NOVEMBER 2022 The trade magazine for servicing and repair professionals COMMERCIAL VEHICLE WORKSHOP SECOND TIME AROUND Bandvulc and Prometeon sing the praises ofretreads Also in this issue… Savings through software ■ Making workshops digital ■ Lifting, testing and alignment ■

REGULARS

DIAGNOSTICS & SOFTWARE

STORY: As part of a programme to digitise its

Consett-operator Elddis Transport recently adopted mobile tablet technology from Freeway. CVW

Shaw & Son has waved goodbye to its vehicle maintenance recording paper trail and is enjoying reductions in time and hassle thanks to electronic management systems. Here’s how.

Impact Diagnostics’ Thinkcar brand has introduced a couple of diagnostic tools designed to help the more budget conscious CV and LCV workshops. We take a look.

Diagnostics & software: what’s new?

Tony Mailling, head of hot retread production at Bandvulc, reckons that retreads are unfairly seen as poor relations to new tyres and seeks to put the record straight.

Malc England, marketing manager of Tecalemit, looks at ways operators can improve their maintenance regimes and take costs out of testing.

fleet development engineer

Lane

why retreads are a smart choice not just for operators’ pockets, but for improving their green credentials as well.

wheels: what’s

TOOLS & EQUIPMENT

shows

how to make

its new Galaxy abrasive.

Story Plant has gone big with a recent £1m plus investment in its new workshop facilities, and the investment is now paying dividends.

alignment needn’t be time consuming nor taxing,

Clive Seabrook, CEO of Pro-Align.

to Totalkare for testing and lifting

to promote efficiencies. Here’s how it got on.

CONTENTS Issue 10Volume 19 5 Viewpoint 6 News 47 What’s new? 50 Digital digest

10 COVER

workshop,

reports. 13 James

28 Prometeon’s

Gary

discusses

30 Tyres &

new?

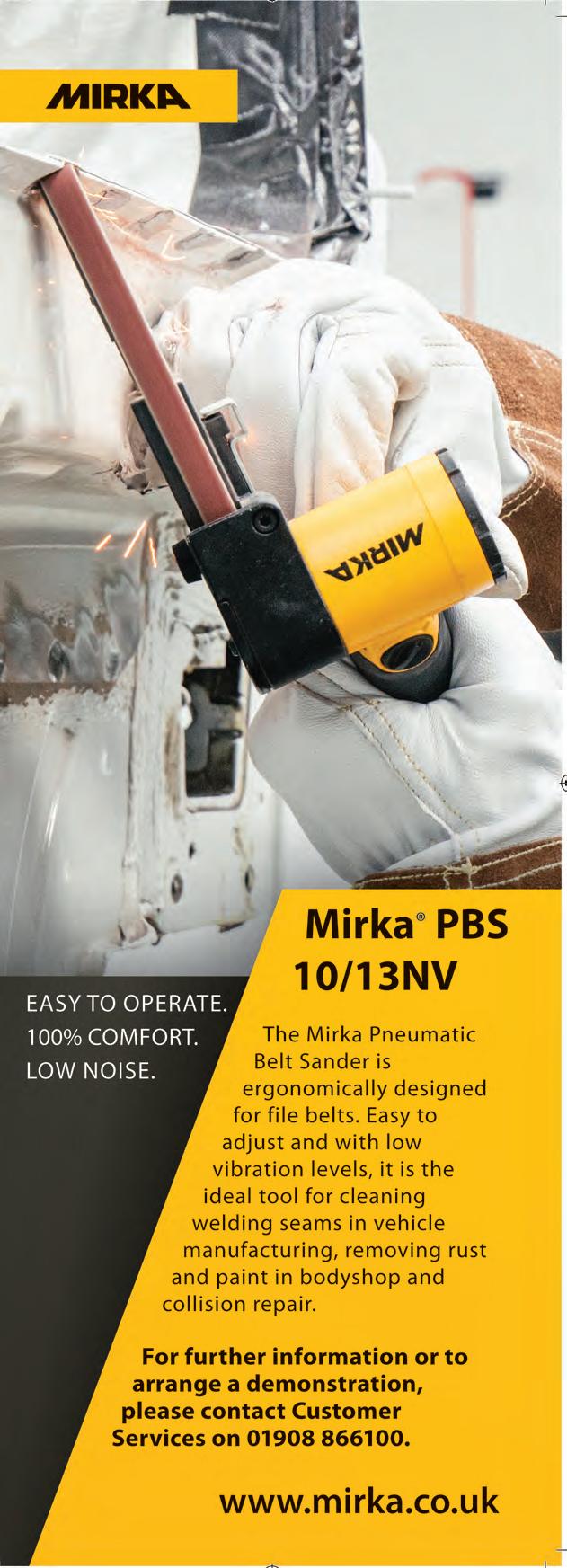

36 Mirka

you

some tasty looking repairs with

39 Carlisle-based

40 Wheel

says

42 Arrow Self Drive turned

equipment

44 Tools & equipment: what’s new? 47 What’s new? NOVEMBER 2022 CVW 3 13 23 39

Editors

JOHNNY DOBBYN

JOHN LEVICK workshop@cvwmagazine.co.uk

Editorial Assistant

FREYA COLEMAN Group Editor

KIERAN NEE Digital Manager

KELLY NEWSTEAD Senior Account Manager

ALEX DILLEIGH Group Manager

ROBERT GILHAM Graphic Designer

GEMMA WATSON Group Production Manager CAROL PADGETT

in

is a

It is published 11 times a year and is

on free subscription to

UK

by Walstead Peterborough

by

CLIMATE FOR CHANGE

Reports and research about the EV market, particularly the LCV and truck market, are like Chancellors of the Exchequer – you get a new one every month. The latest to cross our desk is from Heliox, a Dutch manufacturer of fast charging systems, and it makes very interesting reading. Why? Because, if the findings

are to be believed, we are probably closer to all electric fleets than we think.

Yes, the current charging infrastructure needs improving and that’s across Europe and the UK, but attitudes towards e-mobility are getting more positive. The number of last mile delivery vans for inner city and local distribution is growing, eBus fleets are expanding and, as the report points out, eTrucks are becoming more acceptable as ‘range anxiety’ lessens.

The technology is ready to scale, and industry experts are confident that heavy goods vehicle manufacturers such as Scania, Renault and MAN will develop trucks capable of managing up to 500km on a single charge.

Crucially, the report says, even if eTrucks are still more expensive at the moment of acquisition, the low energy and maintenance cost will reduce the total cost of ownership. This means the battery and truck will pay for themselves in just a few years after purchase. Some recent industry studies show that this might already be the case by 2025.

If there is one stand out phrase that almost sums up what’s being said, it’s this from Fabian Sperka of research group Transport & Environment:” The more and longer I drive, the sooner electric trucks will outcompete their fossil fuel counterparts because electric charging will be cheaper than diesel.”

Of course, it’s not all about EV. The other alternative being explored is hydrogenpowered fuel cells. As announced last May the UK government is committing more than £200m of funding for a three-year ‘comparative’ demonstration programme to determine whether hydrogen-powered fuel cells or batteries would be the best zeroemission solution for HGVs.

According to the Department for Transport (DfT) ‘the demonstrations will help the UK’s freight sector reduce its reliance on fossil fuels by finding which zero emission technologies are best suited to the heaviest road vehicles in the UK.’

Which is just as well since government has already announced plans for all new HGVs sold in the UK to have zero emissions from 2040, while banning the sale of fossil-fuel-powered trucks weighing 26 tonnes or less from 2035.

The fruits of this comparative demonstration programme could ‘see hundreds more zero-emission HGVs rolled out across the nation and save the industry money, thanks to overall running costs of green vehicles being cheaper than petrol and diesel equivalents. More efficient deliveries will in turn enable haulage companies to keep the price of goods down and protect customers from rising costs,’

So, whether the future is electric or hydrogen, there is only one certainty – the future will be different.

Subscriptions Commercial Vehicle Workshop

business magazine for companies and individuals involved

all aspects of commercial vehicle servicing.

available

qualified readers. Subscription rates:

£30 To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk. Printed

Published

HAMERVILLE MEDIA GROUP Regal House, Regal Way, Watford, Herts WD24 4YF Tel: (01923) 237799 Website: www.hamerville.co.uk Copyright © 2022 ©jamesteohart/AdobeStock (pg6) ©Melanie Kocheva/AdobeStock (pg 24) 8,249 The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication

and views

The CVW Team From 1 July 2021to 30 June 2022 Associate member

NOVEMBER 2022 CVW 5 VIEWPOINT @CVWmagazineCVWmagazinewww.cvwmagazine.co.uk

“The technology is ready to scale, and industry experts are confident that heavy goods vehicle manufacturers will develop trucks capable of managing up to 500km on a single charge.”

Energy help is at hand

The Federation of Small Businesses (FSB) has responded to the news that Government’s energy help is to be expanded to businesses on existing fixed price contracts that were agreed on or after December 1, 2021.

