COMMERCIAL VEHICLE WORKSHOP

New rating scheme introduced to raise workshop standards

Also in this issue...

■ How to getthe most life out of your tools

■ Everythingyou need to know about battery testing with an oscilloscope

■ A look inside the process of tyre retreading

21 Stertil Koni helps Econ Engineering boost its vehicle maintenance with the installation of its column lifts.

23 Draper offers its advice and best practice tips on taking the best care of your tools, and the importance of this.

Choosing tools when working on trailers is paramount,

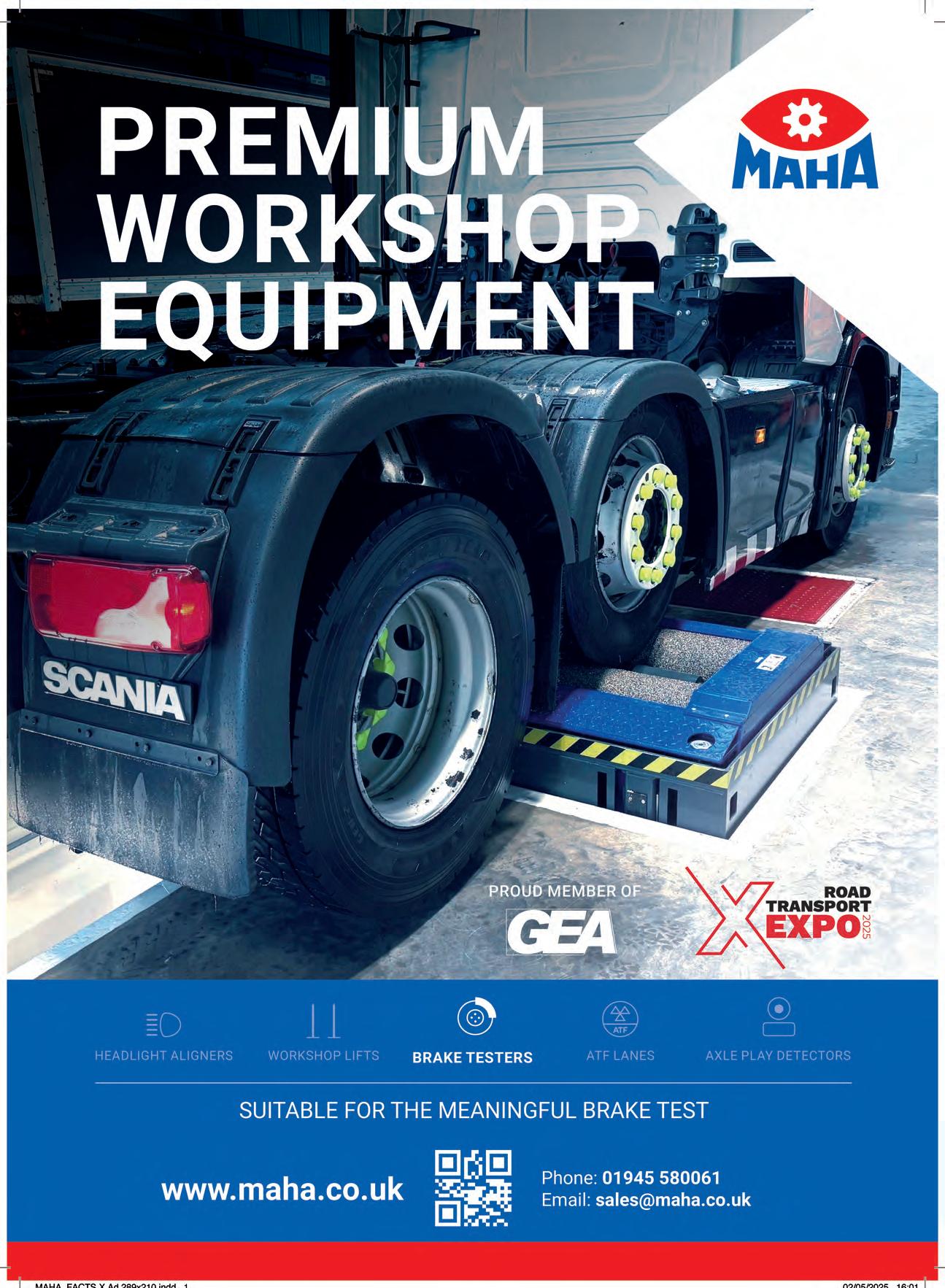

MAHA UK, Manchetts and Premier Pits collaborate on a new ATF lane for Manchetts Group’s Sleaford depot, featuring rising roller brake tester.

ISN Garage Assist are relatively new to the world of commercial vehicles, so consider this an introduction!

A look at the latest trends in commercial vehicle ADAS from Repairify’s director Martin Brown.

37 Want to find out how to test batteries with the oscilloscope? Then look no further than this article from Pico Technology.

40 With the new Knorr-Bremse diagnostics add-on to its ESI[tronic] workshop software, Bosch shares everything you need to know.

41 With the government and industry launching the new MPRS in April for workshops, Logistics UK shares its positive thoughts.

43 Durite helps S&B Transport adapt to new regulations with its new vehicle camera systems.

Over the past 14 years, the National Tyre Distributors Association has helped improve the safety of emergency roadside work.

Safety and operational efficiency are more crucial than ever and FleetIQ.ai shows us just how its responding to this.

