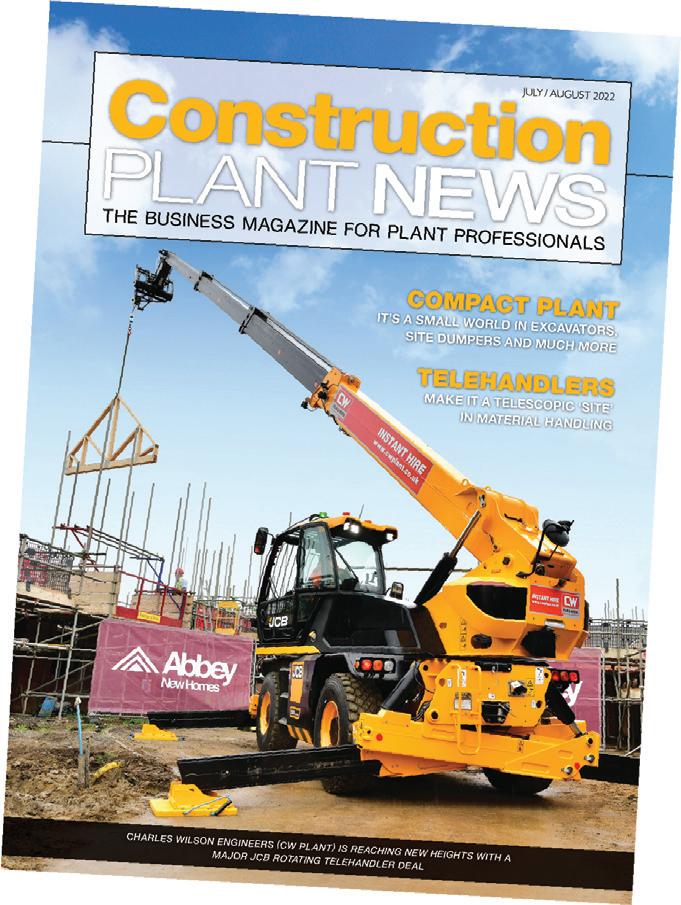

Construction PLANT NEWS

PLANTWORX PICKS

WHAT CAUGHT OUR EYE IN PETERBOROUGH

SMALL IS BEAUTIFUL CREAM OF THE CROP: COMPACT MACHINES

JULY / AUGUST 2023

JCB’S 403E ISN’T AFRAID OF A HARD DAY’S WORK

C ONTENTS JULY / AUGUST 2023 THIS ISSUE... @CPN_mag cpnonline.co.uk Construction Plant News, Regal House, Regal Way, Watford, Herts, WD24 4YF. cpn@hamerville.co.uk e 10 REGULARS 5 EDITOR’S VIEWPOINT 6 NEWS 18 CPN AT LARGE 26 MACHINES IN ACTION 28 FLEET ADDITIONS 30 TECHNOLOGY CORNER 32 NEWPRODUCTS CPN I JULY / AUGUST 3 FEATURES PLANTWORX 15 Plantworx review – the machine highlights from the Peterborough showground. COVER STORY 20 JCB’s 403E isn’t afraid of a hard day’s work. COMPACTS & MINIS 22 CPN rounds up current machine models that might be on your shopping list. 13 22 20 15 SPECIAL REPORTS 10 Industry in Site. It’s electric versus diesel – who comes out top? IDTechEx points to the winner. 13 Polishing up those skills. Flannery Plant plugs the skills gap with its bootcamp.

V IEWPOINT

PLANTWORX PLAUDITS

And relax. Plantworx is finished but what a show. Blessed with the weather, packed with exhibitors and thronged by crowds, it was a success by any measure. Sadly, it is the last one to be held at the Peterborough venue, which is being developed, but the impending relocation offers the organisers some exciting possibilities, venue and format wise, for 2025.

Over 10,000 visitors made the Plantworx pilgrimage, keeping the 300 or so exhibitors on their toes. Feedback from those on the stands was wholly encouraging, with many citing huge interest in their machines and some even getting their order books out.

The international nature of the construction equipment industry was very much in evidence with a host of Chinese OEMs exhibiting machines including XMCG making its first UK appearance, as well as the more familiar Japanese brands. While Plantworx will never be a Bauma or Conexpo, it was reassuring to see this quality of exhibitor on our shores.

Away from the heat and dust of the day, a definite highlight of the show was the Plantworx Innovation Awards dinner, held on the Monday night prior to the first official day. Seven main categories highlighted exceptional advancements in various aspects of the construction equipment sector. Winners, runners-up, and highly commended entries were honoured in each category, showcasing the breadth of innovation taking place within the industry.

But they weren’t the real winners. That accolade, in our eyes, went to the Plant and Hire Aid Alliance who picked up a special recognition award for outstanding humanitarian contribution. For those of you not in the know, the alliance has played a vital role in supporting the humanitarian effort in Ukraine, providing essential supplies to those affected by the conflict.

The figures speak for themselves: 50 tonnes of medical supplies, 48 tonnes of food, 100 generators donated and delivered and more than £80,000 raised to help those in need. It is truly a worthwhile initiative and deserving of the award.

And while the above figures are impressive, what was more so were the words of Jeremy Fish, CEO of Ardent Hire Solutions, who received the award on the alliance’s behalf. Here was a man who was passionate about doing the right thing, appealing to his industry to get involved, become a member, make a difference.

It is perhaps fitting that at a trade show where we are all admiring machines that shape and transform our environment, the biggest transformations – those of human lives – are being brought about by human endeavour and selfless action. So, more power to the Plant and Hire Aid Alliance’s elbow; here’s hoping your numbers increase and your good work continues.

Enjoy this issue.

Editors

JOHNNY DOBBYN

JOHN LEVICK

cpn@hamerville.co.uk

Group Manager

ROB GILHAM

rgilham@hamerville.co.uk

Magazine Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

CAROL PADGETT

Subscriptions

Construction Plant News is a business magazine for plant professionals, contractors, materials extraction and processing companies, waste and recycling operations, as well as local authorities. If you are not on our circulation list and would like to subscribe email circulation@hamerville.co.uk

To be removed from this magazine’s circulation please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens & George Ltd

Published by HAMERVILLE MEDIA GROUP Regal House, Regal Way, Watford, Herts WD24 4YF.

