It’s not often that the CPN mailbox receives a letter from a chairman but when that chairman happens to be Lord Bamford, you’re going to click on the message pretty quickly to find out more.

In this instance the letter concerned JCB’s singular focus on hydrogen as the fuel of the future and the development of the hydrogen engine. The statistics themselves tell a story of a formidable resolve to commercialise hydrogen engines – over 22,000 hours spent in the test cells, machines with over 30,000 hours of testing and 25,000km on the road and more than 150 pre-production engines on the existing production line.

Beyond the hardware, the company has tackled the many legislative and approval hurdles needed to sell and operate the engines – Stage V type approval, EU acceptance across all 27 member states, and the amendment to UK road transport legislation permitting hydrogen-powered machines to be driven on UK roads.

Along the way JCB has actively shared its knowledge, submitted evidence to the Department for Energy Security and Net Zero (DESNZ) highlighting the significant role hydrogen engines can play in decarbonising construction equipment and won endorsement from the Government in its Hydrogen Strategy Update.

There’s still a way to go before we see machines on site in meaningful numbers, but you wouldn’t bet against JCB bringing that day forward. After all the company is a proven performer, generally when it says it’s going to do something it gets done!

“...to say that this machine revolutionised construction sites is pretty much of an understatement...”

This year marks the company’s 80th in business and it reached a bit of a milestone a few months ago when the one millionth JCB backhoe loader rolled off the production line – a 4CX model. If there is one machine that defines the company, then the backhoe has to be it. So, we make no apology for trailing our backhoe write up starting on page 20. To say that this machine revolutionised construction sites is pretty much of an understatement. Imitation is said to be the sincerest form of flattery, and while many equipment OEMs have turned out their own versions of the backhoe, many operators would surely say that JCB’s is the quintessential version, a machine without peers.

Throughout its life it has met the challenges that the construction industry has thrown at it, each iteration bringing something new to the party, keeping the backhoe relevant and very much a part of sites around not just the UK, but globally.

The most recent innovation was Dual Drive, allowing the operator to reposition the machine while facing the excavator, without having to turn the seat to the front-facing position. It might seem an obvious call to make but don’t underestimate the complexities involved.

And looking forward who’s to say that we won’t soon be watching hydrogen enginepowered backhoes doing their stuff. It’s definitely on the cards.

Happy reading

Editors JOHNNY DOBBYN JOHN LEVICK cpn@hamerville.co.uk

Advertising Manager MATTHEW BOASE mboase@hamerville.co.uk

Group Manager ROB GILHAM rgilham@hamerville.co.uk

Magazine Designer GEMMA WATSON

Production Assistant CLAIRE PICTON

Subscriptions

Construction Plant News is a business magazine for plant professionals, contractors, materials extraction and processing companies, waste and recycling operations, as well as local authorities. If you are not on our circulation list and would like to subscribe email circulation@hamerville.co.uk

To be removed from this magazine’s circulation please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens & George Ltd

Published by HAMERVILLE MEDIA GROUP Regal House, Regal Way, Watford, Herts WD24 4YF. Tel: Watford (01923) 237799

Fax: (01923) 246901

Copyright © 2025

The publishers and editor do not necessarily agree with the views expressed by contributors, nor do they accept responsibility for any errors of translation in the subject matter in this publication.

ANOTHER SIGNIFICANT MILESTONE ON ITS PIONEERING HYDROGEN TECHNOLOGY DEVELOPMENT PROGRAMME HAS BEEN MET BY JCB AFTER IT SECURED THE FIRST FULL EU TYPE-APPROVAL OF ITS HYDROGEN ENGINE FOR USE IN NON-ROAD MOBILE MACHINERY.

This means that the hydrogen engine has been approved for sale and for use in machines and third-party OEM equipment in each of the 27 EU member states, and all other territories recognising EU type-approvals (e.g. EEA and EFTA territories).

JCB Chairman Anthony Bamford, who has led the company’s hydrogen engine project, said: “This is another very significant moment for JCB’s hydrogen programme, It

was not so long ago that some said that it was ‘game over’ for the internal combustion engine in Europe. For JCB to have secured full EU type-approval is proof positive that the combustion engine does indeed have a promising future in pursuit of a net zero world if hydrogen, a zero CO2 fuel, is used instead of fossil fuels.”

For more information WWW.RDR.LINK/CBC001 i

CITY HIRE HAS DONATED £1,000 TO THE LIGHTHOUSE CHARITY, REAFFIRMING ITS DESIRE, IT SAYS, TO SUPPORT THE HEALTH AND WELLBEING OF THOSE WORKING IN CONSTRUCTION.

Sales director Russell Alexander said: “This is a cause that City Hire is passionate about. We are pleased to be supporting the important role this charity plays in our construction industry.” Sarah Bolton, CEO of the Lighthouse Charity added: "We would like to say a huge thank you to City Hire for becoming one of our company supporters. Its pledge means that we can continue to proactively support our construction colleagues in need and support our mission that no construction worker or their family should be alone in a crisis.”

TRIME’S MGTP 24000/30 THS 24KVA FUEL-SAVING AND LOW-EMISSION STAGE 5-COMPLIANT GENERATOR RECENTLY SCOOPED THE TOP PRIZE IN THE RENTAL PRODUCT OF THE YEAR CATEGORY AT THE 2025 EUROPEAN RENTAL AWARDS.

The judges’s citation read: “Energy efficiency and reduced carbon emissions were a feature of all of the shortlisted products, but Trime’s genset stood out as a product designed for the rental market.”

Commenting on receiving this award, Paul Hay, managing director of Trime UK said: “Winning this award is a testament to the hard work and innovative processes that the Trime design teams have applied in producing this advanced generator. We believe that the MGTP 24000/30 THS is set to become a worldwide best-seller in the rental industry.”

Trime designs and manufactures a range of generators that are comparable to traditional diesel sets in terms of power provided but give the user a positive reduction in terms of fuel consumption, CO2 emission and total costs.

For further information

WWW.RDR.LINK/CBC002 i

The European Rental Awards celebrate the creativity and innovation in Europe’s equipment rental industry, and, according to the organisers, are the most prestigious awards event for the industry.

MCHALE PLANT SALES, KOMATSU’S DISTRIBUTOR IN IRELAND, IS REPORTING A RISE IN DEMAND FOR WHAT KOMATSU CLASSIFIES AS UTILITY MACHINES.

Typically, these include the micro/mini/midi size diggers and compact-size wheeled excavators popular amongst utility services providers and plant hire renters for whom the ‘short-hire, call-and-collect rental and DIY markets are paramount’. Major deals in this segment include what McHale Plant Sales director, Denis McGrath describes as “multiple unit deliveries to customers such as Kilkenny’s Total Highway Maintenance, Limerick’s Treaty Plant Hire, and Ballina-based plant rental specialist, Davy Tool Hire”.

Explaining this upsurge, McGrath said: “in addition to a naturally occurring growth in demand, the trend towards ‘contracting out’ by local authorities, gas, electricity and alternative energy suppliers, and by major computer, communications and broadcast services providers has increased purchasing and rental activity”.

“Another explanation can be found in an increasing tendency on the part of ‘big plant users’ to include compact-size diggers in their inventory, there to perform minor ‘project finishing’ and final surface dressing, landscaping, rectification, and small-scale ‘second-thoughts’ applications,” he added.Looking ahead, McGrath forecasts a ‘continuance’ of demand at the entry level.

For further information WWW.RDR.LINK/CBC005 i

THE CONSTRUCTION PLANT-HIRE ASSOCIATION (CPA) HAS ANNOUNCED ITS OFFICIAL BACKING OF THE 2025 UK PLANT OPERATOR OF THE YEAR COMPETITION.

Talking about the event, CPA CEO Steve Mullholland commented: “We are delighted to endorse the UK Plant Operator of the Year for 2025. We believe this unique event offers real value to our members, especially as the industry continues to address recruitment and training challenges. It’s a chance to see cutting-edge solutions from leading providers tested in a live setting, and we look forward to supporting this year’s campaign and exhibiting on finals day.”