Editor

FREYA COLEMAN

cvw@hamerville.co.uk

Group Editor

KIERAN NEE

Digital Manager

KELLY NEWSTEAD

Digital Assistant

LYDIA PROCTER

Advertising Sales Manager

MATTHEW BOASE

Group Manager

ROBERT GILHAM

Graphic Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Subscriptions

Commercial Vehicle Workshop is a business magazine for companies and individuals involved in all aspects of commercial vehicle servicing.

It is published 11 times a year and is available on free subscription to qualified readers.

Subscription rates:

UK £30 post paid

Airmail £99 post paid

Europe £70 post paid

To be removed from this magazine’s circulation, please call 01923 237799 or email circulation@hamerville.co.uk.

Printed by Stephens and George

Published by

HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts WD24 4YF

Tel: (01923) 237799

Website: www.hamerville.co.uk

Copyright © 2025

8,249

I'm writing this viewpoint from a lovely Preminer Inn hotel room after wrapping up Day One of Mechanex, PMM Live in Harrogate. If you didn’t already know, shame on you if you don’t, Mechanex is the dedicated trade show for our sister magazine, Professional Motor Mechanic. Speaking of shows, you’ll also find my writeup of the Commercial Vehicle Show in this issue. You might even be picking up this magazine at Automechanika Birmingham at the beginning of the month, or perhaps at the Road Transport Expo at Stoneleigh Park at the end of June. The CVW team will be exhibiting at the latter, and we’re already putting plans in place, and I hope to see many of you there (whilst the team navigates sharing an Air BnB with eachother).

“It’s essential to map out your time properly to ensure you squeeze every drop of value from the experience.”

So yes, it’s safe to say we’re deep in the thick of show season –and I, for one, couldn’t be happier about it. In case I haven’t mentioned it before, I absolutely love getting out there, speaking to as many of you as possible –readers, contributors, and industry pros alike. Trade shows are the perfect opportunity to do just that. Sure, they can be exhausting, with two or three long days packed full of handshakes, sausage rolls, pints, and as much coffee as a human body can safely handle. But they’re also a great way to reconnect with the team, catch up with familiar faces, and build new relationships along the way.

They’re also rich in learning opportunities, but only if you approach them with a plan. At the bigger events especially, it’s essential to map out your time properly to ensure you squeeze every drop of value from the experience. The conversations, demos, and insights are there; you just need to be ready for them.

So, consider this your nudge to close up shop for a day and attend at least one trade show this year. Whether it’s for the valuable knowledge, networking, or the exclusive show deals you won’t find anywhere else, it’s well worth the time. After all, how often do you get an entire industry under one roof?

Editor

■ Fifth month decline for LCV market. In April, light commercial vehicle dealers registered a total of 20,332 new vans reflecting a 14.9 per cent yearon-year decline according to data from the SMMT.

■ Mercedes Sprinter tops recall list of UK’s most popular vans. Data from Tempcover found that between 2020 and 2024, the van had 32 recorded recall incidents. This was followed by the Ford Transit with 13 and the Vauxhall Vivero also with 13.

■ Witham group announces new branding following Royal Warrant of Appointment. This new warrant underscores the continued trust and confidence in the lubricant company’s unwavering commitment to high-quality products, services, and corporate, social and environmental governance.

■ Knowles Logistics signs a new four-year contract with Atlante. The agreement extends a successful collaboration that dates back to 2015 and aims to reflect both company’s commitment to sustainability.

■ Exol Lubricants receives King’s Award for enterprise for international trade. It is one of 197 organisations nationally to be recognised with the award and marks the lubricant company’s growth overseas.

Maintenance Provision Rating Scheme, to be known as MPRS, rolls out officially to the wider industry today as regulators and industry trade bodies join forces to elevate standards in workshops and maintenance facilities.

The scheme, which originated from the industry’s call to reduce prohibition rates and foster more transparency for operators, is the product of a collaborative effort between eleven organisations. Steered by the Institute of Road Transport Engineers (IRTE), the scheme is brought to the industry by Logistics UK, SMMT, RHA, CPT, DVSA, DfT, Traffic Commissioners, BVRLA and NFDA, with Daimler Truck UK and DAF taking part in the MPRS pilot.

The MPRS rating system is split into five distinct levels each indicating the breadth and scale of facilities and workforce.

While a ‘qualified’ rating indicates that basic tools, equipment, and staff competencies are in place to meet minimum industry compliance standards, the advanced level, Platinum, is suited for operators at the cutting edge of maintenance technology and practices, ensuring full readiness for future vehicle trends, including electric, hybrid, and hydrogen-powered systems. The higher the

rating, the greater the confidence operators should have in the competences of their workshop and maintenance providers.

Workshops will apply for their rating through the MPRS portal managed by IRTE on behalf of the industry. MPRS assessment is based on a comprehensive audit criterion where participating entities will require to provide evidence to demonstrate their competencies across staff knowledge and facilities which covers workspace, test equipment, workshop tools, torque wrench, inspection facilities, electric/hybrid equipment and PPE.

While the qualified and bronze levels are based on independent assessment of selfdeclarations, silver, gold and platinum will be audited by approved auditors.

The maintenance provision rating scheme is a landmark step for the industry. For too long, there’s been a lack of clarity around workshop standards the MPRS changes that. It provides a clear, practical framework for both operators and providers, based on what’s truly needed in modern maintenance. By introducing a transparent, tiered system, the industry has help in raising the bar and ensuring safety, compliance, and professionalism are no longer left to assumption.