Tel: Watford (01923) 237799

Fax: (01923) 246901

Copyright © 2023

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

Total Average Net Distribution 8.329 July 2021 –June 2022

CPN I JULY / AUGUST 5 TheCPNTeam

THE JOY OF SIX

USED

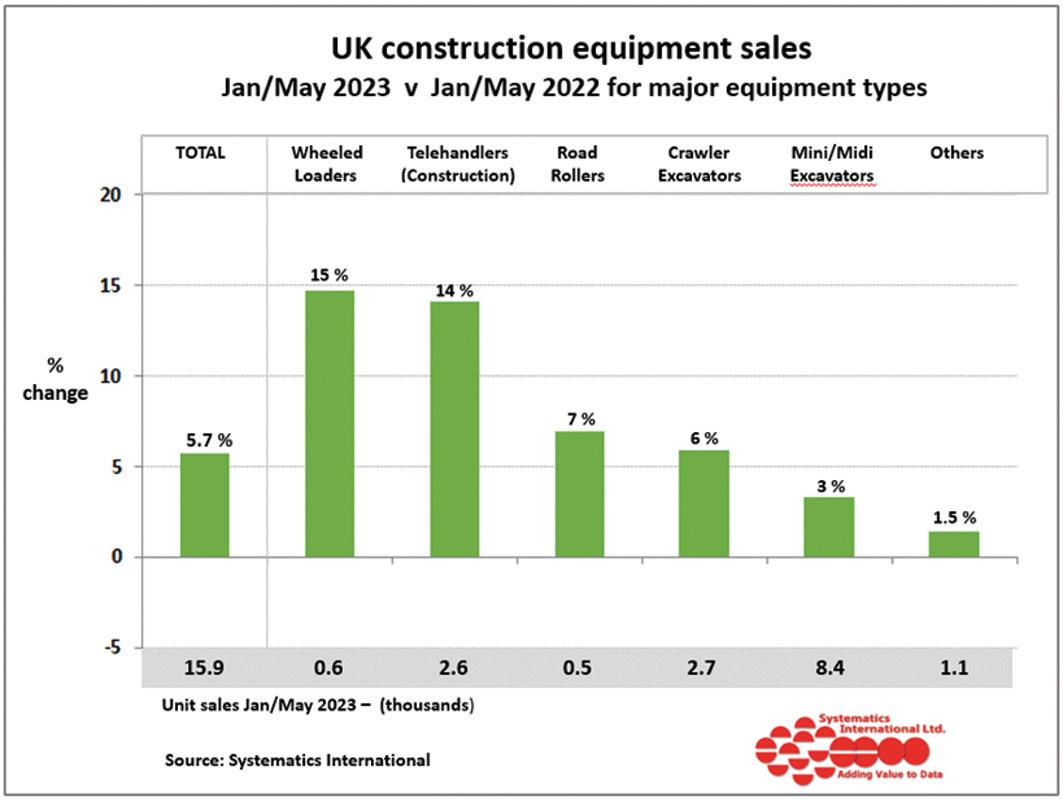

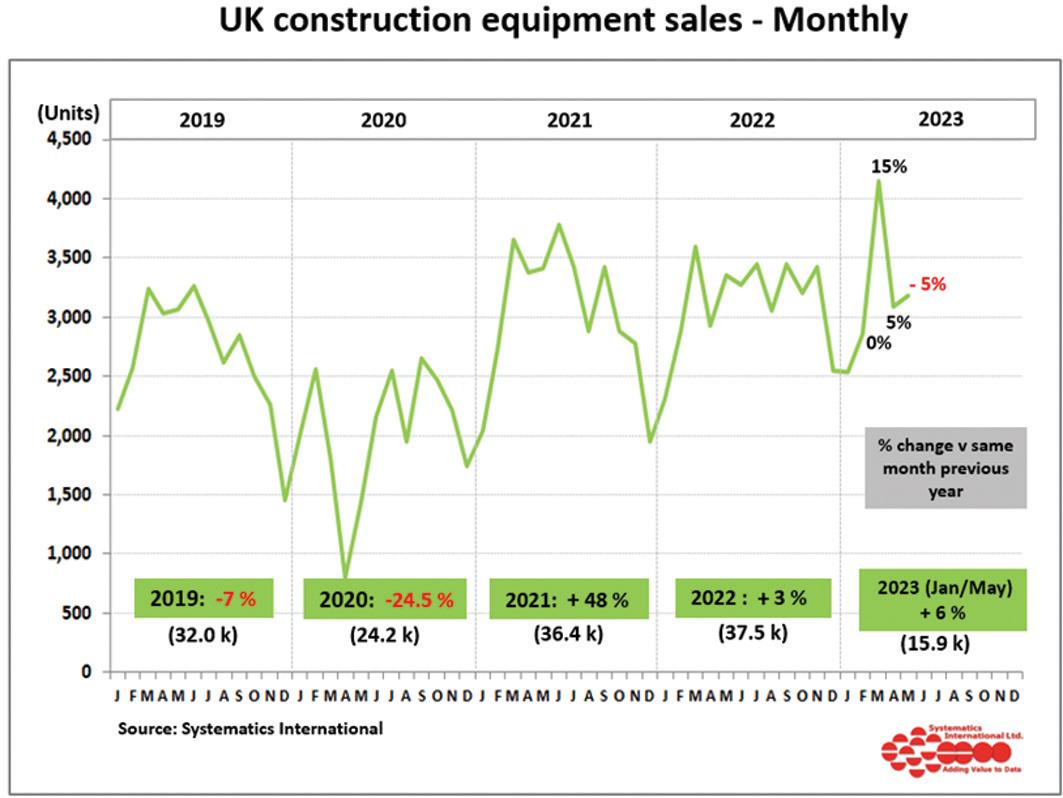

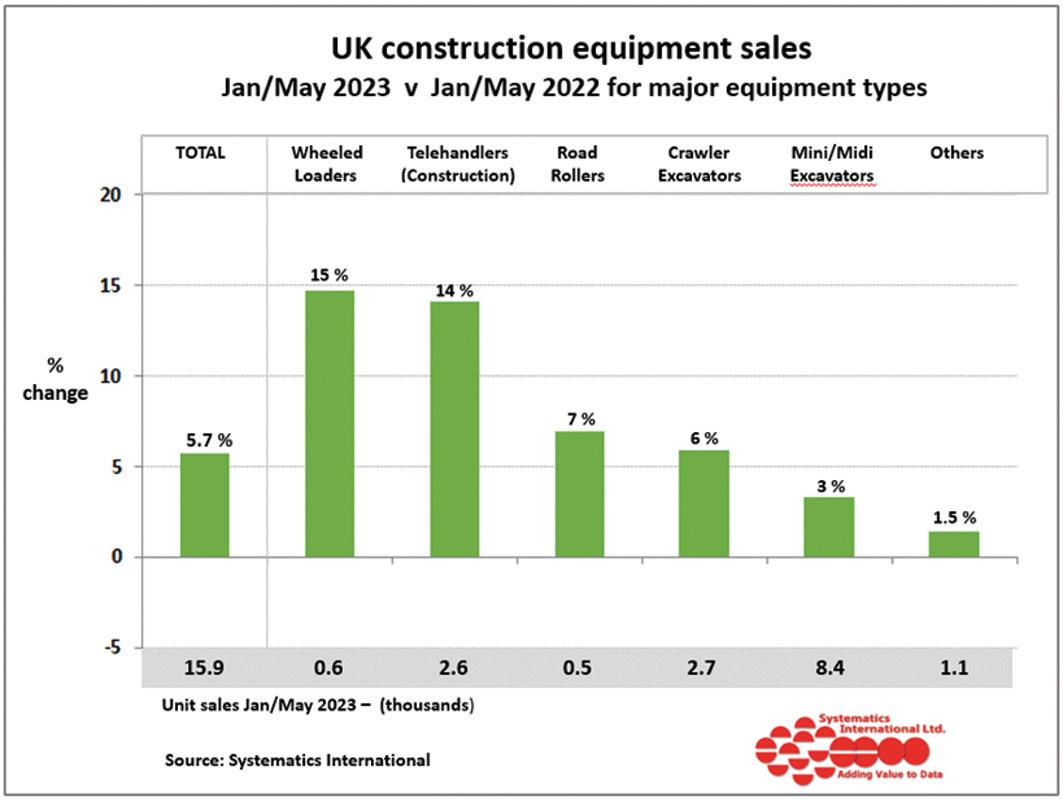

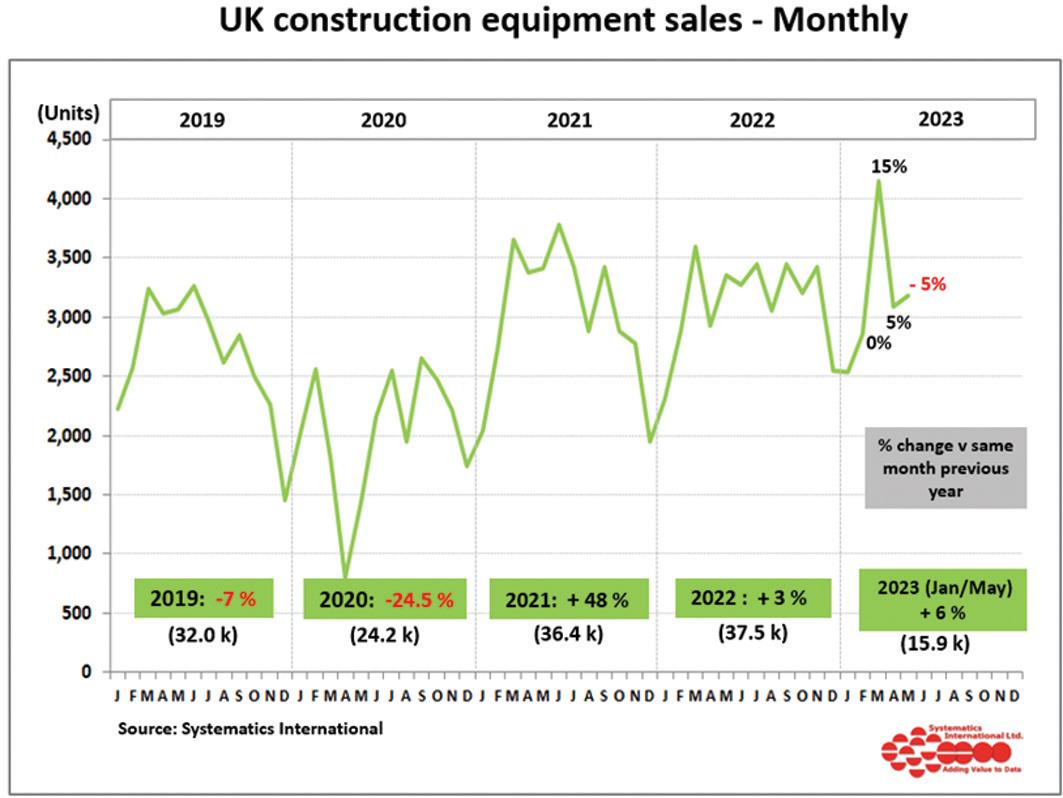

compared to the same month in 2022. Despite this, the total sales for the first five months of 2023 remained nearly 6% higher than the same period last year, with 15,900 units sold.

This slowdown aligns with predictions made by industry insiders at the recent Plantworx show, who anticipated a market ease after record-breaking activity levels in 2022 and early 2023. Further modest reductions are expected in the latter half of 2023, with overall

equipment types varied. Wheeled loaders led the pack with a 15% increase in sales over the first five months of 2023 compared to the same period in 2022. Road rollers and crawler excavators also showed strong growth, while the UK market's most popular product, mini/midi excavators, saw only a modest 3% growth.

Regionally, Scotland and the South East of England boasted the strongest sales, approximately 30% ahead of

last year's levels. Conversely, the North West of England and Northern Ireland experienced the weakest sales, with decreases of 17% and 14% respectively.

Sales in the Republic of Ireland matched 2022 levels in

May, resulting in a 2.6% increase in sales for the first five months of 2023 compared to the same period last year.

For more information

WWW.RDR.LINK/CAL001 i

RECORD DEMAND FOR TEFRA HITCHES

BTE PLANT SALES HAS ORDERED A RECORD NUMBER OF HILL ENGINEERING'S TEFRA HITCHES DUE TO RISING CUSTOMER DEMAND.

In the first quarter of 2023 alone, the company ordered more than 80 Tefra couplers, which will be fitted to a variety of machines, including the Kubota U27-4, U36-4, KX60-5, and the KX080-4a2.

WWW.RDR.LINK/CAL002 i

NEWS 6 JULY / AUGUST I CPN

EQUIPMENT SALES SOFTEN AS WHEELED LOADERS IN DEMAND.

ALL HAIL CESAR AS IT CELEBRATES MILESTONE

CESAR, THE UK'S LEADING EQUIPMENT SECURITY SCHEME, CELEBRATED A SIGNIFICANT MILESTONE AT PLANTWORX, ANNOUNCING ITS 600,000TH PROTECTED MACHINE.

The symbolic CESAR ID plate numbered 600,000 was presented by Suneeta Johal, CEO of the Construction Equipment Association to Manitou, a long-time supporter of the CESAR Scheme.

“We have been supporters of the CESAR Scheme since its inception and recognise its part in reducing theft,” Mark Ormond, managing director at Manitou said. “We are delighted to be the manufacturer of the machine which has reached this incredible milestone and will continue to support CESAR.”

CUSTOM PAINT JOB FOR JCB BACKHOE

For further information

WWW.RDR.LINK/CAL003 i

SOUND THE ALARM

FLANNERY PLANT HIRE HAS WORKED WITH FINNING UK & IRELAND TO TRIAL A SMART DETECTION SYSTEM UNDER DEVELOPMENT BY CATERPILLAR, THAT WILL REDUCE CONSTRUCTION FATALITIES AND INJURIES.

Known as Cat Personnel Detection, the system alerts operators if someone is too close to their machine, thereby reducing the risk of injury to ground personnel. The two-year product development trial involved fitting the smart camera system to eight machines, including excavators and dozers, working on HS2 sites.

The system includes a single rear-facing camera and a 10-inch highresolution touchscreen display with smart detection. It allows operators to zoom in and has a 170-degree field of vision with target areas set at 20, 10, and 5m, each relating to different colour zones and risk levels.

“Where Cat Personnel Detection differs from other smart detection systems is that it can specifically identify people from objects and will trigger an operator response because it sounds either an intermittent or solid alarm depending on how close they are to the machine,” said Chris Phillips, product manager and quality engineer for Finning.

IN MARKED CONTRAST TO THE CORPORATE JCB YELLOW THAT IS SEEN EVERYWHERE, THE JCB 3CX PRO THAT HAS JUST JOINED THE FLEET OF GBSS CIVILS & PLANT HIRE IS DECKED OUT IN BLACK LIVERY WITH RED AND GOLD DETAILS. Despite the distinguished paint job, the unit has been muckshifting on a large-scale school building and housing development project in East Calder. Here it is carrying out stockpiling, loading, excavating and cleaning duties on site with interchangeable bucket, pallet fork and sweeper attachments.

WWW.RDR.LINK/CAL005 i

PLANT HIRE TO GROW UNDER NEXUS

NEXUS VEHICLE RENTAL IS MOVING INTO PLANT HIRE, BASING THE BUSINESS ON ITS RENTAL MANAGEMENT SYSTEM, IRIS.

The company says that the new business, Nexus Plant Hire, enables users to meet all vehicle requirements in a few clicks, through one centralised account management platform that includes a comprehensive view on their rental spend and documentation.

It will provide access to what the company says is the fastest-growing network of plant vehicles and machinery in the sector, including plant vehicles, heating and cooling equipment, welfare and accommodation vehicles, power and lighting equipment, powered access machinery, and sustainable products.

In addition to the wide range of equipment, Nexus Plant Hire customers will also benefit from real-time data-driven insights provided by IRIS’s leading MI reporting suite, helping them identify cost-saving opportunities and efficiencies.

For further information

WWW.RDR.LINK/CAL 004 i

WWW.RDR.LINK/CAL006 i

CPN I JULY / AUGUST 7

FINNING NETWORK GROWS

FINNING UK & IRELAND, THE WORLD'S LARGEST DEALER OF CAT MACHINES AND EQUIPMENT, IS CELEBRATING THE FIRST ANNIVERSARY OF ITS REGIONAL NETWORK WITH THE ADDITION OF ITS 11TH DEALERSHIP, HOWARD PLANT SALES, AS AN AUTHORISED SALES AND SERVICE CENTRE (ASSC).

The expansion of the network comes in response to increased demand for Cat Compact machines in the construction, landscaping, and agricultural sectors. Andrew Davies, head of BCP at Finning UK & Ireland, said: “Our ASSCs will play an integral part in developing our market share.”

The company's goal is to expand the ASSC network to 15 dealers by the end of the year.

SPEEDY FASTTRACKS NET-ZERO ROAD MAP

SPEEDY HIRE PLANS TO PUBLISH ITS CARBON NET-ZERO ROADMAP IN JULY AS PART OF ITS 'DECADE TO DELIVER' STRATEGY.

“At Speedy, we are accelerating product innovation and decarbonisation solutions in collaboration with our partners, prioritising the long-term vision of sustained net-zero,” said Amelia Woodley, ESG director at Speedy Hire.

For further information

WWW.RDR.LINK /CAL007 i

MECALAC TRIUMPHS AT PLANTWORX

MECALAC CONSTRUCTION EQUIPMENT UK HAS WON THE GOLD IN THE ENGINEERING & DESIGN CATEGORY AT THIS YEAR'S PLANTWORX INNOVATION AWARDS. The company was recognized for its innovative Revotruck product, a new earthmoving vehicle that functions as a rear dump truck when carrying materials and a highly manoeuvrable site dumper when loading and unloading.

“Taking home gold at the Plantworx Innovation Awards for Revotruck is testament to the team’s hard work and dedication,” said general manager Heath Davies. “We’re hugely proud of our expanding product range and consider it a real honour to be taking home such a prestigious accolade.”

Revotruck allows operators to receive a load facing the skip, then rotate the entire cab via a multidirectional joystick to face the direction of travel, and so improves productivity, cuts risk, and boosts operator safety.

The company says it is the first in the hire sector to publicly commit to science-based net-zero targets, setting an ambitious goal to achieve net-zero across all scopes by 2040, a decade ahead of the government deadline.

As part of its strategy, Speedy will outline clear steps to reduce Scope 1 & 2 emissions by 50% and Scope 3 emissions by 42% by 2030.

For further information

WWW.RDR.LINK/CAL010

FINNING BIDS TO BOOST USED MACHINERY SALES

FINNING IS INTRODUCING THREE NEW OPTIONS FOR CUSTOMERS TO BUY AND SELL PRE-OWNED MACHINES IN RESPONSE TO A BOOMING USED EQUIPMENT MARKET THAT IS PROJECTED TO GROW TO £505 MILLION BY 2028.

For further information

WWW.RDR.LINK/CAL008 i

GRADING MADE EASY

MDIG IS NOW OFFERING TRIMBLE EARTHWORKS, AND INTEGRATED 3D AFTER-MARKET GRADE CONTROL AUTOMATICS FOR EXCAVATORS, FOR RENTAL.

Developed by Sitech, the device enables excavators to work semi automatically, allowing operators to create smooth, flat or sloped surfaces more easily. The Trimble Earthworks grade control app runs on the 10inch Trimble TD520 touch-screen Android display. The software was created in collaboration with construction equipment operators around the world, so the interface is optimised for ease-of-use and productivity.

Earthworks allows data files to be transferred to or from the office wirelessly and automatically.

These options include a traditional trade-in, direct purchase of used machines, and a brokerage arrangement in which Finning sells the equipment on behalf of the customer.

In the trade-in model, customers can exchange their machines when they’re looking to buy a new one but can use their machine until the new one arrives.

Otherwise Finning will buy used machines directly, without the customer needing to buy a new or used machine, or sell the equipment on behalf of the customer for an agreed fee.

For further information

WWW.RDR.LINK/CAL 009 i

After inspecting a machine, Finning provides a valuation allowing customers to realisethe capital in the machine quickly. If customers wish to keep the machine for an additional period before selling, Finning will project what the hours will be for that future period and adjust its price accordingly, giving the customer total control of what they are realising.

For further information

WWW.RDR.LINK/CAL011

8 JULY / AUGUST I CPN NEWS

i i

DIESEL ELECTRIC letbattlecommence

Like many industries, the construction vehicle and machine industry is on the path to electrification. It has been one of the latecomers to the electrification game, with little happening from OEMs until after 2020. But this is changing, with more electric product announcements covering a wider selection of vehicle types under the construction banner. The new IDTechEx report, Electric Vehicles in Construction 20232043, finds that the EV construction vehicle market is about to take off and grow rapidly, with a 10-year CAGR of 37%.

