REGULARS

BRAKES

16 We talk to Diesel Technic’s Lars and Kevin, whose YouTube videos have over 12,000 subscribers, about brake systems, identifying common error patterns and offering practical solutions.

18 Know your tristop cylinders from your combination brake cylinders? The ins and outs of double diaphragm brakes are explained by febi.

MAHA’s Nick Austin urges operators to check there’s nothing fouling frames and brake testers as part of ongoing maintenance.

TYRES & WHEELS

visits Collins Earthworks whose 100+ strong fleet are putting Continental rubber through its paces.

Trailer wheel alignment is often overlooked says Russ Coad, md, AES UK, but the gains in tyre performance and cost make it worthwhile.

28 Clive Seabrook, CEO of Pro-Align, urges operators to think about alignment as a useful tool in the battle to keep costs down and mileage up.

30 Jeremy Krantz, Steertrak md, looks at tyre particulates and how effective alignment can mitigate them.

32 Tyre changes made easy with a step-by-step guide to the Hofmann Megaplan megamount 352.

34 What’s new?

BODY REPAIR & MAINTENANCE

36 As Mirka approaches its 80th birthday, CVW takes a backwards look at the surface finishing stalwart.

38 CVW covered the launch of the VBRA’s Elite Truck & Van Body Repair Standard last year. Eight months on, we find out how it’s going.

41 CVW learns about IRT’s new launches for the busy paint shop, where the focus is very much on speed and energy saving.

44 What’s new?

CONTENTS Issue 4 Volume 20 5 Viewpoint 6 News 8 Traffic news 10 CV Show Preview –highlights of the show 47 What’s new? 49 Digital digest

APRIL 2023 CVW 3 16 26 32

Editors

JOHNNY DOBBYN

JOHN LEVICK

workshop@cvwmagazine.co.uk

Editorial Assistant

FREYA COLEMAN

Group Editor

KIERAN NEE

Digital Manager

KELLY NEWSTEAD

Senior Account Manager

ALEX DILLEIGH

Group Manager

ROBERT GILHAM

Graphic Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Subscriptions

Commercial Vehicle Workshop is a business magazine for companies and individuals involved in all aspects of commercial vehicle servicing.

It is published 11 times a year and is available on free subscription to qualified readers.

Subscription rates: UK £30

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Walstead Peterborough

Published by HAMERVILLE MEDIA GROUP Regal House, Regal Way, Watford, Herts WD24 4YF Tel: (01923) 237799

Website: www.hamerville.co.uk

Copyright © 2023

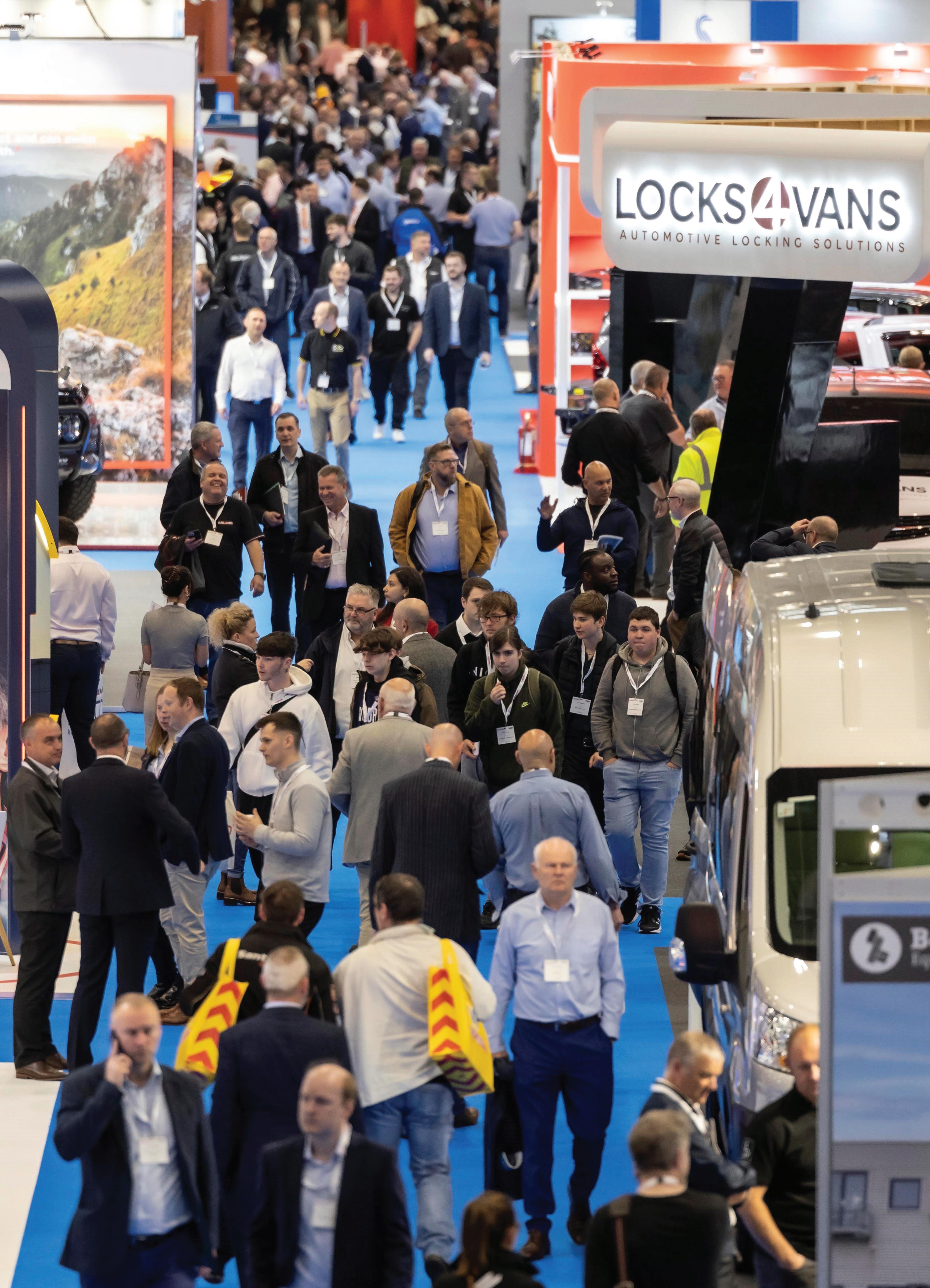

This month we are unashamedly championing the Commercial Vehicle Show. Why? Because it’s our industry event, whose success and future is largely dependent on the numbers turning up. Okay, it’s a day out of the workshop –good or bad, depending on your point of view – but it’s always worth making the effort to attend. Nothing beats the hum and hubbub of people discussing things, learning about new products or services or just catching up with old mates.

This year, there’s plenty to see and do if you put your mind to it. Exhibitors have invested time and money to be there, so it seems only fair that we should give them a willing audience. Nothing ventured, nothing gained.

The key to getting most out of the day is to be organised; plan who you want to see and talk to but be realistic. Ten good meetings or conversations are better than 20 rushed encounters where you learn nothing. And it is about learning and keeping abreast of developments, especially if they make your life easier.

Take advantage of the two live theatres – the Workshop Theatre, in association with Commercial Vehicle Workshop magazine, that’s us, and the Road Ahead Theatre – offering presentations on industry trends and live discussions over the three days of the Show.

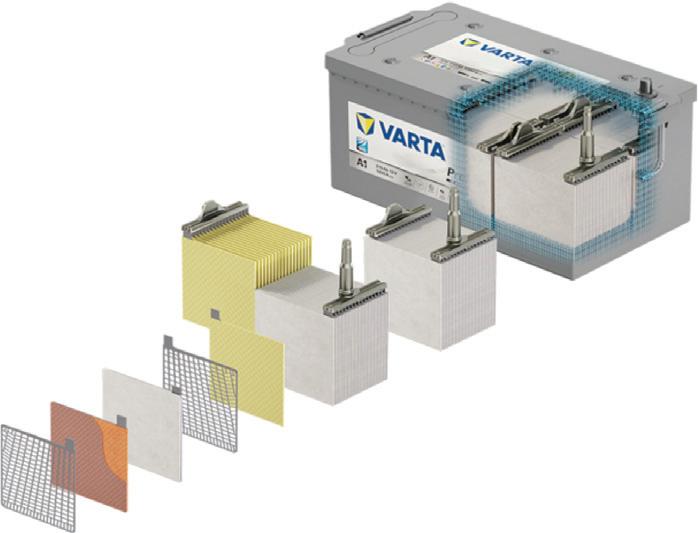

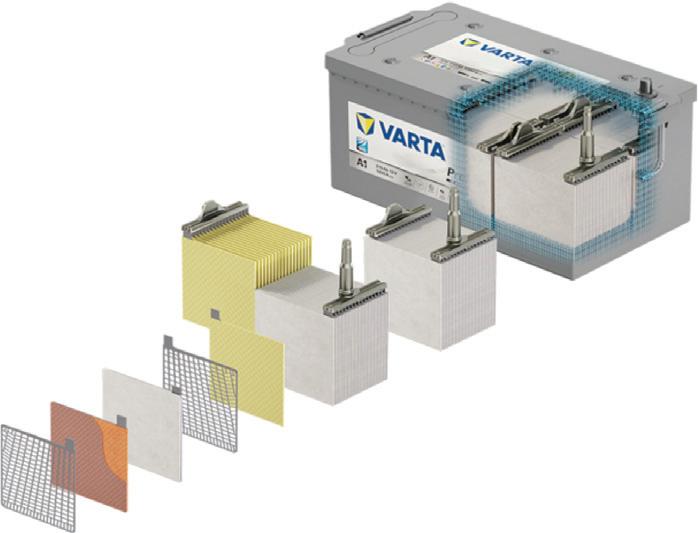

Our Workshop Theatre has some great presenters who’ll be providing insights on a number of topics from the future of lubricants, battery selection and management, body repair and looking after driver assistance systems. Each session is only 25 minutes long, so why not grab a coffee, come along and maybe learn something new.

There’s host of new names this year including FAPI Motors, ETRUX, Webfleet, Trim Technik, Solera, Hikvision, Versus UK, Charge & Recharge and Elerte, all eager no doubt to talk to you. Meanwhile, familiar brands include United Rental Systems, Legend, VFS, Truckman, Gearmate, Locks 4 Vans, Brigade, Gearmate, amongst many others that are just waiting for your custom.