Now in its fifth year, the event returns for its third consecutive final at the CITB’s National Construction College (NCC) in Bircham Newton, Norfolk, taking place on Saturday, September 6th.

Bringing together plant hirers from across the UK, leading global manufacturers, industry professionals, stakeholders - and of course, the nation’s top plant operators - finals day promises a vibrant ‘Festival of Construction’ as competitors battle for a share of the £20,000 prize pot.

This year’s event will also feature an enhanced jobs fair, providing hirers a platform to recruit, promote their businesses, and witness the latest plant and equipment through 12 live operator challenges.

For further information

WWW.RDR.LINK/CBC006 i

MARUBENI-KOMATSU IS INCREASING ITS UK DEALER COVERAGE WITH THE APPOINTMENT OF TWO NEW PARTNERS.

The Crawfords Group has been tasked with covering Hertfordshire, Essex, Kent, Surrey, Sussex, Hampshire, and South Berkshire, where it will offer the full range of Komatsu utility equipment including mini excavators, midi crawler and wheeled excavators, skid steer loaders and compact and agricultural spec wheel loaders.

“Komatsu is a renowned and respected brand, and we are delighted to bring its compact range to our customers,” said Wes Crawford, managing director, Crawfords Group. “This partnership reflects our continued commitment to providing high-quality solutions across multiple industries, including construction, landscaping, and utilities.”

In the Southeast, East Midlands area, Mawsley Machinery will be responsible for all LE, NN, and CV postcodes plus MK40 – MK45, where it will be supplying Komatsu utility mini and midi crawler and wheeled excavators. Mawsley managing director Keith Pearce, commented: ”We are excited to work with MarubeniKomatsu to supply Komatsu excavators to our customers and look forward to the benefits this will bring to all.”

The business was established in 1981 and is located on the outskirts of Northampton to supply the growing construction industry with new and used equipment.

For further information

WWW.RDR.LINK/CBC007 i

THE HUGELY POPULAR OPERATOR CHALLENGE IS SET TO RETURN TO PLANTWORX IN 2025, BRINGING EVEN MORE ENERGY AND ACTION TO THE UK’S LARGEST WORKING CONSTRUCTION EVENT.

Now taking place at Newark Showground, the challenge will again be a major draw, with JCB confirmed as headline sponsor. The manufacturer will supply all equipment used in the competition, including compact excavators, the 145XR X Series, the latest 3CX, and the versatile Hydradig. The challenge builds on the success of its debut at PlantWorx 2023. This year’s edition features eight timed challenges inspired by classic board games, plus two open-access head-to-head events for accredited operators keen to get involved.

Gareth Lumsdaine, JCB UK and ROI sales director, said: "We’re proud to support the operator challenge at PlantWorx 2025. It’s a fantastic way to mark 80 years of JCB and a brilliant opportunity to showcase our machines in action –with real operators behind the controls. It’s set to be an exciting three days.”

For further information

WWW.RDR.LINK/CBC008 i

PLANT HIRE COMPANIES NOW HAVE ACCESS TO A NEW INSURANCE POLICY WHICH PROVIDES COMBINED COVER FOR EMPLOYER, PUBLIC AND PRODUCT LIABILITY.

Providing cover of up to £10m for employer liability, £5m for public liability and £5m for product liability, the policy is being offered by specialty insurance underwriters Fiducia MGA. Available through insurance brokers, the policy is backed by A-rated capacity, which means the policy’s insurers are regarded as having an excellent ability to meet any claims.

In addition, Fiducia offers a combined commercial policy for those contractors who require protection against material damage, business interruption, business all risk and commercial legal protection. Fiducia underwriter, David Heeney, said: “We understand that UK contractors face changing risks and challenges, so we created these policies to ensure our broking partners can provide their clients with comprehensive cover and support.

“We would urge contractors to examine their policies ahead of renewal and discuss with their broker how our new combined liabilities products can help them manage risk effectively and secure peace of mind.”

For further information WWW.RDR.LINK/CBC009 i

CAT SIMULATORS WILL SHOWCASE A RANGE OF OPERATOR TRAINING SYSTEMS AT PLANTWORX 2025, INCLUDING A VIRTUAL REALITY (VR) PAVING SIMULATOR, A COMPACT TRACK LOADER (CTL) TABLETOP UNIT, AND A NEW VERSION OF THE EXCAVATOR SIMULATOR, WHICH WILL BE ON DISPLAY FOR THE FIRST TIME AT THE SHOW.

The VR paving simulator is designed to equip new and experienced operators with foundational asphalt paving and compaction skills. Using a VR headset, aspiring operators can carry out walkaround inspections, familiarise themselves with the controls, pave the highway (curved paths, manholes and material feed) and carry out asphalt compaction using proven techniques.

The simulator includes a headset, controllers, charger, paving software, and device management tools, and an optional laptop is also available. It’s compact and portable –ideal for training centres or companies working across multiple sites. Also on show is the SimLite compact track loader (CTL) simulator that lets operators carry out a number of tasks including walkaround and machine manoeuvring, loading and carrying (with a bucket or pallet forks), finishing grading (with a bucket or box blade and concrete pad removal using a jackhammer attachment.

THE ASSOCIATION OF MANUFACTURERS AND SUPPLIERS OF POWER GENERATING SYSTEMS (AMPS) HAS ANNOUNCED IT WILL ADOPT CESAR ECV, MAKING IT AVAILABLE TO ITS MEMBERS TO HELP TACKLE THEFT AND SUPPORT EMISSIONS COMPLIANCE.

For further information

WWW.RDR.LINK/CBC010 i

HIRE AND SUPPLIES LTD, A GROWING PLANT AND TOOL HIRE BUSINESS WITH LOCATIONS IN THE WEST OF SCOTLAND, IS EYEING EXPANSION INTO NORTHERN ENGLAND THANKS TO A SIGNIFICANT REFINANCING DEAL.

The company, which was founded in 2014 and now has 40 employees, secured a £2.52m asset refinance, facilitated by Greater Manchester-based PMD Business Finance and financed by Praetura Asset Finance. The deal enabled the company to refinance more than 250 assets across 160 hire purchase agreements, significantly reducing its monthly debt commitments and enabling the business to focus on its long-term growth strategy. David Chandler, director of Hire and Supplies, said: “This refinancing deal frees up significant cash that we will use to grow the business, specifically opening a bricks and mortar centre in Cumbria where our sales have been steadily growing in recent years.

“The plant hire sector in Cumbria has seen some upheaval with some competitors leaving or scaling back in the region. We believe there is a gap in the market for a firm like ours, particularly as the economic conditions will lead more businesses to hire in equipment than to buy it.”

Under the new arrangement, AMPS members will benefit from a discounted rate for the scheme. The association currently has over 120 members, including manufacturers, suppliers, distributors, service providers, and rental companies.

Alan Beech, AMPS director general, commented : “Any effort to combat crime –whether theft or the blatant disregard for the law –deserves strong support. As the representative of AMPS, we are proud to endorse this initiative because it is simply the right thing to do.”

JCB, a long-standing AMPS member and one of the world’s leading construction and power equipment manufacturers, is the first to adopt the scheme. JCB plans to fit CESAR ECV across its RS range of Stage V generators, which have been specifically developed for the power rental market.

Kevin Howells, managing director of Datatag ID, added: “CESAR has become a recognised and trusted system across the construction and agricultural markets. Extending its reach into the power sector through AMPS shows the value industry places on clear, reliable machine identification. We are proud to support AMPS members in strengthening their security and environmental standards.” For further information

CPN spoke to Flannery Plant Hire to examine how fleet/plant hire is changing, and if so, in what ways?

accessing vital equipment. This month we thought we’d find out how one plant hire business is reacting. We talked to Flannery Plant's Gareth Corbett , director, and Andy Byatt, head of technology, innovation and sustainability.

has seen the addition of hybrid excavators and dozers, the integration of advanced telematics reporting systems, 3D GPS machine technology and a broader range of machine types across all categories.