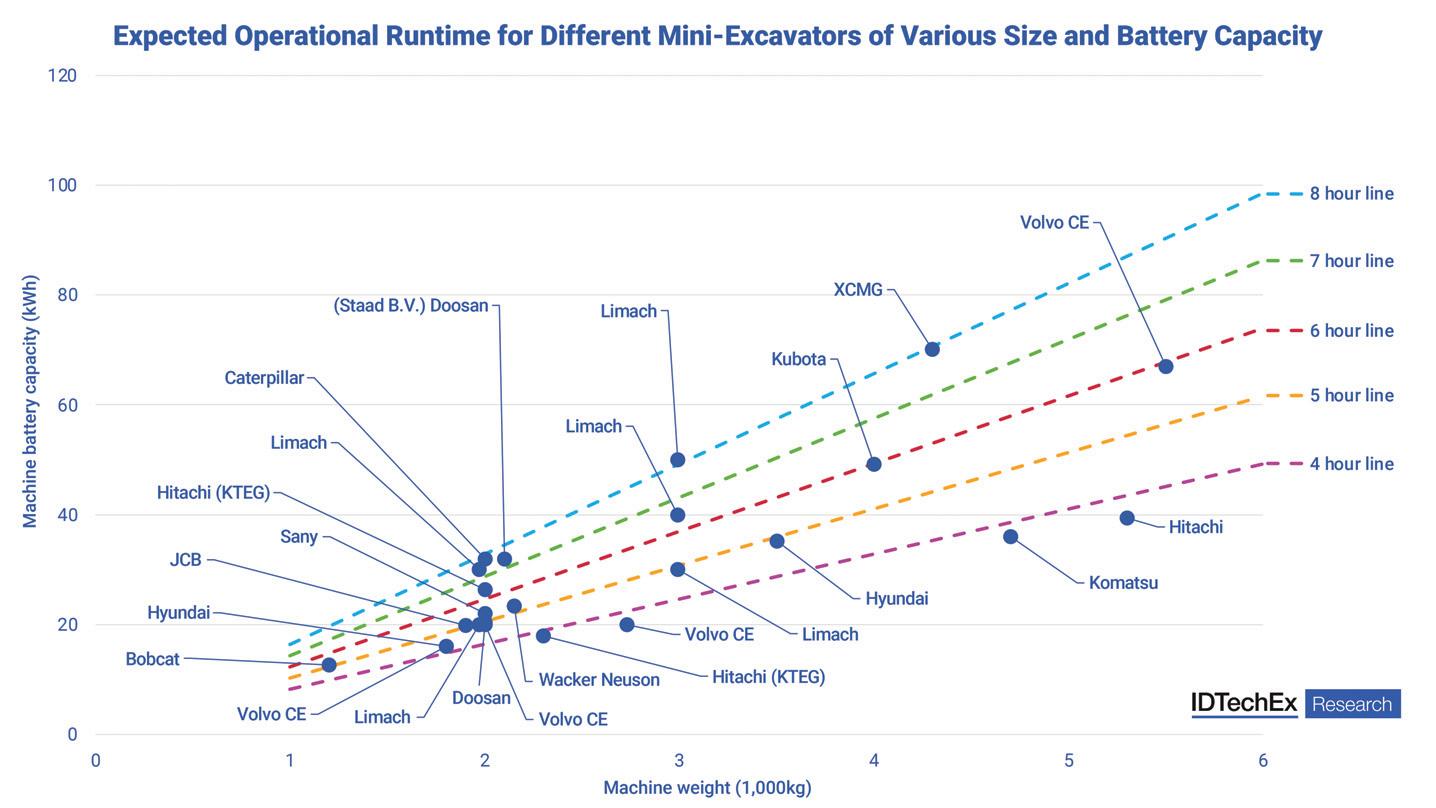

One of the market’s cornerstones of growth will be electric mini excavators. Mini excavators are the third biggest construction vehicle market by volume and the biggest in Europe. Their small size and lighter workloads make them an ideal fit for electrification, and they are a common entry point for OEM electrification.

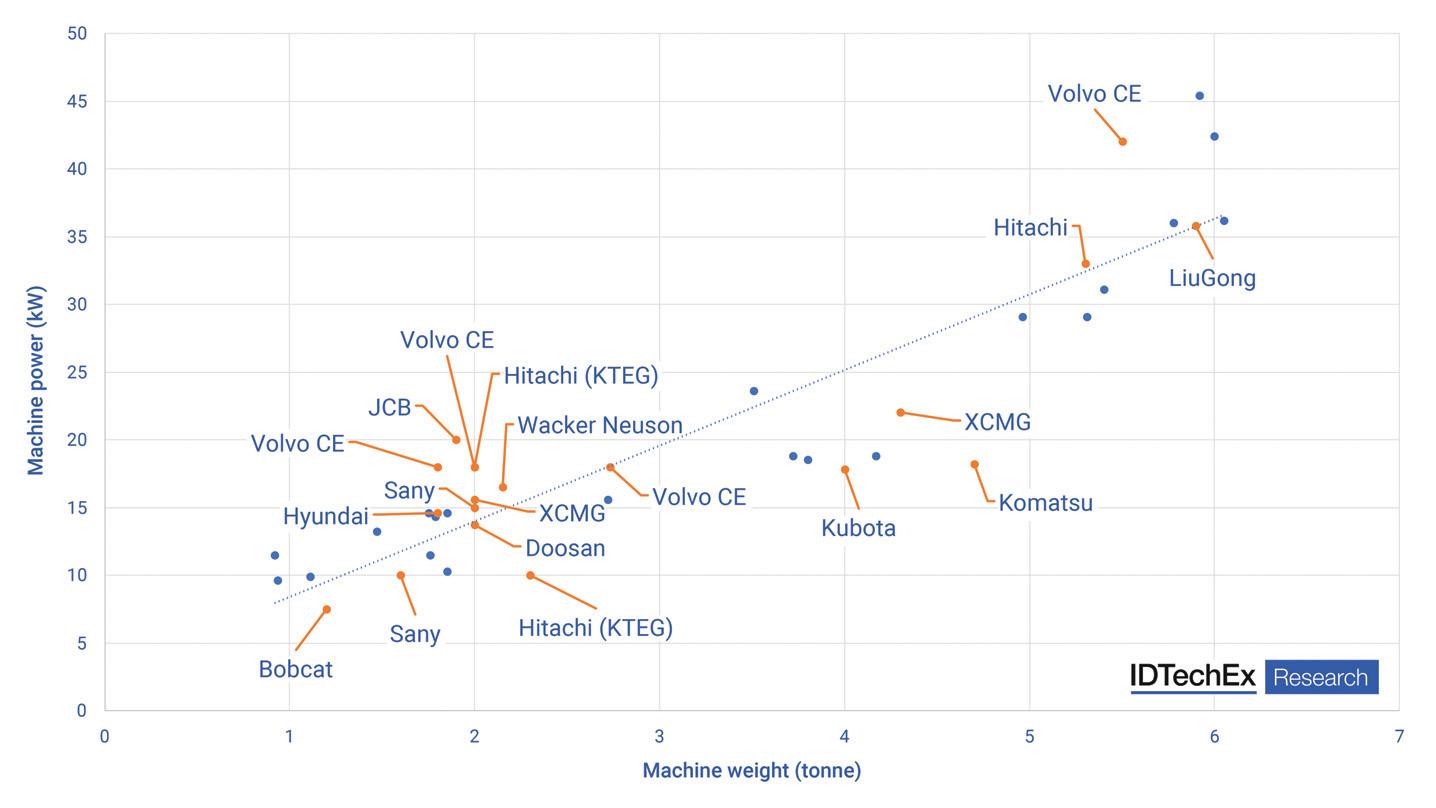

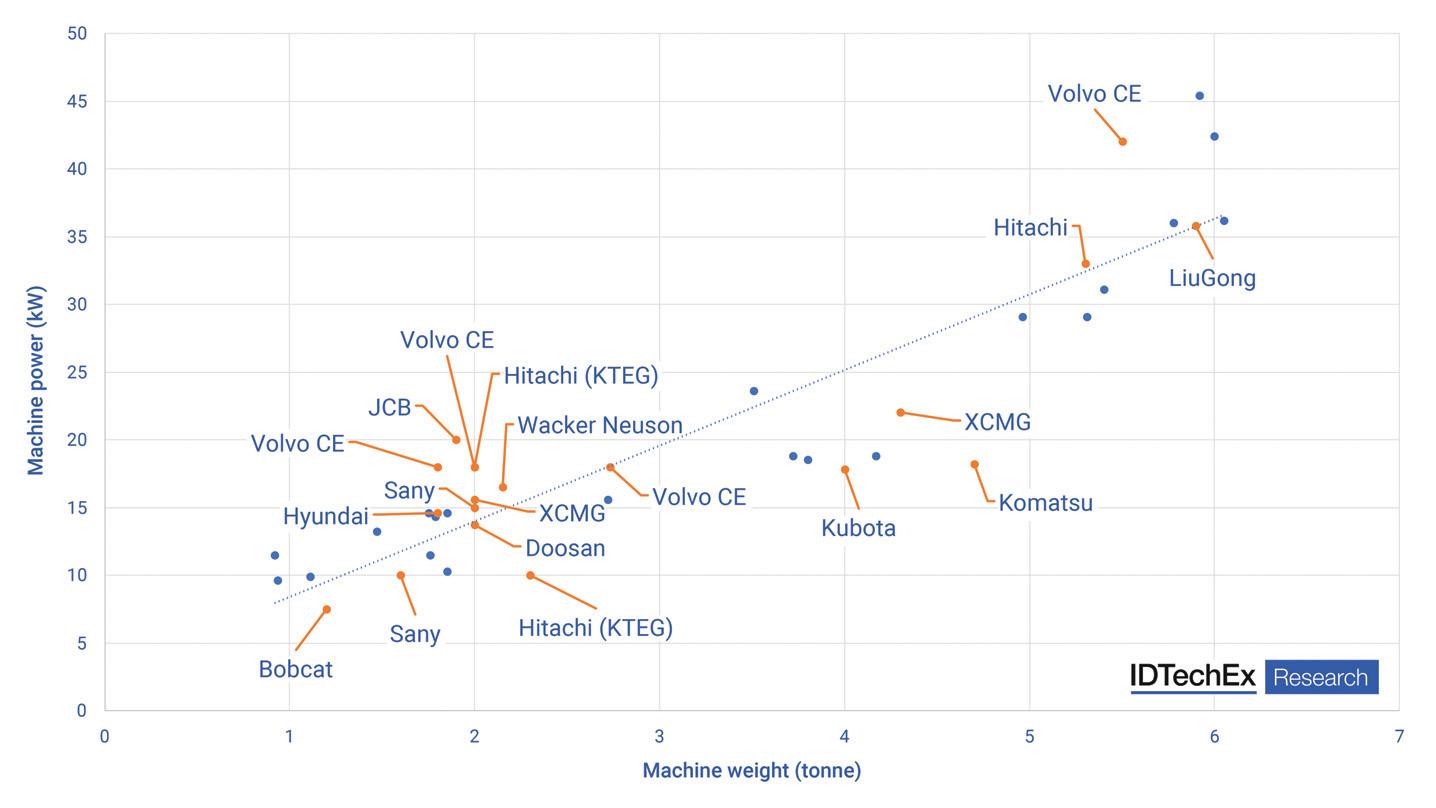

Equal or better performance

One of the main concerns that construction professionals might have when switching to electric is whether the new machines will have

the power to get the job done. IDTechEx’s Electric Vehicles in Construction 2023-2043 report finds that, in many cases, electric machines have equivalent or even superior power when compared with their diesel counterparts. Maybe one of the best examples of this is the JCB 19C-1E, whose motor has a peak power of 20kW, approximately 33% more than diesel examples in IDTechEx’s database, and nearly double the 11.7kW engine found in JCB’s own 19C-1 diesel equivalent.

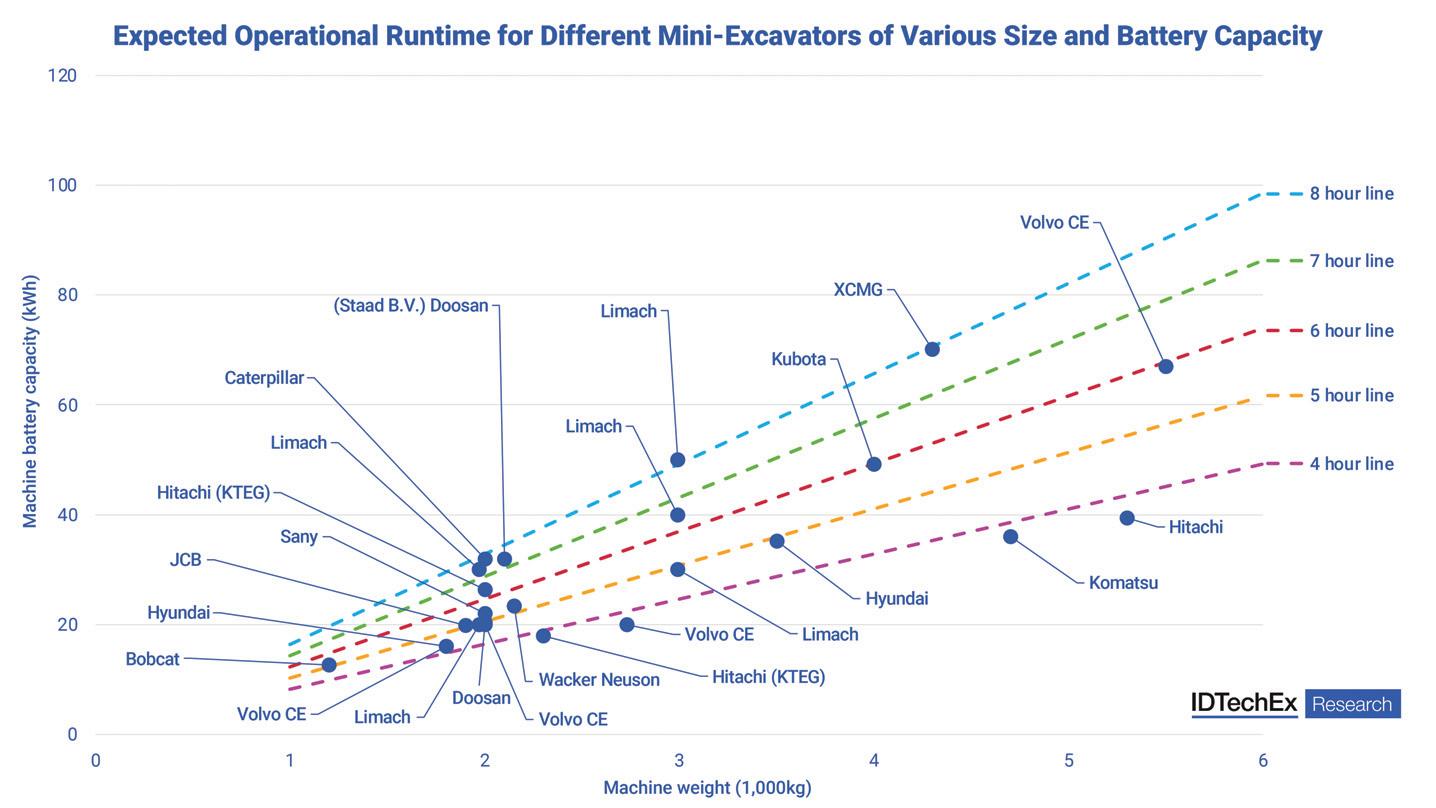

There should be no doubt then that an electric vehicle is every bit as capable as a diesel, but can the batteries provide endurance for a hard day’s work? This is perhaps one of the biggest concerns for people wanting to transition to electric. IDTechEx’s research found many examples of electric mini excavators that offer 6-8 hours of continuous operation, enough to get most operators through a normal work day.