13 %

of fleets already own at least some second-hand vans, while 36 per cent plan to buy these vehicles by 2028. This is according to the 2025 Arval Mobility Observatory Fleet and Mobility Barometer.

63 %

of fleets are reporting customer demand as influential in their decision to switch to alternative energies, and the speed at which they do it. This data was found in Mobilising the Future of Fleets Report: 2025 Energy Edition, a report by Teletrac Navman.

57 %

of automotive workers said stress was their biggest health and wellbeing issue according to the industry charity Ben’s annual health and wellbeing report. 52 per cent sited poor sleep, 44 per cent anxiety and 41 per cent low mood.

27 % of companies can precisely measure their CO₂ output, revealing a growing disparity between data collection and actionable insight. This was found in the European Fleet Emission Monitor by alphabet.

FOR UP-TO-DATE NEWS, SIGN UP FOR OUR WEEKLY E-NEWSLETTER. SIMPLY SCAN THE QR CODE

“ We welcome the agreement between the UK and United States to reduce tariffs and strengthen trade ties. This is a positive step that brings much-needed reassurance to businesses involved in transatlantic trade, including many of our dealer members and their manufacturing partners. This deal represents a significant opportunity for the UK automotive sector. Lower tariffs will help enhance the competitiveness of UK-built vehicles in the US market, support long-term investment, and streamline the flow of goods across borders. We are optimistic about the benefits this will bring to dealers, manufacturers, and consumers alike. The agreement comes at a pivotal moment for the industry, which continues to face pressures from inflation, evolving regulations, and the shift to zero-emission vehicles. Greater certainty and a stable trade environment will be essential in helping the sector plan for the future.”

Sue Robinson, chief executive of the National Franchised Dealers Association.

“ The logistics sector will be intrinsic to delivering the boost to trade that has been promised from the US/ UK trade deal - our members will welcome the fact that a deal has been negotiated. We will be scrutinising the detail of the agreement in the coming weeks to identify the opportunities for growth that the deal should bring. After so much discussion and uncertainty around our trading relationship with the US, our members will appreciate the clarity and greater certainty that the agreement should provide. Businesses have been unsettled by the lack of clarity and consistency provided for traders since tariffs were announced: hopefully the agreement will lead to a period of greater stability.”ignore the issue for a few more years.”

Nichola Mallon, head of trade and devolved policy, Logistics UK.

Chiltern Distribution Ltd has seen a 1.5 per cent improvement in miles per gallon alongside a 2 per cent reduction in fuel consumption, thanks to an integrated fleet management solution from Webfleet.

Commercial brake experts febi argue that when it comes to brake discs, what’s good enough for the race track is good enough for the roads.

Ian emergency, every centimetre counts when braking. The quality of all brake parts installed in the vehicle is extremely important. To find out just how resilient febi brake discs really are, we subjected them to the ultimate endurance test.

On a commercial vehicle test track, the commerical vehicle brake disc febi 12731 was installed in Team Schwa bentruck’s race truck – a team which is sponsored by febi bilstein. With 1,150 hp and 5,000 Nm of

torque, the 5.5 tonne racing machine’s febi brake discs were pushed to the limits of their load capacity – and were heated to nearly 900 degrees celsius at their peak.

During heavy and repeated braking manoeuvres, the temperature of the brake disc is the critical variable. This is due to the fact that, during braking, the kinetic energy of the vehicle is converted into thermal energy through friction. If the brake disc becomes too hot, cracks can form and, in extreme cases, it can break. In order to keep the brake discs at a tolerable

temperature level in spite of this, they are normally water-cooled during racing. Water is sprayed through nozzles from the hub side into the internal ventilation ducts as required. During the load test this water cooling process was disabled.

For the test, a new brake disc, which had been used in races up until then, was mounted on the left front wheel and the febi 12731 brake disc was mounted on the right front wheel. During the test, the temperatures of the brake discs were measured with infrared sensors and recorded with telemetry software. The recorded data is displayed in the diagram. The braking processes can be recognised as vertical deflections. Maximum temperatures of 890 °C were measured, which was also indicated by bright glowing.

Throughout the entire test, the brake disc remained 40 °C cooler on average than the racing brake disc. Even at the maximum thermal load of 890 °C for the racing brake disc, the febi brake disc measured in at a temperature of only 735 °C.

This temperature difference of 155 °C is of enormous importance for the high loads of a truck race and can be the difference

between victory and defeat. If a brake disc fractures during the race, a pit stop is inevitable and the chance of one of the front places is lost. That is why, ever since this test, the truck racing professionals Steffi Halm and Gerd Körber have been confident that they can rely on febi‘s standard brake disc, which has proven itself under even racing conditions.

Three factors are responsible for the load capacity of a brake disc: the material, the material thickness, and the design of the internal ventilation.

The material that is generally used is cast iron with lamel lar graphite. Carbon, as well as silicon and other components such as manganese, chromium, and nickel, are also responsible for certain properties. Depending on the composition, elongation/ductility and tensile strength/ hardness differ significantly.

The material thickness of the friction surfaces is decisive for their ability both to absorb and release energy. The thicker the solid material of the friction surfaces, the smaller the temperature fluctuations all while the temperature resistance increases.

The design of the internal ventilation

pillars has a significant influence on the cooling of the brake disc. The maximum possible surface area improves heat dissipation. However, they also absorb compressive forces as soon as the brake pads grip. If the pillars are too small or improperly arranged, stresses and cracks can quickly form.