You’ll see in this issue we’ve given you the heads up on some of the exhibitors, a useful taster of what to expect, though with over 200 companies in attendance, there’s a lot more to see on the day.

If you’ve time head over to our stand – 4F12 – and say hello. We’re always interested to talk to our readers and find out what really interests you and ways we can improve the magazine to give you the industry coverage you want. Whether you’re a workshop owner, technician or fleet manager, all feedback is gratefully received.

Hopefully we’ll see you there!

Happy reading.

8,249

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication

From 1 July 2021to 30 June 2022 Associate member

APRIL 2023 CVW 5 VIEWPOINT @CVWmagazine CVWmagazine www.cvwmagazine.co.uk

SHOW ANDGO!

“Ten good meetings or conversations are better than 20 rushed encounters where you learn nothing.”

TheCVWTeam

Earn and learn

Sparshatt Truck & Van, the Kentbased Mercedes-Benz commercial vehicle dealership, marked National Apprenticeship Week by celebrating its own success in recruiting apprentices.

Its heavy vehicle service and maintenance technician apprenticeship scheme is delivered at the Sparshatt Training Academy. Here apprentices learn on the job alongside highlyqualified Mercedes-Benz technicians and gain a thorough understanding of the latest automotive technology with up-to-date tools and equipment.

“Here I can learn and earn at the same time, both on the job and while at college,” says Ellie Barton, an apprentice in the program. “I have worked on trucks from a young age, so it made sense to learn something I am passionate about.”

FleetCheck’s Free Learning Library

FleetCheck, the fleet management software specialist, has just released a brand new series of fleet training videos that are available for free on its online Learning Library.

The videos, which last around two minutes each, cover topics such as fuel management, tyre management, telematics, driver safety management, and using spreadsheets. The company has also launched a video on its Fleet Confidence Challenge, a fleet safety assessment programme to help fleet managers ensure that their policies and procedures are up-to-date and in line with current legislation.

The Learning Library can be accessed at: www.fleetcheck.co.uk/learning-library/.

Used van values rise

According to figures from reseller BCA, January 2023 saw a surge in demand for light commercial vehicles (LCVs), with prices reaching their highest point since last July.

LCV values averaged £9,938 at BCA and, thanks to strong online demand, prices rose by £486 (+5.1%) compared to December.

Despite ongoing economic pressures affecting small businesses, BCA's LCV buyer customers reported improved demand at retail level throughout January, with sold volumes rising rapidly and significantly ahead month on month.

Drilling into the figures shows average values rising quickly in the New Year, peaking at over £10,600 later as the UK returned to work, well ahead of where they have reached in recent weeks.

BCA's COO UK, Stuart Pearson, commented: “Despite the ongoing economic issues facing every area of commerce – and small businesses in particular – there was healthy appetite across most of the LCV sectors.” Although small volumes of electric vans defleeted remained a point of volatility.

With the strength of the used LCV market surprising many, further acceleration of demand into February has been seen, said Pearson. With a significant March defleet extremely unlikely, competition for available stock means that used LCV values should remain resilient for some time to come.

Continental Tyres boosts RFU backing

Continental Tyres is now the official partner and title sponsor of the Rugby Football Union (RFU) and the Continental Tyres Schools Cup.

The multi-year partnership will focus on promoting performance and safety on and off the pitch, through the RFU's involvement with schools and other opportunities for boys and girls to play. Continental will also support England rugby fans’ journeys from local to international fixtures so they can support both the England men’s and Red Roses’ squads throughout major stages of their competitions.

“We’re really pleased to announce Continental Tyres’ long-term partnership with the RFU,” said Steve Grainger, RFU Executive Director of Rugby Development. “The Continental Tyres Schools Cup is an important part of the age-grade rugby

Your aid to transitioning

Logistics UK has launched a set of vehicle training courses to assist members as they change over to electric and hybrid vehicles.

The courses cover safety awareness, preparing the vehicle for repairs, and carrying out system repairs and component

competition landscape and support from Continental Tyres to enhance this over time is significant.”

On match days, outside Twickenham Stadium, Continental branded stewards will be present to guide and direct fans, including from the rebranded Continental Tyres Rosebine Car Park.

Inside the stadium, Continental branding will run along the perimeter advertising screens, as well as on television screens around the concourse, entrance, and team areas, and the big screen.

replacements. The half-day online safety awareness course is mapped to the IMI Level 1 Award in Electric/Hybrid Vehicle qualification content and enables learners to continue to work safely within their role following the transition. It is now available on the Logistics UK website.

6 CVW APRIL 2023

NEWS

UFI’s desert wonder

Ecobat partners with electric truck maker

British electric vehicle manufacturer Tevva is partnering with Ecobat, the global leader in battery recycling, for the repair, repurposing and recycling of its lithium-ion batteries.

The partnership starts with a 12-month pilot phase for first-life battery management, which might then extend into additional

energy storage and recycling solutions.

If an issue arises during vehicle life, Ecobat will ensure Tevva's in-house assembled lithium-ion batteries are handled, diagnosed and repaired using the most effective and environmentally-friendly methods.

Tevva founder and CEO Asher Bennett says that the partnership with Ecobat should reassure customers that they are covered for all eventualities and that these batteries would be dealt with responsibly.

Tevva's 7.5t battery-electric truck has recently entered mass production at the company's London facility. The Tevva truck offers up to 140 miles (227 kilometres) from its 105 kWh battery on a single charge and is ideal for last-mile and urban delivery fleets.

Study confirms Bridgestone tyre benefits

Bridgestone's Ecopia and Duravis tyre ranges have received top marks for fuel and CO2 savings in an academic study conducted by Coventry University.

The four-month study by Sreyas Sunil Kunnappally, a business analytics masters graduate, investigated the benefits of Bridgestone's premium products to commercial fleets.

It found that up to 40,000 metric tonnes of CO2 could be saved across the UK's haulage sector each year if every long haul HGV ran on Ecopia H002 tyres. This equates to a fuel saving per HGV between £2,200 and £3,200.

The data was categorised into regional (Duravis tyre range) and long haul (Ecopia tyre range). Only HGVs above eight tonnes were considered for the market split, with 90% weightage given for regional and 10% for long haul.

The same equation was applied to all regional HGVs running on Bridgestone's Duravis range. This calculated there would be annual savings of up to 3 million metric tonnes of CO2, with a fuel saving per regional truck of between £1,300 and £1,900.

@CVWmagazine CVWmagazine www.cvwmagazine.co.uk

This year’s ultra-challenging Rally Dakar truck category was won by Dutch driver Janus van Kasteren in his IVECO PowerStar with a Cursor 13 engine. The desert is a tough place to race, so quality filtration is a must – provided in this case by UFI fuel and oil filters as OE.

Hydrogen truck makes light work of round trip

While EV manufacturer Tevva's focus remains trained on building and delivering its battery-electric 7.5t vehicle, testing and development of its hydrogen-electric counterpart continues apace.

Four Tevva engineers: Charlie Cordell, Byron Dolman, Ryan Clark and Toby Hurst have recently carried out a 'range test' of Tevva's dual-energy prototype truck. The exercise saw the foursome accumulate more than 1,000km (approximately 620 miles) in the 7.5t hydrogen-electric vehicle, driving between Tevva's London HQ and the Scottish border at Berwick-on-Tweed, England's most northernmost town.

The return journey saw the truck cover almost 350 miles alone, without needing a single stop for recharging. This was made possible by the truck's hydrogen fuel cell which tops up

the range-extended (Rex) vehicle's lithium battery when needed.

Lead engineer, Charlie Cordell, said: "It was an amazing trip and we were so pleased the truck covered so many miles on the return leg, without the need to stop for a charge.

MAN for the job

MAN TRUCKS

Award-winning Pallet Plus of Colchester has recently taken delivery of 11 new MAN Trucks and in doing so has strengthened its dedicated palletised goods delivery and collection service.

Ensuring customers receive a focused and flexible service, the new fleet additions comprise one 12-tonne TGL, seven 18-tonne TGM, one 26tonne TGS rigids and two TGX 44-tonne 6x2 tractors. This mix of vehicle size ensures that Pallet Plus can continue to offer a delivery service platform that is built around the customer's

needs, is efficient, environmentally aware and economically cost effective.

Liveried in the traditional Pallet Plus colours of red with white writing and four black pallet-sized squares, featuring the company motto - "Think Pallet Delivery...Think Pallet Plus" all the vehicles will operate out of the Pallet Plus hub situated just minutes from the main A120, between the busy Essex county towns of Colchester, Harwich and Clacton.

The new vehicles are all powered by MAN's latestgeneration Euro 6e engines. Advanced in their design these

"The trip was a terrific demonstration of the range you can achieve in a truck that uses a blended system of electric and hydrogen. The freezing conditions were extremely challenging, but helpful too, in allowing us to gather important

data about vehicle performance, meaning we could make tweaks here and there and tailor its development."

Temperatures rarely climbed above freezing during the trip, and at one point it dropped to below freezing.

The Tevva engineers stopped off for hydrogen refuelling at Element 2 in Teesside on the first leg of the journey, as well as an earlier stop in the midlands. Element 2 is currently building a national infrastructure of hydrogen refuelling sites.

For more information, WWW.RDR.LINK/VAX001

robust power plants, the 4cylinder D0834 in the TGL 12-tonners, the 6-cylinder D0836 in both the TGM 18tonne, the 9-litre D15 in the TGX 26-tonne rigids and the D26 in the TGX 6x2 tractors, all offer outstanding performance and benchmark levels of efficiency.

Andrew Triolo, general manager at Pallet Plus Limited, said: "We've established a great relationship with both MAN Truck & Bus, our local sales executive Mark Richmond and

our local MAN dealerships, Harris Truck and Van, in nearby Witham, and Norfolk Trucks in Felixstowe. All parties involved recognise the importance of our operation. I'm delighted to say that with their partnering approach they totally understand our business and offer us a consistent and very much appreciated high level of wrap-around care."

For more information, WWW.RDR.LINK/VAX002

TRAFFICNEWS

8 CVW MARCH 2023

APRIL 2023

LET THE SHOW BEGIN!

It’s finally here. The Commercial Vehicle Show gets underway later this month. Here’s what you can look forward to if you’re thinking of coming along.

More than 200 exhibitors have confirmed their presence at this year’s Commercial Vehicle Show as the event celebrates its position as the UK’s largest and best-attended road transport exhibition, unmissable for anyone involved in the commercial vehicle industry and road transport.