National Chair Martin McTague commented: “This is an extremely welcome move – the Government has rightly listened to FSB’s call to extend help to small firms which agreed to new or renewed contracts before the April 1, 2022 cut-off, and were excluded in the previous announcement of the Energy Bill Relief Scheme. This is important news for those small firms who locked themselves into contracts just as energy prices originally rose. We have been talking to BEIS about a number of our members who were inadvertently penalised for doing the right thing, trying to protect themselves from even higher hikes. We are very pleased at the action that Ministers have taken.

West Mids investment bid for gigafactory

A bid for Investment Zone status for the West Midlands Gigafactory, and its immediate area, has been submitted to Government.

If successful, Investment Zone status will help secure the £2.5bn investment required to deliver the UK’s largest consented gigafactory. The bid – backed by Coventry City Council – is part of a wider submission made by the West Midlands Combined Authority for a range of Investment Zones across the region capable of accelerating economic growth and delivering tens of thousands of new homes and jobs. The West Midlands Gigafactory alone could create up to 6,000 new jobs directly, as well as protecting and creating tens of thousands more in the automotive supply chain.

Tireless effort brings rewards for Hankook

Against strong opposition Hankook Tyre UK has been awarded the prestigious Tyre Manufacturer of the Year at the annual National Tyre Distributors Association industry awards.

The award is decided by a panel of independent experts who analyse every entry which includes extensive details about the business, the customers and the company's employees.

Speaking on behalf of the judges, NTDA Chief Executive Stefan Hay said: “The judges felt that the Hankook entry demonstrated, in great detail, its growing marketplace leadership in product, performance, innovation, productivity and sustainability. Furthermore, its claims of commitment to employees, customers, suppliers and partners, were more than proven in an array of glowing testimonials, which spoke highly of the company and its

‘exemplary’, ‘exceptional’ and ‘unprecedented’ support. It was unanimously agreed that Hankook is a very worthy winner of this award.”

The award was presented to Hankook Tyre UK's sales director, Paul Emery and marketing and communications manager, Zoë Baldwin. On receipt of the award Paul Emery said: “We are a relatively small team at Hankook and are extremely proud that the UK tyre industry has recognised the strength of the Hankook business. This is truly a team effort and a team award.”

“The revamped scheme will provide a much-needed reassurance for small businesses trying their best to mitigate the impact of rising prices between December 1, 2021 and April 1, 2022. While this discount will only apply to a relatively small number of firms who fixed prices when wholesale prices were spiking, it would have sent the wrong message to the small business community to leave this group unprotected.

6 CVW NOVEMBER 2022 NEWS

Bridgestone, Worldwide Olympic and Paralympic Partner has unveiled its new campaign for Paris 2024, "Prepared to perform", with the five times Olympic games swimming medallist, Adam Peaty, and Olympic games freestyle BMX gold medallist, Charlotte Worthington as ambassadors.

“This is an extremely welcome move. The Government has rightly listened to the FSB's call to extend help.”

Stagecoach shows armed forces support with remembrance livery

Stagecoach has unveiled a special poppythemed livery of its branded Armed Forces Covenant bus, showing its support to those who have served and continue to serve.

The Armed Forces Covenant is a promise by the nation ensuring that those who serve or who have served in the armed forces, and their families, are treated fairly. Over the summer, Stagecoach received a Bronze Employer Recognition Award from the covenant meaning that it is recognised as an employer who supports those defence personnel and veterans, and its future goal is to achieve Gold employer status.

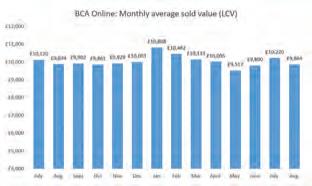

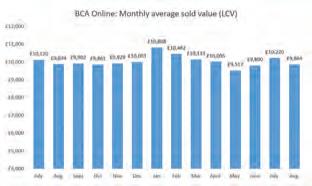

LCV values settle to seasonal norms

Following two successive monthly increases in value, average LCV values at BCA moved to more seasonal levels in August as the UK recorded one of the hottest summers on record.

LCV values averaged £9,864 at the auctioneer in August, down from the figure of £10,220 reported in July, but still ahead of May and June. While average values shifted, this was largely a result of the change in model mix that is typical at the time of year.

Performance against guide prices improved by nearly two percentage points to 97.5% over the month and year-on-year values were virtually level, with just a £10 differential between August 2021 and August 2022. Sale conversion rates lifted during August and average weekly values steadily improved during the month, rising above £10,000 in the final week of August.

In a show of winter solidarity battery manufacturer GS Yuasa is looking to serve up tasty treats for the nation’s vehicle technicians over the course of the next few months. The company has teamed up with world-famous confectionary brand Tunnock's in a mission to feed a hungry workforce over winter, a period associated with high rates of battery failure.

Available at no cost with qualifying purchases of Yuasa and GS-branded batteries from participating distributors across the UK and Ireland, the ongoing promotion will see vehicle technicians receive a free pack of Tunnock's Snowballs with their battery purchases over winter.

The Treat Yourself to a Tunnock’s initiative follows the huge success of GS Yuasa's snack pack and eggstra promotions and brings

together two iconic brands and long-time supporters of the three-time BTCC Champion Gordon ‘Flash’ Shedden who fronts the campaign. This latest initiative will see nearly half a million individual snowballs shipped across the UK and Ireland as the two global leaders join forces.

Gordon Shedden, GS Yuasa and Tunnock's brand ambassador, added: “Winter really is the season of battery failure, and with this promotion, we're forecasting snow too! With the widest range and cold weather performance you can rely on, GS Yuasa are the number one choice for me and the UK’s thousands of mechanics and motorists.”

Stuart Pearson, BCA chief operating officer UK commented, “The ongoing demand for retail quality light commercials means there is plenty of competition for the best examples reaching the market and this was exacerbated in August as volumes of corporate stock tend to be lower. The few late-plate light commercials on offer can make exceptional values and, as always, the best graded vanswith a good specification and in an attractive retail colour remain very desirable.”

He added “It’s becoming a familiar refrain, but the basics are critical in the current market, so vendors should work closely with their remarketing partner to ensure that their LCVs are realistically valued, properly prepared and graded, and accurately catalogued to attract the right buyers.”

@CVWmagazineCVWmagazinewww.cvwmagazine.co.uk

NOVEMBER 2022 CVW 7

The ‘Chammoth’, a modified IVECO Daily powered by compressed natural gas, has completed a 2,100 road trip around the UK and raised £6,000 for The Aspinall Foundation. The Aspinall Foundation strives to protect endangered species, and IVECO pledged to donate £1 for every social media post featuring an image of the Chammoth.

You’ve chance of a snowball...

IMI EV TechSafe qualifications ramped up in first half of 2022 to hit 15% penetration – but still lag electric vehicle adoption predictions, as Auto Trader data suggests the EV skills gap will hit one year earlier than previous forecasts.

The first six months of 2022 saw the highest number of technicians take an EV qualification that is eligible for IMI TechSafe™ accreditation, since its introduction in 2016. The number of technicians now qualified to work safely on EVs is estimated to be 32,900; the equivalent of 15% of technicians in the UK. However, despite the rapid acceleration, the forecast of when the EV skills gap is likely to hit – the shortfall between electric vehicles on UK roads and sufficient approved technicians to service, repair and MOT them – has been dialled back by the IMI, from 2028 to 2027.

The new prediction draws on Auto Trader’s latest Alternative Fuel Vehicle (AFV) data which suggests that there will be 12.6 million AFVs one the road by 2030 and that 9 million of them will be pure EV. The IMI forecasts that the number of TechSafe™ qualified technicians required to work with electric vehicles by 2030 is 90,000.

Technicians who have met the IMI TechSafe™ standards can highlight their credentials by joining the IMI’s industry- wide Professional Register. The Register lists individual members –and their place of work – who have been recognised for their achievements, experience, professionalism and commitment to a Professional Standard of behaviours, and for keeping their knowledge and skills up to date through Continuing Professional Development (CPD).

May the FORS be with you

Road safety experts Brigade Electronics has thrown its support behind the updated Fleet Operator Recognition Scheme (FORS), which for the first-time puts emphasis on the offside blind spot as well as containing updated guidance for right hand drive vehicles.

The organisation released new requirements for achieving FORS accreditation at bronze, silver and gold levels which became effective on July 1st, 2022. These recommend that operators now monitor front and offside blind spots

as this has been identified as an area of concern. According to police database research, 6% of all fatalities occur from vehicles turning right and 32% of accidents resulted from right hand side swipes.

Emily Hardy, UK marketing manager at Brigade Electronics, said: “The latest FORS requirements are welcomed. Fleet operators of all sizes must invest in road safety technology.

Brigade recommends a combination of active and passive systems to alert the driver to threats in the vehicle's blind spot.”

Time to put a Brake on road deaths

Road collisions causing deaths and serious injuries that involve vans, trucks and buses are sliding back towards prepandemic levels, according to latest government data released for 2021 and analysed by Brake, the road safety charity.

The charity’s analysis also highlights that one in four deaths of people on foot on roads are due to being hit by vans, trucks and buses. Brake is calling on the fleet industry to prioritise with urgency road risk management as a board-level business priority to end the carnage.