The excellent temperature behaviour of the febi brake disc can be attributed to the special material and design. The thickness of the friction rings, together with the optimal design of the cooling channels, allow for high operating temperatures without the formation of cracks. In racing conditions, this provides a longer service life and greater reliability. The febi brake disc has been fulfilling the expectations at every race weekend for several years now and has played a role in the success of Team Schwabentruck.

Although febi brake discs are made for the road, it is also effective on the race track. Or as Team Schwaben truck driver Steffi Halm says, “What works here, works 50 times for the road!”

Retreading grants a tyre a second lease of life and sometimes even a third. Here, Continental explains the process and both the environmental and economic benefits.

Retreading saves – or rather reuses –up to 70 per cent of the material in the tyre, in the form of the casing and part of the rubber. Compared to production of a new tyre, retreading requires some 50 per cent less energy, around 80 per cent less water and up to 70 per cent less crude oil. A retread also requires 50 kilogrammes less raw material on average, which likewise equates to a saving of as much as 70 percent compared to production of a new tyre. Overall, production of retreads generates around 30 percent less CO2 than production of new tyres. Two methods are employed here: hot retreading and cold retreading.

Cold retreading begins with an initial visual inspection of the used casing. Any casings unfit for retreading are already rejected at this early stage. Then comes a process called shearography. This optical, non-destructive test will identify any defects that are not visible from the outside − damage such as

belt edge separation, separation between the casing layers, air bubbles or moisture. Here again, defective casings that cannot be repaired are weeded out.

The casing is then buffed by using computer-controlled machines to strip off the old tread. Once any damage has been carefully inspected and assessed, it is time to repair the casing. This involves patching any nail holes and grinding rust off the steel cord. An unvulcanised bonding gum is then applied to the buffed surface in a computer-controlled process.

This is followed immediately by computer-controlled application of a prevulcanised tread strip on top. The tyre is now packed into a curing envelope and a vacuum drawn. It is then cured in an autoclave (a pressure chamber with a hermetic seal), causing the casing, gum and tread strip to bond. Vulcanisation occurs at a temperature of approximately 110°C and takes around four hours. Finally, the finished tyre undergoes a thorough inspection.

In hot retreading, the tread pattern is molded during the vulcanisation process at a temperature of approximately 150°C. The procedure is exactly the same as for cold retreading up to the point where the casing is repaired. The next step involves bead-tobead application of an unvulcanised rubber compound using a computer-controlled extruder. With this tread material applied, the casing is placed in a mold with the required tread pattern and vulcanised. Here too, the process finishes with a thorough inspection of the tyre.

Production of a new bus or truck tyre requires between 60 and 80 kilogrammes of rubber compound. A retread needs just 15 kilogrammes or so – roughly one quarter of the amount. And while producing a new tyre calls for 83 litres of crude oil, a retread uses up a mere 26 litres. That represents a reduction of two thirds. Overall, a

retreaded tyre consumes about a quarter of the raw material required for a new one.

Scientists have registered a new record high for the level of the greenhouse gas carbon dioxide in the atmosphere. For the first time since measurements began, the global monthly average carbon dioxide (CO2) concentration has exceeded 400 ppm. By opting to use retreaded tyres, haulage companies, vehicle manufacturers and consumers are actively helping to ensure that this trend progresses no further than necessary. This is because the greenhouse gas emissions from production of a retread are one third lower compared to a new tyre. At 100 kilogrammes of CO2 per tyre, that equates to annual savings of up to 500,000 metric tons of CO2

As the German Tyre Retail and Vulcanization Trade Association (BRV) points out, retreading truck tyres in Europe aligns well with the principles of a circular economy, benefits the environment and safeguards local jobs. To provide public and private stakeholders with a quantified understanding of the socioeconomic and

environmental issues at stake for Europe due to recent developments in the industry, management consultants EY (Ernst & Young et Associés) teamed up with representatives from the retreading industry to compile a study. According to the findings, retreading supports over 19,000 direct, indirect and induced jobs in the EU today.

FFollowing the acquisition and subsequent multi-millionpound investment in LKQ Digraph, CVW was given a look inside its impressive distribution centre.

ollowing its acquisition by LKQ UK and Ireland in July 2023, Digraph –now known as LKQ Digraph – is undergoing a remarkable transformation. CVW was invited to the heart of the action: a behind-the-scenes tour of the T2 distribution centre in Tamworth, a vast one million square foot facility that now powers the company’s bold ambitions in the commercial vehicle sector.

A new era for HGV logistics

With a multi-million-pound investment, LKQ Digraph is aiming to position itself as the UK’s leading distributor of HGV, coach and bus parts, while drawing on LKQ’s wider experience and capability to modernise the commercial vehicle aftermarket. Central to this strategy is a significant expansion of its branch network, including five new sites across the South and East of England by the end of 2025. These locations are a mix of greenfield branches and shared spaces with LKQ Euro Car Parts, designed to get closer to customers and respond faster to demand.

But it’s the integration into LKQ’s T2

logistics centre that’s arguably the biggest game-changer. So far, around 20,000 of LKQ Digraph’s fast-moving product lines have been brought into the site. These now benefit from overnight deliveries into branches and time-sensitive dispatches to customers – a development aimed squarely at reducing downtime for fleet operators.

An additional £200,000 investment has gone into installing heavy lifting equipment at T2, enabling the storage and rapid shipment of products weighing up to 100kg – including brake discs, clutch kits, and flywheel assemblies. This upgrade means even the heaviest components can now reach workshops quickly and safely.