New names this year include FAPI Motors, ETRUX, Webfleet, Trim Technik, Solera, Hikvision, Versus UK, Charge & Recharge and Elerte. Meanwhile, returning brands include United Rental Systems, Legend, VFS, Truckman, Gearmate, Locks 4 Vans, Brigade, Gearmate, amongst many other names from every corner of the road transport sector.

Exhibiting within the Show’s new dedicated Truck Zone are IVECO, Renault Trucks and Hydrogen Vehicle Systems who will all be offering visitors the chance to see their latest offerings and get up close to their vehicles. More details will be revealed on the precise line-up of vehicles on display in the coming weeks.

Several thousands of visitors have preregistered for their free tickets and many more are expected to do so in the run-up to the Show as more details of what’s on offer

are revealed. Many big brand names will join other well-respected enterprises and start-up innovators, as the Commercial Vehicle Show floor continues its job of providing a platform as the key event in the sector. The Show provides the place for everyone working within the commercial vehicle industry to be at – offering the best opportunity for seeing new products and services, networking with industry colleagues and the event where business gets done.

Live on stage

And with two live theatres – Workshop Theatre, in association with Commercial Vehicle Workshop magazine , and the Road Ahead Theatre – offering presentations on industry megatrends and live discussions over the three days of the Show, it’s one not to be missed. These featured discussions will address some of the most crucial and important topics facing the industry whilst answering questions from attendees and are crucial for anyone wanting to keep abreast of the latest developments and technologies in commercial vehicles, garage equipment and aftermarket, and costeffective technologies.

WHAT YOU NEED TO KNOW

OPENING HOURS

Tuesday & Wednesday: 09:00 to 17:00

Thursday: 09:00 to 16:00

VENUE

NEC Birmingham, Pendigo Way, Marston Green, Birmingham, West Midlands, B40 1NT

Tim Mustin, sales and marketing manager, comments: “The CV Show is renowned for attracting hundreds of exhibitors representing a broad spectrum of vehicle manufacturers, equipment and maintenance suppliers bringing the latest products, services and technology solutions to the industry. The annual business event is the perfect platform to see new product launches, re-engage with existing contacts and connect with key decision makers and 2023 will be no different, demonstrating the longevity and uniqueness of the event as the largest and best attended commercial vehicle event in the UK.”

FOR MORE INFORMATION ABOUT THE COMMERCIAL VEHICLE SHOW, WWW.RDR.LINK/VAX03

10 CVW APRIL 2023

AIR-SEAL PRODUCTS

STAND A33 HALL 4

According to Air-Seal Products, its tyre sealants can prevent up to 95% of tread area punctures up to the legal maximum of 12mm, providing a road-legal repair for the life of the tyre. These tyre sealants will also stop rim, bead, and other slow air leaks which will maintain optimum tyre pressure leading to increased fuel efficiency up to 3%, and increased tyre life of up to 20%.

For further information on Air-Seal Products, please WWW.RDR.LINK/VAX004

STAND B20

HALL 5

Bott – the manufacturer and supplier of vehicle conversions, van racking, workplace solutions and storage solutions – is showcasing the bott vario3, bott uno3 and bott modulo3 ranges. It is also displaying a fully bespoke EV van display. Visitors will be able to find out about the work Bott is doing on its current solutions to cater to all EV van specs. Bott’s team of experts will be on hand to advise visitors on how to customise their own vans and talk through the innovative van racking solutions on offer.

BRIGADE ELECTRONICS

STAND C46 HALL 5

Brigade Electronics will be showing a range of systems that employ artificial intelligence (AI) to predict collisions so drivers can avoid them. SidescanPredict is one example, using ultrasonic detection and AI to analyse the speed, direction and acceleration of both the vehicle and detected object and the probability of an accident. It is also showcasing AI cameras, the latest development in overcoming blindspots. These cameras detect and recognise the human form within the detection zone and warn the driver before a possible collision.

For further information on Brigade Electronics, please WWW.RDR.LINK/VAX006

COMMERCIAL FUEL SOLUTIONS

STAND F67 HALL 5

Commercial Fuel Solutions now supplies AdBlue in containers that are fully recyclable and made using 30% recyclate, reducing the carbon impact of each drum supplied by 3.6 kg. It has also introduced a fair wear and tear policy, so it will replace the internal bottle of customers' IBCs free of charge once it reaches the end of its life. This process reduces the carbon impact by 97.5 kg/CO2e per container lifecycle.

GOTO

For further information on Bott, please WWW.RDR.LINK/VAX005

For further information on Commercial Fuel Solutions, please WWW.RDR.LINK/VAX007 GOTO

EXEROS TECHNOLOGIES

STAND D86 HALL 5

Exeros Technologies, the smart camera systems provider, is partnering with RAC Connected to further protect drivers and vehicles. Customers can choose from multiple camera systems that capture forward and rear views from vehicles to ones that live-stream, monitor drivers’ gestures using AI technology for signs of fatigue or distraction, and provide full security CCTV. Every camera system is integrated into the RAC Connected Platform so fleet managers can be notified about incidents with minutes of them occurring. This combination of dashcam footage, AI driver gesture monitoring and telematics data provides fleet managers with a clear understanding of any incident.

For further information on Exeros Technologies, please WWW.RDR.LINK/VAX008

GOTO

APRIL 2023 CVW 11

GOTO

CV SHOW PREVIEW

GOTO

BOTT

us on Stand 5D41 for our exclusive show offers”

“Visit

FISCHER PANDA UK

STAND E92 HALL 5

Fischer Panda UK is introducing the UK wide service support network it has developed after its first year’s partnership with Autoclima, the air conditioning manufacturer. It says the service network will offer the growing Autoclima customer base a more local service, creating a comprehensive aftersales and servicing provision within the commercial vehicle market.

GOTO

GOTO

For further information on Fischer Panda UK, please WWW.RDR.LINK/VAX009

GYS

STAND F103 HALL 5

GYS will be demonstrating its Powerduction induction heaters – the safe, fast and precise alternative to using oxy-acetylene that can reduce workshop’s insurance premiums by up to 30%. With no gas or flame involved, the GYS induction range is extremely easy to use and therefore requires minimal training. Also on display will be Startflash, an Invertor Starter, Charger & Battery support unit, and the Kronos range of MIG welding machines, which are energyefficient, easy to use and fully compliant with the 2023 Welding Regulations.

For further information on Powerduction, please

WWW.RDR.LINK/VAX010 GOTO

INFOPRO DIGITAL AUTOMOTIVE

STAND G64 HALL 5

InfoPro Digital Automotive will exhibit its data repair and maintenance systems. These include an oil and lubricant database connecting manufacturers, customers and distributors as well as OEMbased technical data for cars and light commercial vehicles. These provide a wealth of information such as repair instructions, wiring diagrams, detailed technical drawings, and technical service bulletins.

MERRIDALE

STAND E11 HALL 4

Merridale is launching FuelWorks, a web-based software that enables fleet owners to adhere to FORS reporting standards because users can monitor fuel usage, efficiency, and stock, predict restocking requirements and evaluate environmental impacts. The scope of Merridale’s products has grown from basic reporting systems to sophisticated data analysis and management packages. On the hardware side, it has a full range of depot refuelling equipment and tank management systems, which now include theft/sudden drop detection. The company will also be displaying its storage tanks, tank management and pump systems.

For further information on Merridale, please

WWW.RDR.LINK/VAX012 GOTO

MOTORMAX

STAND F30 HALL 5

Motormax is exhibiting and demonstrating its latest fleet safety product ranges, including Safetymax. This combines camera, viewing, warning and parking sensor technology to enhance visibility whilst manoeuvring vehicles at low speed. Another product is a driver safety monitor that uses AI to continuously monitor driver behaviour so it can detect fatigue, smoking, distraction, using a mobile phone, and whether the seat belt is engaged. Motormax will also show off Rapid Fix, a plug and play wiring loom that cuts the time taken to install devices such as parking sensors, reverse cameras and sensor step extensions.

GOTO

For further information on InfoPro Digital Automotive, please WWW.RDR.LINK/VAX011

For further information on Motormax, please WWW.RDR.LINK/VAX013

GOTO

GOTO

APRIL 2023 CVW 13

CV SHOW PREVIEW

RING CARNATION

STAND B68 HALL 5

Ring Carnation, the vehicle conversion electrical specialist, will be showing off the genisys gII ECU. This is equipped with a high performance 32-bit 300Mhz Atmel Cortex-M7 processor, with 2MB of on-board memory and 16 analogue inputs, enabling users to monitor multiple conditions such as battery voltages, temperature and pressure. The company, which has supplied switching systems to the emergency services since 1995, will also display the Wireless Switching Power Hub, which cuts installation time by up to 35%.

For further information on Ring Carnation, please WWW.RDR.LINK/VAX014 GOTO

TEXA UK

STAND D42 HALL 5

TEXA is showing off its diagnostic display unit –AXONE Voice – which guides technicians through all the diagnostic phases from finding out what is wrong to putting it right. It covers cars, trucks, motorbikes, off highway and marine vehicles and has the following functions: automatic vehicle search, TGS3s control unit scan, dashboards, interactive wiring diagrams, guided diagnosis, solved problems, technical bulletins, mechanical data, and error help sheets. TEXA is also introducing CCS 2 Dynamics, a transportable device for calibrationg cameras on light commercial vehicles and heavy-duty vehicles.

For further information on TEXA UK, please WWW.RDR.LINK/VAX015 GOTO

TOTALKARE STAND C10 HALL

4

More than 20 items of heavy duty and light commercial workshop equipment from Totalkare, including four mobile column lifts, brake testing equipment, a vehicle inspection kit and a tyre changer, will be on show. The T8 range of mobile column lifters includes both cabled and cable‐free versions and can lift up to 7,500kg per column, as will be shown on the stand where the cordless model lifts a tractor unit.

For further information on Totalkare, please WWW.RDR.LINK/VAX016 GOTO

TRUCKFILE

STAND D96 HALL 5

In partnership with voiceintegration specialist Dakota, Truckfile has developed a module that enables anyone carrying out a service, repair or inspection to use entirely verbal commands spoken into a microphone on a headset to record the job. Featuring Honeywell voice-directed technology, Truckfile Voice can speed up process efficiency by up to 20%. Truckfile software uses data from every inspection to record the maintenance history of a vehicle that will show how it is performing. This then enables the user to cut vehicle downtime through increasingly accurate predictions of any issues impending, so parts can be ordered and workshops booked. The system combines data about advisories, defects and faults, to give transport operators or workshop managers a full overview of the current state of a vehicle or asset’s health.