The Brake analysis shows: light goods vehicles (LGVs) were involved in 2,835 fatal or serious collisions (FSCs) in 2021. This is 12% more than a decade ago in 2012, and

an increase of 24% on 2020. There were eight FSCs a day involving LGVS in 2021.

HGVs were involved in 1,063 FSCs in 2021. This is 36% fewer than in 2012, but an increase of 7% on 2020. There were three FSCs a day involving HGVs in 2021.

Buses or coaches were involved in 585 FSCs in 2021. This is half the number recorded in 2012, but an increase of 23% on 2020. There were about two FSCs a day involving buses or coaches in 2021.

Mary Williams OBE, chief executive, Brake, said: “The statistics show why it is so important for corporations to take responsibility for managing their road risk through policies and procedures. Policing fleet safety can help to put an end to the terrible carnage.”

Collett & Son up to bridge challenge

An innovative cable tow technique recently saw Collett & Son get an 80-tonne transformer for the Harting Rig Wind Farm Substation over a weight-limited bridge.

The bridge crossing came late in a 230-mile journey from Goole to the farm in in South Lanarkshire. To cross it, Collett first uncoupled the loaded trailer from the 8x4

MAN TGX tractor unit, then attached 40m cables connecting the trailer and primary ballast truck; and again using 40m wire cables, connected a secondary 8x4 ballast unit at the rear of the trailer.

When it was time to move, the secondary ballast tractor reversed, and the primary drove forward. With the cables tensioned, both vehicles began the slow drive forward. Controlling the cable tensioning throughout, the primary tractor unit cleared the structure, followed by the trailer, transformer and steersman in tow. Once clear of the bridge, and with the trailer brake applied, the secondary ballast unit took up the cable stack and crossed the bridge. Operation complete!

@CVWmagazineCVWmagazinewww.cvwmagazine.co.uk

NEWS

8 CVW NOVEMBER 2022

EV technician qualifications lagging EV adoption predictions

As part of a programme to digitise its workshop, Consett-operator Elddis Transport recently adopted mobile tablet technology from Freeway. CVW reports.

NORTHERN GLORY

Elddis Transport is a well-established family firm specialising in the storage, supply and delivery of consumer goods for supermarkets and retail outlets. The name Elddis is in fact ‘Siddle’ spelt backwards, a nod to Mr Siddle C Cook, who found the company in 1971. As well as the County Durham HQ, the company has additional depots in Heywood and Doncaster.

The Consett-based company operates a fleet of 150 vehicles and 360 trailers. The firm has a long-standing relationship with Mercedes, with its technicians on site to maintain the trucks. Despite this arrangement, Elddis still has a very busy workshop dealing with the large trailer fleet, older vehicles and other assets.

As well as receiving 700 driver first-

check reports each day, the workshop deals with around 60 weekly preventative maintenance inspections (PMI) and four or five MOT preparations. With the workload increasing, Elddis has been an advocate of technology to increase automation and a central workshop system, supplied by Freeway, was first implemented in 2015.

Workshop digitisation

Now Elddis has been busy rolling out new mobile working technology as part of a programme to fully digitise the workshop using software. The workshop fitters are being equipped with rugged tablets to replace paperwork. These devices synchronise in real time with the central system to provide a real-time view of workshop activity.

Another key aspect of the systems’ recent evolution is the incorporation of daily vehicle inspection data, received from mobile devices used by drivers. This, coupled with digital data from the workshop, gives visibility of the status of the fleet to anyone that needs it, from workshop managers and schedulers in operations, to purchasing managers and directors.

This visibility is particularly useful to transport operations and is the result of integration between Freeway and the Mandata transport management system (TMS). It gives operations around-the-clock visibility of the status of the fleet to minimise disruption and ensure smooth running of the fleet. The ‘information loop’ is closed thanks to integration with mobile

DIAGNOSTICS & SOFTWARE

10 CVW NOVEMBER 2022

data devices used by drivers for their firstuse-checks. Data received gives the workshop immediate information on any new defects, which are matched to the asset record which holds maintenance records including details of previously reported defects and the maintenance history.

“With the digitalisation of the workshop we are closing the information loop giving us 24/7 visibility on the status of the fleet,” says Alan Henderson, fleet engineer, Elddis Transport. “Freeway is proving invaluable as it links engineers with transport planners. This means we can reduce vehicle downtime and ensure the fleet is always operating at maximum efficiency and safety.

another area of integration, with Freeway’s software automatically sending data when parts are issued from the workshop stores. This allows stock to be automatically replenished, minimising out of stock occurrences and therefore job delays.

“For management, the system allows us to see the pressure points of resources so we can smooth things out. It’s a tremendous resource that allows us to better manage and optimise the use of all resources; assets and labour,” Henderson adds.

Labour is another area Elddis is concerned about; something that has come into focus in recent months with a shortage of skills nationally. Optimising the use of existing labour is therefore crucial and software is playing an increasing role here.

“With all the integration work we suddenly have much better intelligence and can manage our resources much more effectively. For example, there are always peaks and troughs in workshop activity relating to the highs and lows of fleet activity. The system highlights these pressure points and allows us to dynamically reallocate labour based on availability and skills.”

The system also gives us insight into the performance of individual by type of job –for example the time taken to do a particular task - so we can pick the most appropriate staff and address any additional training needs.”

Freeway stores parts data and builds records of use and performance over time. Through the mobile app Freeway, fitters have instant access to historical maintenance information so they can immediately spot recurring defects.

“Our ethos is to fix once. We particularly like the fact that we can use Freeway’s analytics functionality to drill down to access the performance and valuefor-money of every asset – right down from an entire vehicle to an individual bolt,” says Henderson.

For parts purchasing Elddis uses a service from North East Trucks Spares (NETS) to manage imprest stock. It’s

Elddis is also planning to integrate Freeway with its local Mercedes dealership to import details of work done and parts fitted. This will ensure Elddis has a complete vehicle history held within Freeway, but without the need for manual data capture.

Elddis isn’t stopping there. The company has just started installing TrailerMaster, a system from Axscend that combines tracking with brake and tyre monitoring. For the workshop, this system is another useful source of data to provide an even more complete picture of the condition and performance of an asset.

TrailerMaster’s tyre pressure monitoring system monitors tyre pressures and alerts users in real time, even when the trailer is uncoupled. This reduces the risk of unplanned downtime, late deliveries and blow-outs on the road. The system’s electronic brake performance monitoring component is interestingly now accepted by DVSA as evidence of braking assessment at each safety inspection. TrailerMaster also provides remote access to diagnostic trouble codesso Elddis can be aware of faults being displayed on the vehicle dashboard.

NOVEMBER 2022 CVW 11 FOR MORE ABOUT FREEWAY, WWW.RDR.LINK/VAS001

“The system allows us to see the pressure points so we can smooth things out. It allows us to better manage and optimise the use of all resources; assets and labour.”

SMOOTH OPERATOR

Haulier James Shaw & Son has waved goodbye to the paper trail it relied on for vehicle maintenance recording – and now enjoys welcome reductions in time and hassle thanks to electronic management systems.

The Merseyside-based operator is now using computer power rather than hand-written notes to keep its fleet of 36 tractor units and 59 trailers safe and compliant, and to ensure the smooth and efficient operation of its in-house workshop, which is staffed by two technicians and a tyre fitter.

James Shaw & Son can trace its history back to the 1950s, when founder James Shaw, along with his brothers George and Peter, commenced trading with a single Bedford rigid. James’s son, Stephen, joined in the 1970s and now the third Shaw generation is at the helm of the company, in the shape of managing director Andrew. The company provides transport services to a wide range of customers, hauling everything from trailers to wet wipes across the UK.

General manager Chris Thompson took the lead in the company’s move to digital workshop and fleet management. He recalls: “I could see the potential for making the management of our fleet compliance much smoother and easier, and the installation cost was very competitive.”

“The best aspect for me is the visibility –every bit of information I need about all our vehicles is there on one screen,” he says. “I can see which trucks need servicing, MOT testing, taxing or tachograph calibration, as well as any reported defects. I don’t have to go looking for anything, it’s all right there in front of me. For our technicians, too, the benefits are clear,” he continues. “They use hand-held tablets and a touchscreen terminal to record all vehicle inspections and jobs completed. It’s so much simpler and quicker than using paper forms.”

DIAGNOSTICS & SOFTWARE NOVEMBER 2022 CVW 13

The ability to easily cross-reference with workshop loading schedules also means forward planning can be much more effective.

“We’ve been able to iron out the peaks and troughs that we sometimes had to endure previously,” says Chris. “So instead of having four trucks in for service one week, and 10 the next; we’re able to ensure there are six or seven week-in, week-out.”

Although the initial plan was only to invest in a workshop management system, the package James Shaw chose from specialist supplier Truckfile also includes a driver application.

“This brings a range of benefits too,” says Chris. “Drivers can do their daily checks with smartphones and don’t have to carry paperwork around with them. It’s also much easier for the office to keep track of all our trailers. The system records whenever one is

collected or dropped off and the information is instantly accessible.

“Defect reporting is far more efficient, as the software removes duplication which allows our workshop to focus on jobs that require attention most urgently. Scaled up across a fleet, that saves a huge amount of time.”