Better environment for workers

It is well known that a major benefit of transitioning to electric is zero exhaust emissions. Even if a car is charged from a grid with high emissions, it still helps to remove emissions from city centres, improving air quality. The effect is even larger on construction vehicles. With open cabins and stationary vehicles, the air quality that an excavator operator and surrounding workers are exposed to can be very poor. This can

I NDUSTRY IN SITE 10 JULY / AUGUST I CPN

Electric Machine Power Compared To Diesel Equivalents. Source: IDTechEx

lead to short- and long-term health effects, but zero-emission vehicles offer a significant quality of life benefit to construction workers, improving the overall air quality around construction sites.

Cheaper

Finally, electric machines can offer a significant reduction in the total cost of ownership. While the batteries add a considerable premium to the cost of building and purchasing the vehicle, the cost of batteries in the construction industry has been coming down. This will be helped further by OEMs like John Deere, Caterpillar, XCMG, and more, bringing electric products in-house and producing in larger volumes (instead of electric vehicles being built in limited runs by retrofitting engineering firms).

Between maintenance and fuel savings, IDTechEx predicts an electric mini excavator owner can expect to see a return on their investment in as little as six to eight years. After which, these vehicles have the potential to save thousands of dollars annually in

operating costs.

Mini excavators are just the start and other vehicle types are now following. When the benefits are proven, the construction industry will quickly switch to electric and gain better job performance, conditions for the operator, and savings for the owners.

To find out more about IDTechEx WWW.RDR.LINK/CAL 012 i

Expected Battery Endurance For A Range Of Electric Mini Excavators. Source: IDTechEx

Polishing up those skills

The way we construct and interact with buildings has evolved over the years, and with it so have the skills required by those working in the construction industry. The past few years have not been easy for businesses. SMEs in the industry have reported multiple challenges, especially when it comes to recruiting and retaining staff with the right skills.

At Flannery Plant, we developed a Skills Bootcamp in Plant Operations in partnership with the Department for Education to proactively help address skills needs within our business and the wider industry. This is a free course open to both adults (aged 19 and over) keen to enter the sector, and current plant operators looking to enhance their skills. The Skills Bootcamp guarantees an interview with an employer on completion. The shorter and more intense nature of the course means they can be beneficial to employers who want to upskill staff quickly but effectively.

We’re hugely proud to have spearheaded the first entirely employer-delivered Skills Bootcamp. Our involvement in the development of the course meant we could shape it to help individuals get the skills and qualifications they need and deliver talent to plug our specific skills gaps.

It took six months –from conception to delivery – to create the course. We worked

closely with the Department for Education in this process, who helped us promote the Skills Bootcamp through their channels.

So how does it all work? Well, the Skills Bootcamp in Plant Operations runs in twoweek cycles and individuals are typically self-referred, through looking for work or referral by their employers. It’s a 77-hour guided course, and once complete, individuals receive a certification in one or two machine categories.

Operating construction plant machinery requires incredibly specialist training and is vital to our operations and growth. Our investment in training has been greatly beneficial to us, allowing us to build a steady pipeline of recruits who are equipped with the specialist knowledge and skills needed to become crucial parts of the workforce. We have also found that the qualification achieved through our Skills Bootcamp is an effective foundation for learning among employees. After they complete the Skills Bootcamp, they can opt to do an apprenticeship to specialise further or to master a different type of machinery.

Our Skills Bootcamp is part of a much wider offering of courses through the

Department for Education’s Skills for Life, with free Skills Bootcamps in different industries from digital and tech to the green sector.

We have had a 78% achievement rate producing site-ready plant operators with the remaining requiring further training and testing to achieve the standard we and other employers require; it is not about attendance. And as a testament to our success, we’ve now been granted another 12-months’ funding by the Department for Education to continue delivering the Skills Bootcamp.

It’s more important than ever for employers to take the initiative and be creative in their recruitment methods in order to attract and retain the skilled employees they want and need. At Flannery Plant, the Skills Bootcamps offer is part of a range of tools that help us to do this effectively. We hope to inspire more businesses across the industry to understand the benefits of the array of training and employment schemes available designed to help employers effectively grow their workforce, fill their skills gaps, and hire the right people they need for the job.

CPN I JULY / AUGUST

S PECIAL REPORT

For more information WWW.RDR.LINK/CAL 013 i

Aaron Davis, head of skills and training at Flannery Plant, describes his company’s efforts to plug the skills gap for site operatives.

PLANT WORX PICKS

In what was unusually sunny weather for a Plantworx exhibition, this year’s event provided the UK launch pad for an array of machines. Chinese manufacturers were there in force including LiuGong, which was displaying new electric models.

The largest was the 856HE EMax fully electric wheel loader. Weighing 21tonnes and fitted with a 3.5m3 capacity standard

loader bucket, this machine utilises 423kWh MSD Catell batteries that are claimed to provide an 8-hour operating shift.

Other new electric LiuGong’s were the 2,680kg 9027FE mini excavator fitted with 20.6kWh lithium-ion batteries and the LA20JE all-electric articulating boomlift.

Two new electric telehandlers were displayed by Manitou. Big brother was the6,000kg maximum capacity MRTE2660 fully electric rotary telehandler which, when fitted with forks, can lift loads up to 25.9m.

The MRTE2660 can be powered by one or two 700V lithium-ion batteries (to provide a nominal energy of 65or 139kWh) and there is the option of having an 18.4kW Yanmar engine as a range extender. This machine was Highly Commended in the Engineering & Design category of the Plantworx Innovation Awards.

Manitou also exhibited its new lithium-ion battery powered MT625 all electric compact telehandler. This machine provides a maximum capacity of 2,500kg and its lift path includes a maximum height of 5.85m and 3.4m maximum forward reach.

Takeuchi made good use of its brand new battery-powered TB20e mini excavator. The machine was used to allow visitors to take part in a timed Operator Challenge. With a

CPN I JULY / AUGUST P LANTWORX REVIEW

Takeuchi used the new TB20e electric mini excavator for its Plantworx Operator Challenge.

Consultant editor Nick Johnson brings the machine highlights at Plantworx to the pages of CPN.

Manitou UK’s David Clark proudly holds the Plantworx Innovation Award gained for the MRTE2660

full charge, the 24.7kWh lithium-ion battery pack in the TB20e usefully provided up to eight hours of operating time at 65% load.

The largest new machine on the Sunward stand was the SWE155UF-2PB tracked excavator shown with a Steelwrist tiltrotator. This short radius newcomer weighs 17 tonnes and is powered by a 90kW Cummins QSF3.8 Stage V emissions-compliant diesel engine.

This Chinese construction equipment maker also unveiled its new 1,920kg SWE 20FED electric mini excavator in the UK. Powered by a 76.8V lithium-ion battery pack, this mini is 990mm wide and it can dig down to 2,057mm.

Clamshell grabs the eye

One unusual machine being put through its paces was the prototype Grumper. This is a self-loading site dumper that is being developed in the UK in conjunction with Lincolnshire-based civil engineering contractor JJ Mac Ltd. It is claimed to be the world’s first grab loading dumper.

To prove the concept, the prototype Grumper has been assembled using the chassis from a used 3 Tonne Thwaites articulated dumper. The 3 Tonner’s swivel skip has been replaced by pair of arms (in the style of a skip lorry) which carry an innovative clamshell grab like self-loading skip.

Controlled by a single lever, this bottomopening skip can grab up to around 2.5 tonnes of material at a time. This arrangement makes the Grumper a selfcontained load and carry machine.

Prominent on the showground skyline was one of the new small trailer-mounted tower cranes shown by The Trailer Crane Company. The models on display were the LT14.14RD and the LT14.14RD-XP cranes which have operational outrigger spreads of 4.4m x 4.4m and 5.2m x 5.2m respectively. Both remote controlled cranes have a maximum capacity rating of 1,500kg and can lift 350kg at 14.0m maximum radius to a maximum height of 14.1m (with jib horizontal).

In response to the success of Wacker Neuson’s Dual View site dumper range with forward facing cabs and reversible controls, Mecalac has introduced its Revotruck designs. Available with payloads of either six or nine tonnes, these machines both feature a forward mounted cab that rotates hydraulically through 180˚ so the operator can always face the direction of travel and load discharge.

The Revotrucks are powered by a 54.4kW Perkins diesel engine and have a swivel skip and a rigid chassis with all wheel drive and steer. The machine’s design innovation was recognised by it being a joint winner in the Engineering & Design category at this year’s Plantworx Innovation Awards ceremony.

16 JULY / AUGUST I CPN

First time showing in the UK of Sunward’s new 17 tonne SWE155UF-2PB short radius excavator.

LANTWORX

The Revotruck’s cab and swivel skip are both able to turn independently through 180˚.

P

REVIEW

Bobcat’s recently launched ‘super compact’ TL25.60 telehandler was a highlight of the company’s stand. Powered by a 54.6kW Bobcat Stage V engine, this manoeuvrable all wheel drive and steer machine has a rated operating capacity of 2,500kg. Maximum lift height and forward reach are 5.9m and 3.3m respectively.

Of particular interest on the Develon stand was the brand new 14.6 tonne DX140LC-7K tracked excavator with a 44.3kW D24 Stage V compliant diesel engine. Replacing the former Doosan DX140LC-7 the newcomer provides better maintenance access, safer access to the upper structure, better rear and right-side

visibility and a new dashboard complete with an improved tablet design.

The big Chinese plant maker Sany really made its presence felt at this Plantworx. Amongst its many exhibits were two new wheel loaders – the 129kW SW305K5 and the 170kW SW405K5 with respective operating weights of 14.5 and 18.5 tonnes. Both machines have Deutz engines and their standard loader bucket capacities are 2.3m3 and 3.2m3.

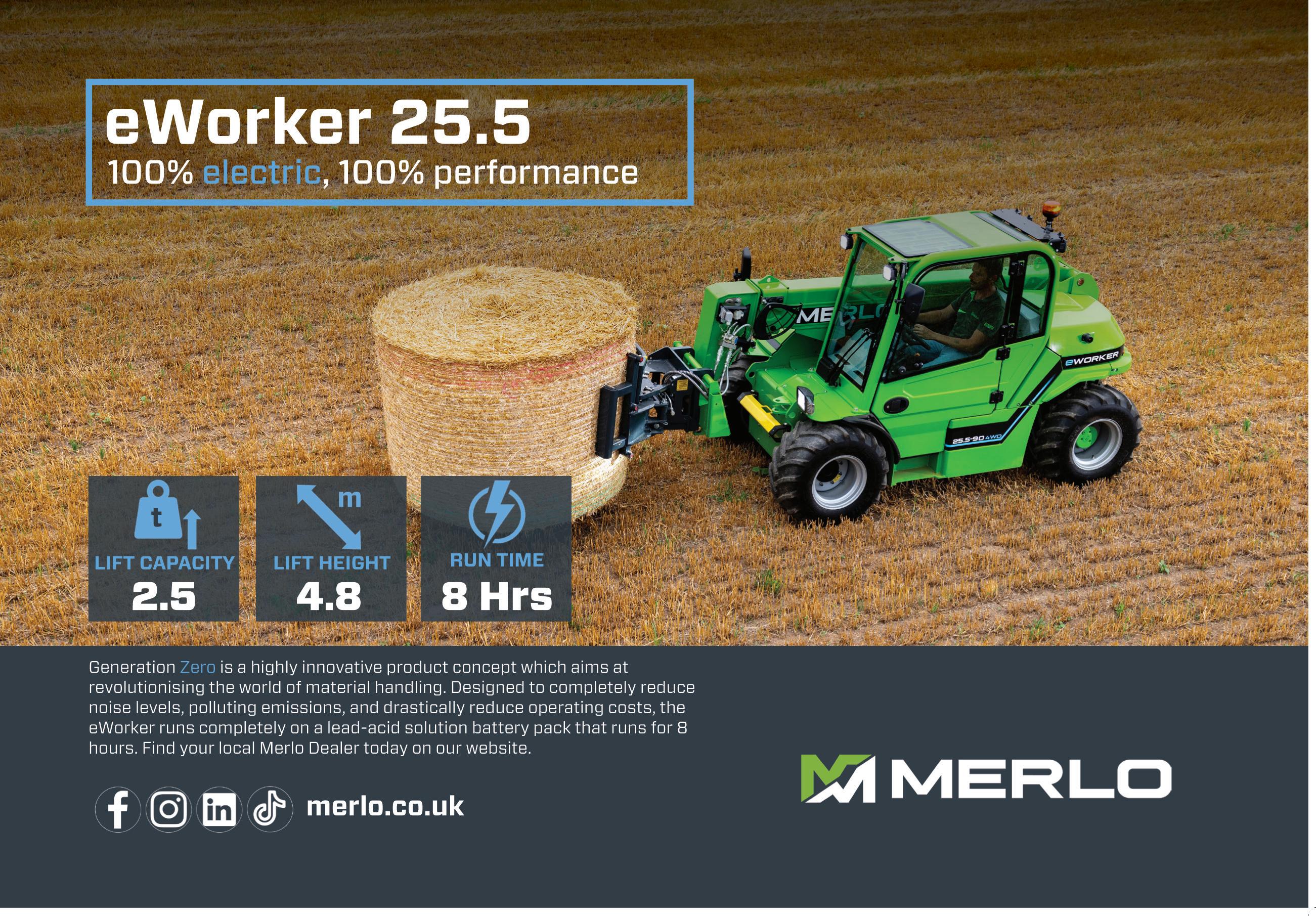

Utilising a chassis produced for its mobile concrete mixers, Merlo used the show for the UK launch of its new 9 tonne capacity DM9 swivel skip site dumper. This rigid frame, all wheel drive and steer machine has a forward mounted ROPS/FOPS cab with a seat that swivels through 180°. Complete with

main wear plates made from Hardox steel, it is due to become available in the first quarter of next year.

