Construction

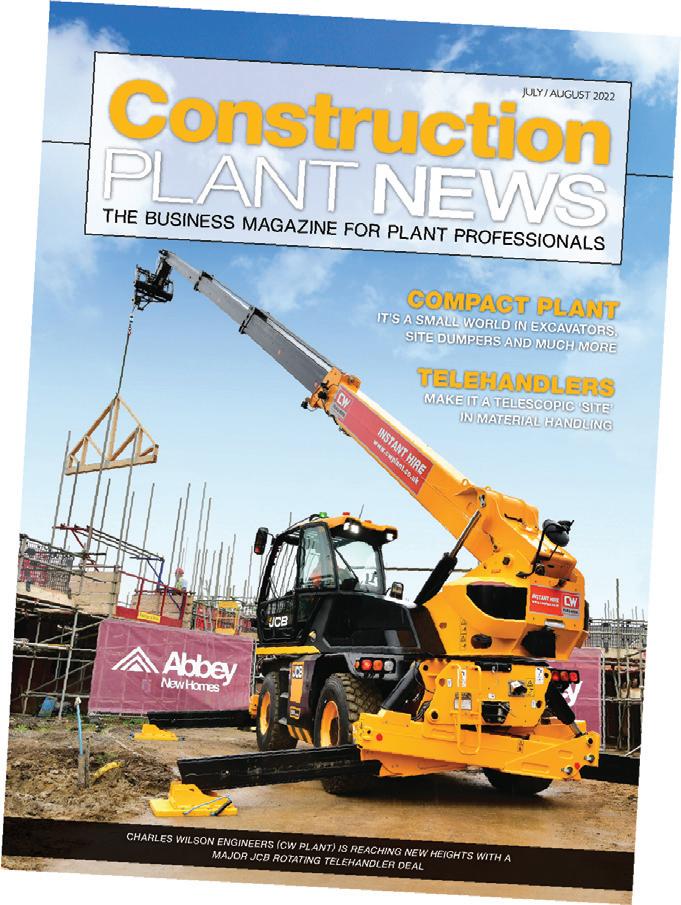

There is no doubt that construction is now edging ever higher on the list of our collective economic priorities – and it is a position it well deserves. Major projects, such as Hinkley Point and the forthcoming Sizewell C, will become integral players in our island’s energy security for decades to come. Indeed, from its completion in 2023 the former will enjoy an anticipated operational life of at least 60 years, whilst the Suffolk site could support as many as 70,000 jobs across the UK, as well as over 2,000 UK-based suppliers. HS2 is an example of what infrastructure schemes with societal benefits can also deliver for hirers and contractors, whilst demand for new housing is likely to increase for generations to come.

Clearly much more needs to be done to untangle the Gordian knot of our complicated planning system and promised reforms will certainly be welcome. At the same time the building industry is in the midst of a transformational era, where changes to working practices, and supply issues are presenting real challenges. In order to navigate what are often uncharted waters the industry needs support and there are other immediate measures that can make a real difference.

The first of these is in facilitating the transition to newer, cleaner, and greener machines. When the then Chancellor, Rishi Sunak announced the introduction of the Super Deduction Allowance – where investors in plant can claim a 130 per cent capital allowance – it was a welcome move, but with one considerable caveat. Hirers who supply machinery on a non-operated basis are excluded from this financial arrangement. With the rental sector remaining the prevailing method of procuring machinery for building projects it is an omission that will inevitably limit the scope and reach of the SDA.

The Super Deduction Allowance is due to come to an end in its current form in April 2023 and it is hoped that this will either be extended – or a successor introduced. In either instance it is imperative that hirers are able to enjoy the

same benefits as contractors. Allowing the group with the sector’s most significant spending power to acquire assets on a more equitable basis will enable the latest emissions-busting and productivity-boosting technologies to proliferate, which is in any case an avowed aim of both government and industry.

Similarly, until sanity prevails in the energy markets, a rethink on the red diesel rebate would go some way to ameliorating price inflation, whilst more support for alternative sources of power would not be amiss. One example of the considerable advantages of introducing a degree of certitude into the market is the recent announcement that the Annual Investment Allowance will remain at £1 million. Placing the AIA on a more permanent footing will help inject a renewed level of confidence amongst those investing in new equipment.

Editor LEE JONES

ljones@hamerville.co.uk

Managing Editor

TERRY SMITH

tsmith@hamerville.co.uk

Digital Assistant

DAVID MOLLOY

dmolloy@hamerville.co.uk

Group Advertisement Manager

CRAIG JOWSEY

craig@hamerville.co.uk 07900248102

Advertisement Manager

JACOB TATUM

jtatum@hamerville.co.uk 07825773737

Account Manager

PAUL FITZGERALD

pfitzgerald@cpnonline.co.uk 07917324995

Magazine Designer

DONNA BOOTH

Group Production Manager

CAROL PADGETT

Construction Plant News is a business magazine for plant professionals, contractors, materials extraction and processing companies, waste and recycling operations, as well as local authorities. If you are not on our circulation list and would like to subscribe email circulation@hamerville.co.uk

To be removed from this magazine’s circulation please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Walstead Roche

Published by

HAMERVILLE MEDIA GROUP

Official figures have revealed that imports and exports of construction plant and machinery remain at very high levels, but whilst supply constraints have eased slightly they still remain an issue.

Empowering the industry to adopt the latest solutions can also allow companies to diversify, a key weapon in the battle for profitably in uncertain economic times. Given the eye-watering sums that have recently been allocated to energy caps, measures targeted at the built environment are relatively inexpensive. At the same time, when its importance to the UK economy as a whole is considered, they are initiatives that will have real social and economic benefits to us all.

Regal House, Regal Way, Watford, Herts WD24 4YF.

Tel: Watford (01923) 237799

Fax: (01923) 246901

Copyright © 2022

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

“The Super Deduction Allowance is due to come to an end in its current

form in April 2023 and it is hoped that this will either be extended – or a successor introduced.”

LeeJones, Editor

standards introduced for eight of the most used plant grants:

360, above 10 tonnes (tracked)

Forward tipping dumper (wheeled)

Alongside the new standards, the grant rates for plant training and tests will also be changed and improved, with a larger single grant available for all CITB registered employers.