Within each machine category ie. excavators, has the mix changed ie. more mini/midi excavators?

The fleet today comprises of a complete range across each category, excavators wheeled and tracked ranging from 0.75tonne micro excavators through to 110-tonne long reach excavators, D2 - D9 dozers, ADTs up to 45 tonnes and a complete range of telehandlers, rollers, cabbed dumpers, tractors and trailers, tracked dumpers and the widest range of attachments available in the UK.

Equally what impact are batteryelectric machines having within fleet composition, and what categories if applicable?

As battery electric machines are released to market, we are actively conducting trials and demonstrations with customers, adding to the fleet ever increasingly. We have added compact excavators in 1.5/2 tonne size, the first 20tonne battery electric excavator working on a UK site, 6m and 17m telescopic handlers along with dual energy rotating telescopic handlers.

What are the current drivers in the market?

Cost as ever is a determining factor along with driving efficiency and productivity improvements. Carbon reductions are ever increasingly being included in tender requirements and a factor in contract award. Safety continues to be a key focus, seen in a recent drive to improve the people/plant interface through systems such as human form recognition through AI cameras and radar.

Flannery is always at the forefront of adopting new technologies and innovations, and the drive to lower carbon and ultimately achieve net zero is no exception. We do not believe that there is a silver bullet as to which technology will be required to achieve net zero, it will require a mix of technologies dependent on the machine type and specific application. Battery electric, cable/tethered electric and the differing hydrogen technologies will all have a place. Flannery Plant is in favour of any net zero emission machines but there is still someway to go before machines are commercially viable and the infrastructure is in place to support charging/fueling.

There will definitely be greater use of technology, autonomy, data and AI. Machine control will likely become adopted on a wider scale, increased amounts of data will be available on a larger scale and will be more focused and acted upon by our customers/clients. Autonomous operation will increase but only in repetitive, consistent operations where people and plant interface can be managed. Increased amounts of net zero emission equipment will be launched to market and over the next five-10 years hopefully the relevant infrastructure will be in place to support this. Grid availability, mobile charging solutions, hydrogen supply at a commercially viable price will be critical to achieving net zero ambitions.

Flannery Plant Hire has invested in a large fleet of construction equipment, with the latest innovations to cover our clients' requirements. We offer a complete solution to our customers including operated plant, operator training and digital solutions. We

the environment.

CPN braved an unseasonal June day in Oxfordshire so you didn’t have to. It was worth the trip...

What started as an overcast morning for the staging of GGR Group’s open day at the beginning of June soon deteriorated into an out-and-out drizzle fest – not that dismayed the hundreds of preregistered guests who descended on the group’s yard in Haddenham, Oxfordshire. With a big shed, a marquee and a fleet of umbrellas as cover, the crowd not only

enjoyed some excellent hospitality, but also some new machines and informative talks. Exhibiting partners included Liebherr, Evercam, Conquip, Pewag, Allmi and Skyline Cockpit. Among the new kit on show were two from GGR’s own brand UNIC – the UMM445, a lithium-ion pop-up spider crane and the URW 806-03 mini spider crane; plus the Palfinger PCC115.002 crawler crane and JMG Cranes’ MC45SB pick and carry crane.

In the talks, we were introduced to Malloy Aeronautics and its ‘heavy lift’ drone. Now, in crane world, there’s heavy lifting and heavy lifting; and so it’s easy to dismiss the company’s 68kg capacity as not heavy at all. As was discussed in the meeting though, 68kg is sufficient to move a significant amount of tools and equipment and other items – such as replacement double-glazing units – to awkward and inaccessible places, whether a ship at sea or the top of a tower block. No-one left the talk unconvinced of the potential of the machine and struck that the company are now trialling the T400, which can manage 180kg. It is also working towards a drone that can carry a single person prone – ideal for casevac applications.

The UNIC UM445 mini spider crane offers impressive specifications for a machine of its size, including a main boom lifting capacity of four tonnes, a lift height of 11.0m, and a working radius of 9.8m, all while delivering pick-and-carry capability. The hydraulic tele-luffing jib further enhances its capabilities with a 1.5 tonne lifting capacity, a 170° working range, and an extended maximum lift height of 17.5m, alongside a working radius of 15.6m.

The crane is equipped with an all new Scanreco radio remote control, featuring colour graphics and realtime data. Powered by a lithium-ion battery, the UM445 offers ‘charge while in use’ capability, lownoise operation, and zero emissions. This ensures minimal disruption and continuous operation in sensitive environments.

Previewed at BAUMA in April, the UNIC URW-806-3 mini spider crane – an updated version of the URW706-2 – boasts an 8,000kg maximum lifting capacity. It includes an updated hydraulic teleluffing jib, Scanreco colour screen remote control with full feedback, variable footprint system and is compatible with the new lithium UNIC ECube system. The new hydraulic tele-luffing jib benefits from an improved lifting capacity of 1000kg, working length of 3.8m –7.5m (configuration dependent), impressive 27.8m lift height and maximum working radius of 21.0m.

This crane’s modular build allows the detachment of the crawler unit from the main body, lowering transport height and making it easier to access tight or low-clearance spaces. The crane body can move along the H-frame outriggers, allowing it to shift position laterally and longitudinally for optimal setup in confined areas. With a main boom outreach of 20.7m and a hook height of 22.5m, the PCC 115.002 can extend its reach to 33.3m and 36m respectively when fitted with its articulated jib. It’s also equipped with a powerful 3.5-tonne hydraulic winch for efficient vertical lifts and offers pick-and-carry functionality.

Powered by a Euro Stage V diesel engine and 415v electric mains power, the PCC 115.002 delivers a dual-powered solution suitable for both indoor and outdoor applications. Controlled via a full-colour radio remote control, and equipped with advanced features like P-fold boom automation—which automatically folds and unfolds the boom—and active oscillation suppression, which hydraulically dampens boom sway, the PCC 115.002 combines high performance with precision control, making it a compact lifting solution for even the most complex lifting tasks.

With a capacity of 4.5 tonnes, the MC45SB pick and carry crane, features a robust batterypowered system, providing power for up to eight working hours. The crane’s compact design makes it suitable for indoor and outdoor applications; and with a lifting capacity of 4.5 tonnes and a max hook height of 7.6m (with searcher hook), the MC45SB is engineered to handle a wide range of lifting operations. The battery-powered crane is equipped with advanced radio remote control technology, offering operation from a distance for enhanced operator safety. The intuitive controls and 180° rear hydraulic steering, ensure that operators can manoeuvre the crane with precision.

One of the highly informative talks was delivered by Rik Wenham, head of the Metropolitan Police’s commercial vehicle unit. It is Rik and his team that oversee the movement of abnormal indivisible loads (AILs) – such as mobile cranes – in and out and around London. Rik outlined many of the unfair anomalies surrounding the treatment of AILs over other forms of transport – for instance, how many pedestrians and cyclists are killed by buses every year, compared to fatalities caused by cranes (answer: loads vs. none). It is his view that, in the modern transport and traffic context, the existing restrictions are not only obsolete, but unnecessary and he has a proposal in with the top brass to scrap them entirely.

CPN will be spending a day with Rik and his team shortly, so watch this space...

Summertime and the living is easy. Some say he takes his work boots on holiday, others that he packs his steel-toed flipflops. All we know is that we call him The Dig. This month he gives a Takeuchi TB290-2 a few work tasks.

Takeuchi’s 9-tonne midi excavator offering, the TB290-2, which was first introduced to the line-up in 2019, continues to be an ever-popular machine with a wide range of customers.

The first series TB290 model was launched in 2014, replacing the 8.5-tonne class TB285, itself the successor to the previous 7.5-tonne class TB175, which was well liked by both owners and operators alike for its smooth hydraulics, boxy nofrills look, durability and reliability.