I was lucky enough to be shown around the T2 facility by the LQK Digraph team, and it’s just as impressive as it sounds. We were shown a demonstration of the heavy lifting equipment, with health and safety being presented at the forefront of everything that goes on at T2. Journalists watched on as a member of staff at the facility effortlessly lifted stock that would have previously taken multiple members of staff to get off the ground, and that can now be integrated into LKQ’s logistics operation as a result.

During the day, LKQ UK and Ireland COO Tony Shearer shared insight into the rationale behind the expansion, as I was curious as to why it hadn’t been done before. “Trying to build an HGV logistics operation from scratch would be incredibly costly and inefficient,” he explained. “By integrating Digraph into our existing infrastructure –like T2 and our regional service centres –we’re leveraging scale to offer the marketleading service our customers need, without passing on excessive costs.”

Shearer added that this move was long in the making. “We’ve had an interest in Digraph for some time, but timing is everything. Now, we’re in the right phase of our journey to build this out properly.”

Mergers of this scale often come with risks, particularly around cultural integration and customer relationships. But LKQ Digraph leaders made it clear to me the importance of managing change carefully.

Commercial director Dave Dimbleby, part of the original Digraph leadership team, acknowledged the transition. “There was always a real entrepreneurial spirit at Digraph – that family-run, pick-up-the-

phone-and-help approach. The key now is to preserve that while benefiting from LKQ’s investment and capability.” This is something the team expressed was very important to them, sometimes making financial sacrifices for the sake of keeping the personal and family feel of Digraph alive.

He also highlighted how health and safety has dramatically improved under LKQ’s ownership. “It used to be a bit of a taboo subject,” he admitted. “Now, from the moment you drive into T2 and see the

WANT TO KNOW MORE? Make sure to scan the QR code!

sign saying, ‘Going home safe to your family is the most important thing’, it sets the tone. I sleep easier knowing our people have that level of support.”

The contrast between the old and new operating models was a recurring theme. “When you’re an independent business, every product sitting on a shelf is your own cash tied up,” said Shearer. “That holds you back from offering customers what they really need. Now, we have the flexibility and backing to say ‘yes’ more often.”

For the Digraph team, the transformation is both operational and emotional. “To take the business from where it was to a point where LKQ wanted to acquire us – and now to be integrated into something as advanced as T2 – is a source of real pride,” Dimbleby reflected, mentioning he teared up when the first ever order was completed.

From speaking to Dave, it was clear how enthusiastic he was about the new venture, describing himself as being ‘born in the back of a truck’, and it was also evident how this enthusiasm for CV infects other members of the team.

With its new capabilities and infrastructure firmly in place, LKQ Digraph is poised to scale its service nationally. The Sunderland branch opening earlier this year set the tone, and the upcoming launch in Orpington signals momentum.

By combining deep sector expertise with LKQ’s logistics power, the company aims on delivering on its promise: faster parts, better service, and a future-ready HGV proposition for the UK aftermarket.

Premium ice cream business, Jude’s Ice Cream has turned to CoolKit –leading specialist in temperature-controlled van conversions – for over six years. CVW hears more.

Widely recognised for its ‘delicious stripy tubs of joy,’ Jude’s Ice Cream has become a celebrated nationwide brand since launching in Hampshire in 2002. Today, its fleet of vehicles travel the roads of the UK supplying its range of ice cream flavours and frozen lollies to a host of major supermarket chains, as well as scores of independent retailers, cafes and restaurants.

Given the extremely chilled nature of Jude’s produce – and the company’s commitment to its certified B Corp status –its transportation requirements are very bespoke and CoolKit has been expert at meeting these needs since 2019.

Jude’s needed two temperature-controlled environments within it vans – a freezer for the ice cream and lollies, and an ambient temperature to ensure its cones and waffles remain fresh. Its fleet of vans are fitted with a Hubbard Zer0° fridge unit, featuring Road & 1-phase standby capabilities and running on direct (engine) drive.

The business benefits from CoolKit’s payload, achieved through the use of light, strong materials that maximise vehicle productivity.

Conversion time

CoolKit’s lightweight van conversions, which are up to 100kg lighter than competitor models, have proven to be a game-changer for businesses like Jude’s Ice Cream. This weight advantage allows companies to transport more goods per trip, reducing both operational costs and its carbon footprint. Additional bespoke features for Jude’s fleet include a movable mid-bulkhead with straps, wheel box flaps, strip curtains, an Orbcomm Euroscan

temperature recorder and printer, LoadLok 1806 load-securing track, and a grey GRP sheet floor with an anti-slip coating.

CoolKit has recently delivered a Ford Custom V710 MY2024 Panel Van L2 H1 and Citroen Relay MY2024 Panel Van L3 H2.

Kim Elliott, Jude’s head of logistics, said: “We choose CoolKit because it understands the unique needs of a growing ice cream company like ours. CoolKit’s expertise in temperature-controlled vans ensures that our ice cream reaches our customers in top condition. The conversions totally align with our brand’s requirements.”

Jude’s produces a range of around 50 ice cream and dairy products at its manufacturing base in the village of

Twyford, near Winchester. It sells a vast variety of flavoured ice creams in an assortment of tub sizes, as well as Little Jude’s Lollies, indulgent stick bars and even single pot and multipack ice cream made especially for dogs.