In the second quarter of 2022, imports and exports of construction and earthmoving equipment both recorded increases on Q1 levels in £ value and tonnage shipped terms. In £ value terms, trade was at the highest quarterly levels for both since 2013, when monitoring of trade has been recorded. Overall, high levels of imports in the first half of the year are consistent with equipment sales in the UK remaining at very high levels compared with earlier years.

The Construction Plant-hire Association (CPA) has announced that the CPA Conference 2022 will be hosted at the Heart of England Conference and Events Centre in Fillongley near Coventry on Thursday 20th October 2022. The theme of the conference is ‘ESG – Driving Change: How Environmental, Social & Governance Benefits Construction Plant Businesses’.

Fifteen organisations– who were selectedfrom 41 finalistsout of an original 133 entries – will compete for first placein the bauma Innovation Award 2022. New categories forthis year include climate protection and digitalisation,whilst mechanical engineering, construction and researchare back in the running. For a full list of nominees use thedigital reader enquiry, rdr.link below:

Speedy has shipped 287 Pramac mobile generators to Ukraine.

units, which produce the equivalent energy needed to power 8,000 homes, will be used for services including hospitals, relief centres, phone masts and water pumping stations in areas where electricity grids have been affected by

An investment in over 100 early careers trainees across the UK will more than double the number of trainees Speedy currently employs. The company is also set to launch a new virtual work experience programme

As well as fuelling its own fleet with the low carbon diesel alternative, Certas Energy has launched HVO delivery to businesses across the UK. The drop-in renewable fuel is also available at selected Certas Energy refuelling sites, including its Thurrock HGV refuelling site – making it the first company in the UK to offer HVO fuel to HGV fuel card users at the pump.

inspire school students

take-up careers in the construction and hire

Two new depots in Warrington and Dundee have been added to the GAP Hire Solutions Pump Services division. The UK’s largest independent hire company has made an investment of over £20million in the division over the first year, with more than 500 Stage V pumps, and 150,000 metres of hose. The division now operates from eight depots nationwide.

The flagship sale site in Leeds, showed a solid £42 million hammer total, as well as smashing the record for the greatest number of excavators ever sold at a Euro Auctions sale, with 769 machines going over the ramp. The event was 25% up on the same sale in August 2021.

Derby-based specialist contractor, Cawarden has achieved a 67% reduction in its carbon emissions in just ten months following an emissions audit, and the successful trial of Green D + HVO (Hydrotreated Vegetable Oil). Based on the success of the initial trial, a phased transition and roll-out of HVO across its extensive fleet of excavators and site machinery has been taking place. “To put it into context, we’ve saved the equivalent emissions of 94 single flights to Sydney, Australia, or 1,072 metric tonnes of carbon – so far,” enthuses Jonathan Groves, Cawarden’s

Director.

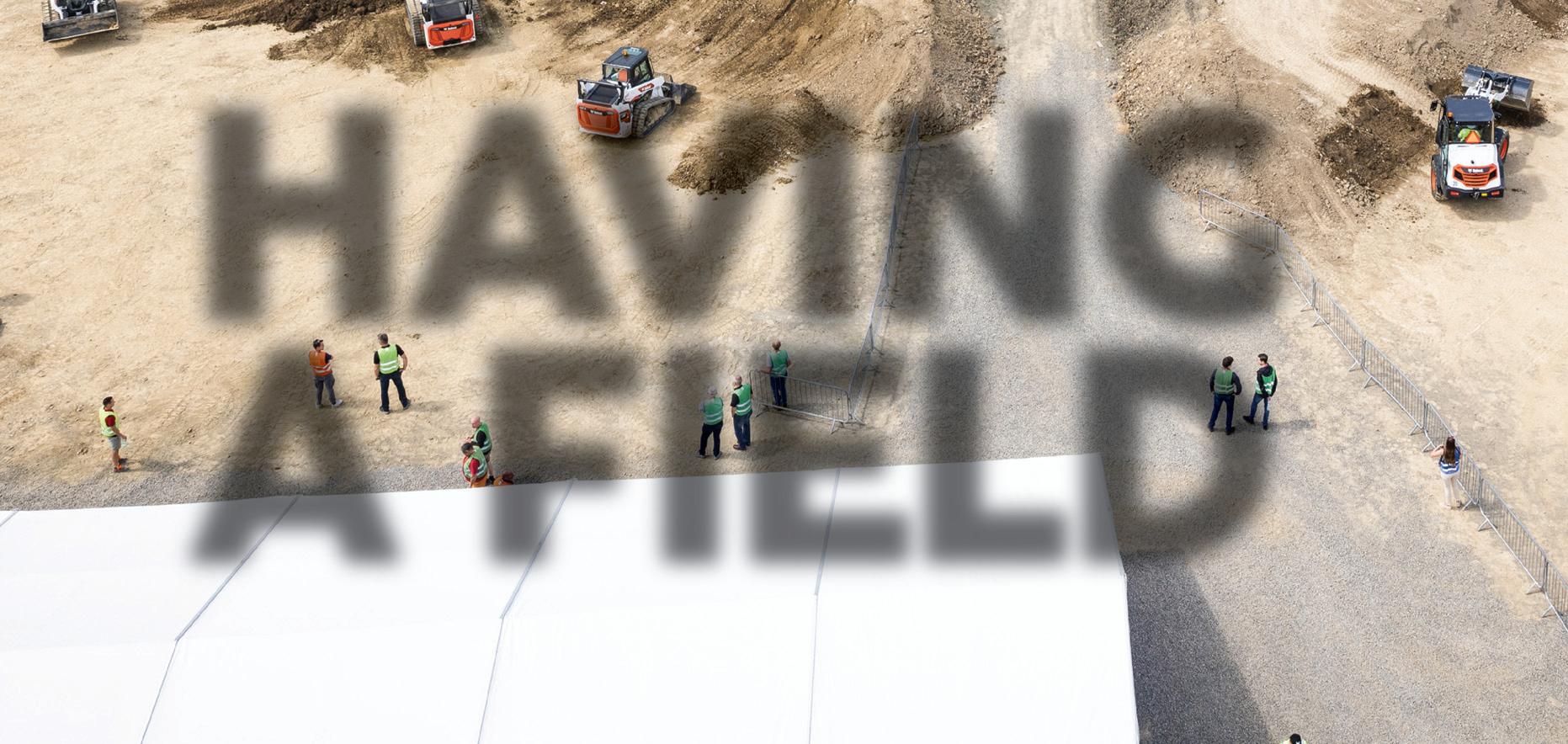

Construction Plant News is treated to a demonstration of the latest technologies and solutions in the Bobcat range