He continues: “Overall the installation of the system into our workshop and fleet has been a real breath of fresh air and is helping the whole operation to run much more smoothly. The support from the company has been great, the system is actually really easy to use but we have been guided through it every step of the way.”

Workshop management system

Truckfile was developed by Magic Internet Technologies, of Redditch, Worcestershire. The company was formed in 2006 to create an innovative and user-friendly fleet and workshop management system for the commercial vehicle and transport sectors. Following the launch of its Electronic Inspection System – later rebranded as Truckfile – it has worked closely with customers across the UK and Europe to develop its market-leading package of solutions covering the needs of fleet operators and workshops alike.

The system means that all vehicle safety checks, workshop inspections and any maintenance or repair activities carried out, from start to finish, are recorded electronically. Details are stored securely in computer files, which remain easily accessible, so there’s no need to keep track of endless sheets of paper. Truckfile is also a validated IT systems provider for the DVSA Earned Recognition scheme

With well over 200,000 individual vehicle records stored for more than 24,000 users, Truckfile is among the largest document stores of its kind in the marketplace. Customers can access the system from any internet-connected device, via a secure log-in, with no need for additional investment in servers or extra hardware. All documents are stored securely and available around the clock, allowing users full visibility of their fleets 24/7, 365 days per year.

DIAGNOSTICS & SOFTWARE NOVEMBER 2022 CVW 15 FOR DETAILS ABOUT TRUCKFILE, WWW.RDR.LINK/VAS002

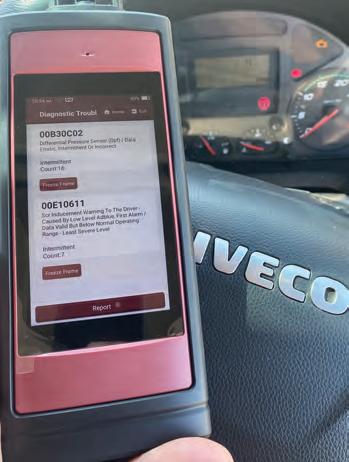

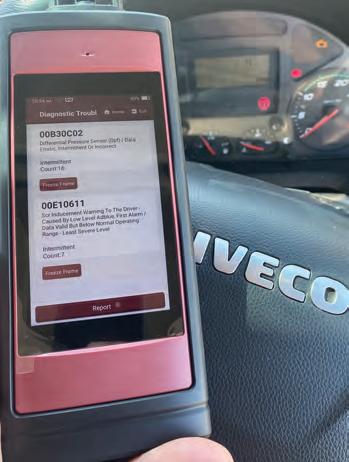

THINK TWICE

Thinkcar UK, a brand of Impact Diagnostics, has introduced a couple of diagnostic tools designed to help the more budget conscious CV and LCV workshops. The Thinktool reader HD is an entry level HGV diagnostic tool covering full systems on 31 commercial manufacturers including DAF, Scania, Volvo, Mercedes, MAN, Iveco, Isuzu and Cummins.

It claims to be far more than just a basic code reader and allows advanced functions such as: DPF regeneration, injector coding, reset service (MIL), maintenance confirmation, injection quantity adjustment, particulate filter replacement reset, pressure differential sensor reset,

pressure limiting valve reset, bleeding the AdBlue circuit, VGT electronic actuator installation and calibration, trip reset, parked SCR efficiency test and DPF ash accumulator reset.

There is also an optional software pack to add a further 42 manufacturers. The tool is a compact size and perfect for a mobile service van or back-up tool to a large workshop. Pricewise, it claims to cost much less than major European brands for 12 months’ updates, but to also offer relatively inexpensive optional updates when required.

The Thinktool Master CV is the Reader HD’s bigger brother. With a 10’’ rugged tablet and full cable set it is a more complete tool, but is said to still offer great value for money with two years’ updates included. Alongside its HGV and off-highway coverage, the Master CV is said to offer excellent coverage of light commercials. One recent claim, for example, is to have had great success in resetting AdBlue non-start lockouts on Transits and Sprinters when other betterknown brands may have struggled.

DIAGNOSTICS & SOFTWARE NOVEMBER 2022 CVW 17 FOR MORE DETAILS OF THINKTOOL, WWW.RDR.LINK/VAS003

“One claim is to have had success in resetting AdBlue non-start lockouts on Transits and Sprinters where other brands may have struggled.”

REAL TIME COMPLIANCE TRACKER IS JUST THE TICKET

FREEWAY FLEET SYSTEMS

Freeway Fleet Systems’ real-time compliance tracker allows operators to maintain tight control of compliance and standards of maintenance. The system is said to protect drivers, passengers and other road users by reducing accidents and breakdowns caused by vehicle defects. It allows workshop managers to prioritise work, minimise disruption and, together with predictive maintenance modelling, reduce downtime and cut fleet maintenance costs.

The tracker uses live data from mobile devices and onboard sensors, processed together with existing defect and maintenance records to provide a complete oversight of the status of each vehicle. Critical defects and compliance issues are highlighted on colour-coded screens. By targeting the most urgent defect rectification requirements and any outstanding compliance issues, the system makes it easier for bus and coach operators to maintain full compliance and manage DVSA Earned Recognition requirements. Live data is pooled from apps used by drivers for their first-use safety checks and onboard systems. Integration has been completed with Stratio, a system that monitors and transmits fault alerts from vehicle sensors, and Wheely-Safe, a system for monitoring wheels, brakes and tyres.

WANT TO KNOW MORE?

WWW.RDR.LINK/VAS004

GET ON BOARD WITH TELEMATICS TRUTAC

Northgate has re-launched its intelligent telematics service to provide fleets with live fleet user data that will help maximise cost efficiencies and alleviate operational expenses. Northgate offers two service levels of telematics provision: Control provides live vehicle tracking, journey history, the ability to monitor out-of-hours use, vehicle activity, and can generate reports which help the effective utilisation of vehicles; Control+ delivers additional features such as out-of-hours reporting, driver behaviour alerts, a full report suite, as well as access to performance dashboards, and real-time alerts via SMS.

The company also offers useful optional add-ons to further enhance its telematics capabilities. Front-facing cameras can be requested for capturing any evidence required in the event of an accident as well as informing operators on driver behaviour. In scenarios where drivers hop in and out of multiple vehicles, Northgate can add driver tracking as a bolt-on service. Esso Fuel Card connectivity is also available to keep track of fuel expenses, saving customers an average of 7p per litre on pump prices. It can also provide face-to-face training sessions to ensure the telematics services are used to maximum effectiveness.

Northgate’s cloud-based telematics platform is not only designed to gather impactful data on fleet usage but is also intuitive to use. With the ability to prioritise key information via branded dashboards, individual users can view different information according to their needs. Its clean interface clearly displays live locations via a map view, while additional data is accessed via easy-to-navigate tabs.

Recording multiple data points, from journey history and average speeds to vehicle idling times, the reporting software arms fleet managers with the information needed to maximise the efficient use of fleets.

WANT TO KNOW MORE?

18 CVW NOVEMBER 2022 DIAGNOSTICS & SOFTWARE: WHAT'S NEW?

WWW.RDR.LINK/VAS005GOTO

GOTO

MOBILE POWER HELPS SEMIS

BOWMONK

Like most powered vehicles on the road, a semi-trailer requires maintenance to ensure it runs as safely and as smoothly as possible. Unlike rigid-framed vehicles, where the electrical and air systems are all charged and accessible, it is not always the case when maintenance has to be carried out on a semi-trailer, as there are often no units available with which to power up the trailer`s electrical and air operated systems.

That problem is solved with the arrival of the Bowmonk TrailerCheck Plus, a mobile power source that replicates a unit, connecting with the trailer`s air and electrical circuits. It is designed to fit inside a mobile service vehicle taking its electrical power from a rechargeable 24V battery situated inside the enclosure, with the air being fed from a small portable compressor located inside the service vehicle.

The TrailerCheck Plus will power up all the trailer`s electrical system to check the lighting circuit, the ISO 7638 ABS and EBS function, as well as the integrity of the HI and LO CAN communication circuits. By connecting the TrailerCheck`s 24N and 24S sockets to the trailer and turning on the ‘Auto Light’ test switch, the trailer lights will illuminate in a pre-set order for approximately 10 seconds each, allowing the operator time to check each light.

Connecting the TrailerCheck`s red emergency and yellow service air lines to the trailer allows the technician to manually operate all of the braking components and check for any failure, whilst being able to check or adjust the rake pressures using the regulators. This can also be checked remotely with the 15m remote control unit, enabling the operator to view during component operation. The TrailerCheck Plus can also be located in the workshop, mounted on an appropriate work station.

WANT TO KNOW

MORE? WWW.RDR.LINK/VAS006GOTO

ORCHESTRATING EFFICIENCY

ZF

ZF’s Commercial Vehicle Solutions (CVS) division has launched SCALAR, its advanced new digital fleet orchestration platform. Offering a diverse suite of features designed to optimize commercial fleet operations, SCALAR supports a wide range of customer requirements including fully automatic and live planning, routing, scheduling and dispatching solutions.

The company claims that it will help commercial fleets achieve new levels of efficiency by establishing intelligent end-to-end systems which ‘orchestrate’ the whole process of freight logistics as well as passenger transport.