The business is proud to be a certified B Corp that supports community and charity events with a focus on children and young people. Jude’s is also dedicated to environmental, social and governance – a set of standards measuring a business’s impact on society, the environment and how transparent and accountable it is.

Jude’s has reduced its carbon intensity by 31 per cent since 2020 which is over halfway to its 43 per cent reduction target by 2030. All of these values run parallel to those set out by CoolKit and over time the relationship between the two has grown stronger by the year.

Kim said: “Our dealings with CoolKit have been great. The team is responsive, knowledgeable, and always goes the extra mile to ensure our needs are met.

“We are happy with our collaboration with CoolKit and appreciate the support it gives in helping us deliver our products in top condition, while increased payload means we make fewer trips.”

Mark Beaton at CoolKit added: “If a business ever needed its refrigerated delivery vans chilled to critical temperatures, it has to be an ice cream maker. We worked closely with Jude to meet their specific requirements, which included creating temperature-controlled environments capable of maintaining a precise range of +0° to -20°C whilst maximising payload capabilities.

“Every aspect of the conversion was designed to ensure their ice cream is transported in optimal condition, aligning with their high standards and operational needs.”

CoolKit continues to set the standard in the refrigerated van industry with its lightweight conversions that maximise payload capacity and boost operational efficiency.

UK’s largest road transport event. Held at the NEC Birmingham, this year’s show welcomed 13,016 visitors and over 250 exhibitors, signalling a bold new direction under new ownership by Nineteen Group. CVW was there at the NEC, so is here with the details.

In a significant development, Nineteen Group officially became the owner and organiser of the CV Show on the eve of the event. Having previously managed the show on behalf of the SMMT and RHA since September, the transition grants Nineteen Group full control over the show’s future direction, investment, and growth. Speaking at the event, show director Mike Costain shared with me the group’s vision:

“We now steer the direction of the event. We’re investing in data, marketing, and re-engaging key manufacturers. The industry wants this show to succeed, and we’re determined to deliver.”

That investment is already showing results, with an increase in exhibitor and visitor numbers and a revitalised show floor buzzing with innovation, energy, and purpose. Whilst the company still has a long way to go to return the show to its former glory, I believe this to be a step in the right direction.

One thing that was highlight at this year’s CV Show was the scale of the sector’s decarbonisation challenge –commercial vehicles account for 36 per cent of road transport CO2 and 12 per cent of the UK’s total emissions. But it also showcased the opportunities, as manufacturers, policy makers, and infrastructure leaders came together to drive progress.

Key product launches from Renault, Farizon, ISUZU, and others demonstrated the sector’s pivot toward electrification. Notably, Renault Trucks returned to the show after a 12-year absence, marking a renewed engagement with heavy vehicle OEMs. Meanwhile, Ford UK revealed that 1 in 4 of its vans will be electric by 2026.

However, the numbers show there’s still a long way to go –only 6.3 per cent of new vans are electric today, with HGV decarbonisation lagging at just 0.5 per cent.

Policy leadership from Mike Hawes (SMMT) and Chris Ashley (RHA) opened the show with calls for faster action and strategic investment. Both emphasised the need for grid infrastructure, affordable energy, and clear regulatory pathways to support operators in making the transition.

“We need consistent planning policy and lower energy costs,” said Hawes.

“Four public HGV chargers across the country is simply not enough.”

Ashley introduced the RHA’s fivepoint roadmap covering cost, infrastructure, vehicle performance, skills, and mindset, warning that the shift will require up to £100 billion in investment. This followed along with the show’s invested interest in the future of the industry, the NEC flooded with AI, telematic and EV centred exhibitors, setting the tone for the three days.

At the EV Café Village, fleet operators, infrastructure experts, and local authority leaders shared their real-world experiences in transitioning to electric fleets. Discussions went beyond vehicles, addressing the critical role of energy planning, cultural change, and depot upgrades.

Local authority speakers from Oxford, Islington, Nottingham and others framed fleet electrification as a matter of public health and sustainability, not just regulatory compliance.

Success stories like the Battery Electric Truck Trial (BETT) and the ZEHID programme, backed by Innovate UK, offered encouraging proof points, with over 230 zero-emission trucks already on order.

The heavy-duty segment remains the sector’s most pressing challenge. Despite more than 30 models now available, uptake is slow, hampered by a lack of charging infrastructure and uncertain total cost of ownership.

Volvo Trucks’ Amy Stokes was candid: “Battery electric trucks are ready –we’ve had them in use since 2019. What’s missing is the infrastructure and support to scale deployment.”

With only four public HGV chargers operational across the UK, major investment in depot upgrades and charging hubs remains an urgent priority.

When at the show, I spoke with Mike about the HGV hurdle the Nineteen Group has faced and this is what he had to say:

“We aim to be representative of the full market –both the heavy and light commercial vehicle sectors. We’ve started reengaging key players like DAF, Mercedes, Daimler, and Renault. Renault Trucks, for example, is here for the first time in 12 years. This is just the beginning. We’re combining that momentum with our work on the light vehicle side to make the show more inclusive and relevant to the entire sector.”

While reflecting on this year’s success, Mike Costain and his team are already looking forward. Planning for future additions is underway, with ambitions to re-establish strong truck manufacturer presence and create a UK equivalent of IAA, fully representative of the sector’s breadth and ambitions.

“We’re aiming to build an event that’s number one in the UK market,” said Costain. “This show should be a celebration of the commercial vehicle industry –not just a trade event.”