The Doosan Bobcat Campus at Dobris in the Czech Republic was the setting for the company‘s Demo Days. The

sense. Instead of a hydraulic system transferring power, for example, the T7X features an electrical drive system consisting of electric cylinders and electric drive motors. Powered by a 62kW lithium-ion

Bobcat anticipates that the performance of the T7X will actually be greater than its T76 Compact Track Loader diesel counterpart across a number of parameters, including breakout force. Moreover, this a

One of the most intriguing units on show was what is described as the first fully electric compact tracked loader – the T7X. The machine will shortly be available in the US and, in order to gauge the European appetite for such a solution, a prototype version was in attendance at Demo Days. Its drivetrain delivers all the noise and emissions-busting

The entire Bobcat excavator family was on display at the testing ground of the Bobcat Innovation Centre on the Dobris site, starting with the E08. This highly compact digger has a retractable track width of just 71cm and a reduced tail swing design, which makes it an option where only manual labour would otherwise be practical. Other models in this smallest 0-1 tonne category include the E10z and the lithium-ion battery pack powered E10e. As with all Bobcat excavators the ‘z’ denotes zero tail swing. Not only that but, with this manufacturer, that also means that the front of the machine remains inside the tracks. The 4-6 tonne units are some of the newest products in the portfolio with four models availble – E55z, E57W, E60 and E50z.

Further up the weight class the 8-tonne E88 is a completely new model, featuring a 65hp 2.4litre Bobcat engine. The machine can be equipped with up to five auxillary lines, and, with a 2.2metre width and overall height of 2.5 metres, it marries power and versatility with a compact design.

Visitors to Dobris got a first look at another Bobcat concept – the E35 Operate By Wire Mini-Excavator. This 3.5 tonne unit sees the hydraulically controlled joysticks replaced by an electro-hydraulic system. With the help of integrated sensors, semi-autonomous functionality is introduced and machine controls can be customised according to the operator’s skill level, helping with precise grading and levelling, for instance, as well as repetitive digging functions.

The Bobcat Depth Check system is available on excavators from the E35z and upwards and helps the operator achieve the request digging depth. A zero level can be set when the bucket touches the ground. Enter the required depth on the in-cab display and three sensors on the boom, arm and bucket, will calculate the exact position of the bucket’s teeth, with the current and desired depth displayed as well as additional audible alerts.

Continuing this theme of making life easier for the operator the latest Object Avoidance with Radar Sensors concept was demonstrated. Partnering with a US-based company called Ainstein, the result is a radar sensor concept similar to parking sensors on cars. The device – which is essentially a sensor on the back of the unit – is suitable for any machine and, depending on whether it is equipped with electronic or mechanical control, can stop, derate and alert the operator using light or sound warnings.

Bobcat also previewed the new S86 R-Series Skid-Steer Loader and T86 R-Series Compact Track Loader. Both machines makes us of a Stage V compliant 3.4-litre Bobcat engine – producing 78 kW (105 HP) at 2,600 rpm.

Furthermore, the S86 and T86 are for the first time equipped with three different auxiliary flow outputs. There is a standard flow configuration providing 87 l/min for applications such as load and carry, or where low hydraulic flow attachments are used. Bobcat also offers two additional hydraulic

performance functions using the new Electronic Displacement Control (EDC) Pump: a High Flow function giving 138 l/min and a new, industry unique Super Flow function taking auxiliary flow to 159 l/min.

The Super Flow function typically increases productivity with like-for-like attachments by 15 to 20%, and it has a new 5coupler connection block allowing the use of

Designed to replace hard manual labour, the MT100 mini track loader will be launched by Bobcat later this year, but visitors to Demo Days got a preview. Capable of passing through gates, doorways and other narrow spaces, the MT100 still offers a big boost in power, with a rated operating capacity of more than 450 kg, a powerful breakout force and an impressive lift height.

The Bobcat Demo Days gave hundreds of fleet operators, end users and dealers the opportunity to speak to experts, enjoy some time on the machines, and experience the latest developments from the manufacturer.

Powered access, cranes and glass lifting specialist, Hird has become the first powered access rental company in the UK to take delivery of the new Genie S-60 FE hybrid telescopic boom lift. Ordered from the manufacturer’s authorised distributor, Workplatform, the S-60 FE – the FE stands for fuel and electric – is the first hybrid and lightweight rough terrain telescopic boom in the 20m working height class.

“Maximising site safety is a key priority,” for the Staffordshire-based plant hire firm, according to company owner Mick Silvester, and the rationale for investing in a further cabbed unit. The Mecalac 3.5MDX site dumper, sold by SM Plant, joins an existing six-tonne 6MDX model on the hirer’s fleet.

LGMG scissor

and boom lifts are amongst the machines in an investment of over £2million by FGS Plant. It represents the rental firms largest ever order for access platforms with the units supplied by UK and Ireland distributor for the Chinese manufacturer, Access Platform Sales. Quality, an excellent specification and fast delivery were amongst the reasons for sealing the deal.

West Yorkshire-based J H Fencing Contractor is making use of the first Bobcat MaxControl Remote Control system in the UK. Supplied by Bedalebased Grays Machinery, the system is being used to remotely control the company’s Bobcat T450 compact track loader.It is “perfect for remote control of the T450 with our post knocker attachment, which we use to install fence posts at a fixed distance apart,” explains Jack Hampshire, owner of J H Fencing.

“For general building and domestic landscaping applications, it’s a really competitive model,” reveals the eponymous David Ryan of D Ryan

He cites a compact design and safety-critical technologies as an ideal combination for job sites where space is at a premium.

Yanmar SV15VT, acquired from dealer, MTS Plant, has a a transport weight of just 1,465kg.