When the TB285 was first introduced, it featured a much more modern rounded and compact rear end, which was not only pleasing to the eye, but more importantly less prone to damage when working in

tight quarters. This has continued with the TB290 and the very popular TB290-2, which with a few tweaks along the way, is now considered to be a heavyweight product in the Takeuchi line-up. In addition, since the start of this year, all Takeuchi machines now come with a 3-year/3000hour warranty as standard, not that you are very likely to need it, such is the legendary standard of reliability of the Japanese built excavators.

We were offered an opportunity to take another look around one, on site in Daventry, the machine having recently been purchased by Northamptonshire-based Rowan Groundworks from its local dealer Willowbrook Plant.

The TB290-2, which comes with a whole raft of features as standard, is distinguished from its predecessors by the addition of red paint work which rises up along the side of the machine and drapes around the rear engine bonnet. This cosmetic splash really does set it apart from the previous model, which featured largely grey upper body work.

The rear bonnet raises up to reveal the heart of the TB290-2, the 4-cylinder turbocharged Yanmar 4TNV98CT-WTB diesel engine, which is Stage V emissions compliant, and uses a DPF to achieve these standards. It offers a power output rating of 51.6kw @2000rpm. This unit replaced the Isuzu power pack in the previous model which was rated at 52.0kw producing a maximum torque of just 255 N/m while the new Yanmar motor produces significantly more at 308 N/m at the same rpm.

Nestling in the engine bay is the state-ofthe-art Kawasaki variable hydraulic pump; this blue-chip component is larger than what was fitted on the previous models and offers vastly improved oil flow delivery which ensures enhanced hydraulic performance.

The engine and hydraulic components work in unison, enabling the machine to perform better and in a seamlessly smooth manner when using multiple functions during things like precision lifting, or tracking and slewing with a heavy load on the end. In this way you don’t get that feeling of one circuit slowing down another, or the jerkiness of movements you sometimes get from a machine with a less refined hydraulic system.

Same as on the earlier TB285 and TB290 models the gas strut assisted gull wing bonnet cover on the offside of the machine raises up to reveal a host of tightly packed in components including the main valve block, hydraulic oil tank, expansion bottle and screen wash bottle, which are located side by side and the 128-litre fuel tank. An electric refuelling pump is fitted as standard and a handy sight tube, with the familiar floating red ball, is located down the side of the tank so you can easily gauge when refuelling is complete. The diesel tank filler point can also be accessed via the smaller lockable opening side panel too, which is very handy, rather than lifting the whole canopy, especially if filling up from a bowser.

The TB290-2 now features a full LED work light package which comes as standard; this one features an impressive rooftop lightbar, two boom mounted lights and one forward facing on the offside canopy. Additional lights can be fitted to meet the specific customer’s needs.

This machine is fitted with the standard boom and long arm combination which offers

a maximum reach at ground level of 7,290mm and a maximum dig depth of 4,580mm. Also, as standard boom and dipper check valves are factory fitted and the machine pre-piped for 3rd auxiliary lines. Boom off-set is 70˚ to the right and 60˚ to the left.

I have always been impressed with the twin boom lift ram set-up on this 9-tonne model. It gives the boom far more stability and powerful lift performance overall. The only bit of negativity is the procedure for the quick coupler, which involves using your heel on a pedal to the right-hand rear of the floor while pressing a button on the righthand joystick. Sometimes it can be a bit tricky, and if you release the button on the joystick too early, you have to go back and start the whole procedure again, but it is what it is and you would get used to it.

Our example featured the standard fitment 450mm rubber tracks, with an overall track length of 2855mm. Other options including steel track shoes are available on request. Track guards can also be specified but this machine was not fitted with them.

At the business end of the dipper this machine was fitted with a Tefra fully automatic hydraulic quick coupler from Hill Engineering and was supplied with a full set of buckets from Rhinox, including a supersized grading/rehandling bucket.

Climbing into the cab and it’s all that we have become accustomed to with Takeuchi machines - a nice spacious interior, with all the appointments one expects in a modern midi excavator.

Everything you could possibly need is fitted in the cab, with standard fitments being full climate control air conditioning and Bluetooth mobile phone connectivity.

For improved cab comfort, there are no less than five air vents located around the cab, to provide a good flow of hot or cold air as required to suit the climate and another nice little feature is that all important cup holder, but with quite literally a special twist. By rotating the cup holder slightly, it opens up ventilation holes in the bottom, which depending on the climate control setting, can keep your beverage hot or cold. It’s a neat feature that, in all fairness, often goes unnoticed by operators until it’s pointed out to them.

For fresh air freaks, the two offside windows can both open independently by means of sliding, and of course the top front screen can be raised up, and the bottom portion can be stored at the rear of the cabin. In addition, the main cab door can be locked in the open position as per the industry standard.

The full colour monitor offers a whole host of information to the operator in a clear, easy to use and read format. The main screen reverts automatically to a rear-view camera as soon as reverse tracking is activated for improved safety not only for the operator, but for any ground crew who might have accidentally entered the working area.

Operators can also pre-set auxiliary modes on the VDU to match individual attachments flow requirements. The machine also features TFM, Takeuchi’s new telematics system. This monitoring system keeps an eye on the overall health of the machine

dramatically changed persona. That little bit of extra poke makes the machine perform how I felt it should do. In P mode it powered up the pile reaching the plateau on top easily.

I set myself up to trim up the sides of the pile, to weather it in, as it looked ominously cloudy and full of rain on the horizon. Considering this is just a 9-tonner, its reach down the side of the heap was impressive and nothing was too much bother for the machine.

Being very familiar with Takeuchis, I was very quickly at home and working in unison with the machine, it just does everything you expect from a quality hydraulic excavator. Having sealed up the sides, I sat atop the heap to do something that Takeuchi machines have become so well known for, grading. The smoothness of the controls is the stuff of legends, every service works as you would expect it too, cutting through the material effortlessly, in super smooth controlled motions, it really was an absolute pleasure to be onboard.

I had heard tales about the machines being a little light on the back end but throwing material around even with the slightly oversized grading bucket, the machine never once felt unbalanced to me, despite my efforts to prompt a tip at full tilt! Slew speed remains as it was on the original TB285, a respectable 10.3rpm with a nicely controlled take off and slow down.

No doubt this machine will eventually be given the Takeuchi 3-Series upgrade, although from previous experience we know that the Japanese don’t like to rush into things and make sure they have everything just right before launching anything new, but at the moment, I see no need to change, as this model is as good as it gets in the 9-tonne class sector, I certainly enjoyed my time in the seat!

P a c k e d w i t h a r t i c l e s o n a w i d e r a n g e o f i n d u s t r y t o p i c s , w w w. c p n o n l i n e . c o . u k i s t h e

f i r s t p l a c e t o v i s i t f o r a l l t h e l a t e s t n e w s i n p l a n t a n d m a c h i n e r y – f r o m t h e s m a l l e s t s k i d s t e e r s a n d m i c r o e x c a v a t o r s t o t h e g i a n t s o f t h e t o w e r c r a n e m a r k e t , o r t h e

h e a v y w e i g h t s i n c r a w l e r e x c a v a t o r s , w e ’ v e g o t i t c o v e r e d

G e t t h e l a t e s t i n f o r m a t i o n o n t h e i n d u s t r y ’s b i g g e s t d e a l s , a s c o n t r a c t o r s a n d p l a n t h i r e r s r e n e w t h e i r f l e e t s i n o u r F l e e t A d d i t i o n s s e c t i o n , a s w e l l a s a l l o f t h e n e w e s t

p r o d u c t s t o h i t t h e m a r k e t . O u r w e b s i t e i s u p d a t e d d a i l y, b r i n g i n g y o u t h e m o s t i m p o r t a n t i n d u s t r y n e w s q u i c k e r t h a n e v e r b e f o r e YOU CAN ALSO FOLLOW US ON TWITTER @CPN mag OR FOLLOW

Most construction equipment OEMs have an iconic machine. For JCB that is the backhoe loader. CPN charts its history and looks at recent developments to keep this versatile bit of equipment a firm favourite on site.