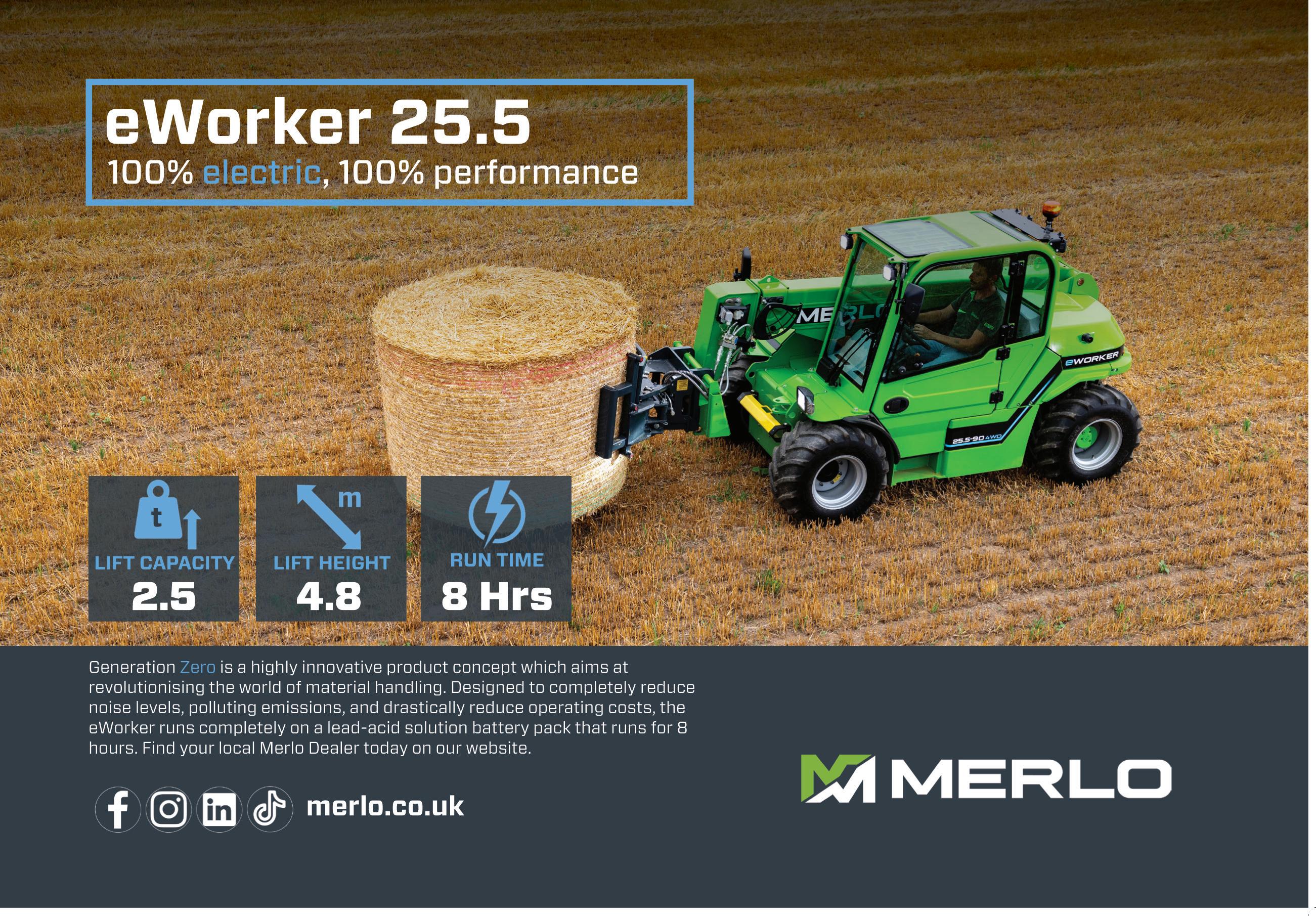

Another Merlo product getting its UK debut was the lithium-ion battery powered Cingo M600TD-e tracked dumper. Able to carry a maximum load of 500kg, this 750mm wide machine provides a maximum high tip height of 1.47m.

Turkish plant manufacturer Hidromek showed three new machines.The 16.8 tonne H4 Series HMK150WR was its first wheeled excavator to arrive in the UK. This wheelie has a 105kW Deutz TCD4.1 diesel engine and the show machine was equipped with a two-piece boom, front stabilisers and a rear dozer blade.

Also creating interest were the new K4 Series HMK102B Supra wheeled backhoe loader and the HMK62T compact tracked backhoe loader.

Plantworx 2023 saw the large Chinese construction equipment maker XCMG putting on a big display of its earthmovers in the UK. As a new Plantworx exhibitor, the company showed 13 excavators ranging from the 1.5 tonne class XE18E to the 22 tonne XE220E. New tracked excavators on show included the new 13.5 tonne class XE135E and the 23.5 tonne class short radius XE235ECR.

For more information on Plantworx WWW.RDR.LINK/CAL 014

CPN I JULY / AUGUST

i

XCMG exhibited no less than 13 excavators as it ramps up its presence in the UK.

Merlo’s new 9 tonne capacity DM9 features a front mounted cab with a 180˚ swivel seat.

Sany’s two new wheel loaders – the 129kW SW305K5 and the 170kW SW405K5.

Hidromek introduced its H4 Series HMK150WR wheeled excavator to UK customers.

MACHINESGALORE!

Bobcat demo event reveals array of new models and technologies; JCB extends electrics; Molson serves up a day of exciting machines. CPN travels to Prague, Cologne and Bristol to bring you the latest in construction equipment.

Avery warm welcome and even warmer day at Doosan Bobcat’s campus in the Czech Republic set the stage for the unveiling of some exciting new models from Bobcat.

The L95 is newest addition to the company’s compact wheel loader line-up, following on from the original L85 machine launched in 2021. The L95 is powered by a Bobcat 75hp engine and offers a top speed of 40km/h and an increased lift capacity.

Like the L85, there are multiple loader attachments approved for use on the L95. Among them are a 1m3 general purpose bucket and a 1.5m 3 light material bucket and new grapple bucket and tines attachments for agriculture. Other new features include an air-ride heated seat; DAB+ radio with phone connectivity and improved automatic ride control, high flow and quick tach systems.

At the smaller end of the range, the company displayed a new concept machine –the L40 –in the 2-3 tonne category. The L40 weighs less than 2.5 tonne and is intended as a powerful load and carry, application-focused machine. Whilst it is simple, robust, and easy to operate, the L40 is designed for heavy duty applications such as road maintenance and construction.

Further down the scale, the L35 is a new small articulated loader (SAL) concept machine, which is an extension of the existing SAL portfolio to cover the market segment for high performance machines which are trailer transportable. The machine weight is again below 2.5 tonne. The engine is rated at 57hp, which allows for higher travel speeds and pushing power. Designed to be a tool carrier with high hydraulic power available for demanding attachments such as snow blowers, sweepers or angle brooms, it is equipped with a telescopic boom as standard to ensure a higher working range.

Eight-hour day

No day would be complete without a glimpse of an electric machine and the S7X prototype is that machine. This all-electric skid-steer loader is powered by a 60.5-kWh, lithium-ion battery, features electric drive motors and utilizes ball screw actuators for lift and tilt functions.

Together, Bobcat says, the battery and electrical powertrain generate incredible performance characteristics, with instantaneous torque that is as much as three times greater than traditional loaders. The powerful loader balances sustainability and performance with zero emissions and is equipped to outperform its diesel-powered equivalent, while offering operators a smooth and comfortable experience with minimal vibration and nearly silent operation.

According to Joel Honeyman, VP Global Innovation, the S7X can operate for up to eight hours on a single charge depending on the application, giving most operators more than a full day’s work when breaks and downtime are considered. A full charge takes approximately 10 hours.

Being transparent

Away from machines Bobcat was eager to showcase some of its technological developments. One of these was its T-OLED touchscreen which was mounted on the windscreen of a compact loader. It is advanced

C PN AT LARGE

18 JULY / AUGUST I CPN

transparent display technology, developed together with LG, that gives operators the ability to touch and customize their user interface with smart widgets and interactive applications. This transparent, multifunction set-up, delivers jobsitespecific data, providing vital information and machine insights for users in realtime. Moreover, thanks to its transparent nature, operators can simply refocus their vision to see everything that is going on around them on site.

Another piece of wizardry was the company's MaxControl remote operation system mated to the Bobcat E35z electro-hydraulic mini excavator. This enables operators to control their excavator from outside of the cab at a variety of distances using their iPhone to maximize versatility on the jobsite.

The 3.5-tonne E35z features an electro-hydraulic control system rather than conventional hydraulic joysticks, meaning it can be customized and programmed to suit all levels of operator skill. Thanks to its integrated sensors, the model can perform a variety of semiautomated tasks, helping users to conduct precise grading, levelling and trenching activities in addition to other repetitive operations such as return-todig movements.

Bristol cream

The culmination of the spring/ summer collections – as they say in the fashion biz – were the Molson Demo Days at the group’s headquarters in Avonmouth, Bristol. Hosted by group MD Robin Powell, over 800 visitors attended site between June 20th and 22nd to enjoy a vast array of attachments and machines new and old from 35 manufacturers. Also to be seen were industry innovations based around fleet management and connected sites.

The demo week got off to an inauspicious start on the 20th with early risers being greeted with dark Bristolian clouds and torrential rain; yet by mid-morning the company was blessed with blue skies and the great heat many of us have enjoyed lately and were so for the rest of the week.

Excavators from Hyundai and Kobelco –including a good few in demo spec – were writ large, alongside waste, scrap, timber and port handlers from Sennebogen. Dumpers from Rokbak and Thwaites loomed over us, while crushers, screeners and shredders from Finlay, Terex, Ecotec and Evoquip dominated long stretches of Molson’s massive nine-acre yard.

There were attachments galore, with the very latest in shears, breakers, tiltrotators

and grapples from the likes of MB, SMP, NPK, Daemo, Genesis and Rotobec on display.

Offsite, there was a chance to visit Plantforce’s ‘Discover Digital’ site where it presented a connected construction site utilising machine telematics, GPS technology from Leica and Trimble and information on its HireInsights package.

One final treat was a whistle stop tour around one of the big machines – a Sennebogen 870E – at Bristol docks, supplied by Molson seven months ago. Weighing in at 110 tonnes, with a 24m reach and a 5000litre fuel tank; the 870E was delivered in kit form on 10 trucks and built in situ over three weeks.

CPN I JULY / AUGUST

Sennebogen 870E at Bristol docks, supplied by the Molson Group

At a recent presentation at its Cologne facility JCB introduced its first full electric wheeled loader, which it claims, delivers best-in-class performance and full working day use, with low noise and zero-emission operation for customers.

JCB rolls out new 403e compact electric loader

The machine is powered by a 20kWh lithium-ion battery pack, assembled from proven JCB modules. These batteries, coupled with high efficiency electric motors and optimised traction and hydraulic systems, deliver class-leading performance, with the loader capable of completing a full working day, or 4-5 hours of continuous use in a mixed duty cycle.

In common with the JCB E-Tech range, the 403E has a built-in charger that allows connection to a range of on-site power sources. A 110V socket will fully charge the batteries in 12 hours, while a 230V industrial or domestic plug will charge the battery pack in just eight hours. JCB’s off-board rapid charger can also be used with the 403E, delivering a full charge from a three-phase supply in just two hours.

The machine is equipped with two independent electric motors, one for the driveline and one for the hydraulics. The drive motor offers 33.4kW of power and comes with three driving modes, that the operator can toggle between using two buttons on the top of the joystick: hare mode has a maximum 20kph drive speed for the most dynamic performance and productivity; tortoise mode is limited to 8kph for improved speed modulation; snail mode has a 5kph maximum speed, that can be adjusted in 0.5kph increments through a new rotary controller and the multifunction display. This delivers precise speed control for precision driving and inching.

Drive is transmitted through an integrated drop-box to ZF axles, that can be supplied with open differentials or with differential locks for maximum traction. The loader is

offered with a choice of narrow or wide wheels, plus the option of agricultural or industrial tyres, making it suitable for a wide range of applications.

Carried over from the 403-diesel model, the loader arms are available in standard and high-lift configurations. The standard lift arms deliver a pin height of 2.9m, while the high-lift model achieves a 3.1m pin height. Both loader arm set-ups come with a hydraulic quick hitch as standard, and the loader arms provide a true parallel lift capability.

The 403E offers a tipping load of 972 kg with pallet forks, within a transport weight of just 2,671 kg. This puts the 403E within EU trailer towable standards, making it an ideal machine for landscape, municipal and rental customers. A heavy-duty counterweight is available as an option, increasing the tipping load by 118 kg and the transport weight by 121kg.

The machine has a single joystick with a proportional auxiliary controller on top. An optional second auxiliary roller can be provided, allowing the operator to access all loader functions from one lever for faster operation.

A 20kW high efficiency hydraulic pump motor is at the heart of the hydraulic system, which offers two operating modes, controlled by a rocker switch on the main console. Shovel/bucket mode provides dynamic response, while the fork mode delivers increased precision control. A programmable constant flow auxiliary feature is also standard, to power motorised attachments, with the operator setting the flow rate through the main display and rotary controller.