Plant

taken delivery of

the past

Isuzu Grafter

described

delivery

Dragon Equipment

300 compact crusher

by Tring-based Boss Plant Sales, has

compact residential site where a patio was being replaced.

used as hardcore under the new patio, saving transport

entrepreneur, Adam Weaver

business

years ago

of a second-hand

Weaver

a fleet of over 60 machines

Kubota minis, and midis,

in the last three years from Tring-based Boss Plant Sales. Adam’s total

to 14 tonnes,site-dumpers,

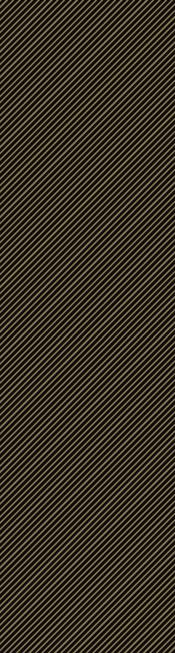

management, technicians or operators, everyone at FP McCann’s quarries in Northern Ireland was in agreement when it came to adding a second Rokbak RA30 to the fleet. Both the RA30 and RA40 feature the latest EU Stage V emissions-compliant engine, boasting up to a 7 per cent improvement in fuel efficiency and make use of ZF’s EP320 fully automatic gearbox.

lumens) and enables the user to optimise the light projected onto the worksite area –measured in Lux – to suit his/her specific application.

Compared to the Ritelite K65 Beam Control, typical lighting tower designs project a much smaller percentage of useful light onto the work area, therefore generating a much higher level of wasted light and light pollution. This also means a lot of energy is unnecessarily wasted.

It standards to reason that lighting equipment should be maximising the possible useful light reaching the working area, and minimising the wasted light, or light which is projected outside of the working area – but this is not always the case in practice.

Wasted light can also be referred to as light pollution, which not only wastes energy but can also be a significant safety risk. It is a particular problem in areas close to airports, busy roads, and railway tracks, for example, as well as causing problems in neighbouring residential areas.

Founded over 35 years ago, Ritelite (Systems), based in Stamford (UK), are a leading manufacturer of innovative, high performance mobile and portable industrial work light solutions designed to meet the specific demands of the construction and hire industry.

Launching officially at bauma 2022 in Munich, the Ritelite Quad Pod K65 Mobile Lighting Towers exhibit what is described as class leading safety, performance and mobility features as well as the considerable benefits of Ritelite Beam Control.

The manufacturer’s new Beam Control technology gathers the maximum light emitted from the LEDs (measured in

The new Ritelite K65 Beam Control lighting towers reduce wasted light, energy and light pollution by up to 70% compared to typical lighting tower designs. Beam control also optimises the uniformity of the illumination, eliminating very bright and very dark areas which can cause visual safety hazards for workers when moving around the work site.

Specially designed optics enable the LED modules to be aligned almost parallel to the ground instead of pointing directly in the worker’s line of sight. This helps prevent accidents on the construction site due to distraction from light glare.

Beam Control LED light heads are driven by remote and dimmable LED drivers mounted at the base of the light mast. Compared to typical lighting towers, with drivers mounted on the light heads, the weight at the top of the mast is greatly reduced. In addition, the new low profile light heads present a much smaller surface area in windy conditions. These new features result in a lower centre of gravity and enhanced stability in windy or adverse weather conditions.

Rapid deployment light heads enable adjustment for optimum illumination to be easily achieved within seconds, according to the requirements of each work site. A new stepless dimming function is also included, providing the user with additional control

The Vertical Surface Illumination Mode is specially designed to provide a uniform illumination when working on the exterior walls of buildings, or any other vertical structures.

The new Ritelite K65 Beam Control lighting towers also feature a comprehensive and class leading array of safety functions designed to help protect both the user and the equipment during use. These include a safety interlock between the mast and stability legs that helps prevent raising of the mast until all legs are correctly deployed. This also prevents a leg from being raised until the mast is fully retracted.

Double load security on each mast section, with twin wire ropes and automatic double locking pins, allows the mast to be safely deployed. Moreover, an automatic slack rope detection system helps protect the winch rope from damage, increasing service life and reliability.

The safety, mobility and power efficiency of K65 Beam Control lighting towers make large, heavy and trailer-based lighting towers a thing of the past. High mobility and one person deployment allows for the illumination of areas that would be impossible with traditional lighting tower designs. Due to its unique parallel mast system, low centre of gravity and lowpressure tyres, the units can be easily moved and deployed even on soft grass and uneven terrain.

The extremely compact design is small enough to fit through standard doorways yet powerful enough to illuminate a football pitch. Zero emission worksites, especially within cities or conservation areas, are a growing requirement and will become more critical in the future. With its excellent power efficiency, the K65 Beam Control lighting towers have been optimised for use on zero emission worksites and for use with zero emission power sources including Ritelite’s own range of RITE-POWER rechargeable battery powered generators.

“Class leading illumination, safety, mobility and power efficiency – the K65 LED “Beam Control” is designed to reduce wasted light, energy and light pollution” over the illumination.

When it comes to green solutions one company has proved to be a very deep thinker. Construction Plant News visits the Boss Cabins factory to find out about the latest in solar powered welfare facilities.

As a manufacturer, Boss Cabins is no stranger to a challenge. When Covid19 first brought the shutters down on much of our society, for example, this Lincolnshire-based welfare cabin specialist was charged with designing and building bespoke units for rapid deployment at NHS testing centres. Today, in response to an on-going environmental emergency, a major product development has positioned the company as a champion of climate-friendly solutions.

The essence of sustainability is to do more with less and the Boss Cabins Deep Green 2030 range exemplifies that principle in practice. It maximises the amount of sunlight and rainwater harvested from the roof whilst minimising the amount of energy used in operation. The welfare cabins are at least 90 per cent solar powered, with near zero emissions and, whilst a generator may be

required to be employed as back up in the darkest days of the winter months, that has also been designed to run on HVO (Hydrotreated Vegetable Oil) and other biofuels.

“The Deep Green 2030 has been so wellengineered that with average levels of sunlight and rainfall, we could completely eliminate the need for a generator or to fill it with water,” explains Boss Cabins Managing Director, James Kearsey, “but in our climate that, of course, cannot be guaranteed so there is the reassurance of an internal combustion engine on standby. At the same time we have worked hard to ensure that service intervals on our patented 3.5kW Stage V Infinity generator –which is already available on our standard range of cabins – are significantly longer than anything else that’s currently on the market, with up to 2,000 hours compared to an industry-standard of 200.”