For over 73 years, the backhoe loader has been the foundation, the very cornerstone of construction and plant hire businesses across the world. Who would have thought back then that the concept of a wheeled machine, with a bucket at one end and a shovel at the other, would prove so successful? But successful it has proved, with the company responsible for its genesis, JCB, celebrating the production of its one millionth backhoe loader at the start of this year.

Designed initially for post-war reconstruction, as a machine that could complete a host of tasks on site, the concept started as an agricultural tractor with a Major Loader fitted to the front and an excavator arm to the rear. By 1953, Joseph Cyril Bamford had designed and launched the Mk 1, which turned out to be one of the most important and influential machines that the construction industry has ever seen.

This early model was strengthened and performance improved, with the launch of the Hydra-Digga in 1956 and the more powerful JCB 4 in 1960. Demand for a smaller, more manoeuvrable model would soon lead to the JCB 3, a backhoe loader for the housebuilder, rather than the civil engineer and a model that would launch plant hire businesses across the world.

In the seven decades since, JCB has continued to develop and evolve the concept, adding longer loader arms, a horizontal ‘side shift’ for the backhoe mounting, the six-inone front shovel and even a kettle for the operator. Turbocharged engines, powershift transmissions, all-wheel drive, the extending dipper arm and auxiliary hydraulics, have turned the humble backhoe loader into one of the most versatile, productive and reliable master-of-all-trades machines.

From those early days, JCB realised the benefits and potential of vertical integration, designing and engineering its own components specifically for the backhoe loader and its other equipment lines. Transmissions, axles, hydraulic cylinders and cabs are all sourced internally, more recently being joined by JCB’s award-winning range of low emission diesel engines. As has been publicised the company is working on an innovative hydrogen engine, that will take the backhoe loader into a zero-emission future.

The backhoe loader concept continues to expand, from the skid steer loader-based 1CX, through the 3CX Compact and the various 3CX models, to the all-wheel steer 4CX and powerful 5CX. There are Highways Master and Wastemaster trims, even a Polemaster Plus for specialist utility work. There is a JCB backhoe loader to suit every application, anywhere in the world and the JCB backhoe loader is built in multiple sites around the world, to better suit local demand.

For more than 70 years JCB has continued to develop and refine the backhoe

“... there is a JCB backhoe loader to suit every application, anywhere in the world...”

JCB has produced a

loader, achieving sales success and market leadership in every corner of the globe.

The secret of its success? Here are a few stats from JCB: the backhoe loader can load 20-tonnes of material in less than five minutes, while using 10% less fuel than a 13tonne excavator; it can move material across site 25% faster than an 8-tonne excavator and 9-tonne site dumper, while using 50% less fuel; it is able to level material three times faster than a 13-tonne excavator, while using 25% less fuel; plus, the backhoe loader can drive itself to and from site, with no requirement for additional transportation.

Alternatively, customers can remove the bucket and shovel and operate the backhoe loader with a host of other attachments, from road sweepers to patch planers, hydraulic breakers to compaction, pallet forks to post-hole augers. Most recently JCB has introduced further refinements with upgrades across the range, to make an operator’s life easier and more productive.

These include:

■ the launch of Dual Drive allowing machine repositioning without rotating the driver’s seat

■ single loader lever to reduce operator effort

■ revised direction control for quicker and easier use

■ return to grade function for improved performance

■ laser level mount for simple 2D installation

■ upgraded quick hitch with wider fork carriage

Available as standard on 3CX Pro and 4CX Pro machines with servo controls, Dual Drive allows the operator to reposition the machine while facing the excavator, without having to turn the seat to the front-facing position.

This is particularly useful when ditch cleaning, grading, breaking or patch planning, as the operator can simply drive the machine along the job site while looking at the work area.

A roller switch on the left-hand servo lever controls the steering, while the righthand lever has a forward-reverse selection switch. The two pedals in front of the operator are used to control the throttle and the brake system. A 7in monitor, positioned at the rear of the machine next to the side console, provides a wide-angle view to the front of the machine, while facing to the rear thanks to a bird’s eye camera positioned on top of the cab.

JCB says it studied how operators work and concluded that the single ease of use and productivity improvement would be the ability to drive the machine in both directions while operating the excavator.

It’s a move that JCB believes sets it further apart from the competition and reinforces its commitment to have the easiest and most comfortable backhoe to operate.

Loading and excavating with Dual Drive is said to be an absolute game changer for operator ease of use, which is why the company has standardised this functionality on premium models.

Using experience from the wheeled loader market, JCB has also adopted a single lever 6-in-1 loader control lever as standard on all manual control machines, allowing operators to control the loader and transmission with one hand and the steering with the other, without the need to use the column shift. A proportional switch on the side of the lever operates the 6-in-1 clamshell function. With a large capacity shovel, autoshift transmission and return-to-dig function, it is possible to load a truck in as little as five minutes.

A switch is incorporated into the loader lever for transmission directional control, in addition to the standard column shift control. As in JCB’s Loadall telescopic handlers, the column switch maintains priority over the loader lever switch.

To simplify angle setting of the 6-in-1 shovel for grading work, JCB has introduced a return to grade function on all servo control machines. With activation through a switch on the side console, the operator simply opens the clam shovel, before moving the loader lever to the right. The system automatically stops the shovel rotation when it reaches the optimum angle for grading.

With widespread adoption of laser levelling systems across the industry, JCB has added a 2D laser receiver mount to the front loader torsion box. A mounting pole can be installed and extended to suit various types and sizes of receiver. This allows the operator to set grade depth and to grade more accurately while reducing time taken and fuel used. A 2D laser can increase grading accuracy to within 10mm, offering the operator up to a 25% time saving over standard manual grade control. The 4CX can level and grade 50tonnes of stone 63% faster, using 73% less fuel, than a 13-tonne excavator.

JCB’s integrated quick hitch with forks, which allows the shovel to be removed for dedicated fork use with a 2,000kg lifting capacity, has been upgraded with a 220mm wider fork carrier, to improve stability of wider loads. The forks now sit outside of the carrier frame, making it easier to reach the forks and to stow after use. Hydraulic

couplings are also repositioned for easier access, to reduce changeover time. Rubber mounts have been introduced to reduce noise between the forks and the frame, while the wiring harness and hoses are repositioned for improved protection.

A twin camera and screen option is now offered with the integrated forks, for improved visibility when rehandling materials. An anti-misting camera has been integrated into the quick hitch frame, providing improved visibility of the forks and the load, especially at ground level. A second camera,

mounted in the roof, allows the operator to see the quick hitch bar, making it easier to change attachments, while a 7in colour screen to the right-hand side of the front console can be switched to show the feed from either camera.

A standard six-speed Autoshift transmission has replaced all manual and Powershift transmissions on the 3CX and 4CX. Transforming roading and loading performance, TorqueLock has also become

standard, reducing travel times by up to 10% and improving fuel efficiency by 25%.

The floor-mounted manual gear lever has been substituted for a simple column switch, with automatic gear changing through fourth, fifth and sixth gears. Loading is also made easier, with a kick down switch now mounted on the floor, which automatically drops a gear from second to first for maximum traction and shovel penetration.

All 3CX, 4CX and 5CX models now benefit from the standard fit of eight LED work lights, four to the front and four to the rear of the machine. Offering 1,000 lumens of light each, these work lights improve visibility all-round the machine in poor conditions. A 10 LED higher powered work light package remains available as an option.

A seat interlock has been introduced on joystick machines, to avoid the possibility of longer joystick levers hitting the steering wheel when the operator turns the seat. The seat will now only rotate when the steering column is in the fully retracted position, while the steering column foot release remains on the floor of the cab.

JCB has included a host of smaller upgrades into the backhoe loader range, including simplified excavator quick hitch activation, the option of new 20in Michelin Power CL tyres on 3CX and 3CX Plus models, a new seat belt warning feature and a green beacon socket for the UK market.

While it was the bigger, next generation ‘-9’ smart crawler excavator range that caught the eye at Bauma, Develon is not ignoring the compact excavator market. Far from it in fact, as it expands its smaller offering with the launch of its new DX25Z-7 mini excavator and the introduction of an enhanced version of the 2.8-tonne DX27Z-7 model.