The platform leverages unique vehicle data and takes real-time, AI-based automated decision-making and fleet optimization to the next level. Its open, modular platform can support a wide range of customer requirements for both homogeneous and mixed fleets.

The integration of Bestmile’s Orchestration solution represents both a technology enabler as well as a significant commercial milestone for SCALAR in preparing the ground and delivering orchestration services. Underpinning ZF’s strategy to realize Mobility-as-a-Service (MaaS), ZF is already successfully commercializing the Mobility Service Orchestration Solution, enabling public and private mobility providers to plan, launch and operate highly efficient fixed-route and demand-responsive transportation services for passengers.

WANT

WWW.RDR.LINK/VAS

NEW PARTNERSHIP DRIVES PREDICTIVE MAINTENANCE FOR IRISH FLEETS STRATIO & GENIE INSIGHTS

Stratio, the predictive fleet maintenance platform, has teamed up with Genie Insights, the provider of fleet technology and marketing services, to implement and support the rollout of real-time predictive maintenance technology to Irish transport fleets. The Stratio platform allows transport companies to understand what is happening to vehicle components without physically looking at them. By harnessing the power of data, Stratio provides realtime insights to fleet managers through a platform that collects, analyses and explains vehicle errors, component failures and fluid or wear levels that are outside of safe tolerances to predict defects or breakdowns before they happen.

County Antrim-based Genie Insights is a fleet and workshop technology specialist that helps transport operators to manage compliance, improve safety and reduce costs by digitizing fleet management processes.

Genie Insights is already working with other technology partners, including the fleet maintenance software provider, Freeway Fleet Systems, which now integrates with the Stratio Platform. Genie Insights has supported many of Ireland’s largest fleets to adopt Freeway, including Go-Ahead Ireland, McBurney Transport, Calor Gas, McCulla Transport, P&O Ferries and Agro Merchants (now Americold).

For Freeway customers choosing to integrate with Stratio, fault codes and maintenance metrics are automatically pushed into the Freeway system if a defect or out-of-range parameter is detected. Whether using Freeway and Stratio combined, or using Stratio as a standalone platform, fleet managers can get alerts at the early signs of malfunction so action can be taken.

WANT

20 CVW NOVEMBER 2022 DIAGNOSTICS & SOFTWARE: WHAT'S NEW?

TO KNOW MORE? WWW.RDR.LINK/VAS008GOTO

TO KNOW MORE?

007GOTO

In the automotive industry we look after

our own. Life can throw the odd curved ball no matter what stage of life you're at: money worries, illness, mental health issues, social isolation. It can create a downward spiral for you and your family. It's why Ben's here. At these moments our support and care services can be life-changing. Ever since there's been an automotive industry Ben has been helping its people and their loved ones keep life on track. Together we’ll tackle the challenges that get in life’s way and make sure they don’t, for life. Here for the automotive industryFind plenty of advice, online chat and self-help tools on our website, or talk to us on the helpline, free and in complete confidence, Monday-Thursday 8am-8pm, Friday 8am–5pm Always here for you www.ben.org.uk Helpline 08081 311 333

Tony Mailling, head of hot retread production at Bandvulc, reckons that retreads are unfairly seen as poor relations to new tyres and seeks to put the record straight.

RUNNING HOT AND COLD

What’s the first thing that comes to mind when you think of retreaded tyres? You might automatically associate retreads with beingcheaper than the equivalent new tyre. Or you may focus on their role in reducing rubber waste.

Unfortunately, one often encounters a misguided perception that retreads are somehow a poorer relation to box-fresh tyres. There’s a view that they’re just a cheaper option to reduce fleet costs. The reality couldn’t be further from the truth. While retread tyres often retail at a lower price than their brand-new counterparts, their reduced cost does not translate into a lack of quality or innovation.

What’s involved in retreading

There are two main types of retreading –hot and cold. Both methods offer different advantages to the customer. Cold retreading involves the application of a new patterned tread onto a buffed casing. This allows for a wide selection of tread designs to be applied.

Hot retreading, on the other hand, has a lot in common with the production of new tyres. The casing is stripped, and the carcass is retreaded from bead to bead using the same profiles and rubber mixtures found in a factory-fresh tyre. This method allows the sidewalls to be renewed and maintains its ability to be regrooved –but more on that later.

As you might expect given the processes mentioned above, the research, development and engineering involved in delivering a new retreaded tyre is exhaustive.

Setting the standard

A well-designed, well-made retreaded tyre should be indistinguishable from new rubber. Retreading is actually a highly regulated industry with safety and durability at its core. Though every manufacturer is different, all will conform to the UN’s ECE Regulation 109, which ensures that the performance, dimensions and tyre sidewall markings are similar to those of a brand-new tyre.

TYRES & WHEELS NOVEMBER 2022 CVW 23

“While retread tyres often retail at a lower price than their brand-new counterparts, their reduced cost does not translate into a lack of quality or innovation.”

Tyre choice

Bandvulc retread ranges are its own designs, brought to market using its own in-house formulated rubber compound. Sister company ContiRe’s tyres, on the other hand, are designed to be identical to its newly made siblings.

At the leading proprietary plants, high standards of production are assured by the use of ISO auditing criteria. By using an internationally recognised quality management accreditation, the production of a consistent product is ensured.

Dispelling any fears about the safety or longevity of a retread tyre comes from ensuring that the donor casing is fit for reuse. Tyre retreaders have expert teams tasked with inspecting each tyre by hand. As it’s impossible to see any issues lurking under the surface, shearography is used. This works like a tyre ultrasound to analyse the core structure. If a problem is found, the tyre will be rejected and recycled, rather than retreaded.

A greener choice

When it comes to sustainability, retread tyres stand head and shoulders above new rubber. It’s an important consideration for fleet operators, many of whom are becoming increasingly aware of their environmental overheads.

Retread production uses less energy than new tyre manufacturing and requires fewer raw materials, too. Although I can’t speak for our competitors, we only use on average 20% of the comparative resources to make

our products.

One of the reasons is that the casing, which is constructed using steel, is reused. Steel manufacturing is an energy-intensive operation and contributes significantly to a tyre’s environmental impact. As there’s no need to add any new steel in the retreading process, a major contributor to the overall emissions is avoided.

Even the discarded rubber crumb produced when preparing a tyre for retreading is incorporated into the formula for the new compound. Disused rubber is recycled and will often find its way into the likes of playground matting and carpet underlay. The environmental benefit of retreading doesn’t end once a tyre has left the plant, either. If it has been produced by the hot retread method, the operator can in most cases regroove their tyre, extending the life even further. In practice, that means that one casing can feasibly have at least four service lives.

Next time you’re reviewing your tyre policy, spare a thought for the retread. They more than deserve our respect.

TYRES & WHEELS

FOR MORE INFORMATION, WWW.RDR.LINK/VAS009 24 CVW NOVEMBER 2022

“A well-designed, well-made retreaded tyre should be indistinguishable from new rubber.”

KIT INSPECTION

Commercial vehicle operators are presented with many challenges in order to maintain a safe, efficient and effective vehicle fleet. From daily safety checks to periodic brake safety testing, all of the checks and tests have to be scheduled around the daily operational activities and requirements related to consignment schedules.

The outsourcing of checks and certain repairs can further impact the smooth flow of operations and incur increased fleet downtime and costs. Equipping commercial vehicle workshops with the appropriate equipment to test and maintain tyres, axles and suspension can significantly improve workshop operations and the subsequent fleet utilisation.

Fleet operators can select a suite of equipment to improve their maintenance regimes respect of:

■ Brake testers, for in-house safety checks and MOT preparation.

■ Tyre changing and wheel alignment equipment.

■ Suspension play detectors.

Integrating brake testing in-house can deliver significant benefits to the fleet operator. For example, the DE-9700 commercial vehicle roller brake tester allows the operator to build their own fleet database, automatically recording vehicle test results and removing all of the administrative activity of creating a manual records system up in the office. Add in the ability to test a vehicle within minutes

together with minimal down time for the trailer, tractor, driver and no third-party fees to pay, then the benefits start to multiply dramatically.

It isn’t all about safety checks though: it is also about preventing system failures and eliminating on road problems. Brake binding and orality issues can be diagnosed early and preventative maintenance scheduled appropriately. The binding brake that causes overheating and wheel bearing damage can be addressed in good time, reducing the risk of the potential subsequent on road failure with expensive call out repairs and delays to the load shipment.

To benefit from in-house tyre and when maintenance, operators need to consider four stages of operation. Fit efficiently, inflate safely, balance effectively and align accurately. A wide range of proprietary equipment enables operators to adequately address these requirements and reduce their dependency upon third party maintenance providers. Commercial vehicle tyre changers will safely handle large HGV wheels. Robust jaw-clamping systems

ensure wheels are held securely during the tyre changing operation, and tyre inflation cages will ensures tyre inflation can be undertaken in safe conditions.