GOTO

For further information on Truckfile, please WWW.RDR.LINK/VAX017

VUE

STAND B73 HALL 5

Specialists in fleet CCTV and vehicle safety, VUE will exhibit its latest developments, such as its Driver Distraction AI and its Low Bridge Alerting System. There will also be live demonstrations of its Pedestrian AI camera system which intelligently pinpoints any pedestrian or cyclist around the sides or rear of a vehicle.

For further information on VUE, please WWW.RDR.LINK/VAX018

GOTO

14 CVW APRIL 2023 CV SHOW PREVIEW

WORKSHOP THEATRE

ROLL UP! ROLL UP!

One of the key features of the CV Show is the packed timetable of live events with industry and technical information being provided by some of the top players in the sector. The Road Ahead Theatre is backed by the IRTE, the RHA and the SMMT, while CVW Magazine supports the Workshop Theatre (Hall 4, F16) and this year’s looks like this at the time of writing.

TIMETUES18THAPRILWEDS19THTHURS20TH

10.00 – 10.25 hrs

Damian Milling, national Sales Thomas Hudd, national Simon Wallace, Customer manager, aftermarket, technical manager, VBRA.Engineering Trainer & Support Mann+Hummel (UK). Importance of certified repairs. Knorr-Bremse. Calibrating The E-volution of CV filtration.driver assistance systems (DAS).

11.00 – 11.25 hrs

Ken Clark, managing Ken Clark, managingAndrew Gibson, commercial director, Rotronics. Batteries, director, Rotronics. Batteries, fleet sector manager, Shell. It’s you – not me!It’s you – not me!Lubricant demand: now and in future (trucks and buses).

13.00 – 13.25 hrs

Vince Ward, technical sales Vince Ward, technical sales Damian Milling, national Sales & training, Varta. Advanced & training, Varta. Advanced manager, aftermarket, lead acid batteries; select lead acid batteries; select Mann+Hummel (UK). and maintain the correct and maintain the correct The E-volution of CV filtration. technology to save your technology to save your fleet time and money.fleet time and money.

14.00 – 14.25 hrs

Thomas Hudd, national Simon Wallace, Customer technical manager, VBRA.Engineering Trainer & Support Importance of certified repairs. Knorr-Bremse. Calibrating Driver assistance systems (DAS).

PUTTING THE BRAKES ON VIDEO

When you’re looking for answers, video has now become the go-to. CVW talks to Diesel Technic’s parts specialists, Lars and Kevin, whose YouTube videos have over 12,000 subscribers, about brake systems, identifying common error patterns and offering practical solutions.

‘Show’ is often better than ‘tell’ when it comes to problem solving, according to the Parts Specialists. “We always work through a live issue in our workshop videos, for example in the brakes systems video we are working on a transporter that is experiencing one-sided sluggishness on the right brake,” says Kevin.

When checking the service brake, Kevin quickly sees that the sleeves are damaged, and dismantles the brake caliper and brake pads, including the caliper carrier.

Lars runs through some of the common error patterns to look out for on brake pads, using examples to highlight key issues.

“Wear patterns and glazing on brake pads can indicate whether the pads are installed correctly or need adjustment. In the first example, the contact pattern was incorrect, and the disc has worn unevenly. As a result,

the pads are also glazed due to thermal load, with a shiny appearance across the surface. The bluish discoloration and porous surface also indicate extreme thermal stress. The consequences here are stiff brakes or other defects in the brake system,” he explains.

“Checking is absolutely essential,” cautions Lars. “It becomes dangerous when the brake pads no longer completely bear on the friction surface of the brake disc, as this reduces the braking effect.”

In another example, he points to a pad, once again glazed due to thermal load, where the brake disc is smooth at the top on the edge. “If the pad only rests at this point or the brake disc only grinds here, it can begin to squeak.”

Most vehicles are equipped with wear sensors (simple contact wear sensors or digitalised detection systems) that indicate

BRAKES

16 CVW APRIL 2023

the wear of the brake pads. This allows a defect, or ‘normal’ wear of the components to be detected in time. “For any pads that you want to replace but you want to keep the old brake disc, if the gauge hasn’t been reached yet, lightly chamfer the edges, this way you prevent noise,” he says.

Thermal overload is also reflected in drum brake linings through glazing, discolouration, cracking or even the parts being torn apart. Lars shows an example with extreme glazing which as a result means the braking effect cannot be achieved. He points to the bluish discolouration and crack formation, all of which indicates a thermal overload. “In this case the trailer control valve was defective. Here a compressed air system caused this, which resulted in the thermal overloading of the brake pads, and therefore the drum is now also defective. It’s really important to make sure that the pressures are right.”

In the next step, the two Parts Specialists show what should be considered when changing the brake pads for the parking brake. “Among other things, greasing the parts should never be neglected. However, care should be taken that the lubricant does not come into contact with the braking surfaces,” says Kevin.

The new brake caliper is installed together with the repair kit, including guide rails, screws, sleeves and grease to ensure that the items run smoothly.

Key tips from the Parts Specialists:

● Cleanliness is the be-all and end-all, because impurities that get into the brake system or the brake fluid can damage the sleeves or seals internally. The consequences would be repeated failure of the brake caliper.

● To find out the wear limit of the brake discs, use a caliper gauge. It is important to use a special brake disc caliper with measuring tips to obtain a meaningful result.

On the brake disc that Kevin is working on, the wear limit is 14mm, which is written on the disc but is now difficult to see. They replace the disc not only because at 14.3mm it is almost on the wear limit but also because it has a slight edge. Kevin notes that it’s also possible for brake discs to be cracked. “If they are completely cracked or cracked through to the cooling channel for larger brake discs, they must be replaced. Sometimes they may only have a small crack, in which case please check the manufacturer’s information as to when they need replacing.”

After the complete renewal of the brake system, Lars takes the transporter out for a short but slow spin around the yard to loop the handbrake in. More detailed information on the individual work steps can be found on the company’s YouTube channel.

APRIL 2023 CVW 17

FOR LARS AND KEVIN'S YOUTUBE VIDEOS, WWW.RDR.LINK/VAX020

STOPPING POWER

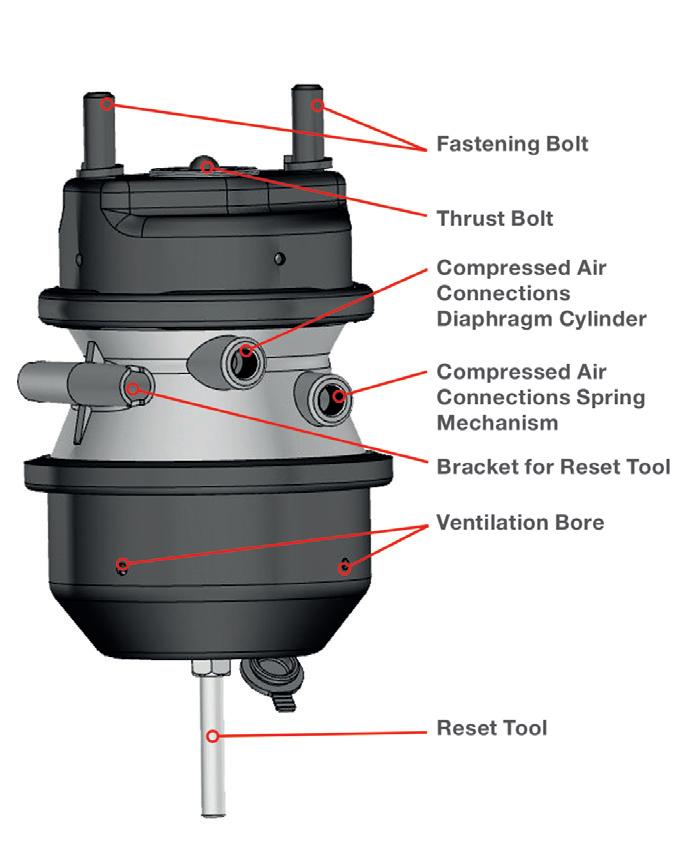

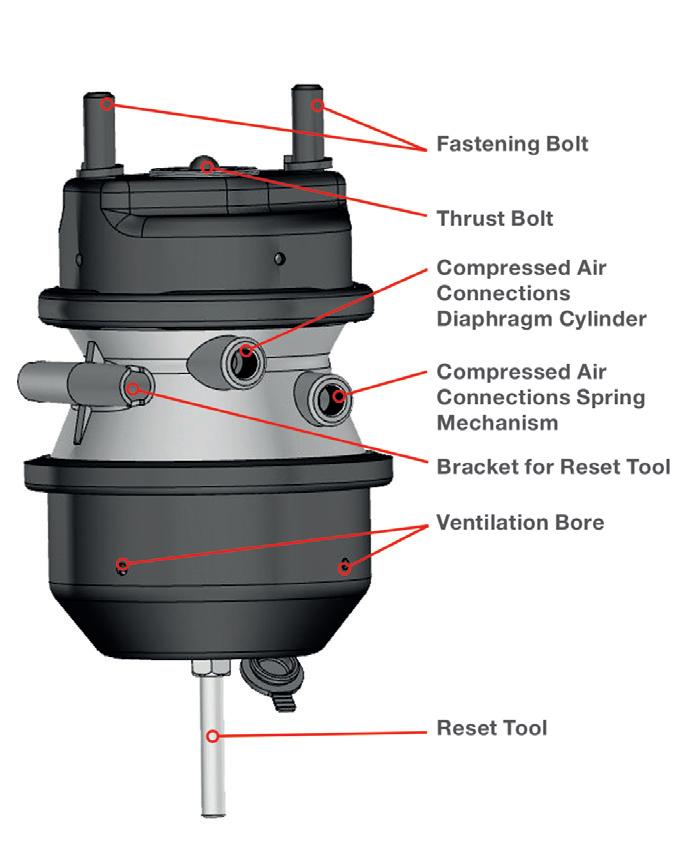

Know your tristop cylinders from your combination brake cylinders?

The ins and outs of double diaphragm brakes are explained by febi.

It comes as no surprise that heavy commercial vehicles require a particularly powerful braking system. Nearly all vehicles with a gross vehicle weight of more than 7.5 tonnes are equipped with a compressed air brake system.

Brake cylinders are required to convert theenergy contained in the compressed air into mechanical force. This takes place with the aid of a diaphragm, which is located in the housing of the brake cylinder. When the driver presses the brake pedal, compressed air flows into the brake cylinders. The diaphragm moves a piston and a pressure rod which transmit the force to the wheel brake.