The energy derived from the roof-mounted solar array is stored in a 5.2kWh lithium-ion battery, the ultra-efficient electrical system cutting wastage. All mobile models in the range can be towed by a pick up or van with a 3.5tonne towing capacity, and units can be configured for an individual customer’s requirements.

or via a desktop computer. Fuel and wastewater tank levels can be viewed, for example, alarms can be set when they reach a designated point, and fleet managers then alerted by email. Not only that but types and patterns of usage can be scrutinised, allowing customers to optimise the use of the cabin, and potentially make further savings, whilst enabling maintenance visits to be scheduled for exactly when they are required.

Boss Cabins was actually the first manufacturer in the sector to produce units in stainless steel, where its competitors have largely continued with mild steel or aluminium foam composite. That more durable and robust construction provides the reassurance of a 25year anti-corrosion warranty. With 95 per cent of its customers in the rental sector, welfare units will inevitably be abused, but with stainless steel they won’t rust. Not only that but Deep Green 2030 cabins are up to 97 per

With the removal of the red diesel rebate in April 2022, the adoption of alternative powertrains and renewable sources of energy are a far more appealing proposition, and it is here that calculations of total cost of ownership have to be made. At the same time, Tier 1 contractors are now routinely obliged to demonstrate the impact on the environment of any project at the tendering stage. Both make adopting Deep Green 2030 an attractive option.

The design of these distinctively green solutions dramatically reduces the amount of energy used. Moreover, the combination of rainwaterharvesting with solar panels and intelligent telematics slashes the number of times the cabins need to be visited for servicing. With units owned by hirers potentially located right across the country, the efficiency savings are obvious, as well as the integral environmental benefits.

“In terms of performance, the product has actually exceeded our expectations,” concludes James. “We now have over 400 units in the marketplace, and that has provided a huge bank of data with which we can further develop our ideas. The driver is to save costs but there is also a wider ambition to reduce and the use of fossil fuels. The beauty of Deep Green 2030 is that it achieves both.”

“The driver is to save costs but there is also a wider ambition to reduce CO2 and the use of fossil fuels. The beauty of Deep Green 2030 is that it can actually achieve both”

Packed with articles on a wide range of industry topics, www.cpnonline.co.uk is the first place to visit for all the latest news in plant and machinery – from the smallest skid steers and micro excavators to the giants of the tower crane market, or the heavyweights in crawler excavators, weʼve got it covered. Get the latest information on the industryʼs biggest deals, as contractors and plant hirers renew their fleets in our Fleet Additions section, as well as all of the newest products to hit the market. Our website is updated daily, bringing you the most important industry news quicker than ever before.

(Construction) – Site Security at DeterTech discusses how you can reduce the risk of fuel theft

arousing suspicion.

For most construction sites, no single security measure can effectively reduce your risk – a layered, bespoke solution that can adapt to your environment will offer the best protection.

In the first instance, physical barriers and gates should be installed. They’re an effective deterrent against less sophisticated opportunists and help to limit the severity of more serious attempted thefts from organized criminal gangs. By installing physical barriers as a first line of defence at key entrances and around vehicle stores and fuel bowsers, potential thieves are deterred from pillaging larger quantities of fuel by inhibiting the size of vehicle or container they can get in and out of site.

Access control systems are also crucial in controlling who is permitted to enter the site, as well as specific

areas of the premises. Enabling security managers to have greater visibility and control over who has access, and what time access is granted, means security measures don’t impede a project’s progress, by allowing the flow of authorised personnel and restricting access to unwanted individuals.

Although they are strong deterrents, determined criminals can still evade physical barriers and access control systems. It is, therefore, advised to consider deploying self-monitored camera systems and intrusion detection units in strategic site locations to deter potential thieves. Equipped with vocal warning systems and low lighting capabilities, verified visual monitoring and 24/7 surveillance will detect anyone who approaches a unit.

Additionally, linking these units to an in-house Alarm Receiving Centre (ARC)

Supported by a team of SIA licensed operators in the ARC, fuel is better protected with 24/7/365 monitoring that ensures an immediate response to alarm activations.

Unique forensic marking solutions can also be implemented as a final step in a fuel protection package. Fuel bowsers, stores, vehicles and machinery can all be protected with an invisible forensic liquid providing forensic trace evidence to link a criminal to the scene of the crime. SmartWater scientists only need a sample size of a speck of dust to test, giving police forces powerful trace evidence to detect fuel thieves.

To alert potential thieves to the presence of SmartWater, forensic marking can be paired with visual signs and stickers.

Fuel thefts remain an issue for the industry, making a combined, adaptable and bespoke fuel protection solution critical for site security managers. By understanding the threat level and adopting a combination of deterrent technologies it is possible to deter and detect fuel-hungry criminals, preventing future diesel pillaging and managing the risks surrounding construction sites.

With the cooler months closing in, it’s the perfect time to service the air and water heaters in your welfare units.

W orkers’ welfare and comfort has become a priority in the modern working environment and yearly servicing minimises heater downtime and makes happy customers.

Your reputation as a welfare unit supplier will be enhanced by supporting the installed heating systems with regular preventative maintenance.

In the welfare unit rental business, planning ahead is as important as a hard-hat on an active site. Don’t wait for winter to blight your books - don’t wait for your heating units to pack up before you step up.

Keeping your customers’ welfare units up and running is crucial, especially in the winter when it’s needed the most. Even the most reliable heater can encounter problems when fired up again after being left unused over the summer months.

You wouldn’t repair a roof during a rainstorm, and you know finding a roofer in their busiest time is almost impossible. Neither should you wait until the mercury

drops before checking your welfare unit heating. Taking action now will minimise problems and costs later on. Preventative maintenance is the key.

Plan ahead by having your welfare unit heaters serviced before the frost arrives. At Butler Technik, we offer a free UK-wide courier pick up service of your heater units. We specialise in the servicing and repair of Eberspacher and Webasto diesel heating systems, using manufacturer-approved diagnostic software to give your system a full health check. Our experienced technical team carries out all necessary repairs in our workshop using only genuine replacement parts. Competitively priced replacement heater units are also available for rapid deployment on-site, minimising downtime and keeping your customers’ workforce busy on-site.

Butler Technik is the largest UK independent stockist of genuine, manufacturer guaranteed Webasto and Eberspacher parts. Unlike most Eberspacher and Webasto heater service centres, Butler Technik holds a comprehensive stock of spare parts on-site, so in most cases we can quickly fix any issues to get your welfare unit heating systems up and running again.