20 JULY / AUGUST I CPN C PN AT LARGE

W W W. CPNONLINE . CO.UK

P a c k e d w i t h a r t i c l e s o n a w i d e r a n g e o f i n d u s t r y t o p i c s , w w w. c p n o n l i n e . c o . u k i s t h e f i r s t p l a c e t o v i s i t f o r a l l t h e l a t e s t n e w s i n p l a n t a n d m a c h i n e r y – f r o m t h e s m a l l e s t s k i d s t e e r s a n d m i c r o e x c a v a t o r s t o t h e g i a n t s o f t h e t o w e r c r a n e m a r k e t , o r t h e h e a v y w e i g h t s i n c r a w l e r e x c a v a t o r s , w e ’ v e g o t i t c o v e r e d

G e t t h e l a t e s t i n f o r m a t i o n o n t h e i n d u s t r y ’s b i g g e s t d e a l s , a s c o n t r a c t o r s a n d p l a n t h i r e r s r e n e w t h e i r f l e e t s i n o u r F l e e t A d d i t i o n s s e c t i o n , a s w e l l a s a l l o f t h e n e w e s t p r o d u c t s t o h i t t h e m a r k e t . O u r w e b s i t e i s u p d a t e d d a i l y, b r i n g i n g y o u t h e m o s t i m p o r t a n t i n d u s t r y n e w s q u i c k e r t h a n e v e r b e f o r e

YOU CAN ALSO FOLLOW US ON TWITTER @CPN mag OR FOLLOW

P I C K U P T H E L AT E S T I N D U S T R Y N E W S A N D N E W P R O D U C T I N F O R M AT I O N AT

CONSTRUCTION PLANT NEWS ON LINKEDIN

A mini adventure

machine

Some models have heavier counterweights, and optional angled blades are available on models above the HX35A Z. The excavators come with both long and short dipper arms. A rearview camera is available as an option on excavators with an operating weight

For more information, please WWW.RDR.LINK/CAL020

Self-checking keeps 36C-1 in working order

The JCB 36C-1 is equipped with a Perkins 18.4kw Stage V engine and an electronically controlled pump, making it ideal for even the toughest jobs. With an operating weight of 3,759 kg and a maximum dig depth of 3.48 m, it provides exceptional productivity, with bucket tearout forces of up to 32.0kN and fast cycle times. The machine health-check system ensures that it is always in excellent working order, and the fully adjustable suspension seating offers operator comfort throughout the day. Its long greasing intervals of 500 hours reduce downtime, thanks to graphite impregnated bronze bushes. Load sensing hydraulics conserve fuel by consuming power only where it's needed. Additionally, it has programmable auto-idle and four different engine modes that further reduce fuel consumption. The machine's easy-to-clean sloping H-frame undercarriage ensures quick turnaround.

For more information, please WWW.RDR.LINK/CAL021

C OMPACTS & MINIS

22 JULY / AUGUST I CPN

CPN takes a look at the most recent mini

offerings from some of the sector’s biggest names.

CASE CONSTRUCTION EQUIPMENT

20 model range to meet every need

Ranging from 1.2 tonnes to 6.2 tonnes, the D-Series of mini-excavators from CASE Construction Equipment consists of 20 models – two of which are electric – that includes two-piece boom, zero-tail swing and short radius. Features include electronic proportional RPM control with auto-idle for greater fuel efficiency, tiltable cab (ROP/TOPS - FOPS Level 1), hydraulic reversible fan drive with automatic functionality, electric fuel refill pump with auto-stop function, and optional anti-theft technology. Each model can be customised to boost productivity as users can specify up to three auxiliary circuits with electro-hydraulic proportional control plus a range of hydraulic and mechanical quick couplers to drive attachments from buckets to breakers and mulchers. All models are equipped with LED working lights, automatic air conditioning and heating, automatic courtesy light in the cab, and rear view camera to improve operator safety, control and comfort.

For more information, please WWW.RDR.LINK/CAL022

JCB

Electric machine cuts maintenance

The all-electric mini excavator JCB 19C-1E is five times quieter than its diesel counterpart. It can be fully charged in under two hours using either a 110V, 230V, or 415V supply and can complete a typical full shift on a single charge. Its maintenance-free batteries require minimal daily checks and less

servicing, while the electric motor requires less servicing time. JCB's 2GO system safely isolates all the controls, and the canopy is ROPS, TOPS, and FOGS certified for full safety compliance. Additionally, the excavator has been designed and built to withstand the toughest job sites with long-lasting components that minimise downtime. Its 100% steel bodywork provides maximum protection and easy repair, while the fullwidth rear cast counterweight gives full protection against site damage.

For more information, please WWW.RDR.LINK/CAL 023

TAKEUCHI

More short tails for Takeuchi

Weighing 3.8-tonnes, the Takeuchi TB335R short tail excavator is Stage V ready with 18.2kW and an eco-operating mode. Its larger than average track frame and optimized counterweight provides excellent stability and just 75mm maximum track overhang. Designed for all day operation, the TB335R’s cab is equipped with a high back suspension seat and good foot room plus climate control, DAB radio, microphone socket, Bluetooth, and a 12V charging socket. For safety, the excavator has LED work lights – front, back and internal – and the blind-side window is larger and lower for maximum dig and slew area visibility. Holding check valves are fitted as standard along with audible warning lift alarm.

For more information, please WWW.RDR.LINK/CAL 024

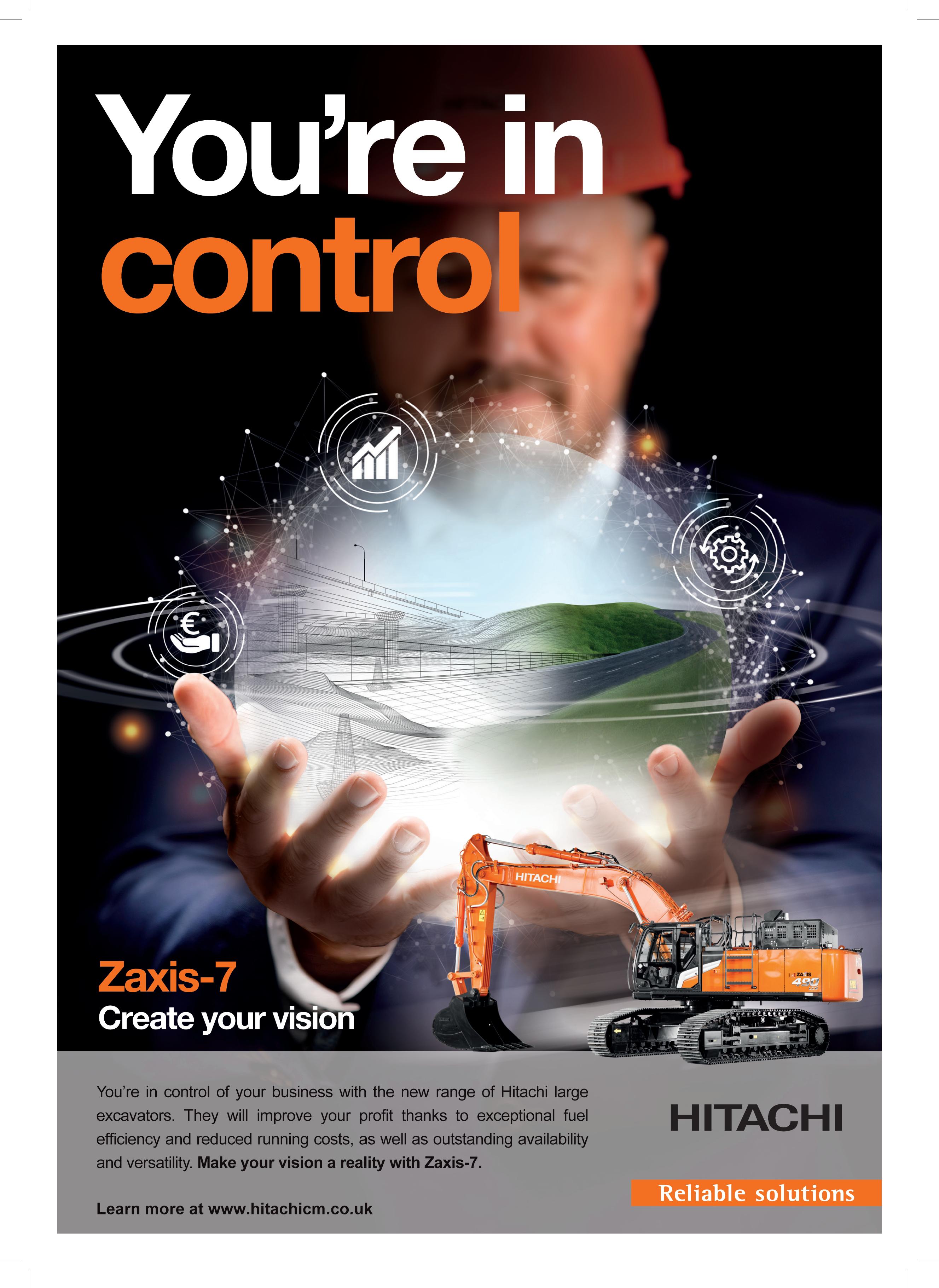

HITACHI CONSTRUCTION MACHINERY

Manoeuvrable and cordless

Hitachi Construction Machinery's ZX55U6EB is an electric five-tonne excavator that can be cordless, using 39kWh lithium-ion batteries, or wired so it can work while charging from a CEE 400VAC 3-phase power source. It is exceptionally manoeuvrable

thanks to its short tail swing of 1.1m cordless or 1.8m when wired. Owners of the ZX55U-6EB can expect reduced maintenance costs and downtime compared to diesel-powered excavators, says Hitachi. The electric drive system's status, including battery level and motor load factor, can be remotely monitored while a rear camera monitors the cable during wired operation to ensure it is secure. The machine's reduced external sound levels of 91dB should extend working times and possible locations.

For more information, please WWW.RDR.LINK/CAL 025

HYUNDAI CONSTRUCTION EQUIPMENT

Lightweight E18 charges swiftly

Providing emission-free working for urban and underground construction, Hyundai's 18E electric mini excavator weighs just 1,863kg with a canopy and 2,030kg with a full cab. Powered by a 20.7kWh battery pack, it can work all day but only takes 5.6 hours to recharge from a standard 220V site supply. The 18E’s 13kW electric motor is fed by an inverter and provides a peak power of 27kW, driving the hydraulic pumps in the same way as a diesel-powered equivalent. With a 0.04m3 bucket, the machine boasts a bucket breakout force of 15.1kNm and a dipper arm tearout force of 9.4kN. It has a 1,800mm monoboom, 960mm dipper arm, dozer blade, and quick couple for attachment changing.

For more information, please WWW.RDR.LINK/CAL 026

i i i i i CPN I JULY / AUGUST 23

maximum operator comfort and short pitch rubber shoes smooth out travel on any surface. Safety features include double lock function for PPC, engine shut down secondary switch, seat belt caution indicator, tie down points on the revo frame, and lifting points on the cab.

For more information, please WWW.RDR.LINK/CAL 030

productivity, outstanding user comfort and control with zero emission performance, giving operators the same level of excellence they’ve come to expect from Kubota machines – without the carbon output. Both machines feature an extremely powerful, high torque electric motor that can be recharged within 90 minutes when using the optional supercharger, making them a reliable choice for a wide range of projects and tasks. Powered by a 48V system with modular 260Ah lithium-ion batteries as standard, the machines regenerate energy when the machine decelerates or travels downhill, further enhancing their reliability.

Boasting enhanced loading versatility, the RT210-2e’s long loader arm has a reach of up to 2,852mm, while the RT220-2e shorter loader arm has an increased lift capacity of

Compact and agile, both the RT210-2e and RT220-2e are highly manoeuvrable with allwheel steering on each axle, with a pivot steer of 44˚, making them perfect for work in restricted spaces. Further versatility is added by a hydraulic quick hitch which is compatible with a host of attachment options.

Both the RT210-2e and RT220-2e also have electric / hydraulic integration that delivers complete multi-functionality for operators, particularly for lifting and the top cylinder. The machines also have optional boom suspension to provide even better retention of load inside the shovel, even at

For more information, please WWW.RDR.LINK/CAL 031

C OMPACTS & MINIS 24 JULY / AUGUST I CPN

Construction PLANT NEWS INTRODUCING

A digital service for our readers...

With a wide array of online resources supporting the latest solutions – from videos to technical guides, PDFs to podcasts – it can be a challenge to locate what you need.

To ensure you don’t miss out on these valuable resources, we are introducing rdr.link/ – a new, rapid service to transport you immediately to the online resources mentioned in our stories.

So, in articles you may now see things like:

For further information on Volvo Construction Equipment

WWW.RDR.LINK/CAE 017

Simply enter rdr.link/ followed by the unique six digit code into your browser and it will take you to the required resource

Designed to help busy professionals rapidly locate more information – look out for & use RDR.LINK/

i

RDR.LINK/

West Country contractor boosts productivity with Yanmar's adaptable excavator.

Dorset-based fencing and agricultural contractor, Hurn Bridge Fencing (HBF), chose Yanmar’s SV26 Conventional Tail excavator when it came to replace its tractor.

“When researching excavators, we found that the SV26 is a lot more versatile than others on the market, which is exactly what we need. We’re only a team of four, and therefore depend on a machine that can wear many hats and keep up the pace with our diverse day-to-day activities,” explains Lawrence Wickham, director.

“The great thing about the SV26 is that it can be fitted with a ton of different attachments – not only your typical buckets

BOBCAT GIVES CONTRACTOR THE EDGE

The firm employs a versatile Bobcat fleet –which includes E10z, E17, and E26 mini-excavators and an S175 skidsteer loader, along with a variety of attachments such as a planer and a sweeper –in delivering projects throughout the region.

According to managing director Jon Sculthorpe, the Bobcat equipment is wellregarded by its workforce for its strength and compatibility with various attachments. He particularly likes the S175 skid-steer loader, calling it “our most versatile piece of kit”.

He backs this up with the example of a recent block paving project in Letchworth and Welwyn Garden City where the S175 showed it could tackle many tasks: unloading blocks with the fork attachment, moving granular sub-base in and out of the site with the bucket, and leaving the car park clean and tidy with the sweeper attachment once all works were completed.

“In addition, when we are machine lay surfacing, the skid-steer loader is always on site and can be relied on to feed the paver with the bucket

attachment, scrape the surface to remove snots, plane tie-in joints, and once all completed, the sweeper attachment makes light work of tidying up,” Jon continued.

The E17 and E26 mini-excavators are integral to ProEdge Construction's daily operation, which include Section 38 and 278 works, asphalt machine and hand lay, block paving, kerb laying, surface water drainage and fencing.

Sculthorpe explains, “The E17 is a dependable workhorse, while we complete most of our small highway jobs with the E26, which has a good deal of power, especially when using a breaker. The Bobcat hydraulic clamp attachment fitted to this machine gives it another dimension, and the initial outlay was soon repaid as it just speeds things up.”