There is a distinction made between brake cylinders with one and with two diaphragms. Brake cylinders with one diaphragm are generally used on non-driven axles. Brake cylinders with two diaphragms, also called double diaphragm cylinders, combination brake cylinders, or tristop cylinders, are installed on driven axles.

Double diaphragm cylinders consist of a combination of a diaphragm brake cylinder and a spring mechanism part. In addition to their function as normal driving brakes,

they also serve as parking brakes and as auxiliary brakes. The diaphragm brake cylinder acts as a driving brake, the springloaded part as a parking brake.

In contrast to the driving brake, which is pressurised for braking, the double diaphragm cylinder also brakes when no compressed air is applied. A spring in the spring mechanism part actuates the brake until compressed air reaches the spring mechanism of the brake cylinder. Only then is the spring compressed by the diaphragm and the brake released.

No air apparent

If the vehicle has no compressed air available, for example, due to a defect in the engine or the compressed air system, it is first braked by the spring in the spring mechanism. However, this spring can be retracted or tensioned with a reset tool which is inserted at the rear of the brake cylinder. Only then is the braking effect of the spring mechanism released.

A great danger is posed by the enormous force of the spring mechanism. If the clamp of the spring mechanism part is

loosened, and the spring is not tensioned with the reset tool, then there’s the risk of personal injury. And don’t forget to remove the reset tool after use!

There are several reasons why the brake unit might fail, from corrosion of the sheet metal parts, leaks, the spring fracturing to even a torn diaphragm.

Not only should the brake cylinder be checked regularly for secure fastening, function, and wear, but also the mounting and surrounding components. If there is any doubt about the correct function of brake cylinders, they should be replaced.

The vents must always be free and must point downwards. If this is not the case, water and dirt can collect inside the brake cylinder and lead to corrosion.

BRAKES

FOR MORE INFORMATION WWW.RDR.LINK/VAX021 18 CVW APRIL 2023

SectionalviewExternalview

ZERO TOLERANCE

Getting into the habit of completing routine checks and thorough maintenance of brake testers should help extend the life of equipment and ensure accurate results time after time. This will not only mean offering customers a professional and competent service but maximising the return on investment.

At a very minimum make sure the brake tester is reset to zero daily, as not doing so can distort results. During visits to workshops, particularly where those businesses are running 12 or 24-hour shift patterns, we have seen situations where the brake tester is never turned off and reset.

But the equipment is designed to be switched off and on again so it can be zeroed. That way, the user can be guaranteed of accurate results. The process of switching a brake tester off and on again, ready to be used, is approximately five minutes.

What’s more, operators need to ensure that there is no vehicle sitting on the equipment or someone standing on the edge of the brake tester; otherwise, the tester will add that weight to the ‘zero’.

Clean the frame recess!

As part of basic housekeeping a brake tester should be kept clean, tidy and free from debris. It’s important to clean out the frame recess as a minimum annually, and this is something we encourage when attending to calibrations.

When a brake test is in progress, rubber dust comes off the tyre, as well as general dirt. Over time, when that rubber mixes

with the dirt, it can set like concrete, especially when it’s wet inside the frame. As a consequence, inaccuracies can occur.

MAHA UK’s MBT 7250 is used extensively in ATF stations by DVSA, as well as franchised dealer and independent workshop sites preparing vehicles and trailers for test.

The MBT 7250 measures brake system performance quickly and accurately. Its large centre roller sensor, with a diameter of 100mm and axle load of 20 tonnes, guarantees excellent coverage across every tyre’s dimensions.

Its electronic, temperature-compensated strain gauge system produces precise measurements results, irrespective of the conditions, thanks to its robust and longlasting design.

It is also possible to connect additional floor units to the MBT 7250, so it can be used as a base module for installing test lanes. It’s also ideal for diagnostics, even when vehicle throughput is high, with the roller set dimensions making the equipment versatile. It can also be upgraded with many accessories.

BRAKES APRIL 2023 CVW 21

FOR MORE INFORMATION WWW.RDR.LINK/VAX022

Nick Austin, sales manager at MAHA UK, urges operators to reset their brake tester and ensure there’s nothing fouling the frame and the brake tester itself as part of their ongoing maintenance.

BRAKES: WHAT'S NEW?

PIPE BENDER AND CLAMP SET LASER TOOLS

Need to make up a new section of brake pipe? Want to accurately mirror the original pipe’s bends and curves when making up the new pipe? Then reach for this nifty brake pipe bender and clamp set from Laser Tools (part number 8523).

Included are a pair of brake pipe bender tools for shaping both copper and cupro‐nickel brake pipes in situ on the vehicle, or on the bench. They are designed to be used with a standard 6mm hex key or a 1/4"D ratchet (not included). Two pairs of brake pipe clamps are also included, to enable the new pipe to be held securely next to the existing pipe, so that the new pipe can be shaped to replicate the one that it’s replacing.

With the existing and new pipes clamped together, the bender tool is steadily turned, the tool’s radius ensuring a smooth curve without any kinking or flattening of the new pipe. Fabricate an accurate new pipe in minutes.

WANT TO KNOW MORE?

WWW.RDR.LINK/VAX023 GOTO

GREEN BRAKING BREMBO

Braking specialist Brembo has released its Greenance kit concept. This jointly developed new range of both special alloy discs and dedicated brake pads is the company’s latest solution to combine top braking performance with a lower environmental impact, while also increasing disc life.

The company claims that the new range has a much lower environmental impact with a significant reduction in emissions: 83% in PM102 and 80% in PM2.5. These solutions have already achieved the ECER90 homologation tests as well as the most stringent benchmark road tests, conducted by the company’s technicians.

Deriving its name by merging the words ‘green’ and ‘performance’, the Brembo Greenance kit concept is a solution that anticipates low environmental impact requirements. It matches both customer expectations and eagerness to contribute to a sustainable environment, without any compromise on top braking performances, says the company.

This pioneering solution is said to guarantee extended mileage and a significant improvement in terms of the total cost of ownership of vehicles. It ensures better durability of the brake discs, tripling their expected lifetime.

WANT TO KNOW MORE?

WWW.RDR.LINK/VAX024 GOTO

22 CVW APRIL 2023

HEAPS OF PRAISE

After almost a decade of partnership, transport and earthworks firm, Collins Earthworks, continues to be impressed by the service standards afforded to it by leading fleet service provider, Tyre Maintenance (TM). The long-standing contract now sees Continental’s CrossTrac steer, drive and trailer tyres fitted exclusively to its 100+ strong haulage fleet.

Established in 2000, midlands-based Collins has built a strong reputation for its work on major public and private sector infrastructure projects. The business has been involved with high-profile motorway upgrades, as well as in the construction of new business parks, distribution gateways and rail freight terminals. In addition to transportation and earthworks, the company offers demolition, ground stabilisation, training services and, more recently, construction and building services.

“Though I’ve only been with Collins Earthworks for three years, the relationship

I inherited was a good one,” explains workshop manager, Richard Williams. “Due to the size of the business, it makes sense for us to look after our own maintenance – TM is our tyre retailer. We do, on occasion, also utilise their fitting service at our other depot when we’re particularly busy. It’s always brilliantly managed and carried out perfectly – a lifeline, especially considering the shortage of tyre fitters.

“One of the biggest compliments I can give to TM is that they give us no reason to change suppliers,” Richard adds. “They’re reliable, consistent and always keen to make sure that we’re happy. Our TM sales manager, Darren, often comes to meet us in person and is always glad to share his knowledge. He’ll advise if there’s anything else we could be doing to the running on our trucks to maximise tyre longevity and

TYRES & WHEELS

24 CVW APRIL 2023

When the going gets tough, the tough get going. CVW visits Collins Earthworks whose 100+ strong fleet are putting Continental rubber through its paces.

“We like that we’re using the same product range across every truck and on every wheel.”

performance. We trust him to make the right decision on tyre supply based on our needs.”

Collins Earthworks made the switch to Continental rubber around five years ago. Although they occasionally trial tyres from other manufacturers, the company has stayed loyal to the marque.

“Again, for us, Continental hasn’t given us a reason to move tyre suppliers,” Richard says. “We like that we’re using the same product range across every truck and on every wheel. Continental is a premium brand, which fits into our ethos of using only premium equipment.

Consistent wear

“Our transport division is primarily focused on the facilitation of earthworks. That means the movement of heavy plant equipment, the haulage of construction supplies and the removal of waste. We can be managing loads of anything between one and 170 tonnes in gross weight. The tyres are also facing an assault from the rough and sharp surfaces on which they travel. Overall, they stand up to the task exceptionally well. We have a very strict service policy, which keeps them within their optimal window of performance.”

All new vehicles ordered by Collins Earthworks are supplied from the factory on Continental CrossTrac tyres. Richard reports that his most recent truck and trailer arrivals are still on their original tyres –some 14 months after delivery.

“Wear is consistent and evenly spread across the tyre,” claims Richard, “and the overall tread design really does help to prevent damage. Both the cost and reputational implications of a breakdown are huge. Given the immense weights we can carry, we often require road closures and police escorts. A failure in these

circumstances can cause unimaginable difficulties for our business, our customers and those services on which we depend.

“We struggle to fault TM’s service and the performance of the Continental tyres,” Richard concludes. “Time is the ultimate premium, and both allow my team and I to focus as much as possible on other demands. We know what we’re getting and there’s huge value in that.”

APRIL 2023 CVW 25 FOR MORE INFORMATION WWW.RDR.LINK/VAX025

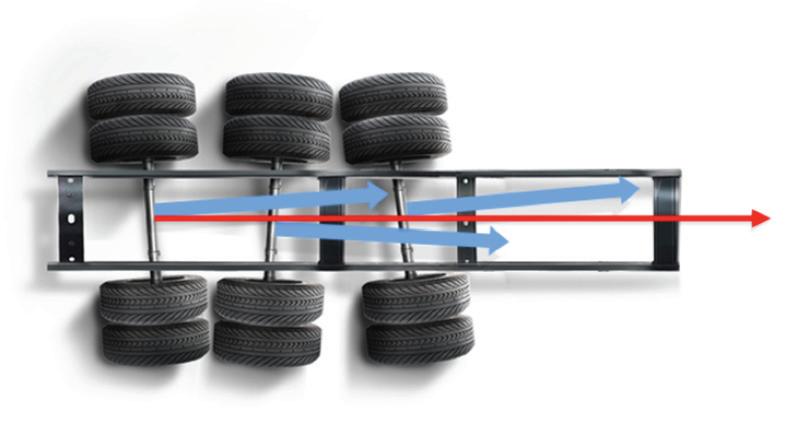

PULL IN THE RIGHT DIRECTION

Trailer wheel alignment is often overlooked says Russ Coad, managing director, AES UK, but the gains in tyre performance and cost make it worthwhile.