Prepare your welfare units for this winter now; your customers may not notice, but their staff will be warm, comfortable and productive. They’ll be happy to recommend you to others and your business will feel the benefits.

A smaller footprint, upgraded systems and both static and trailer options are some of the upgrades to the AJC EasyCabin SolarPod, hybrid, off-grid site generator. These advanced products

solar, battery, and HVO fuel

to deliver low-emission, and emission-free power

The range of products now available from Nixon Hire’s Renewables Division includes Solar Pods, Solar Smart Frames and EV Chargers. The fleet also includes the new ProPower Solar Hybrid Generators from Prolectric, whilst a large order has just been placed for battery

Group Hire Solutions

investing in sustainable site lighting equipment from Trime

including X-SOLAR and XSOLAR/HYBRID sets. The former is an emission-free tower light that operates

from solar and battery power, with energy-saving

lamps.

hybrid unit

from the latest solar and battery

small fuel-

Datatag Trailer Security

First launched in 2012, the Tefra has since established itself as the industry’s leading hydraulic coupler for excavators from 2 –120 tonnes, with a dedicated mini excavator solution for machines under 10tonnes. With only three moving parts, there’s very little about the Tefra that can actually go wrong, virtually guaranteeing an extended operational life.

Most importantly, it’s the unique double locking design that helps the Tefra exceed the demands of the ISO 13031 global safety standard. The cast steel front and rear hooks are powered by a single cylinder, which works in tandem with a solenoid valve to securely lock the attachment in place, with immediate front pin capture ensuring attachment retention.

The second part of that two-stage locking system is known as Hill APS (Active Protection System) consisting of two separate powerful springs that apply pressure to the hooks to ensure the

ensuring the rear hook stays in place. A reverse hose system also reduces the risk of damage and resulting downtime. In addition, the cast steel frames, provide maximum strength and minimum weight, which is crucial when installing a coupler onto smaller machines.

CBL services the whole of the south of England and south Wales from seven strategic locations – with its Welsh depot situated in Bridgend. In addition to Takeuchi and Hill Engineering, other premium brands on its books include Bomag, Atlas Copco, Epiroc, Thwaites and Messersi tracked dumpers. Ford Civil Engineering has been a long-standing customer, particularly for Takeuchi machines. “All of the Japanese manufacturer’s excavators from 3tonne are now supplied with the fitting kit for a Hill Engineering quick hitch”, explains Richard Sturgess, CBL’s Sales Director. “It’s plug and play, easy to operate and, as system, it can’t be faulted for safety, so we get very good

application. Both machines are compatible with Volvo’s range of fast chargers, which allows charging from 0-80 per cent in just over an hour.

The Eskilstuna site in Sweden which plays host to the Volvo Days event features 66,000 sq m of testing track with the vast Volvo Construction Equipment range represented at every turn. The Swedish manufacturer is ploughing huge levels of investment into electrification and the consequence is a whole series of innovations in the compact class. In fact, the company can now point to the largest range of electric solutions on the market, and it is a continually expanding family of products.

First launched in 2020, the Volvo Days event showcased the 2.5 tonne ECR25 Electric, for example, as well as the newly launched EC18 conventional and EC18R Electric with reduced tail. The former is available with a heated cab or canopy, a battery capacity of 20kW hours, and a run-time of between 3-5 hours depending on application.

The EC18R short radius has a 12mm overhang at the rear, whilst the front right corner will stay within the frame when rotating. It is available with canopy only, boasts a 16kW hour battery capacity, with a run-time between 2-4 hours depending on

If a wholesale switch to batterypowered equipment is to become a reality then the planning of a project will need to accommodate their use at the earliest stage, with the provision of electricity on site a prerequisite. That will require a change of mindset but there are considerable rewards.

When electric machines are discussed it is invariably zero emissions, their use in LEZs, working in indoor areas, and sensitive locations – such as around schools and hospitals – that is discussed. These are, of course, paramount but end users often cite one other feature as a particular favourite. The benefits of low noise for operators –and pedestrian workers around the machine – cannot be underestimated, not just from the improvement to the working environment and surrounding area for site personnel and the public alike, but also in the added safety of being able to easily communicate with co-workers.

The electric theme continues with the L20 and L25 Electric wheel loaders. The first and smaller of these offers a 1.8tonne payload and comes with Paralleltype linkage and a choice of a 33 kWh or 40 kWh battery pack.

The larger L25 now also benefits from a number of new upgrades, including the option to fit a new

Parallel linkage, as a complement to the existing Z-type, and an increase in the maximum speed up to 20kph. Volvo actually reports that its battery powered wheel loaders out-perform their diesel siblings in many respects. The L25 Electric is stronger, quieter and quicker to respond, for instance, with more sensitive joystick control. Moreover, an already quiet machine is made even quieter with the introduction of a new hydraulic pump and the relocation of the Main Control Valve from the cab to the front frame.

Accelerating up the weight scale, and on

Construction Plant News continues its focus on the machines and solutions on show at the Volvo Days event

shared platform machines in that they utilise the same upper structure. Powered by a D13J Volvo engine, and a with a robust 60tonne class undercarriage, there’s also a completely new hydraulic system. Here, both machines are fitted with what Volvo calls Independent Metering Valve Technology, an electronically controlled system that offers more precise operation and efficiency than a traditional mechanically coupled hydraulic system.

The 35-tonne Volvo 350E is a new size of excavator for the manufacturer with additional options and components, not least the D8M Volvo engine. That powertrain features a maximum 1,600 rpm, but with very high torque, which can improve fuel efficiency by up to 10 per cent

With the EWR130E Volvo is promising a more powerful and yet more compact class of wheeled excavator. It’s a multi-tasking tool in the 13-tonne weight class that will equally be at home on infrastructure and highways projects as in landscaping. A reduced centre of gravity means the unit can 4.3tonnes and 6metre reach, whilst inline outriggers means it can be stabilised within a compact footprint.

In the next issue of Construction Plant News we explore how Volvo CE is helping its customers increase revenue with its range of services, including its Connected Map concept

For further information on Volvoi

“The EWR130E is promising a more powerful and yet more compact class of wheeled excavator. It’s a multi-tasking and versatile tool in the 13-tonne weight class. ”

With a wide array of online resources supporting the latest solutions – from videos to technical guides, PDFs to podcasts – it can be a challenge to locate what you need.