For more information

WWW.RDR.LINK/CAL 032

for groundworks and digging trenches, which most are familiar with, but also wire rollers and post drivers for erecting fences. We even fit our Yanmar unit with a rock spike, which is great when we need to firmly position our fencing posts in hard or rocky ground.”

With an operating weight of 2,740 kg, class-leading stability and low ground pressure, the SV26 has worked well for HBF’s projects on rough, uneven or unstable terrain. The machine benefits from a conventional structure with reduced tail overhang, which gives it increased lifting performance and stability in even challenging work environments. In addition, a long track base adds to digging stability and lifting capacity, while the 300mm wide tracks offer excellent traction.

“Due to the compactness and weight of the SV26, we can also easily work on steep inclines or boggy areas without scuffing up the areas too much with the tracks,” says Wickham. “Whereas with larger excavators or tractors, we have found that they can weigh a lot and sink into the ground, especially when it’s wet. The arm is also a good length (115/1400mm), helping us to carry out our projects safely and with ease”.

Wickham purchased his Yanmar unit from Hunt Forest Group.

For more information

i 26 JULY / AUGUST I CPN

WWW.RDR.LINK/CAL 033

i

A broad array of Bobcat equipment has become an indispensable asset for ProEdge Construction, an East Anglia-based family-run business specializing in civil engineering and highways maintenance.

Yanmar’s SV26 mini excavator is jack of all trades

machinesinaction

Bespoke machine multi-tasks for drainage board

Collaboration between suppliers produced an excavator tooled up for specialist operations.

Faced with the need to replace its existing plant, The Upper Medway Internal Drainage Board presented Gem Plant Sales with an unusual challenge.

The board, responsible for ensuring adequate drainage and water management within specific districts surrounding the country's primary river catchments, needed a specialist machine. Instead of a large, tracked machine typically used for tasks like weed clearance and desilting operations, it wanted a more versatile solution. Instead, it required a smaller, more flexible machine with a large reach and a double-jointed boom section. Despite its compact size, it should not compromise on its ability to reach the far sides of the banks, both on and off-road.

To meet this requirement Gem arranged for joint visits to various sites with works supervisor, John Davis, to look at both the larger wheeled offerings and the tracked variants. They selected the Wacker Neuson EW65, a 6.5 tonne wheeled excavator, with a double boom, extended dipper, and additional Steelwrist omni-hitch.

To tailor the machine the board’s needs, they turned to Exac-One, west country attachment specialist, which demonstrated a selection of suitable kit at its Swindon HQ. The board chose a tree shear and a mulcher head, both of which were integrated with the Wacker Neuson wheeled excavator. The tree shear, equipped with a gripping arm, can cut up to 300mm and retain cuttings, while the mulcher head, featuring a fixed teeth drum, enabled high impact debris clearance. A 2m Bradshaw type bucket from Flails

VERSATILE EXCAVATOR PROVES A WINNER

Following a severe health crisis, David Hardgrave, owner of Harwinn Agricultural and Construction Services, has successfully reinvented his Leicestershire-based company with the help of the Develon DX100W-7 wheeled excavator.

Hardgrave suffered a heart attack in 2021, which required a strategic shift in the operational direction of his company. No longer able to perform physically demanding groundworks contracts, Hardgrave switched to vegetation management and other aspects of highway management work. In this transition, the Develon DX100W-7 emerged as an invaluable asset.

“The DX100W-7 is the ideal size of machine for me, combining the ability to operate attachments such as mulching heads and tree shears with the capability to drive from one location to another,” says Hardgrave. “This flexibility ensures that we can securely store the machine overnight, instead of leaving it on-site.”

Designed primarily for urban and road maintenance applications, the DX100W-7 provides a high-performance solution in the 10-tonne weight class. It offers the highest engine power, hydraulic flow, and traction force in this category, powering a diverse range of attachments with smooth and precise hydraulic flow. It also offers independent hydraulic flows for transmission and tool powering.

“We have been carrying out a number of ecology projects using the DX100W-7 on behalf of quarry operators, helping to

Direct, completed the order but set further challenges. This bucket, designed for weed and reed clearance works, required the installation of additional low flow circuits, which in turn necessitated multiple settings, hookups, and limiters. Gem’s team worked around this by installing a system that not only accommodated the bucket but also allowed for easy equipment swapping depending on the task at hand.

For its part, the board is grateful for the contribution that each and every supplier made.

For more information

WWW.RDR.LINK/CAL 034

clay line used quarries to turn them into lakes for use by the community,” said Hardgrave. “We recently completed a project like this for the Yorkshire Wildlife Trust. We continue to take on topsoiling and verge projects on behalf of developers and the agility and manoeuvrability of the DX100W-7 are excellent for projects like this, allowing us to easily get between new properties on these developments.”

Hardgrave credits Pioneer Plant, the authorised dealer for Develon in the region, for the smooth transition of his business, praising its speed and efficiency: "All aspects of the machine are dealt with so quickly –we've even had engineers from the company in overnight, allowing us to begin work again first thing the next day.”

For more information

WWW.RDR.LINK/CAL 035

CPN I JULY / AUGUST

i

i

ZOOMLION AFI RENTALS

AFI Rentals has bought around 100 machines from Zoomlion Green range to boost its fleet of more than 7,000 powered access machines. The purchase was in line with the company’s policy of replacing this fleet with specialist hybrid or electric equipment to keep up with market demand and comply with increasingly strict emissions regulations, said David McNicholas, the company’s CEO.

“Approximately 70% of our rental fleet is now battery and bi-fuel,” he said. “The Zoomlion equipment offers high capacity and outreach and easy maintenance.”

The models bought include two electric telescopic boom lifts, the ZT22JE and ZT26JE, and two electric scissor lifts, the ZS06007ACW-Li and ZS121AC-Li.

The ZT22JE and ZT26JE are equipped with the latest intelligent connectivity technology, a customised lithium-ion battery, and a maintenance-free AC Drive system. The lithium-ion battery has an energy management system that prolongs operating time and extends the battery's service life by at least 10%.

The ZS06007ACW-Li and ZS121ACLi electric scissor lifts also have lithiumion batteries, which offer a longer service life that extends the operation time by 30%, even under cold working conditions down to -20'C.

WWW.RDR.LINK/CAL036 GOTO

ANDOVER TRAILERS FM CONWAY

Continuing a 20 year relationship, Andover Trailers has provided FM Conway with four custom-built step frame trailers, featuring specifications similar to their previous 73tonne, 15.1m four axle Andover builds, four of which remain in service. Two of the new trailers are 1.2m shorter to deal with less accessible sites.

“We started with two Andover four-axle step frames around 10 years ago and now we have eight, which speaks to their build quality and longevity,” said FM Conway's senior transport manager, Steve James. “What sets Andover apart is its willingness to tailor its work to our needs, as it did by shortening two of the trailers this time. They still offer the same strength and specs, but with enhanced manoeuvrability.”

The step frames incorporate a robust, four-member design with slide-out side extensions for ultimate load stability. They also feature 1m wide power toe ramps with sliding width adjustment and knife edge toes to facilitate loading and unloading of FM Conway's 40-tonne road planers.

With features accommodating a variety of plant types, including heavy rollers, pavers, and excavators, the trailers are equipped with hydraulic steady legs at the rear, steel underplating on the main deck’s outer bays, the beavertail and ramps. The deck also has 20 pairs of D-ring and eight screw-in lashing points for secure loading, built-in chain storage, and a robust six-tonne electric winch. For safe operation, the trailers have a full working at height system with a removable walkway, LED strobe lights, work lights, and extra flashing beacons. The SAF axles, fitted with 285/70 R 19.5 tyres, have disc brakes and a rear-steer feature operable from the tractor unit or the trailer.

The step frames, which will be on the road from Monday to Friday, will transport plant to highway and infrastructure projects across Southern England, logging around 180,000km per year.

WWW.RDR.LINK/CAL037 GOTO

F LEET ADDITIONS 28 JULY / AUGUST I CPN

JCB TOOL HIRE

Jewson has signed a deal with JCB for 900 machines, in one of the largest orders this year for the construction equipment manufacturer. Worth more than £12 million, this is the most substantial order placed by Tool Hire –Jewson's rental division –since it began sourcing from JCB two decades ago.

A highlight of the order is the inclusion of 19C-1 E electric mini excavators and 1TE electric site dumpers. These electric models operate quieter, emit zero emissions at the point of use, and their performance is comparable to their diesel counterparts. Notably, they can operate for a typical full day on a single charge.

The order also comprises JCB 8008 micro excavators, JCB 16C-1 mini excavators, 1T site dumpers, and VMT160-80 vibratory tandem rollers. The fleet will be supplied through JCB dealer, Gunn JCB.

GOTO

WWW.RDR.LINK/CAL038

JCB TATE FENCING

Tate Fencing, operating frombranchesinEast Sussex andKent, hasincorporated a new JCB 35-22E electric Teletruk into its Flimwell, East Sussex warehouse and workshop operations.

“We’ve been really impressed by the electric Teletruk,” transport manager Mark Ashdown said. “The ease of the fork operation is smoother than previous models. Its loading capabilities are reliable, and the low emissions it produces are helping us reduce our carbon footprint. It's a benefit to work with this quiet and versatile machine.”

The electric Teletruk is responsible for handling incoming timber loads and feeds them to the workshops and on-site processing plant, accumulating 20-25 hours of usage weekly. Its forward reach capability is key in the warehouse, especially where space restrictions could challenge conventional machines.

The JCB 35-22E electric Teletruk, part of the JCB E-TECH range, is designed for indoor and outdoor operations, aligning with the varied needs at Tate Fencing. This forward reach electric forklift can sustain a full 8-hour shift on a single charge, ensuring zero emissions at point of use without any compromise on performance.

GOTO

WWW.RDR.LINK/CAL039

CPN I JULY / AUGUST 29

HYDROGEN DEFINITELY IN THE MIX

JCB’S £100 MILLION INVESTMENT IN ITS PROJECT TO PRODUCE SUPER-EFFICIENT HYDROGEN ENGINES HAS REACHED A NEW MILESTONE WITH THE PRODUCTION OF ITS 50TH HYDROGEN COMBUSTION ENGINE.

Chairman Lord Bamford said: “The JCB engineering team has done a fantastic job to develop a brand-new hydrogen engine. They have gone back to first principles to completely re-design the combustion process to work for hydrogen. In doing so the team achieved two major things: secured JCB’s place in history as the first construction equipment company to develop a fully working combustion engine fuelled by hydrogen and steered us towards the production of a landmark 50 hydrogen combustion engines.”

As the company examines future fuels which deliver zero emissions, it has left no stone unturned. In its search for a mobile fuel which can be taken to the machine, ensuring maximum uptime and fast refuelling, HVO, biogas, E-fuels, ammonia and hydrogen have all come under the microscope.

KOMATSU GOES FULL GAS

KOMATSU HAS DEVELOPED A NEW CONCEPT MEDIUM-SIZED HYDRAULIC EXCAVATOR THAT COMBINES A HYDROGEN FUEL CELL AND KOMATSU-DEVELOPED KEY COMPONENTS TO ACHIEVE CARBON NEUTRALITY.

By advancing its proof-of-concept tests it started in May 2023, the manufacturer has accelerated its efforts to start commercial production of medium-sized and large construction equipment powered by hydrogen fuel cells in the near future.

For the concept machine, Komatsu used a hydrogen fuel cell system and hydrogen tank, produced by Toyota, and is working towards zero exhaust emissions and a significant reduction in noise and vibration, while delivering the same powerful digging performance and high operability as diesel engine-driven excavators.

Lord Bamford said: “The majority of these alternative fuels require the production of hydrogen to make, so it makes perfect sense to use hydrogen in the first place because it is a clean zero carbon fuel which can be produced from renewable energy. Hydrogen also offers a potential solution to the challenge of batteries on larger machines; it allows for fast refuelling and is a mobile fuel solution, allowing fuel to be taken to the machine.”

As part of its hydrogen development, JCB also investigated its use in fuel cells and in July 2020 unveiled the construction industry’s first ever hydrogen powered excavator –a 20-tonne 220X.

For the time being, JCB has come to the conclusion that fuel cells are too expensive, too complicated and not robust enough for construction and agricultural equipment.

For more information

WWW.RDR.LINK/CAL040 i

In challenging the JCB engineering team to think differently using technology that is around us in a zero-carbon way, the JCB hydrogen engine was born. Now these hydrogen engines are already powering prototype backhoe loaders and Loadall telescopic handlers and the company has recently unveiled its very own designed and built mobile refuelling bowser to take the fuel to the machines. The bowser has enough hydrogen to fill 16 hydrogen backhoe loaders and is able to be transported either on the back of a modified Fastrac tractor or on a trailer.