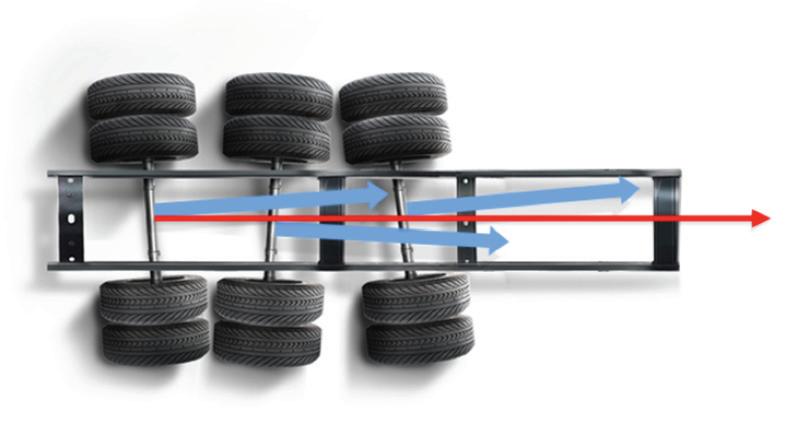

It is estimated over 50% of trailers on UK roads are out of alignment, with fleet operators often focusing on tractor units and overlooking trailers due to the nature of how they’re exchanged. AES believes there are enough benefits to be had for larger fleets to consider corrective wheel alignment on trailers including:

● cost savings – up to 15% savings on tyres costs with correct wheel alignment

● fuel savings – a correctly aligned trailer can reduce the pulling force (drag) on the towing unit lowering rolling resistance

● safety – misaligned trailers often take up more room on the road due to ‘dog-run’ or ‘crabbing’ that can create uncomfortable and unsafe handling behaviour for the driver

● environment – fuel and tyre cost savings reduce your CO2 emissions and tyre dust pollution

Cost effective

As an example, using data from the Department for Transport study (see below) AES has created an example of tyre cost saving for correctly aligned trailers versus incorrectly aligned trailers.

Though AES recommends annual proactive alignment checks on trailers, some fleet operators don’t have the luxury of being able to for whatever reason. If that is the case, we’ve outlined some pointers that could indicate issues with trailer alignment:

tyres – premature tyre wear, blow-outs and damage to trailer tyres. Premature wear on the towing unit crabbing / dog-run – driver complains or observable crabbing on a trailer instability – driver complains of bad driving behaviour such as pulling or additional drag beyond the norm

Corrective procedure

Wheel alignments on trailers can be carried out by trained contractors or through owned equipment, such as Josam alignment systems, which can measure all types of trailers and provide a detailed before and after report within the software, which also offers a tyre management system to monitor tyres alongside wheel alignments.

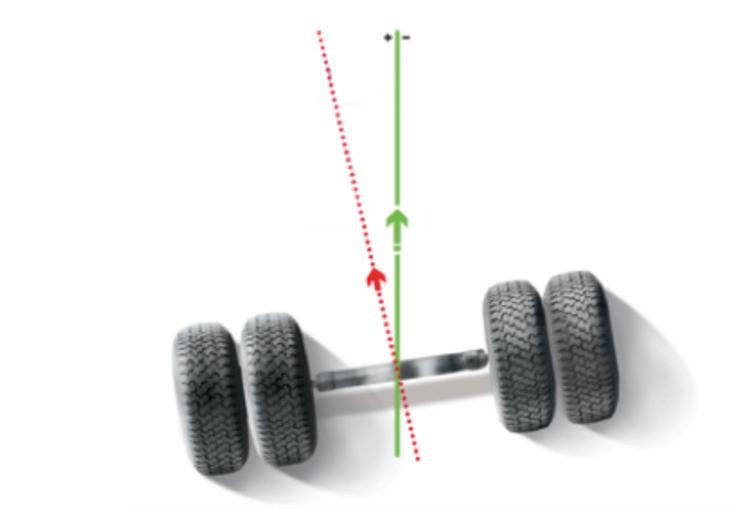

When measuring a typical trailer with three non-steered axles there are two main measurements to look for - out-of-square and parallelism. Out of square is the angle of the axle in relation to the centreline and

TYRES & WHEELS 26 CVW APRIL 2023

Potential annual tyre cost savings£10,800

EXAMPLE

TRAILER TYRE COSTS SAVING

Avg. super single tyre cost£300 Avg. mileage of super single200,000 miles Avg. annual driven miles100,000 miles Avg. no. of tyres on trailer6 Fleet size 80 Trailers

“It is estimated over 50% of trailers on UK roads are out of alignment, with operators often focusing on tractor units and overlooking trailers.”

Parallelism

Keeping trailers on the straight and narrow

A wheel alignment case study performed by the Department for Transport, using Josam equipment, performed in the early 2000s highlighted that a 0.5° misalignment can reduce tyre life by up to 50%.

A Lancaster-based company that employed 30 drivers and ran a 12-hour operation from Monday to Friday at the time of the study, with a that fleet consisted of 80 semi-trailers plus other vehicles. The company, running trailers on super single tyres, observed a 15% increase in super single tyre life on their trailers reducing costs significantly.

parallelism is the angle of two or more axles in relation to each other.

Right is an example of a 3-axle trailer with each axle having largely unique out-of-square axles in relation to the centreline. As you can imagine there would be increased tyre wear and drag on the towing unit.

In this particular example, depending on the OEM tolerances, each axle would have to be adjusted to bring it within tolerance in relation to the centreline, only adjusting one axle would have minimal impact.

FOR MORE INFORMATION

WWW.RDR.LINK/VAX026

Out of square

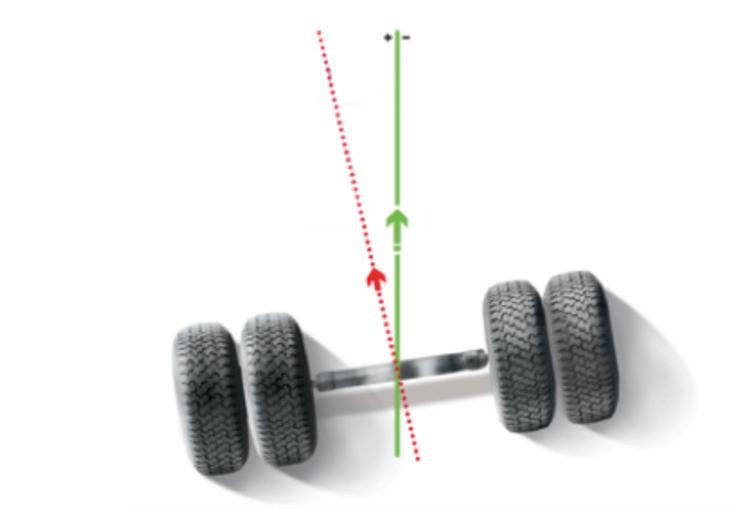

Ensuring vehicles get to their destination on time, safely and efficiently is of paramount importance for fleet operators. Any vehicle downtime can result in a serious loss of cash for businesses which often has a knock-on effect for its customers and can end up tarnishing reputations due to unreliability. Furthermore, with many multi-drop commercial vehicles heading from one job to the next, drivers often find themselves mounting kerbs and hitting potholes, meaning vehicle damage and wheel alignment is affected by the hour.

Regular vehicle maintenance plays a crucial role in reducing vehicle downtime, but one service that is often overlooked by fleet operators is wheel alignment.

Accurate and regular wheel alignment checks can help reduce fuel consumption, tyre wear, vehicle emissions and even driver fatigue, which in turn helps to increase driver safety. This also helps businesses

STRAIGHT

TALKING

save money on fuel and expensive new tyres, while reducing their carbon footprint. Wheel alignment servicing can help fleet operators seriously reduce their overheads and keep vehicles on the road earning money, yet it is still often disregarded by many across the industry.

Save thousands

When a truck’s wheels are correctly aligned, tyre life can be extended by as much as 22% and 10 % for drive and steer axle tyres respectively. This is because the properly aligned tyres no longer scrub across the road surface, causing additional rolling resistance and higher fuel usage.

Some studies have shown that fuel economy can be improved by up to 19%, helping to reduce running costs by tens, or even hundreds, of thousands of pounds a year for operators. These figures simply cannot be ignored.

Fleet operators must work with workshop owners and their technicians to ensure the right work is being conducted to help trucks and other commercial vehicles keep businesses from hitting a massive financial bump in the road.

TYRES & WHEELS

Clive Seabrook, CEO of Pro-Align, urges operators to think about wheel alignment as a useful tool in the battle to keep costs down and mileage up.

FOR MORE INFORMATION WWW.RDR.LINK/VAX027

28 CVW APRIL 2023

“...wheel alignment can seriously reduce overheads...”

SOMETHING IN THE AIR

As most will be aware, as vehicles move along, friction between the tyres and the road surface generates tyre ‘dust’. These particulates, alongside those released from brakes, are extremely small and are known as PM2.5 emissions. These can impact directly and negatively on human health as well as on the wider environment.

In the UK, The Department of Transport has been working with consultants to “develop recommendations on how to better assess and control these emissions” with media speculation around the possibility of a so-called ‘tyre tax’ being raised.

Respiratory problems

One of the main concerns of tyre dust particles is their impact on human health. When inhaled, these particles can cause respiratory problems such as coughing, wheezing, and asthma. This is because they contain harmful chemicals such as zinc, lead, and polycyclic aromatic hydrocarbons (PAHs). PAHs are also known carcinogens, and long-term exposure to them can increase the risk of cancer.

Tyre dust particles can also have a significant environmental impact. When they enter the soil or water, they can harm plant and aquatic life. In addition, they can pollute the air and contribute to climate change. A study from Imperial College suggests that approximately 6 million tonnes of tyre wear particles are released each year globally.

When compared to cars it is even more critical to address the issue of tyre dust particles generated by EVs, HGVs and other commercial vehicles due to their greater weight and higher propensity for tyre wear. These vehicles are often used for long distances and carry heavy loads, compounding the tyre wear and particulate issues.