To ensure you don’t miss out on these valuable resources, we are introducing rdr.link/ – a new, rapid service to transport you immediately to the online resources mentioned in our stories.

in articles you may now see things like:

enter

Central Piling is using two continuousflight auger (CFA) piling rigs to install deep foundations on a former quarry site in Kent. The project is the latest phase of a major residential development with piles up to 40m deep, which it has achieved by using two Soilmec machines – a SF50 CFA rig and its larger stablemate, the SF65 rig –

Hitachi Construction Machinery (Europe) NV (HCME) has expanded its range of wheeled excavators with the addition of a new short-tail model. The ZX135W-7 has a compact 360-degree swing radius (1,740mm to the rear and 1,750mm at the front) for what is described as exceptional performance in confined areas. This makes it an ideal solution for residential construction sites –

A Heavy Duty Box Blade is the latest addition to the extensive line-up of Bobcat attachments A Plug & Play integrated solution, it can be installed on the company’s loaders within a minute, and is suitable for use with most of the models in its skid-steer and compact track loader ranges. The new tools saves time and money while producing a more accurate and higher precision finish grade, even on

Described as bridging the gap between compact and construction-sized machines, the Komatsu PW98M–11 tight-tail wheeled midi excavator moves within its own circle. Powered by an EU Stage V compliant engine with DPF, it is more powerful than its predecessor; 5% more productive – thanks to its faster hoist/swing operation – and 10% more fuel efficient. Other features include reduced transport height and faster attachment switching.

Simplicity of use, excellent stability, optimum comfort and safe operation is what Bobcat is promising for its TL25.60 Super Compact Telehandler. Powered by the manufacturer’s 75 HP Stage V engine, the machine has a rated operating capacity of 2,500kg, offers a maximum lift height of 5.91m and a maximum reach of 3.31m. The Bob-Tach carriage increases versatility by allowing the TL25.60 to utilise attachments designed for the loader range.

bauma stand will feature its latest wheeled and tracked loaders, mini-excavators, including four new additions in the 5 to 8 tonne category, the latest R-series telehandlers, light compaction products and a number of new attachments. Complementing these are new machinery premieres and the very latest in electrification, digitization, and autonomy.

“Let’s Do The Work” is the CAT theme for the 2022 exhibition, where more than 70 pieces of equipment will feature, including the world’s first high drive electric drive dozer – the D6 XE, and the tethered electric MH3024 material handler. Among the multiple technologies available will be the Cat Command Station, Cat Productivity and Cat Grade with Assist.

Amongst the world premieries at bauma is Doosan’s new 4x4 articulated dump truck.

Complementing its standard range of 6x6 ADT models, the new 4x4 version of the DA45-7 ADT is intended to compete with rigid dump

NV (HCME), the trade fair plays host to a Zaxis-7 medium excavator with a 3D machine control solution from Leica Geosystems. This

The Spanish tower crane manufacturer is expanding its range of luffing jib cranes with the launch of the LCH300, its first hydraulic model, with a maximum load capacity of 16 tonnes and reach of 60 metres. The unit is available in various versions: embedded, supported on bases of 6 or 8 metres, or movable, and can be assembled with 2.5 x 2.5m tower sections.

The Doosan stand is centred around a dedicated Innovation Centre and will present the latest developments in the company’s Concept-X, Xitecloud and DoosanCONNECT systems. The new DX225LC-7X – the manufacturer’s first

The industry’s first wheel loader ‘Transparent Bucket’ system allows the driver to see blind spots in front of the bucket on the machine, using the monitor in the cab. It records images in front of the wheel loader via top and bottom front-loaded cameras and shows combined images on the cab monitor in real time using a curved projection method.

Demonstrating the expanded range of connected machinery from Hitachi Construction Machinery (Europe)

The hydrogen fuel cell powered Hyundai Construction Equipment HW155H concept wheeled excavator, offers 8 hours of operation, with a 20-minute refuelling time, whilst the only emissions from the machine is water. It is anticpated that the technology will be better suited to larger classes of machinery than lithium-ion batteries.

Amongst the 23 machines from Hyundai Construction Equipment (HCE) will be its mini excavator range, new compact radius wheeled excavators, articulated dump trucks, wheeled loading shovels and updated crawler excavators. Technological solutions include the Hi-Site planning and surveying system, and Hi-Assist 2D and 3D machine guidance and control.

now rotate the entire cab at the touch of a button with the Mecalac Revotruck site dumper. The infinite cab positions open up visibility in all directions, whilst drivers can constantly maintain the correct body posture.

The tradeshow will witness Kohler’s transformation from power producer to energy supplier. The acquisition of Curtis – a leader in electric vehicle and hybrid applications – signals a commitment to hybrid and electrified solutions, whilst there will also be a focus on new fuels. HVO can now be used on its entire range of diesel engines, for example.

A dozen cranes from Grove and Potain will be joined by news on an expanded range of support solutions that cover monitoring, parts, service, rental, remanufacturing, finance, and more. The new technologies will include CONNECT, an advanced telematics platform which is being unveiled at the exhibition.

Alongside the heavy-duty Komatsu HD785-8 dump truck, and D71 PXi dozer, will sit an ultra-short tail, PC228USLC-11 excavator and WA475-10 wheel loader. The tight-tail wheeled PW98MR-11 midi excavator is described as bridging the gap between compact and construction-sized machines and there’s an upgraded WB97S-8 backhoe loader on display.

The huge Liebherr presence at bauma includes the 50-tonne LTC 1050-3.1 compact crane equipped with an electric motor. The LR 12500-1.0 crawler crane benefits from 2,500tonne load-bearing capacity whilst the LRH 100.1 unplugged and LRH 200 unplugged piling rigs can work four to five hours in battery mode with a 200 kWh battery package.

Visitors to the Manitowoc booth can also enjoy the first public showing of the Grove GMK6400-1 all-terrain crane. A 400t capacity, and main boom of 60m, is complemented by improved hydraulics, Crane Control System (CCS), MAXbase variable outrigger positioning, and MEGATRAK suspension system driveline with MegaDrive hydrostatic drive.

A luffing jib crane and a topless crane are the two new additions to the Potain tower crane portfolio. Both units exhibit what is described as quick and easy transport, fast assembly, impressive capacity, fast and precise hoists. These will be joined by the MDT 489 topless crane, and the Igo T 99 and Hup

cranes from the self-erecting range.