Detecting wear and play in steering and suspension joints can be made easier and quicker by installing DVSA-approved MOT play detectors, known affectionately as shaker plates. This allows all the vehicle maintenance technicians to subject the vehicle to the same standard of test procedure that is used in DVSA MOT Authorised Test Facilities. By testing to the same standard, technicians can identify and rectify and potential MOT failure items prior to the test. This can save significant vehicle downtime that arises from dealing with a MOT failure together with all of the time-consuming and costly return visits to the workshop and back to the testing station for re-test.

For instance, the Tecalemit DE/7353 Commercial Vehicle Hydraulic Play Detector consists of two Electro-hydraulic recessed floor plates. A single axle is presented to the play detector plates and the technician controls the movement in four directions using a simple hand control with integral illumination. This allows the steering and suspension joints to be examined for wear in a safe manner whilst avoiding the need to handle the road wheel or use pry bars to identify steering and suspension joint movement.

TYRES & WHEELS NOVEMBER 2022 CVW 27

can improve their maintenance regimes and take costs out of testing.

FOR FURTHER INFORMATION CONTACT THE TEAM AT WWW.RDR.LINK/VAS010

SECOND TIME AROUND

The retread process for truck tyres has evolved significantly over recent years. In fact, retreads today offer the same high level of safety and performance on the road as new tyres.

With the current economic climate and pressure on costs, we’re receiving more requests from our fleet customers for cost savings around tyre management. At the same time, they also need to reduce the impact their deliveries are having on the planet and are being asked by their customers to prove their green credentials.

This is why retreads are a smart choice for fleet operators - they use fewer natural resources and consume less energy to manufacture than a new tyre, so are kinder to the environment. They also produce less CO2 emissions compared with a new tyre.

For commercial vehicle workshops, being clued up about retreads is vital. Knowing when a retread makes sense for a particular type of operation, and helping your customers understand the benefits of retreads, will strengthen the relationship and firmly cement your role as trusted adviser to their operation.

For those on the fence about retreads, here’s top five arguments for why they should consider retreads in their fleet tyre management programme.

A worn tyre being inspected during the initial inspection process.

■ Environmental benefits

Retreads boast a number of environmental benefits that can boost operators’ own green credentials. From a production point of view, the retread process uses 75 litres less oil than manufacturing new tyres, so typically around 40% – 60% less energy is consumed in the process of retreads. While from an operating point of view, retreads can produce up to a 30% reduction in CO2 emissions compared to

A worn tyre placed on the buffing machine before the buffing process.

a new tyre. This is based on a standard size tyre for an 18 tonne or 26 tonne truck, and taking into account that the right tyre pressure is adhered to and the vehicle is being properly operated and maintained. Again, another key stat that operators can use when proving their sustainability commitments to prospective customers.

Moreover, the reuse of tyre casings means rubber and steel waste is minimised, and on average, we say that with a retread policy, transport operators can reduce their tyre waste by 50%.

■ Economic benefits

Retreads are economically more viable than new tyres. A retread on average is around 20% – 25% cheaper to purchase up front than a new tyre, thanks to the lower costs associated with producing a retread versus a new tyre. Even with rising energy costs and other overheads going up, retread manufacturers are constantly looking at ways to reduce costs so that they don’t get passed onto the customer.

The tyre after the buffing process has been completed.

Not only that, but if a transport company operates in an environment where its vehicle tyres are constantly suffering damage, it is more economical to use retreads than continually replacing new tyres.

TYRES & WHEELS

28 CVW NOVEMBER 2022

Prometeon’s fleet development engineer Gary Lane discusses why retreads are a smart choice not just for operators’ pockets, but for improving their green credentials as well.

■ Quality

Retreads are designed to be durable, long-lasting and safe. When a premium quality tyre is used for retreading and the casing is also of premium quality, a retread today is easily designed to do half a million kilometres quite easily and comfortably.

The quality checks that a retreader performs on every single worn tyre that comes through their facility is also seriously impressive. Our retread partner Vaculug performs a total of eight quality checks throughout the retread process. This includes visual and tactile inspections, an electronic penetration test to detect any minute holes within the tubeless liner, and time, temperature and pressure checks.

Even at the very final stage, if any imperfections are discovered, the tyre will be rejected. Very rarely are failures seen, but these rigorous quality checks provides confidence and reassurance that every retread produced meets the utmost quality and safety standards.

Most retread tyres will last several years when maintained effectively due to the fact that they are made of similar rubber compounds and tread designs to new tyres, so they definitely tick the durability box.

■ Innovation and investement

The retread industry is constantly innovating and investing in new technology. More than 80% of retreaded truck and bus tyres used in the UK are made in the UK, and the sector contributes £230m to the UK economy ever year. It is by no means a small industry, and constant advances and investment in technology and processes are being made.

At Prometeon, we have recently been involved in designing a new retread product with Vaculug. This has involved changing the compound and tread profile on one of our most popular retread products, the Prometec Retread

trailer tyre. The result is a reduction in friction thereby improving the longevity of the tyre. We have also invested in a 12segment high pressure mould [an advancement on the standard six-piece mould] that produces a better quality remould, thereby improving the longevity of the finished tyre.

■ Wide range

Retreads are available for a range of applications. Although retreads make practical sense for transport operators involved in off-road and rugged environments (such as quarries and construction sites) where the rate of wear and tear on tyres is more rapid, retreads today are manufactured to suit a range of applications and fleet vehicles. From long haul to short haul and last mile operations, and from agriculture and waste vehicles to ports and deep mining operations, there are retread tyres available to suit all these different use cases.

It’s also important to point out that retreads work best when used in tandem with new tyres as part of a tyre management programme. We typically advise operators to adopt a standard tractor/trailer combination using new tyres on the front and rear axles of tractor units, while the other two axles can be retreads.

Retreads can without doubt hold their own when it comes to performance, safety and sustainability, and as operators face ever more pressure to manage costs while also improving their impact on the planet, retreads are a smart choice.

NOVEMBER 2022 CVW 29

“More than 80% of retreaded truck and bus tyres used in the UK are made in the UK, and the sector contributes £230m to the UK economy ever year.”

FOR MORE INFORMATION ON PROMETEON’S FULL RANGE OF RETREADS, WWW.RDR.LINK/VAS011

The carcass having new tread material applied.

The empty press before the built tyre is placed inside.

Cured tyre in the press after curing, awaiting final inspection.

Final finished retreaded tyre.

TYRES

FRONT TO BACK COVERAGE HANKOOK

Hankook has expanded its SmartFlex range with two new tyres: the SmartFlex AH51 for steering axles and the SmartFlex DH51 for drive axles. They cover a particularly wide range of applications including long distance, regional traffic and last mile distribution.

The company claims a considerable increase in mileage performance for both these latest tyre patterns – namely 15% for the steering axle and 20% for the driving axle compared to their predecessors. Moreover, a 10% reduction in rolling resistance for the SmartFlex AH51 and DH51 contributes to a further reduction in fuel consumption when compared to its 31 series tyres. Both the two new treads can be regrooved and are retreadable.

The SmartFlex AH51 can be used as an all-position tyre and is equipped with wide tread blocks and additional supports (TWES: Tread Wear Equalised Stepper) in the outer grooves, significantly increasing tread stiffness which ensures even wear across the entire width of the tyre and further improves mileage and rolling resistance. The SmartFlex DH51 has a wider contact patch than its predecessor, which increases traction while improving mileage and rolling resistance.

WANT TO KNOW MORE?

WWW.RDR.LINK/VAS012

FAST FORWARD FOR FLEETS

BRIDGESTONE

Bridgestone has launched Fleetcare, an integrated tyre and fleet management solution designed to improve business for fleets. An evolution of Bridgestone’s Total Tyre Care, Fleetcare combines the company’s tyre range and tyre management solutions with fleet management solutions from Webfleet. Fleetcare is claimed to provide a host of benefits to customers, including total cost of ownership reduction, maximised customer satisfaction, time saving, regulatory compliance and increased sustainability, safety and security.

Fleetcare also delivers business benefits through IoT and data driven insights and services. It has been developed for managers of commercial fleets who are looking for a comprehensive and modular solution package that adds cost control and automation into their daily work, enabling better decision making.

WANT TO KNOW MORE?

WWW.RDR.LINK/VAS013

LEVERLESS TYRE CHANGER RAVAGLIOLI

The G1250.30 is a new a new leverless tyre changer from Ravaglioli. The new changer is claimed to make tyre assembly and disassembly operations even easier and is fitted with a patented leverless head and advanced automatic functions which provide for fast, precise and effortless tyre work, including on run flats.

An electromechanical actuator controls the synchronous movement of all three operating arms with a chain synchronization system. The center post locking with floating plate (patented), also suitable for reverse rims, offers a selflocking mechanism that reduces the effort of the operator. A memory system results in automatic head repositioning on rim edge that allows a new disassembly and assembly process to be rapidly resumed.

A sensor with automatic disc indent function activation guarantees precise and risk-free tyre bead breaking. The bead breaking system operates with two discs: the bead is broken quickly and safely by two opposite synchronized discs.

The rear of the unit is cable-free so as to guaranteeing the operator improved maneuverability and freedom of movement.

WANT TO KNOW MORE?

WWW.RDR.LINK/VAS014GOTO

30 CVW NOVEMBER 2022

GOTO

GOTO

& WHEELS: WHAT’S NEW?