The company says that the new DX25Z-7 was developed to complement its existing mini excavator line-up, offering a compact and transportable machine that meets the needs of a wide range of applications.

Moreover, it sees the DX25Z-7 as a costeffective option in the compact sector, built for durability, ease of use, and low maintenance.

Designed with rental markets in mind, it includes reinforced components, cylinder and vandal guards, and a simple interface for less experienced operators. Safety features include a ROPS/TOPS/FOPS-certified cab, travel alarm, emergency stop, safety belt warning and LED lighting with a rotating beacon.

Weighing in at 2691kg, the DX25Z-7 is powered by the well-proven Kubota D1305 Stage V -compliant diesel engine, pushing out 18.5kW (25hp) at 2600 rpm for reliable and efficient performance. A 2030mm boom and 1300mm arm come as a standard specification and its heavy-duty counterweight boosts stability and digging performance in tough conditions.

The heated cab provides good visibility and comes equipped with a 5-in digital display, Bluetooth radio and smart safety functions such as ESL (engine starting limit) anti-theft technology. The machine’s highefficiency hydraulics enable smooth, proportional control with selectable flow modes and optional quick coupler piping.

Serviceability is also prioritized, with a smart engine layout, wide-opening access panels and extended service intervals to reduce downtime and costs.

Speaking about the new machine, Ohjong Choi, head of product management at Develon Europe, said: “With the launch of the DX25Z7, Develon is expanding its mini excavator lineup with a highly transportable, lowerweight model that offers excellent versatility. The DX25Z-7 can be easily transported on a trailer along with a range of buckets and a hydraulic breaker while staying under the 3.5 tonne transport limit. The new machine is

Korean manufacturer Develon continues to strengthen its range of compact excavators, including giving some existing models a twist – they are electric. CPN takes a look.

therefore an excellent solution for the rental industry and for self-drive hire in particular.

“In addition, the DX25Z-7 is designed with a practical feature set, making it a smart and cost-efficient solution for a wide range of applications. Its durable build and easy transportability make it especially well-suited for rental fleets and customers seeking reliable Develon performance at an accessible entry point.”

The upgraded 2.8-tonne DX27Z-7 is claimed to deliver improved performance, safer operation and easier maintenance and transport. It’s powered by the reliable Kubota V1505 Stage V diesel engine with 18.5kW (25hp) on tap at 2300 rpm, and combines reduced noise, less vibration and improved cooling efficiency for longer engine life and lower maintenance costs.

Operational enhancements include an enlarged cab entry, thumbwheel auxiliary control, improved front visibility and wiper coverage and a large glass door for easy access. Comfort has been improved with a heated, adjustable suspension seat and optimized interior temperatures from the repositioned radiator.

Safety is increased with ROPS certification, an overload warning system, rearview and around-view cameras and additional LED lighting. The auto shift travel system provides smooth movement, while optional counterweights enhance lifting stability.

Cylinder guards, a reinforced boom and robust design features add to the machine’s overall durability, while transport has been made easier with enhanced tie-down points. Better engine and component access improve serviceability, while real-time

diagnostics and the My Develon telematics system come as standard.

Like its new sibling, the DX27Z-7 features compact dimensions suited to work in tight spaces such as in urban construction, landscaping, rental and general contracting.

Like many of the mainstream OEMs Develon is taking electrification of machines seriously. To that end it is introducing a new range of electric excavators that support the transition to cleaner, quieter and more sustainable construction.

The company insists that the new machines form part of its European roadmap for zeroemission machinery but it has based the new models on established platforms, known for their reliability, power and comfort, so there will be a degree of familiarity for operators.

As part of the development programme the company collaborated with Netherlands-based ETEC Zero Emission to integrate electric drivetrains into its models, ensuring performance remains high, while emissions drop to zero. ETEC’s experience in energy storage and electric platforms supported the integration, while Develon remained responsible for product direction, branding and customer interface.

The line-up includes multiple electrified machines: the DX160WE-7 wheeled excavator, and two crawler excavators based on the DX225LC-7 platform. Customers can choose from battery options, including extended range packs that allow for a full day of work without recharging. These new electric models are fully branded and supported by Develon, ensuring that customers receive the same level of service, distribution and product confidence they associate with the name.

With growing interest in low-emission alternatives across Europe, especially in northern markets, these new electric excavators offer a solution that balances environmental performance with practical job site needs. The machines are quiet, efficient and built to handle tough conditions –reducing both emissions and noise without sacrificing productivity.

With a wide array of online resources supporting the latest solutions – from videos to technical guides, PDFs to podcasts – it can be a challenge to locate what you need.

To ensure you don’t miss out on these valuable resources, we are introducing rdr.link/ – a new, rapid service to transport you immediately to the online resources mentioned in our stories.

So, in articles you may now see things like:

Simply enter rdr.link/ followed by the unique six digit code into your browser and it will take you to the required resource

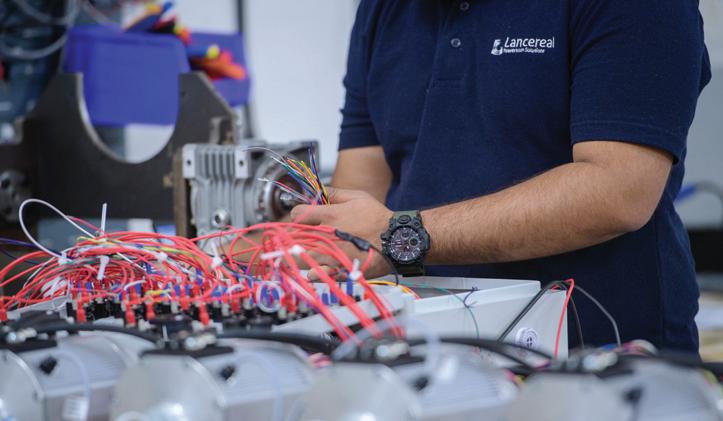

powertrain and systems integrator for industrial and mobile equipment, explores the developments of electrification within material handling and how they might influence the construction machinery sector.

electrification and move away from diesel and LPG has been on the rise ever since. If you consider forklifts; the noise they produce and the fumes from internal combustion engines (ICE) are not conducive to enclosed environments, such as warehouses. Therefore, forklift OEMs were one of the first to switch to battery powered machines because of the benefits –quieter operation than ICEs, more ergonomic and not relying on fossil fuels.

Initially, lead-acid batteries were used and for forklifts especially the large size and heavy weight were beneficial as they had space to accommodate it and it could be used as a counterbalance. However, they can be prohibitive in continuous operations as they require a long charge time.

As technologies develop we’re seeing more adoption of machine manufacturers using lithium-ion batteries. They provide longer run times, faster charging, and increased energy efficiency compared to lead-acid alternatives. However, operators not only want equipment that is quieter to operate with zero emissions they are looking for machines that are safer, autonomous and more efficient and as such are looking at all operations of

MOFFETT (a Hiab brand), who we started working with back in 2017. The company had begun converting diesel truck-mounted forklifts to electric in 2010 in response to customers requesting a quieter solution for early morning and late-night deliveries.

We got involved when the company was

“... they are looking for machines that are safer, autonomous and more efficient...”

planning a new design for its next generation of e-trucks, which launched in 2020. The company wanted to keep the size of the drive similar to the engine-driven truck, so the challenge was to find a compact solution that would fit within the existing chassis.

We worked with the engineering team to find a suitable solution, which was a compact permanent magnet motor, a planetary gear box and a chassis mounting plate – designed to suit the existing chassis. In addition, integrated failsafe brakes (spring-applied) were included in the assembly. This provides

battery systems. And looking to automation, proximity sensors can be used to alert when people walk behind equipment. Further safety features can be found in the software such as access control, impact detection, battery monitoring and emergency stop mechanisms.

The experience for the operator is also improved, as the smoother operations means there are less vibrations. And the noise reduction is twofold from quieter operations to also being able to hear more clearly.