The mobile power products from Pramac and Generac Mobile include the Stage V compliant and rental-ready GPW and GRW series of power generators, with supersilent and hybrid versions. Also on show will be the VT-Solar and PRO line, mobile lighting towers, as well as an off Grid range of battery energy storage systems.

Operators can now experience improved reliability when using the fully automatic Rototilt QuickChange quick coupler, thanks to the introduction of the Q14 electrical connector. A precondition for drivers being able to exploit all the benefits of the system is that the technology has a stable electrical contact with the control and excavation systems.

Enjoy emission-free working with the Sennebogen 30 t electric material handler 825 Electro Battery. Intelligent dual power management allows autonomous working in battery operation as well as when connected to the mains. Depending on the power requirement, the 378 kW lithium-ion battery pack enables working times of up to eight hours without recharging.

WWW.RDR.LINK/CAF060

The launch of the Tadano AC 2.040-1 all terrain crane introduces the first member of the manufacturer’s AC family. All future models will share the same DNA, with a standardised crane control system, cab, on board diagnostics, and telematics. Since the last baumatrade fair Tadano has launched 12 new cranes and solutions onto the market.

WWW.RDR.LINK/CAF061

The recently introduced Takeuchi TB335R will be joined by the brand-new TB350R and TB395W models. Many other Takeuchi compact excavators and compact track loaders will also be at bauma, including the world’s first 360-degree compact excavator, the TB1000, which celebrated its 50th anniversary in 2021.

WWW.RDR.LINK/CAF062

Trackunit products on display at bauma include Kin, Raw, 5G-ready Spot 2, Manager and the Iris Platform. The manufacturer’s commitment to connectivity has been boosted by breaking through the 1.4 million barrier of linked assets to make the biggest construction network ecosystem in the world.

WWW.RDR.LINK/CAF063

The third generation Wacker Neuson WL20e ewheel loader will be presented with a powerful lithium-ion battery. In the future, customers will have the option of choosing between three battery variants so that running and charging times can be optimally tailored to work requirements.

WWW.RDR.LINK/CAF065

Bringing its mini excavator expertise into the field of electrification, Yanmar Compact Equipment is introducing the SV17e prototype. The quiet, zero emission machine is powered by 48-volt batteries and is aimed at customers in the 1.5 to 2.0 tonne segment. For those who cannot wait until bauma 2022 a short teaser film shows the SV17e in action:

It’s always been pretty good in Trafic – 42 years, 2.2 million sales and counting – but it would seem that Renault’s medium sized panel van just got even better! It follows the recent launch of its special RED edition featuring a number of styling changes exclusive to the model and a level of 24/7 after care service, and 100,000 mile warranty package, that is already enjoyed by its bigger brother the Master and, of course, its extensive HGV range.

It prompts the question, of course, why bother to go the extra mile when the impressively face-lifted 2019 version is already a popular choice in a very competitive market? Adding bits and pieces always comes at a premium although, increasingly, it is a price many businesses feel is worth it to stand out from the crowd.

Graham Neagus, Head of LCV and Municipal, explains the rationale behind the expansion of the Red concept: “Despite all the logistical problems presented by the pandemic over the past two years, we have

remained firmly focused on our mission to create an aspirational, driver centric range of products that go beyond the traditional onetonne market operators’ expectations, by infusing our formidable truck DNA into the new Trafic. The new Red models are the pinnacle of how the Trafic has evolved to suit even the most discerning of operators across the full business spectrum.”

The company had already seized something of a prepandemic advantage over its competitors in the summer of 2019 with a significant refreshing of the Renault van brand which saw an industrial sized scalpel taken to both the Trafic and the Master. Shared features across the board

included a new more imposing modern design from its 2014 incarnation, new fuel efficient engines, bespoke cabin layouts to facilitate the growing demand for a moving

all of this, customers are now invited to choose from a bespoke range of four special Red edition models, offering two transmissions, four engine types, 2 to 9 seats with payloads from 5.8 to 17 m3 (Pcab), all with stand-out exclusive prestige trims.

This includes the DAKAR edition, in recognition of the company’s performances at the iconic Rally. A two-tone interior, illuminated step well and additional lighting add a touch of style, but thanks to an

with its own internal fridge

development of an inbuilt security deterrent. We know from all of the letters and emails we receive on a weekly basis –as well as the shocking crime statistics –just how devastating the loss of tools and materials can be to a construction company. Renault has invested heavily in trying to find a viable and simple solution to the problem and have come up with the Trafic OptiSafe.

Heavy gauge internal metal ribbed doors are enhanced with a toughened polycarbonate exterior which would make even the most determined thief think twice about attempting a break in. “Time is everything to the opportunist criminal,” says Graham, “and anything which significantly delays the process will make them look for softer targets.” He continues: “We are still working on final installed prices of the OptiSafe, but they are expected to be around the £2,000 mark, which we believe is a small price to pay for that level of peace of mind.” You ‘Red’ it here first!

leather interior, illuminated

leather interior, illuminated

Suitable for non-powered equipment,

’s Spot 2 is a 5G-ready solution.

IoT device bridges the gap between the same company’s Raw and Kin products, and features a fast set-up and instant connectivity. The self-contained, batterypowered unit works independently of machine power and connects equipment of

shapes and sizes.

The biggest model yet has been introduced to the VolvoConstruction Equipment (Volvo CE) hybrid range. The 38-tonne class EC380E Hybrid offers a reduction in CO2 emissions of up to 15%. The Volvo hybrid concept uses the up and down motion of the boom to capture free energy, where other systems use the swing motion. As a result, customers are able to capture the energy of a typical loading

The Mecalac MCL range of compact loaders includes six models, ranging from 1.74 t to 2.85 t. The MCL4+ and MCL6+ are short arm versions which the manufacturer describes as perfectly suited to the construction sector. All six machines will be available in three versions: canopy, canopy with foldable top or cab, each coming with a wide selection of attachments.

FOR MORE INFORMATION

WWW.RDR.LINK/CAF072

On sites where heavy hoists are required

Liebherr’s 300 EC-B 12 Fibre and 270 ECB 12 flat top cranes will come to the fore. The fibre rope on the 70 metre jib, 300 ECB 12 Fibre delivers what is described as significantly better performance values than similar cranes with a steel rope, and has a much longer service life. The crane has a

truck

four-axle