To find out more, WWW.RDR.LINK/CAL041

T ECHNOLOGY

30 JULY / AUGUST I CPN

CORNER

i

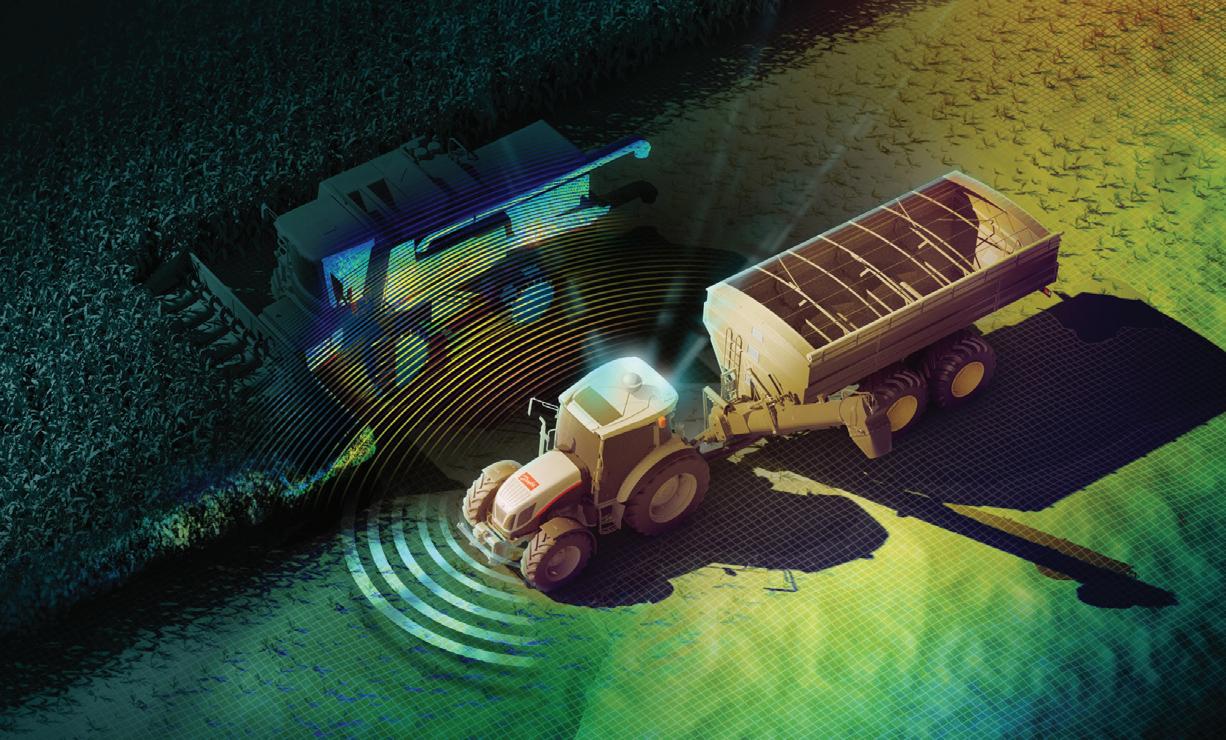

MACHINE AUTONOMY ON THE RISE

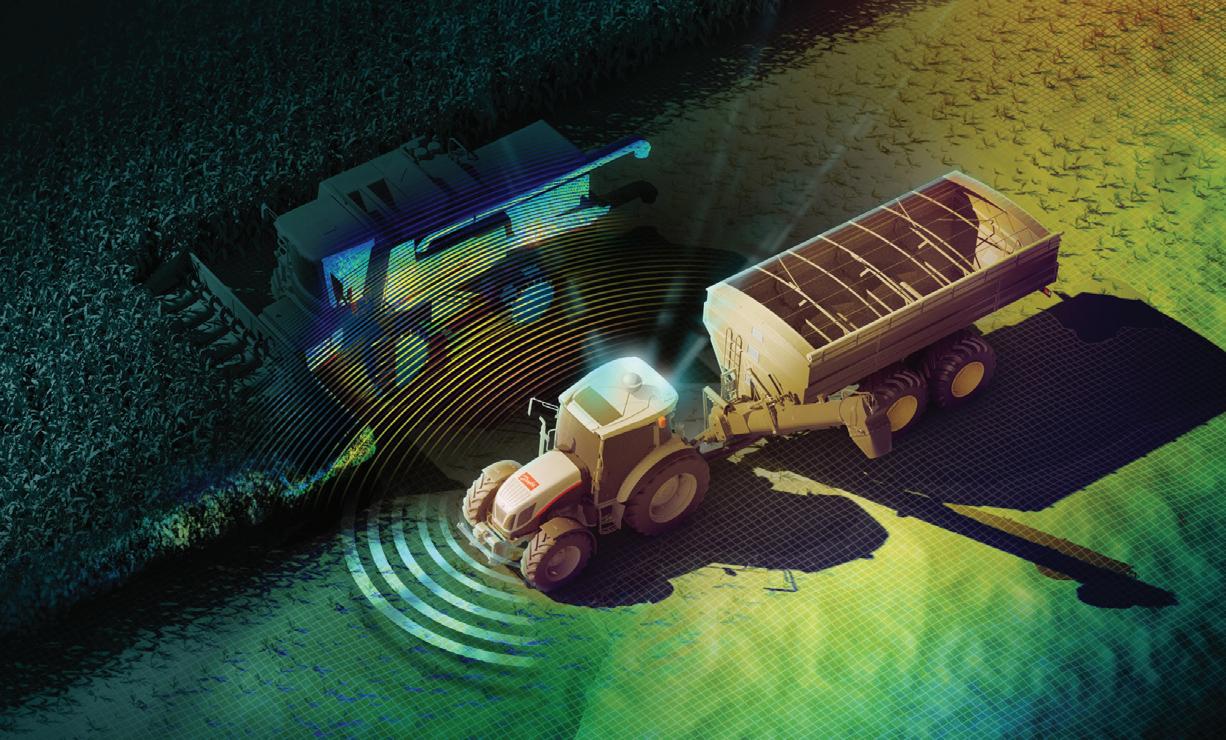

DANFOSS POWER SOLUTIONS HAS PARTNERED WITH SWIFT NAVIGATION, BONSAI ROBOTICS, AND HARD-LINE TO EXPAND THE OFFERINGS IN ITS AUTONOMOUS MACHINE DEVELOPMENT PLATFORM.

Danfoss will integrate the companies’ solutions into its PLUS+1 Autonomy software, enabling users to enhance their autonomous machines with Swift Navigation’s high-precision positioning service, Bonsai Robotics’ camera-based vision systems, and HARD-LINE’s teleoperations solution.

“Autonomous off-highway machines are becoming more sophisticated. As we advance towards Level 4 and even Level 5 autonomy, high-precision navigation and remote control beyond line of sight will become requirements,” says Peter Bleday, head of autonomy, Danfoss Power Solutions.

PLUS+1 Autonomy is a software platform designed to substantially reduce development time and facilitate rapid vehicle prototyping, helping OEMs get autonomous and semi-autonomous off-highway machines to market faster.

Swift Navigation's Skylark precise positioning service offers decimeter-level accuracy from the cloud to PLUS+1 Autonomy,

eliminating the need for additional ground infrastructure. It is well suited for industries such as construction, agriculture, and other applications that demand high-precision GNSS capabilities.

Bonsai Robotics specializes in camera-based vision systems for adverse conditions such as heavy dust, debris, vibration, and lack of GPS. The system uses cameras instead of traditional positioning systems, enabling greater accuracy at very low cost when navigating the toughest conditions, including narrow rows of trees, vines, or crops.

HARD-LINE offers teleoperation services that enable monitoring and control of machines over the internet. The service complements Danfoss’ radio-based remote-control solutions, which allow operators to remotely control machines within line of sight. Teleoperations are ideal for operators supervising multiple autonomous machines. If a machine stops due to an unknown obstacle, the operator can log in to the HARD-LINE system, navigate around the obstacle then resume autonomous operation without needing to be close to the machine.

For more information WWW.RDR.LINK/CAL042 i

KUBOTA’S FEATURE-PACKED MINI-EXCAVATOR

Powerful and loaded with productivity-enhancing features, the KX085-5 offers real time tracking of relevant data such as work rates, idling times and location as well as sophisticated controls.

Kubota’s latest offering is the KX085-5, an 8.5-tonne mini-excavator driven by an advanced Kubota engine that combines high power with low emissions, ensuring efficient completion of diverse tasks.

The KX085-5 incorporates a robust hydraulic system, offering reliability and seamless operability. An optional twopiece boom provides extended working and dumping ranges, proving particularly efficient in narrow spaces. Productivity should be greater too, since the hydraulic mechanism allows simultaneous control of the arm, boom, bucket, and swivel.

Easy finishing

High-performance features are aplenty in the KX085-5. These include two auxiliary circuits with adjustable maximum oil flow, load sensing hydraulic system for smoother operation regardless of load size, float function for easy ground finishing, as well as an auto-shift system that offers intuitive control when dozing and turning.

Designed with energy efficiency and costeffectiveness in mind, the KX085-5 employs an auto idling system that automatically reduces the engine RPM to idling speed when the control levers are left in neutral for more than four seconds. Additionally, an engine auto stop system comes as standard, automatically turning off the engine after an adjustable idling time.

The mini-excavator features a spacious cabin, providing ample legroom and a wider

entrance. A double adjustable air suspension seat offers enhanced comfort levels, and a high-resolution, full-colour 7” LCD digital display screen presents all vital operational information, augmented by LED working lights and a rear view camera for improved visibility.

Maintenance is made straightforward with a triple opening bonnet and an optimal arrangement of internal parts. The KX0855 has a shorter rear overhang, ensuring operability in restricted spaces and better stability. Cast-iron protectors on the rear overhang reduce potential machine damage on restricted work sites.

Security is a key aspect of the KX085-5, which uses the company’s innovative tracking system technology, granting operators access to real-time data for increased efficiency and safety. The intuitive and user-friendly portal can enhance

productivity thanks to the constant review and analysis of real-time parameters of parts such as machine work rate, operating times, actual operation, occupancy rate (as a percentage), idling time, DPF regeneration history, water and oil temperatures, and fuel consumption. In addition, the portal provides alerts that show a machine's faults enabling a fast response and resolution, cutting downtime to a minmum.

Through the portal, machine owners can view GPS-tracked locations, monitor the KX085-5’s movement, and use geofencing to designate specific areas of use. Notifications are sent if the machine leaves the set area. Additional security features include the company's anti-theft system, allowing only programmed keys to start the engine.

N EW PRODUCTS

FOR MORE INFORMATION WWW.RDR.LINK/CAL043 GOTO 32 JULY / AUGUST I CPN

COMPACT CRUSHER

Geared towards demolition tasks requiring superior crushing power, the CR400 Crusher from Dragon Equipment is compact, with a width of 800mm and a weight of less than 1,200 kg, making it easy to transport. The machine runs on a Vanguard EFI 23HP V-Twin petrol engine with a large 33l fuel tank and incorporates 'no stress' and 'anti-stall' features, to maximize productivity.

FOR MORE INFORMATION

GOTO

WWW.RDR.LINK/CAL044

FENCING FOR CRANES

CraneSAFE from Panthera Group is a high-security fence system designed to protect tower cranes, hoists, staircases, and other vulnerable access points. The fence stands independently from the tower crane, providing security without affecting the crane's operations, and can be adapted to site requirements, offering either a full kit or customised setup. The hot-dip galvanized system, comprising 3mm steel posts, high-security panels, and a high-security gate, can be swiftly assembled on-site. Optional higher panels and security toppings further boost security levels. Benefits include a one-day installation process, a reusable design reducing labour and material costs, temporary works compliance, zero landfill waste, enhanced health and safety due to full visibility and improved manual handling, robust security features, and zero maintenance.

FOR MORE INFORMATION

GOTO

WWW.RDR.LINK/CAL045

DUMP TRAILER

The PD20 dump trailer from HiSpec Engineering can carry a heaped load volume of 14.5m3 weighing up to 20 tonnes. It offloads using a hydraulic moving floor headboard, offering clean and efficient unloading once the tailgate has been lifted. This design feature is safer in use than conventional tipping and enables unloading in various situations such as on slopes, in height-restricted areas, and on the move, without the risk of tipping over. Another bonus is that is the trailer has a lower centre of gravity because it does not have a hydraulic tipping ram and hinge points, making it stable on the road and reducing the load height to just 2.39m, so it is easier to overlook from the tractor cab. Other features of the PD20 include a hydraulically sprung drawbar, a parabolic sprung tandem axle fitted with commercial axles, and tyres with air/hydraulic brakes.

FOR MORE INFORMATION

WWW.RDR.LINK/CAL046 GOTO

DIGGER HANDRAILS

GENERATOR

DRIP TRAYS

SpillTector, a generator drip tray from First Mats, comes in four sizes, accommodating small, portable generators to larger heavy-duty generators. Each contains a mat, composed of absorbent layers and a robust PVC grid, that can absorb oil while repelling water. This ensures oil leaks are contained, while any rainwater can drain through the tray holes. Each mat can soak up between four and 32 litres of oil, based on size, and can be replaced when full.This means leaks can be contained quickly and efficiently with minimal fuss.

FOR MORE INFORMATION

GOTO

WWW.RDR.LINK/CAL047

Digger Guard now uses a ‘dry-fit’ design for its polymer handrails that employs an internal mechanical connector, eliminating the need for adhesives or external connectors. This design results in a sleek, modern rail that is faster and neater to install. The design allows for individual rail components to be replaced rather than entire sections, cutting costs and reducing downtime. The improved handrails are non-corrosive, 75% lighter weight compared to steel counterparts, mitigate vibration fatigue and do not disrupt 3D guidance systems, a common issue with metal alternatives.

FOR MORE INFORMATION

GOTO

WWW.RDR.LINK/CAL048

CPN I JULY / AUGUST 33

EW PRODUCTS POWERPACKS

JCB has added three larger models to its electric Powerpack range, providing a 400V, three-phase output and total storage capacities of a total storage capacity of 46kWh, 69kWh and 104kWh. These powerpacks can replace diesel generators when power requirements are minimal but continuous and support JCB E-Tech electric machinery charging, The models –the 3.50QE, 3.75QE and 3.100QE –come with JCB LiveLink, which allows remote monitoring and control, increasing the site's efficiency. The powerpacks’ robust design ensures low maintenance and high availability.

FOR MORE INFORMATION

GOTO

WWW.RDR.LINK/CAL050

ELECTRIC DRIVE SCISSOR LIFT RANGE

JCB Access is revamping its hydraulic-driven scissor range with six electric drive scissor platforms. The transition to electric drive motors from hydraulic ones results in an increase of up to 53% in runtime, contributing to improved productivity and lower total cost of ownership. These models feature up to 50% fewer hydraulic connections, simplifying machine maintenance and minimizing potential leak points. The electric drive motors also deliver enhanced torque to the wheels, improving the machines' traction and their ability to navigate inclines and truck ramps. These new models offer platform heights ranging from 5.71m to 13.8m and capacities from 230 kg to 450 kg. The new electric scissor lifts retain the safety features found on JCB's hydraulic models, such as a full height entry gate, pothole protection, and intuitive operator controls.

FOR MORE INFORMATION

GOTO

WWW.RDR.LINK/CAL051

DUST SUPPRESSORS

BATTERY ENERGY STORAGE SYSTEM

Volvo Penta is expanding its power generation business into battery energy storage systems (BESS) with OEMs. This modular and scalable solution is intended for integration into manufacturers’ BESS applications to accelerate market entry. The signature attribute in this subsystem is a high-energy-density and high-power battery system.

FOR MORE INFORMATION

GOTO

WWW.RDR.LINK/CAL049

TOOL ATTACHMENT FRAMES