Having worked at the forefront of powertrain products and solutions for decades, we’re able to support with the whole vehicle architecture, which for some companies can really simplify not just the engineering transparency but also the purchasing and supply chain management. And when making the move to replace traditional components with electrified alternatives this can provide reassurance that there’s a single source for managing the overall system, who really understands the benefits of components and how they can work together. For some customers we aren’t just supplying the components and controllers, but the software development

CPN TALKS TO BART VINGERHOETS, SENIOR COMMERCIAL MANAGER AT KOMATSU SMART CONSTRUCTION, ABOUT THE BENEFITS OF SMART TECHNOLOGY, THE POTENTIAL APPLICATIONS FOR THIS IN EXCAVATORS AND HOW INNOVATIONS ARE CHANGING JOB SITES.

Have you found users asking for more technology on their excavator? If so, what are they specifically asking for?

BV: There has been a significant push towards digitisation by excavator operators, construction companies and governments. Technology is not only improving the efficiency of excavators but also aiding in increasing safety.

The earthmoving industry understands the benefits of technology. In Europe, some regions were initially priced out of being early adopters of new innovations. However, with hardware solutions becoming more cost-efficient, adoption rates are on the rise. We have seen this firsthand, as 38% of our 3D machine guidance system sales took place in East and South Europe.

Customer demands vary depending on the region and client size. Many technologies that were initially adopted in West and North European sites are now being adopted elsewhere. In the early adopter countries, the main concern is safety, along with a productivity increase.

At its core, digitally enabled hardware on excavators and machinery helps teams work more efficiently, make better decisions, and deliver stronger project outcomes. For example, our dashboard creates a digital version of the job site, showing live data on materials, measurements and potential issues.

BV: Construction companies are seeking technological advancements to enhance profitability, save time, and reduce costs. Every year, businesses become more eager to improve risk management, leading to enhanced safety on construction sites, which can be facilitated by digital solutions.

Excavator operators, who see the direct benefit of enhanced technology, experience numerous advantages from incorporating digital solutions into their day-to-day work, such as time savings for site managers, enhanced problem solving and improved efficiency in data and file transfers. This enables managers to allocate more resources to oversee multiple sites and communicate with suppliers and clients. Furthermore, digital construction allows stakeholders to virtually inspect job sites, reducing the necessity for frequent on-site visits and creating a more efficient workforce with fewer errors and re-work.

For example, our intelligent machine control excavators have semi-automatic features that eliminate the possibility of overdigging, avoiding costly re-work, especially important when working with various material layers. Teams can respond quickly, solve problems as they arise, and maintain progress without unnecessary delays.

Do you anticipate users' tech needs changing in the next five years? Will they stay the same until there is a new wave of technology developments?

BV: The technology needs of excavator users and the construction workforce is expected to naturally evolve over the next five years due to several emerging trends and advancements in construction and heavy machinery technology.

Due to the growth in digital twin technologies, we believe excavators and other earth movement equipment will take a pivotal role in capturing survey-grade data. Having every bucket or blade move represented in a highly accurate model means all members of the workforce can access remotely, adding significant productivity gains.

In 2025 and beyond, we can expect the adoption of smart technology and the use of AI on construction sites to continue to rise as more cost-effective options hit the market. In fact, the global AI in construction market was estimated at £1.3 billion in 2023 and is projected to reach £9.1 billion by 2030.

The digitisation across earthmoving and construction is making notable strides in line with the increased adoption of technology. The ability to gather and analyse data from various sources is becoming increasingly

important. Advanced analytics can offer insights that aid in planning, risk management, and decision-making, ultimately enhancing operational efficiency and effectiveness.

For example, our Smart Construction’s remote solution allows users to send new design data to machines in the field, or remotely support operators, without travelling to the jobsite, making data transfer take significantly less time than before whilst also reducing fuel usage.

Are the users who are currently using specific technologies coming back and asking for additional tech solutions?

BV: We reported a 44% adoption increase in our software as a service (SaaS) technology from FY2023 to FY2024, highlighting a rising demand in construction. Users have found that our solutions greatly improve their site's performance and profitability, with many stating they couldn’t work without them anymore. Smart Construction solutions work well independently but have enhanced capabilities when used together, for example, dashboard and 3D machine guidance.

We spend significant time with our customers while they are on the job. This leads to a close relationship between us and the customer base, so we often hear what our customers are thinking. We use this information to see how we can assist in bringing their ideas to life by presenting new solutions, building new features, or products.

As a result, in each country we operate in, we have customers who are aware of our development roadmap and actively ask to test the new products due to our previous performance, such as the latest version of Edge, which launched last year.

As the industry continues to evolve and new technology develops and rolls out, we can expect our users to want additional technology solutions that work alongside our existing solutions.

To find out more, WWW.RDR.LINK/CBC019

With plant hire, demolition, earthworks and transport divisions, including sweeper and tipper hire, Hawkes Group is a one-stop-shop for customers that require reliable machinery on a nationwide basis. Now the Ketteringbased company has added two Hyundai CE HX220AL crawler excavators to its rapidly growing fleet of equipment.

“Hawkes Demolition purchased its first Hyundai excavator in 2018 and the brand has been a consistent part of our fleet ever since,” said Reece Hawkes, managing director.

“We operate 34 Hyundai excavators across the business, currently ranging from 13 tonnes to 30 tonnes. That number continues to grow, as we expand our operations and invest in reliable, well-supported equipment.”

“Most recently, we’ve added the two new HX220ALs to our fleet of excavators. Hyundai has always delivered a strong balance of performance and value, which has been a key factor in our continued investment,” continued Hawkes.

The business is continuing to invest to meet the needs of customers in all areas of the business. With such a strong relationship with Hyundai and dealer Willowbrook Plant, the company is now expanding into other machine categories.

“We’ve placed an order for the first Hyundai dozer to enter the UK through Willowbrook. It will be joining our contracting division,” added Hawkes.

In a bid to to improve productivity and economic efficiency at one of its cement plants, quarry operator Breedon Group has invested in its first Cat 395 excavator.

Talking about the purchase, Tim Palmer, quarries development manager at Breedon, said: “Straight away we could see that the Cat 395 was a true powerhouse of a machine. We were impressed with the higher capacity regarding bucket size, which for us means greater payloads and faster material movement.

“Durability and productivity are also key to our investment. The reinforced booms, sticks and frames on this machine go a long way in ensuring reliable performance in very demanding conditions. It is also a highly productive machine thanks to increased swing torque and stick force, which enable faster cycle times and improve material handling.”

The excavator was supplied by Finning and will be used with Sleipner E90 dollies.

Dean Turner, corporate account manager – mineral products at Finning, explained:“Sleipner are the experts in transport systems that reduce track wear, fuel consumption and downtime for heavy machinery and we knew this was going to be a vital asset to Breedon to ensure this impressive machine runs at peak performance whilst on site.

“The delivery of the machine and Sleipner dollies truly marked a collaborative effort between Finning, Sleipner and Breedon. We are thrilled to have supported Breedon in the acquisition of this machine that will go on to enhance their operations for many years to come.”

WWW.RDR.LINK/CBC021 GOTO

Swindon-based Tiger Plant Hire is upping its game with the acquisition of a number of new Kubota U50 and KX085 excavators, specially equipped with PVS Data’s B1 telematics units and keypad immobilisers. According to the business the move reinforces its dedication to providing customers with the best equipment and technology available in the market. By integrating PVS Data’s B1 telematics units into its expanding fleet, the company says it will ensure unparalleled machine performance insights, operational efficiency, and enhanced security for both them and their customers.

With the addition of keypad immobilisers, Tiger Plant and its customers are in complete control when it comes to operator usage. The additional security that comes from the keypad immobilisers allows owners and customers to change keypad combinations remotely, view tried and tested combinations and set exact times for machines (being turned on and off) to be locked down.

The B1 telematics units provide customers with real-time data on machine engine hours, battery levels, and machine locations to a 3m x 3m point.

