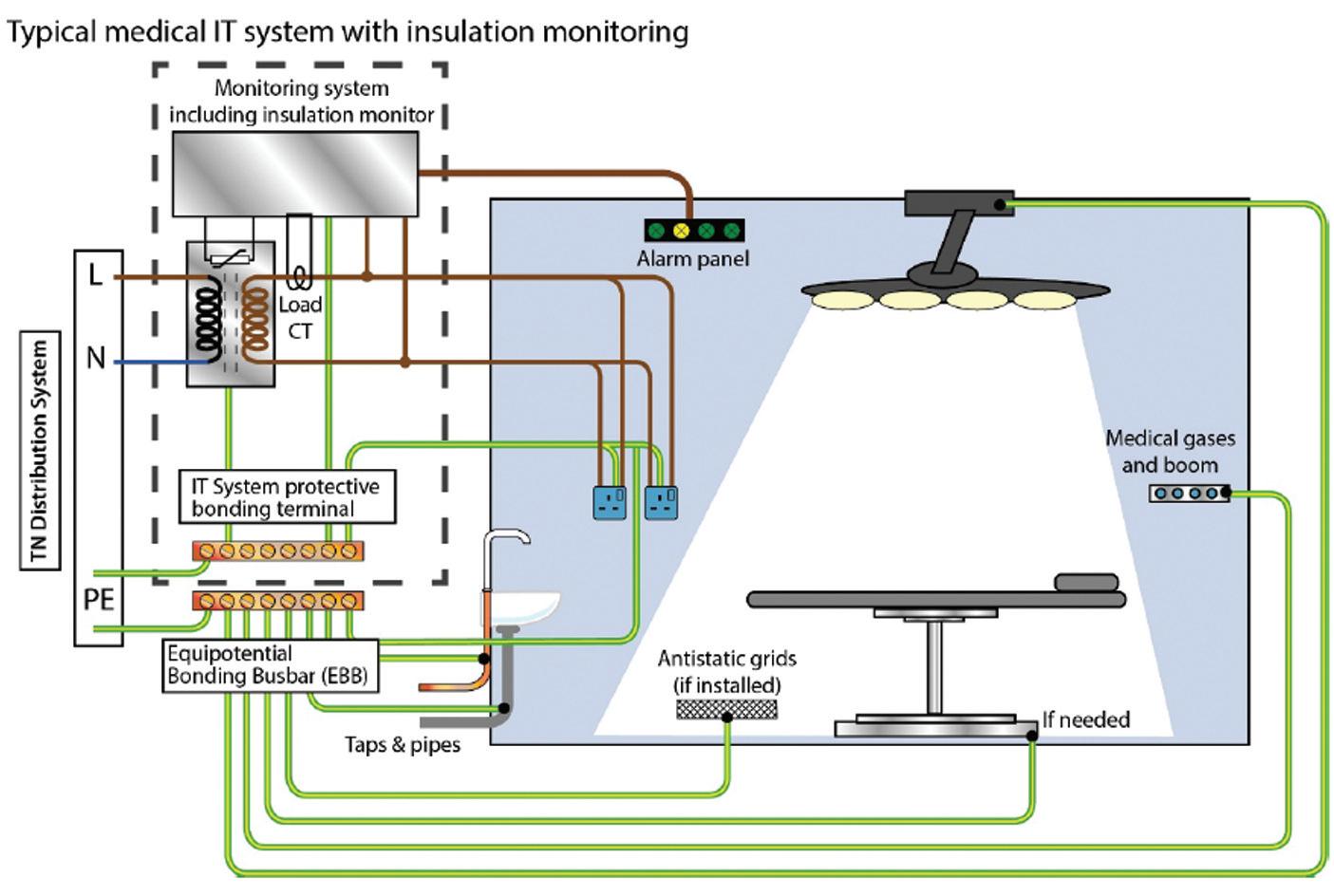

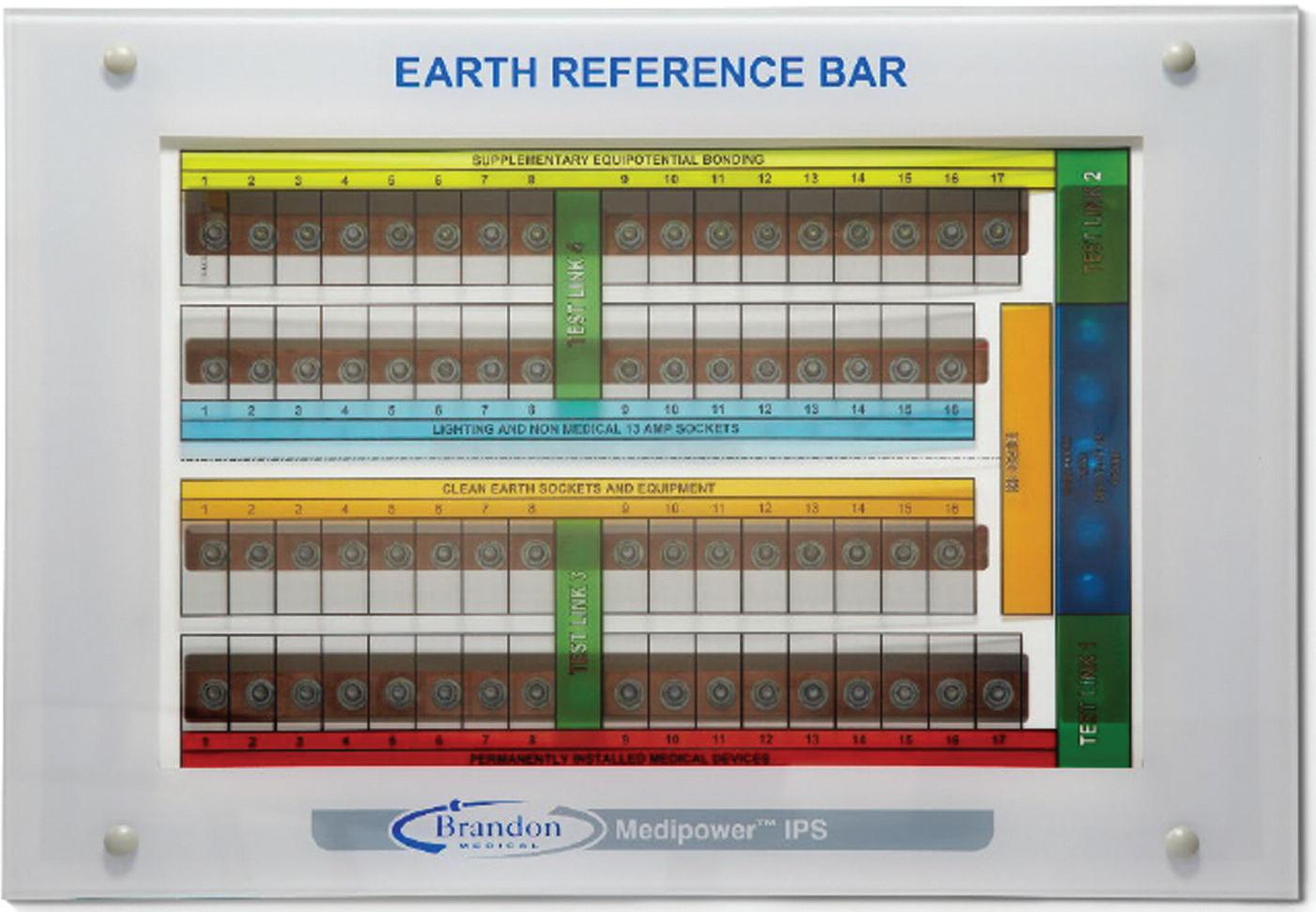

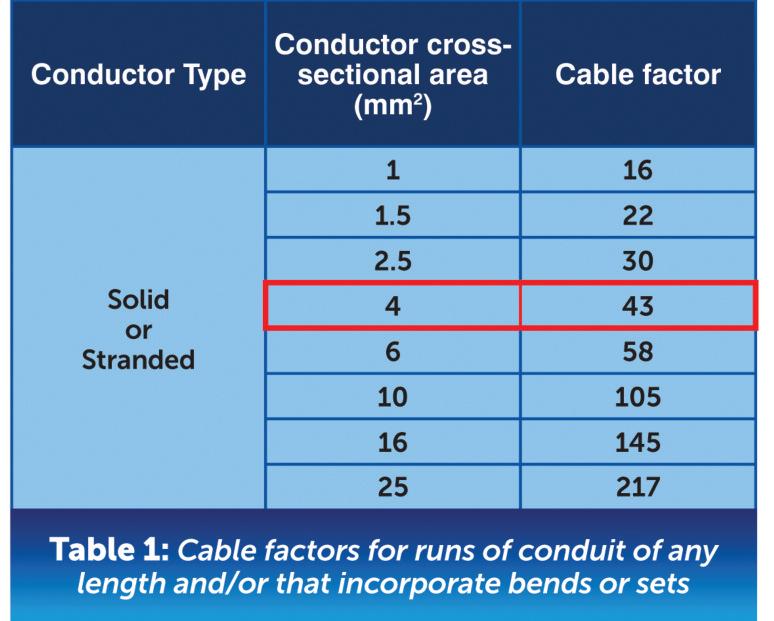

The earth fault loop path typically consists of the external impedance (Ze) and the resistance of the phase and protective conductors (R1 + R2) If the total