GET IN LINE FOR FUEL SAVINGS

ABSOLUTE ALIGNMENT

Increased fuel economy is one of the main benefits of regular and accurate wheel alignment. For trucks, even a 1mpg improvement can negate over half the increase in fuel prices seen in the UK since the spring. As well as cost savings thanks to fuel efficiency, the amount tyre wear can be reduced due to correct wheel alignment should not be underestimated. In addition, if a vehicle is aligned as per manufacturer recommendations, there is a reduction in the amount of stress put on the driver resulting from the vehicle being more comfortable to drive, particularly over long distances.

Forward-thinking workshops could ensure that they can provide commercial vehicle wheel alignment services to meet current demand with the Absolute Alignment CV Wheel Aligner. The company claims it’s accessibly priced and can be easily upgraded to work with smaller cars and vans for mixed fleets or mixed customer workshops. All the latest features you would expect are incorporated into the aligner which has a small footprint when not in use and is claimed to have one of the speediest set up times in the industry.

Fast and reliable Bluetooth data transmission marks the unit out as an efficient part of any workshop, with the specific truck alignment software developed with and for CV garages. Lorry-specific Pro Wheel Clamps eliminate run-out compensation procedures and selflevelling measurement heads make for the speedy set-up times.

With the optional car/van extension pack, smaller Pro Wheel Clamps and straight front measuring heads are said to instantly make the CV aligner into an all-round general-purpose aligner. Extra heads fit securely on the cabinet/charging dock when not in use. Absolute Alignment offers full on-site training and installation, 12-month warranty and technical support. WANT TO KNOW MORE?

WWW.RDR.LINK/VAS015

GOTO

RIM READING

HOFMANN MEGAPLAN

The range of tyre changers and wheel balancers for commercial vehicles from Hofmann Megaplan currently comprises three tyre changers and two wheel balancers. The Megamount 352 Tyre Changer is available in single and threephase and is claimed to be the ideal machine for owner/ operators and truck tyre specialists alike. A rim clamping capability up to 27” and a 1600mm (63”) OD make it extremely versatile, while a two-speed hydraulic chuck makes fast work of any job.

The heavy-duty Megamount 752 is a tyre changer for truck and plant applications. Boasting a rim diameter capability of 14” to 56”, OD of 2300mm (90.5”), and rim width up to 1065mm (42”), this model is an ‘all-rounder’ for anything from buses to heavy plant machinery. It’s available in single and three-phase, and a two-speed chuck and portable control unit complete the specification.

The Megamount 852 is an extremely heavy-duty unit for handling the widest variety of CV and plant rims, from buses to earthmovers. Available in three-phase only, it will handle rims from 14” to 56” with OD up to 2400mm (98”) and width up to 1300mm (53”). An industrial strength gearbox and clamping chuck mean the Megamount 852 can work in the harshest conditions, such as mining facilities and military field operations.

The wheel balancer range comprises the Junior Truck Tyre Balancer, an affordable, heavy-duty truck wheel balancer; and the Megaspin 250, a portable, hand spin commercial wheel balancer, which can be operated in a workshop environment or on a mobile van. Both feature built-in wheel lifters and the ability to cover all car, LCV and HGV wheels.

PLASTIC FANTASTIC GOODYEAR

Goodyear has showcased an innovative “demonstration” truck tyre made with 63% sustainable-material content. The 63% sustainable-material tyre includes 15 featured ingredients across 20 tyre components and is labelled A in fuel efficiency, meaning it can offer the same fuel saving as the most efficient Goodyear truck tyres currently available. The demonstration tyre features four different carbon blacks that are produced from plant-based oil, end-of-life tyre pyrolysis oil, carbon dioxide capture and conversion and a low-carbon methane pyrolysis process. Some of the petroleum-based oils in the tyre have been replaced by rapeseed oil.

Silica is an ingredient used in tyres to help improve grip and reduce fuel consumption. This demonstration tyre contains a variety of silica produced from rice husk ash, a byproduct of rice processing that is often discarded and put into landfills. A high-quality silica has been produced from this waste ash. Finally, technical grade polyester utilized in tyre cords, which enables better ‘retread-ability,’ has been generated from plastic bottles and other plastic waste.

WANT TO KNOW MORE?

WWW.RDR.LINK/VAS017

STRAIGHT FORWARD ALIGNMENT SUPERTRACKER

Supertracker – now owned by Straightset – offers a complete range of computer sensor and laser aligners for commercial vehicles. Claimed to be uncomplicated and simple to use, the range consists of laser aligners for commercial uses, either wall-mounted or available on mobile units; computer aligners with either six sensor or eight sensor versions; and both with customizable options to meet the needs of fast fit workshops, used vehicle centres, independents and dealerships. Calibration and servicing are managed using what the company says is the latest service management software, dedicated in-house support and its own knowledgeable field engineers.

WANT TO KNOW MORE?

WWW.RDR.LINK/VAS018

32 CVW NOVEMBER 2022 TYRES & WHEELS: WHAT’S NEW?

WANT TO KNOW MORE? WWW.RDR.LINK/VAS016GOTO

GOTO

GOTO

ww w.cvwmagazine.co.uk CVW magazine @ CVW magazine For all the latest industry news, business advice and technical guides from the trade magazine for CV servicing and repair professionals

TYRES & WHEELS: WHAT’S NEW?

MONOBLOCK IN MOTION

THE PROMETEON TYRE GROUP

The Prometeon Tyre Group has unveiled a new 325/90 R24.5 tyre size under its Pirellibranded Serie 02 range. Developed in collaboration with wheel manufacturer Accuride Wheels, Prometeon is the first tyre manufacturer to propose this new size of tyre. To support the new size, Accuride has produced a specially designed wheel – a monoblock 24.5x9.00 wheel which replaces the current 24x8.5 (one-piece) tubeless wheel (TL) and the 8.5-24 (multi-piece) wheel, which are significantly heavier for tube-tyre (TT). Prometeon has developed the tyre for easier assembly and dismantling, and improved safety during operations. In addition, the new tyre has a greater load capacity (up to 5 tonnes per tyre) that ensures a broader application spectrum. It offers an alternative to 325/95 R24 and 12.00 R24 sizes on a new rim type specially developed by Accuride. This tyre/wheel rim combination becomes up to 957 kilograms lighter when shifting from a TT to a TL rim.

The performance of the new tyre offers greater strength and durability, higher mileage and a lower rolling resistance. The new rims are fully compatible with tyre pressure monitoring sensors (TPMS), which will be standard in the future.

WANT TO KNOW MORE?

019

TAKE THE WEIGHT OFF MAXION WHEELS

Maxion Wheels has launched what it claims to be Europe’s lightest massproduced steel truck wheel. With weight savings of 3kg across the wheel line-up, compared with current state-of-the-art steel truck wheels, Maxion’s lightweight wheels are said to can a payload increase of 40kg or more. The company asserts that its lightweight, high-performance wheel expertise has made it the leader in the supply of steel truck wheels and says that this new generation – as beginning with the first wheel, a 22.5 x 11.75 – will raise the standard even higher.

WANT TO KNOW MORE?

WWW.RDR.LINK/VAS

ALIGN IN REAL TIME

RL AUTOMOTIVE

RL Automotive has introduced a tyre management platform with a range of monitoring systems to help fleet managers reduce running costs, increase safety and limit the environmental impact of their operation. One such system, AutoAlign, is a dynamic and real time vehicle monitoring module designed to combat the problem of wheel misalignment. According to the company, misalignment is unknowingly suffered by a third of all commercial vehicles and around half of all cars and vans in the UK.

AutoAlign is a low-cost solution consisting of sensors fitted to the steering axle to detect wheel mis alignment as soon as it occurs. RL Automotive’s cloud-based servers automatically alert fleet managers so that they can take remedial action, saving fuel costs and excessive vehicle emissions. Just one degree out of alignment between wheels and/or the vehicle centre will cause a 15% deficiency in tyre wear and 3% increased fuel cost. Therefore, early corrective action will greatly reduce carbon output and keep PM 10 and PM 2.5 tyre particulate emissions to a minimum.

WANT TO KNOW MORE?

WWW.RDR.LINK/VAS

WWW.RDR.LINK/VAS

GOTO

020GOTO NOVEMBER 2022 CVW 35

021GOTO

LOOK, NODUST !