Tiger Plant’s managing director, Shane Sherbourne, commented: "Investing in Kubota and PVS Data’s telematics is an investment in our customers. We want to provide them with not just quality machinery, but the insights and tools to get the most out of every machine on their site. These innovations bring smarter hiring solutions, allowing for more informed decision-making and a seamless operational experience."

GOTO

WWW.RDR.LINK/CBC022

Civil engineers Cooney Construction has boosted its fleet with the addition of two Hyundai CE HW65A wheeled excavators.

The 6.5-tonne machines deliver the combination of power and compact dimensions for Cooney’s highway construction and repair contracts.

Traditionally, the company had used backhoe loaders for much of its highway work. However, they have been replaced by the versatility and manoeuvrability of the compact wheeled excavators.

“Working in confined spaces and under temporary traffic lights, trying to manoeuvre a machine like a backhoe was a nightmare,” explained founder James Cooney.

“With the wheeled excavators, we can stay within the works to service the job. We can use the machine to service the site with stone, tarmac and other materials, not just for digging. We’re still one of the very few that operates like this, but the wheeled machines are absolutely key to our business.”

The two wheeled excavators are the latest models to have been supplied by Hyundai dealer HES Enterprises. The two companies have a built a strong relationship over more than 25 years of Hyundai supply and service and Cooney now operates Hyundai excavators from 1.5-8 tonnes operating weight.

“We like the personal approach that we get from HES. Like us, they are a family business and they are very easy to deal with,” said Cooney. “We also get an excellent level of service and aftercare.”

Formed in 1984, Cooney Construction was initially a sub-contractor to larger civil engineering businesses in the West Yorkshire area. As the company expanded, it moved to its Rochdale base and took on an increasing volume of work as a main contractor, to local authorities throughout the area.

WWW.RDR.LINK/CBC023 GOTO

Scottish crane rental company, Bernard Hunter, has taken delivery of its first LTM 1150-5.3 and put the newly-acquired machine straight to work, assisting in the construction of the Edinburgh Royal Military Tattoo grandstand.

The five-axle crane comes equipped with a 66m telescopic boom, which can be topped by a 10.8 to 19m double swingaway fly jib. When a seven-metre insert is added between the boom nose and the jib, a hoist height of 92m and a radius of 72m can be achieved.

The 150-tonner has low axle loads of 12 tonnes, making it possible for the unit to carry nine tonnes of ballast on public roads, enabling the crane to complete a considerable amount of work without the need for an additional vehicle to transport its counterweight.

Bernard Hunter’s managing director, Mark Rafferty, said: “We are delighted to take delivery of the LTM 1150-5.3. It is an extremely versatile mobile crane and a great addition to our fleet of Liebherr cranes.”

The growth of the company’s fleet does not end there, as Bernard Hunter also ordered an LTM 1300-6.3 at Bauma.

Established in 1946, Bernard Hunter Mobile Crane and Metal Recycling took delivery of its first Liebherr crane in 1995, an LTM 1050.4. Today, the company operates a fleet of mobile cranes ranging from 40 to 700 tonnes, as well as mobile tower cranes, spider cranes and truckmounted cranes.

Heidelberg Materials is investing in three Cat AP400 wheeled asphalt pavers through Finning UK & Ireland, in a move to reduce fuel burn and carbon emissions by up to 20% compared to existing models in its mixed fleet.

Scott Szafranski, national asset manager at Heidelberg, said: “This investment marks a significant step towards achieving our 2030 sustainability commitments as the Cat AP400s are incredibly fuel-efficient machines, needing less fuel and demonstrating a lower fuel-burn rate than we see across our fleet currently.

“Although this was driven by the fuel efficiencies promised by the Cat AP400s, we were also interested in the potential for enhancing productivity thanks to the manoeuvrability, agility and wide paving range of these machines. They surface a 2.4m to 4.8m screed and offer sub-2.5m transport width and sub-14 tonne weight, making them a highly versatile asset to both small and mid-sized sites.

The delivery of the machines is taking place over the summer, with each machine being sent to a different region to enhance the versatility and sustainability of infrastructure projects across the country.

Paul Walton, paving and compaction sales manager at Finning, commented: “This investment demonstrates why the Cat AP400 is popular in the UK market, reflecting the highly desirable fuel efficiency benefits of Cat products, backed by the Finning fuel promise. Features including exclusive advanced eco-mode and automatic engine speed control reduce fuel consumption by up to 20% which in turn, reduces carbon emissions and enhances sustainability across the company.

“Heidelberg Materials UK will benefit from the support of Cat-certified engineers, quick access to parts and condition monitoring through VisionLink telematics to preempt service needs, reducing the risk of costly downtime. With the combination of machine and service, we are confident that Heidelberg will be well placed to meet its sustainability targets and tackle the potential growth in the infrastructure sector proficiently for years to come.”

GOTO

WWW.RDR.LINK/CBC025

To help its customers meet changing regulatory requirements, Mecalac is adapting its entire range of dumpers to the new European standard EN 474, which came into effect last February. The company says the aim is to guarantee machine compliance while maintaining efficiency and ease of use in the field.

The TA, MDX and Revotruck ranges - 15 models in all - have been adapted to fully meet the new safety requirements. Every Mecalac dumper is now fitted as standard with features that enhance safety and ease of use, including hydrostatic transmission for smooth, controlled driving, side mirrors for improved visibility, an inclinometer to ensure safe tipping operations, additional side protection for the operator, in addition to the ROPS (for 6- and 9-tonne models) and a front-facing camera (except for the TA1 model).

because of the constraints imposed by the EN 474 standards, Mecalac has chosen to keep the front-dump TA9H in its catalogue.

While most manufacturers have withdrawn their cabless 9-tonne dumpers

To ensure compliance, the model has undergone specific development, incorporating structural modifications, the integration of a hydrostatic transmission and the addition of side guards. This approach meets the regulatory

In response to EN-474, Mecalac has updated its range of dumpers but maintains its offering of the cabless TA9H.

requirements while retaining the qualities that have made the TA9 a popular machine namely simplicity, reliability and robustness.

The TA9H is a safe, compliant solution, perfectly suited to the needs of those seeking a cab-free alternative for its ease of transport and its ability to operate in environments with limited height, without compromising safety or operating costs.

Because safety is nonnegotiable, Mecalac says it designs its machines to protect operators and their environment. This commitment is reflected in all its machines, and is fully reflected in the Revotruck: designed from the outset with particular attention to visibility, stability and ergonomics, it goes well beyond the requirements of standard EN 474.

Komatsu has introduced the new WA170M-11 wheel loader, expanding its wheel loader series in the 9-10 tonne operating weight range. This new model made its first appearance at Bauma earlier this year.

With an operating weight of around 10 tonnes, the WA170M-11 is seen as a versatile machine capable of handling a wide range of jobs, from demanding tasks as a multi-role loader, to performing typical earthmoving work.

According to Komatsu it has been developed in close collaboration with customers and distributors based on feedback. It features a powerful 96kW Stage V diesel engine and is designed for comfort, durability, and ease of maintenance. With its compact dimensions it facilitates quick and easy transport. Furthermore, a wide range of factoryinstalled options allows for customisation to suit almost any application.

The new WA170M11 can be ordered with two different loader linkages.

In addition to the

classic Z-kinematics, Komatsu is now offering its Tool Linkage kinematics, fitted on larger models, for the first time in this class. The Tool Linkage kinematics are suitable for heavy attachments that are changed frequently. This means that the machine can be used flexibly and with existing attachments for a wide variety of

tasks. The new loader can be supplemented with high-flow hydraulics, additional control circuits, tool management or a trailer coupling.

The new diesel particulate filter, which only requires replacement at 6000 hours, helps extend service intervals. The exhaust gas treatment is fully automatic, so work cycles are uninterrupted and productive. All maintenance points are centralised and easily accessible from the ground thanks to a hinged engine hood. As with all Komatsu compact wheel loaders, the cabin can also be tilted to quickly access all components. All important functions are displayed on the machine monitor and on the Komtrax fleet management system.

FOR MORE INFORMATION, PLEASE WWW.RDR.LINK/CBC027 GOTO