When speaking with Mike about the future of the show he also explained that “planning usually starts around three months before the current event is delivered. One of our main goals is to embed the larger truck manufacturers back into the heart of the show. We're also looking at being more technology-driven in how we structure the exhibition.”

With continued collaboration from the SMMT, RHA, and the wider sector, the CV Show under Nineteen Group’s leadership is poised to meet that goal –and then some. So, let’s hope they deliver!

Econ Engineering has boosted its vehicle maintenance with Stertil-Koni column lifts.

Econ Engineering Ltd – a leading manufacturer of winter and road maintenance vehicles – has boosted efficiency and safety at its busy Halesworth service depot by upgrading to a set of Stertil-Koni mobile column lifts.

Previously reliant on a fixed platform lift, the team at Halesworth sought a more flexible solution to keep pace with their evolving workload. By investing in StertilKoni’s powerful ST1075FSA mobile columns, Econ has gained the freedom to easily adapt its workshop layout for different vehicles and servicing tasks, while enhancing overall safety for their technicians.

Built for demanding daily use, each mobile column offers a robust 7.5-tonne lifting capacity, combining for an impressive 30 tonnes overall – ideal for Econ’s heavy-duty gritters, de-icers, snow ploughs, and highway maintenance

vehicles. The ability to safely and efficiently lift these vehicles ensures quicker turnaround times, helping to keep essential services moving through even the toughest conditions.

One of the key advantages for Econ’s technicians is Stertil-Koni’s ebright Smart Control System. Featuring touch-screen operation, the ebright system allows the lifts to be controlled individually or in unison, streamlining the servicing process and minimising downtime.

Safety and reliability are at the heart of the ST1075FSA design. Each column features an independent mechanical locking system and precision synchronisation technology which aims to ensure smooth, accurate lifting at all times. With a rapid lifting speed of just 75

seconds to a height of 1.85 metres, technicians can complete tasks faster without compromising on safety.

The cabled mobile columns are powered by a standard 415V supply and use heavyduty communication cables to guarantee strong, consistent connectivity. Practical design features, including synthetic runner wheels and an integrated hydraulic pallet truck mechanism, make repositioning the columns quick and effortless.

Econ Engineering’s investment in Stertil-Koni’s mobile column lifts underlines their commitment to providing safe, high-quality vehicle maintenance services and ultimately keeping roads safe and operational during cold weather and throughout the rest of the year.

Automotive tool specialist Draper is here to offer its advice on taking the best care of your tools.

In the commercial trade, your tools are investments that can directly impact the quality, efficiency and safety of every job undertaken. Yet in busy workshops across the country, the proper maintenance and careful selection of the right tools can often take a back seat to the daily rush of service and repair work.

Taking proper care of your tools can sometimes seem like an extra job for a commercial vehicle mechanic’s already hectic workload – but the truth remains that a well-maintained toolkit is about more than simply preserving expensive equipment. It's about maintaining professional standards and ensuring consistent, reliable results for every customer who entrusts their vehicle to you.

The saying ‘a poor workman blames his tools’ might be familiar, but in the workshop, even the most skilled technician can be hampered by poorly maintained or inappropriately used equipment. From precision diagnostic tools to basic spanners, each instrument in a mechanic's kit requires specific care and correct usage. The initial investment in quality tools, while sometimes substantial, pales in comparison to the potential costs of repeated replacements, damaged vehicle components, or worse, workplace injuries resulting from tool failure.

When you’re using your hand tools every day, it’s essential to invest in the best quality, make sure you’re choosing those made for heavy duty, commercial use. A lifetime warranty on hand tools can be a good indication of their quality.

“From precision diagnostic tools to basic spanners, each instrument in a mechanic's kit requires specific care and correct usage.”

Keep an eye on the condition of your hand tools. Always inspect your tools for wear and tear. Worn spanners can slip off nuts and bolts, potentially stripping them or damaging the surrounding area. This not only increases repair time but also raises the risk of injury. Worn spanners should always be replaced, but a ratchet’s mechanism or breaker-bar end can simply be replaced, giving it a new lease of life. Torque wrenches are indispensable, but regular calibration is essential to maintain accuracy and prevent any issues which could lead to overtightening. After use, always wind them back to their minimum setting as this maintains their accuracy.

‘Buy cheap, buy twice’ doesn't always mean spending a fortune or choosing the most expensive brands. But you should choose wisely from reputable sellers with brands you trust. Conduct a little research before making online purchases to avoid lower quality or even fake tools. Look out for the brand being embossed on the tool and packaging that clearly states compliance with industry standards.

When dealing with heavy lifting in the commercial vehicle workshop, it’s crucial to check the weight and size limits of your equipment to make sure it’s up to the job.

Trolley jacks are essential, make sure to select the appropriate heavy lifting model based on the vehicle's weight and access requirements. Always inspect the jack before use and adhere to the manufacturer's maintenance guidelines. Regular greasing is necessary for optimal operation.

clutch, timing belt, or gearbox itself. For commercial vehicles, Draper offers a 1,000kg hydraulic transmission jack.

One of the most common examples of misuse in the workshop is using something other than the correct breaker bar to apply extra force to a corroded fixing. This approach invariably damages ratchets and sockets, increasing the risk of slipping. NEVER slip a pole over the handle to extend it! Always use the correct tool for the job – it saves time and money in the long run.