To mitigate the impact of these particles it is essential to reduce their release. There are several ways to do this that might include reducing the speed of the vehicles (therefore reducing the friction between the tyres and the road), making sure tyres are not over or under-inflated, and ensuring that vehicles are properly maintained.

As part of that maintenance programme proper wheel alignment is crucial. When a vehicle's wheels are not aligned correctly, the tyres wear unevenly, leading to increased production of particulates.

TYRES & WHEELS

30 CVW APRIL 2023

Jeremy Krantz, Steertrak managing director, looks at tyre particulates – which are likely to be next on the Government’s pollution hitlist – and how effective wheel alignment can mitigate them.

Additionally, misaligned wheels can cause tyres to overheat, which can further increase the wear and tear on the tyres and generate more dust particles. Therefore, regular wheel alignment is essential for extending the life of the tyres. Unsurprisingly carrying out this type of preventative maintenance not only provides cost benefits on tyre purchases but also the financial benefits on fuel economy attributed to optimised wheel alignment.

In conclusion, governments around the world are increasingly acknowledging the importance of addressing the issue of tyre dust particles and their impact on the environment and human health. HGVs and other commercial vehicles play a crucial role in our economy but are recognised as being significant contributors to the generation of such particulates.

For commercial vehicle owners and operators alike, roadmaps for sustainability decarbonisation involve major infrastructure and asset changes as well as large capital investments. However, prioritizing simple, inexpensive, and effective strategies of embracing regular maintenance and proper wheel alignment checks are available and can make a difference right now. This will

help reduce the impact of particulates generated by these vehicles, improving air quality and creating a healthier, more sustainable future for everyone.

FOR MORE INFORMATION ON STEERTRAK, WWW.RDR.LINK/VAX028

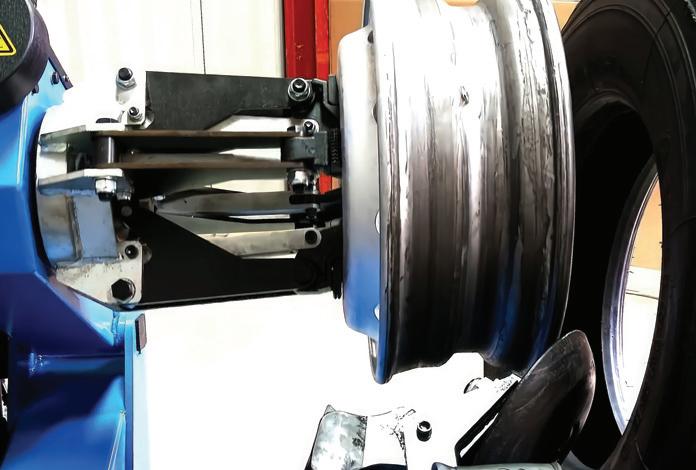

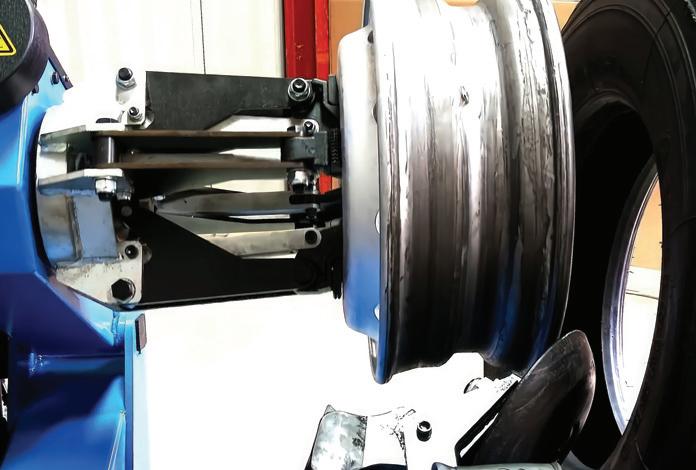

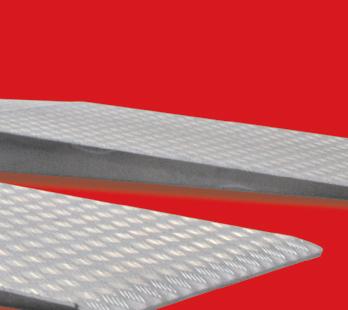

Before attempting any tyre change, remove the valve core and release the air from the tyre. Roll the wheel onto the platform of the megamount 352; the type of rim will determine which side of the wheel should face the jaws (or chuck) of the tyre changer.

ALL CHANGE

Andy Currell, Training, Product & QC Manager at ISN talks you through the process of changing a truck tyre, using the Hofmann Megaplan megamount 352, one of the specialist commercial vehicle tyre changers available in its range.

Once in position the jaws of the chuck can be opened to grip the centre of the wheel.

the disc for this operation but, depending on wheel/tyre combination, the hook could also be used for this purpose. However, it’s mainly employed to remove one side of the bead if the tyre has a puncture. If a valve needs replacing, the disc can be used to push the bead out of the way to allow access to the valve without removing the tyre.

While steadying the wheel with one hand, use the controls on the portable control unit to move the platform toward the chuck.

Using the controller, lift the wheel off the platform and reverse the platform out of the way. The platform carriage incorporates a multi-function ‘Double Tool’ – a bead breaker/tyre demount/remount disc and hook all-in-one, which is now manoeuvred and locked in position by hand, ready to break the bead of the tyre away from the inside of the rim. It’s most likely you’ll use

The easy to use controller allows you to lift the wheel to the optimum height and position the Double Tool, mounted on the carriage against the tyre. A combination of wheel rotation and Double Tool pressure on

TYRES & WHEELS

32 CVW APRIL 2023

the bead gently forces the tyre off the rim, allowing you to apply tyre paste/soap to lubricate the bead.

The next step involves retracting the Double Tool, moving it to the other side of the wheel and rotating it through 180 degrees. The carriage will then press it against the other side of the tyre, to break bead on the other side of the wheel.

Mounting the new tyre is, arguably, an even simpler process and, once again, it uses the Double Tool to press the beads of the tyre over the wheel rim. Start by laying the bead of the tyre over the rim.

A specially designed clamp stops the inner bead from rolling back off the rim as the mounting head pushes it over. A kit for alloy wheels is available, which includes a set of jaw inserts and a clamp, both designed specifically for alloy wheels.

Position the Double Tool against the tyre and the machine can go to work, pressing the outer bead over the rim while the machine rotates the wheel.

And that’s it! Once the machine has done its work you can retract the Double Tool, lower the wheel back onto the platform and release the chuck.

FOR DETAILS OF THE MEGAMOUNT 352, WWW.RDR.LINK/VAX029

As the bead is broken, lubricate it with tyre paste; the carriage will continue to press the Double Tool against the tyre as the wheel rotates…

…eventually pushing it off the rim.

APRIL 2023 CVW 33

TYRE TIPS FROM CONTINENTAL CONTINENTAL TYRES

Continental Tyres has launched a new tyre maintenance awareness campaign for commercial vehicle operators, with the aim of drawing attention to common faults, issues and failures. The launch comes as the company’s popular in-house training centre, ContiAcademy, announces the reintroduction of its full face-to- face training programme for the first time since the start of the COVID-19 pandemic.

Comprising of a series of five short films, the tyre maintenance campaign covers key topics such as getting the best performance from your tyres, how to inspect a tyre, reducing the risk of a blowout and how to correctly regroove a tyre. Many of the hints and tips featured within the videos will be relevant to all operators, irrespective of their current tyre brand.

Steve Howat, general manager for technical services at Continental Tyre Group, said: “As an expert in the commercial vehicle industry, Continental is proud to support hauliers across the UK, by sharing knowledge and best practice. Preventable tyre issues can not only cost fleet operators money, but they can also pose a risk to drivers and public safety.

“These videos will help everyone, no matter the brand of tyre that they use, to reduce the danger posed by a failing tyre, maximise rubber longevity and cut vehicle running costs.”

WANT TO KNOW MORE?

WWW.RDR.LINK/VAX030 GOTO

NEW APP RELIEVES THE PRESSURE CONTINENTAL TYRES

Optimal tyre inflation pressure and the right tyre selection mean the best possible tyre performance and the greatest possible fleet efficiency. What sounds so simple is not always easy to implement in the price-driven day-to-day business of fleets. Continental therefore supports fleet operators, dealers and service technicians in maximising the safety and efficiency of their tyres with the TireTech mobile app for agricultural tyres, which is now also available for truck and bus tyres.

Available to download for free on both iOS and Android, the Continental TireTech app is a technical advice tool developed for dealers, fleet managers and technicians. The platform provides quick and easy access to up-to-date tyre and service information for Continental's full range of tyres for agricultural and commercial vehicles. The app is ready to use within seconds of installation, and can be easily configured to meet individual needs.

Amongst the app’s features is an integrated pressure-load calculator, which helps determine the correct pressures for each tyre based on the vehicle axle load and tyre size. The database of technical tyre data and library of supporting images provides another powerful function. Plus, the technical data can also be accessed without an internet connection.

WANT TO KNOW MORE? WWW.RDR.LINK/VAX

NEW TYRE DOESN’T LAG BEHIND PROMETEON

The PIRELLI-branded Serie 02 tyre range is expanding with the introduction of the H02 Pro Trailer, a new series of tyres designed for use on articulated trailers for large loads and volumes, singleor multi-axle, and ideally suited for long-haul operation.

The H02 Pro Trailer range benefits from the Serie 02 Prometeon technological innovations, and has been designed to offer the highest levels of efficiency and optimised operating costs. It offers new standards of safety and load capacity, and a fuel consumption category which is now Class A for the 435/50 and Class B for the 445/45.

Compared to the previous range, it offers improved safety (+20%, thanks to the greater wet grip performance, 3PMSF approval and new tread design); load capacity (+10%, up to 10 tonnes per axle); reduced rolling resistance (-20%) for lower fuel consumption; and installation operations are also streamlined (+20%).

Compared to the competition, the H02 Pro Trailer is claimed to be best-in-class in the 435/50 R 19.5 size for fuel consumption, wet grip performance and external rolling noise, while the 445/45 R 19.5 size is best-in-class for load index (up from 160 to 164), as well as being the only model among its premium competitors with 3PMSF marking and RFID sensor.

Like the whole Serie 02 series, the H02 Pro Trailer range has 3PMSF winter marking (which can only be applied to tyres which pass a specific test defined in UN Regulation No. 117), is fitted with an RFID sensor, and benefits from approval from the major European vehicle manufacturers.