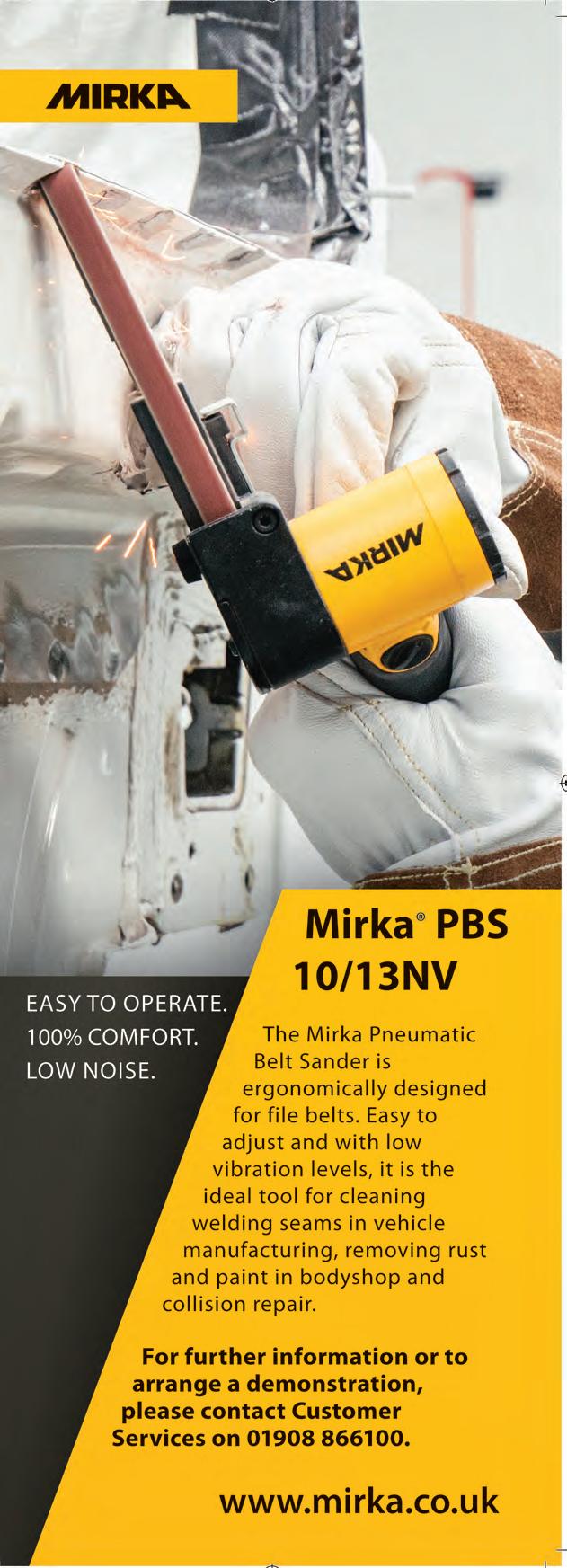

Make some tasty looking repairs with Mirka’s new Galaxy abrasive. Here’s how.

Surface preparation is key. De-grease surface prior to sanding with both a water borne and solvent degreaser.

Remove paint from repair area and feather out edges, with sander at a small tilt and strip layer by layer. Use grit 80/120 disc at 8000-9000 rpm.

Feather edge, sand flat and make a smooth transition from old paint to metal using 180 at 8000rpm.

Apply filler

Apply dry guide coat and sand body filler. Start with 80 or 120 and continue on to grit 180. Set sander to 8000rpm

Scratch conditioning/feather edgeing. Use dry guide coat, sand with 240 grit at 8000rpm

Move to primer preparation

TOOLS & EQUIPMENT 36 CVW NOVEMBER 2022

Apply dry guide coat to primed area.Use black or white guide coat depending on primer colour.

Block sand primed area. Use Mirka hand block or Mirka DEOS with 320 grit Galaxy strip.

Sand primed area with the sander set to 7000rpm.Use dry guide coat and 500 grit Galaxy disc with 5mm or 10mm interface pad.

Sand awkward areas. Use Goldflex Soft P500 or P800.

Clear coat sanding/ blending. Use Galaxy grit 800 or 1000 with the sander set to 7000rpm with 5mm or 10mm interface pad.

Sand edges and swage lines with Mirlon by hand. Use: Mirlon UF (grey).

De-grease and inspect repair and mask ready for paint

NOVEMBER 2022 CVW 37

FOR MORE ON MIRKA, WWW.RDR.LINK/VAS022

THINGSAREONTHE UP FOR STORY

Carlisle-based Story Plant has gone big with a recent £1 million plus investment in its new workshop facilities. Included in the expenditure was a set of four heavy-duty 10 tonne Stertil Koni Earthlift wireless mobile column lifts, type ST1100FWA.

The investment allows the business to upgrade and refurbish its fleet of road rail plant in line with Network Rail certification requirements. In addition, the company sees this as not only an upgrade opportunity but also to introduce improvements in performance, safety and reliability.

The Earthlifts are used to raise wheeled excavator-based road rail vehicles with a future capability to raise tracked variants using a bespoke designed track carrier. Each lift provides a safe lifting capacity of 10 tonnes which, when used as a set of four, provides an overall lifting capacity of 40 tonnes.

“Prior to purchasing the Earthlifts, we relied upon workshop pits which restricted where and how works could take place,” says Mark Bruce, Head of Technical Development at Story Plant. “The new lifts now give us the opportunity and flexibility to work on machines anywhere in the workshop to maximise available space whilst having multiple projects ongoing at any one time.”

A key factor in Story Plant’s decision to specify the Earthlift is the model’s Active Energy Retrieval System. The principle is simple - to use the energy generated by the raised vehicle as it comes back down to recharge the batteries: in other words, to harness the gravitational energy. The new system increases the number of lifting cycles by about 35%, compared to a fullycharged set of wireless mobiles under maximum load. In addition to the reduced power consumption, the batteries need less recharging, increasing productivity and reducing costs at a stroke.

As Mark Bruce says: “The combination of a reduced need for recharging, plus the harvesting of energy as the lift lowers, supports our drive towards sustainability. Consequently, the Active Energy Retrieval System was an important consideration when reaching our purchasing decision.”

New investment pays dividends for plant company.

reports.

Fingertip control

The heavy-duty model also benefits from the incorporation of a wireless-mesh connectivity system that’s been specially developed for industrial applications. Featuring fullcolour touch screen control consoles, the Earthlift’s eBright Smart Control System has been designed and developed to simplify operation by providing intuitive ease of use with maximum visual information about every lifting operation – all at the fingertips of the workshop technicians.

For added safety and performance, the eBright Smart Control System also shows how many columns in the set are being used and the battery status of each column. Safety is further enhanced by an independent mechanical locking system, incorporated into each column, which allows workshop technicians to securely lock the lift to prevent inadvertent lowering.

Thanks to the lift’s special characteristics, including bio-degradable hydraulic oil, 98% of it can be recycled at the end of its long life. The combination of this, plus the Earthlift’s energy-saving features make it the world’s most advanced and

sophisticated wireless mobile column lift, according to the manufacturer.

“Our projects are intensive over the duration of an upgrade,” says Mark Bruce. “Various stages in a project require access to different areas of machines as they are stripped and reassembled. We generally have five ongoing projects at any one time taking an average of 15 weeks per project. However, where an unplanned repair is required, the Earthlifts give us immediate access to the underside of machines outside of planned activities if required.”

As with all models in the Stertil Koni range, the Earthlift is supported by comprehensive after sales service options. These options have been designed to ensure that lifts are inspected and properly maintained and all required certificates are renewed annually in accordance with customer requirements.

TOOLS & EQUIPMENT NOVEMBER 2022 CVW 39

FOR DETAILS OF THE STERTIL KONI EARTHLIFT, WWW.RDR.LINK/VAS023

CVW

Whether you’re conducting axle and suspension repairs on a van, truck, bus or coach, completing a full wheel alignment check before signing off the vehicle is essential. And choosing the right tools to help you do this can be a difficult task.

However, by utilising technologies and innovative designs found in more modern systems, such as the Hunter WAHD, your workshop is capable of saving both time and labour costs, all while increasing profits and revenue and reducing vehicle downtime for your customers.

Making a difference

Many workshops have long recognised the impact that correct wheel alignment can have on the management of both tyres and fuel. After all, when a truck’s tyres are correctly aligned, tyre life can be extended by as much as 22% and 10% respectively for drive and steer axle tyres.

What’s more, the number of revenue opportunities available for workshops through wheel alignment servicing are huge. Research suggests that eight out of 10 trucks on the road suffer from some form of misalignment, so it really is an opportunity not to be missed.

A typical wheel alignment check requires technicians to carry out 17 different operations to get a full set of results which can take them around 15 minutes. But, with the WAHD from Hunter, the process is much simpler and slicker, requiring just seven steps, which can all be completed in just four minutes,

TOOLS & EQUIPMENT

Wheel alignment needn’t be time consuming nor taxing, says Clive Seabrook, CEO of Pro-Align.

“When a truck’s tyres are correctly aligned, tyre life can be extended by as much as 22% and 10% respectively for drive and steer axle tyres.”

40 CVW NOVEMBER 2022 ALIGN WITH THE

TIMES

helping to reduce labour hours and costs for your business, and delivering vehicles quickly back to customers to increase satisfaction levels.

Time saving

A huge concern for workshops that specialise in commercial vehicles is the time drain that a standard wheel alignment check can have on technicians. With a more advanced system, such as the WAHD from Hunter, this time is significantly reduced meaning technicians have more time to focus on other tasks and reduce vehicle downtime. This is essential for fleet managers, as keeping vehicles on the road making money is paramount to the success of their business.

TO DISCOVER MORE ABOUT THE DEDICATED COMMERCIAL VEHICLE EQUIPMENT AVAILABLE FROM HUNTER, WWW.RDR.LINK/VAS024

ARROW TARGETS IMPROVED PRODUCTIVITY