WANT TO KNOW MORE?

WWW.RDR.LINK/VAX032 GOTO

34 CVW APRIL 2023 TYRES & WHEELS: WHAT'S NEW?

031 GOTO

AIR:

TRAILERCHECK ‘PLUS’

TRAILER AIR & ELECTRICAL SYSTEM TESTER FOR WORKSHOP AND MOBILE SERVICE VANS

LIGHTS:

Designed to enable the operator to test the completer trailer lighting system using the 24N & 24S power sockets and to test the EBS warning light function on the trailer using the ISO 7638 socket.

Connect an air supply from your compressor to be able to test the braking system, test the service brake manually or via the wired 15m remote control, adjust the rake pressures with the regulators.

For more information, please call our sales team on 01603 485153

Email: info@bowmonk.com www.bowmonk.com

SANDS OF TIME

The journey to where Mirka is today began when engineer Onni Aulo founded Oy Mirka Ab in Helsinki, Finland, in December 1943. A three-year lease for the 388m2 original facilities was signed in 1945 and the business ended up staying there for a total of five years. However, due to the Second World War and technical problems, the first production of abrasives did not start until 1946.

Now headquartered in the heart of rural Ostrobothnia, Finland, the company has expanded with a network of subsidiaries that spans the entire globe, with Mirka (UK) becoming the first subsidiary to be established in 1979; and it is now celebrating its 80th anniversary.

The production of Mirka’s products moved to Kiitola in Jeppo in 1962. This move was the next logical step for the business because of how much the company had grown over the previous 16 years. Like any business, it was looking to open new sales avenues and this was achieved with the first international order of products from Iceland and then two years later with an order from the USA.

In 1973, the Kiitola site had been opened for 11 years but like any growing business there was need for expansion. As a result, Mirka built further manufacturing halls in Jeppo, where the current group office is still located. These facilities helped significantly

improve the production capacity and overall efficiency of the business.

The late 1970s was also an important period for the business, with 1979 seeing the launch of the first subsidiary of the group –Mirka UK. This marked the launch of a systematic global expansion of the organisation which continues today. This is highlighted by the fact there are now subsidiaries in the USA, Germany, Brazil and India to name but a few.

BODY REPAIR & MAINTENANCE

36 CVW APRIL 2023

As Mirka approaches its 80th birthday, CVW takes a backwards look at the surface finishing stalwart.

“Due to WW2 and technical problems, the first production of abrasives did not start until 1946.”

In the UK, Mirka initially served the market through an importer but saw an opportunity to move into industrial processes from early hand sanding applications. The UK has been a leader in

industrial trends and industry development and was an important early market for Mirka. The UK business has opened a national training centre in Milton Keynes, which enables the company to provide its customers with expert training and development around the abrasives, tooling and polishing solutions available in its portfolio. Attendees can increase their knowledge and skills, improve their workflow

and expand the services they can offer.

The last 80 years has gone by quickly but as a business Mirka will continue to take advantage of new market opportunities and launch more innovative products that will ensure the end user has access to the right tools for the job at hand.

FOR MORE ABOUT MIRKA SURFACE FINISHING, WWW.RDR.LINK/VAX033

APRIL 2023 CVW 37

SETTING HIGH STANDARDS

CVW covered the launch of the VBRA’s Elite Truck & Van Body Repair Standard last year. Eight months on we find out how it’s going.

Back in September 2022, the Vehicle Builders and Repair Association (VBRA) launched its Elite Truck & Van Body Repair Standard. Its rationale was clear. “We wanted to reduce risk, improve the quality of the repair network and ultimately lower costs by avoiding costly rectification of poor workmanship,” explains Tom Hudd, National Technical Manager. “Only the framing of a nationally recognised repair standard for commercial vehicles could achieve that. Hence, we launched the Elite Truck & Van Body Repair Standard.”

At the heart of the new standard was safety. The potential for disaster from a badly repaired commercial vehicle is much greater than any car. And yet there has been a body repair standard for car repair in place since 2007, originally called PAS125. It subsequently developed into a full BSI standard becoming BS10125.

With no thought given to the much more important area of body repair comprising trucks, bus and coach, trailers, and large vans (panel vans and chassis cabs up to five tonnes), the VBRA decided to act.

The standard consists of several grades of membership:

Elite Truck & Van Body Repair (structural with cab and chassis repair)

Elite Truck Repair (structural with cab and chassis repair)

Elite Van Repair (structural with chassis repair)

Elite Truck & Van (non-structural no cab or chassis repairs)

In the intervening months since launch, support for the Standard has grown with notable work providers backing it unreservedly. Jamie Sopp of fleet accident management specialists Sopp+Sopp believes that a standard for commercial vehicles was long overdue and utilising a transparent auditing and deployment platform that encapsulates the essence of competent repairs is a must-have.

Sean Harper, fleet supply chain manager at S & G Response says his company can see significance benefits in the Elite Truck Standard and echoes the importance of safety underpinning the need for certified repair work.

“For a fleet manager, vehicle safety should be a top priority. This is because there are many benefits to having a safe fleet. It helps protect drivers, reduces costs, improves productivity, maintains compliance, and protects the company's reputation. By making safety a top priority, fleet managers can ensure that their fleets operate efficiently and effectively while keeping their drivers safe and secure on the road,” he explains.

BODY REPAIR & MAINTENANCE

38 CVW APRIL 2023

“...the potential for disaster from a badly repaired commercial vehicle is much greater than any car...”

Long term benefits

Workshops are also seeing the benefits of obtaining the standard. The latest member to achieve the Elite Truck Standard (Structural) for Cab and Chassis repair is CarComm Coachworks based in London and Home Counties. Managing director Jason Mole is very proud of the newfound

status, adding that the interest from his customers has been significant. “Gaining the award highlights our commitment to the high standard of repair that we give to all of the vehicles that come through our doors and we couldn’t be prouder to lead by example in the standard that has been set out by the VBRA.”

Longer term Tom believes that attaining the standard will confer some major benefits, not least of which will be the

opportunity for members to charge in line with their capabilities and being able to attract new work. “We understand that workshops are busy right now, but there is no time limit for achieving the necessary certification, so it can be embarked upon in stages. The journey will be worthwhile.”

APPLY NOW USING THIS LINK

WWW.RDR.LINK/VAX034

CVW learns about IRT’s new launches for the busy paint shop, where the focus is very much on speed and energy saving.

FINDING THE RIGHT CURE

With energy costs going through the roof, the launch of IRT’s ICure is timely. The company claims that the ICure cuts energy use and reduces process time in paint shops considerably. The unit is a robotic, compact and automated rail dryer that handily retrofits to most spray booths and prep zones. With infrared (IR) and ultraviolet (UV) curing in one unit, paint shops can reduce both energy spend and time per vehicle.

ICure includes robotic travel and automated curing along a side or short end of the vehicle. It can also be moved manually through the whole rail system and offers pre-programmed and customized curing alternatives. It comes equipped with a new robotic cassette configuration with powerful 2000W UV lamps, in combination with IRT’s proven infrared lamps. This new combination cures all the latest products developed by the paint manufacturing industry, including UV clearcoats.

The compact design takes up very little space. It pulls out smoothly when needed

and tucks back in a corner when it isn’t. The adjustable, user-friendly operator panel is easily reached. Reliable curing results are achieved in minutes and the vehicle is ready to move to the next step.

Better for the environment and for the operator

This new I-shaped robotic dryer is IRTs smallest, yet most complete booth and prep zone rail dryer. Drying and cooldown phases in the spray booth are carried out with just a fraction of energy spend and time is saved in the prep zone, compared to conventional drying methods. There’s no need to increase the temperature in the whole booth, nor any need to reduce the temperature back down to comfortable work environment after drying. The throughput efficiency in the paint shop can immediately be increased by several cycles per day. Energy is saved and the work environment improved.

“Bringing IR and UV drying to your paint shop is always a win-win,” explains

Linus Ekfeldt, IRT product company director. “Less energy spent and faster curing means it’s better for the environment and for profitability. ICure retrofits into most spray booths and prep zones, installed on rails with integrated cables for operational safety.”

Not surprisingly operator safety is a top priority, including compliance with UV safety regulations (Directive 2006/25/EC), to minimize the health and safety risk arising from artificial optical radiation.

BODY REPAIR & MAINTENANCE APRIL 2023 CVW 41

“Drying and cool-down phases in the spray booth are carried out with just a fraction of energy spend and time is saved compared to conventional drying methods.”

BODY REPAIR & MAINTENANCE

Spot on

Not content with bringing the new ICure to market, IRT has also upgraded its curing lamps. Its pioneering ultraviolet (UV) curing lamp SpotCure has received a makeover and now brings three times the power to UV-activated spot repairs in paint shops.

The UV SpotCure2 allows for larger curing areas and shortens curing time, with a clear visual guide with multifunction timer display to improve process control. Downtime and fluctuation are addressed and minimized with new advanced software and overheating protection. With more light intensity over a bigger surface, UV-activated products cure in seconds with reliable result every time.

SpotCure2 features an ergonomic grip for user comfort and a lightweight stand for larger spot repairs. It is built to last with an overheating guard and filter clogging indicator. A new two-filter ventilation system keeps the UV lamp cool, with reduced risk of filter clogging. The corded tool is even equipped with a step-by-step easy to replace power cord, should it be subjected to excessive wear and tear. SpotCure2 joins IRT s market leading range of battery powered and corded handheld UV-LED machines for spot repair.

“Our bestselling UV-LED curing range expands with this power-packed unit. We have taken user comfort and curing reliability to a new level,” says Ekfeldt. “We are ticking all the boxes; short curing time, large curing area and best all-round ergonomics with the unique design and stand option. An unbeatable combination of power and curing size.”

All IRT UV dryers are third-party tested and classified in accordance with EN62471, by SP Technical Research Institute of Sweden (RISE). This includes calculation of the safety radiation level per working day at different distances for UV lamps.

By way of conclusion the company believes vehicle repair and paint shops are facing constant time-saving challenges, which can be met by introducing UV curing to the process. Its solution is to increase throughput while maintaining a healthy environment. IRT´s product development traditionally works in tandem with paint manufacturer developments and the day-today needs of users.

42 CVW APRIL 2023 FOR MORE INFORMATION, WWW.RDR.LINK/VAX035

“A two-filter ventilation system keeps the UV lamp cool, with reduced risk of filter clogging.”