Power Tools require proper maintenance to perform at their best. For cordless models, make sure you keep them regularly charged, but don’t leave them on charge permanently, remove from the charger once full to avoid over charging. You should also try to avoid letting the battery go completely flat before charging.

Never work under a vehicle supported solely by a jack – always use axle stands, primarily for safety but also to ensure you don’t damage your jack. Look for the appropriate height and weight, for example, the Draper Expert range features heavy duty 20 tonne axle stands suitable for use with heavy goods vehicles, trucks and buses.

Always use a gearbox support to safely support the engine or gearbox during repair and maintenance, especially when removing or replacing components like the

Don’t overwork your power tools, if a tool seems like it’s getting too hot from continuous use, give it a break. As with garage equipment, make sure you follow the manufacturers guidelines for maintenance, some tools may require lubrication for example.

Tool storage is especially important to consider when it comes to power tools, you want to avoid extremes of temperature or any kind of damp, moist environment. A tool chest is a great place to store your tools when not in use, as this helps avoid dust and debris. Draper’s Bunker collection of tool storage solutions makes a great, versatile option for organising your workshop.

A regular cleaning regime for your tools, whether hand or power, is one of the best and simplest ways to ensure they’re well maintained. It may seem like extra work, but it really does help avoid premature wear and tear and ultimately tool failure.

Ensure that your tools are free from oil, grease and dust once you finish a job – don’t put it off as this only makes the cleaning job harder. You can use specialist wipes for this, such as Draper’s Hard Graft range, which can remove everything from sealants to oil. These kinds of wipes are often antibacterial too, helping protect you as well as your tools. Always ensure your tools are dry before you store them too.

Some garages may want to consider investing in an ultrasonic cleaning tank. Not only are ultrasonic tanks great for cleaning intricate parts like injectors, but they can be very effective at removing dirt from some tools, leaving them sparkling clean again (just make sure before you put anything in an ultrasonic cleaning tank, that you’ve checked it’s suitable).

Investing time in tool maintenance isn't just about protecting your equipment, it's about protecting your reputation and your future. By establishing proper tool care routines, making informed purchasing decisions, and using equipment correctly, you’re not just maintaining tools, you’re maintaining high standards in the workshop.

Make sure to scan the QR code!

BPW argues that you shouldn’t settle for second best when it comes to choosing tools for working on trailers.

When it comes to safe, efficient trailer maintenance, using the correct workshop tools is essential. BPW special tools are said to have been specifically designed to complement BPW running gear? Providing workshop technicians with quality tools means they can service and maintain trailers easily, helping to minimise downtime and extend the life of a trailer.

The right tools are key to keeping your fleet moving. From axle servicing to brake

maintenance, BPW special tools aim to deliver reliability and precision for every task. The BPW spindle nut socket, for example, says to ensure an accurate torque application. While the hub puller aims to allow for safe hub removal without damaging other components.

It’s also worth remembering, air tools should never be used on BPW spindle nuts or bolts, on any BPW axle, as this could lead to a damaged axle and result in costly repairs.

When you’re working with quality, don’t settle for tools that are second best. While it may be tempting to opt for cheaper alternatives, using non-genuine tools to service BPW running gear can come with significant risks. Counterfeit tools may look similar but could compromise the integrity of your BPW running gear, increasing the likelihood of dangerous malfunctions or safety risks jeopardising the vehicle or the well-being of a driver.

With over 250 spare parts distributors across the UK and Ireland, the BPW aftermarket parts network aims to ensure

Air tools should never be used on BPW spindle nuts or bolts, on any BPW axle.

that you're never far from the support you need. From c-clip installation tools to slack adjuster pullers, BPW aim to provide quality tools to assist technicians in your day-to-day service and maintenance tasks.

BPW offers an aftermarket training course for spare parts distributors. With up-to-date information and a good understanding of BPW products, including the special tools range, distributors can confidently advise and support their customers.

When you choose BPW, you’re not just choosing quality products; you’re becoming part of a network that’s committed to optimising maintenance, improving operations, and ensuring your investment goes further.

According to the DVSA’s guide to maintaining roadworthiness: commercial goods and passenger carrying vehicles, it is expected that every safety inspection will include a brake performance assessment using either a roller brake test, a suitable electronic braking performance monitoring system (EBPMS) or a decelerometer with temperature readings.

In the guidance, DVSA states that conducting a laden brake test using a calibrated roller brake tester is the “most effective method of measuring individual and overall braking performances”.

MAHA UK’s MBT 7250 commercial brake tester includes a rising roller bed

The ATF lane and rising brake rollers were essential at our Sleaford depot to make sure we have a onestop-shop for our customers.

MAHA

UK, Manchetts and Premier Pits collaborated on new ATF lane for Manchetts Group’s Sleaford depot – featuring a rising roller brake tester.

option. It can be raised by 250mm; doing so simulates axle loads of up to 10 tonnes and offers a reliable alternative to traditional laden testing when external loading isn’t possible.

Space constraints, time inefficiency, availability of load equipment, safety risks, operational restrictions and vehicle suitability are all possible reasons for this –but, nevertheless, staying compliant with the latest legislation is paramount.

At Manchetts Group’s Sleaford depot, it has taken a major step forward towards this goal with the installation of a new ATF lane. Delivered in partnership with MAHA UK and Premier Pits, the project has highlighted the importance of collaboration, namely teamwork, leadership and speed.

Manchetts is a family-run business and a Cambridgeshire top 100 company, specialising in HGV and LCV vehicle service,

repair and roadside recovery. Beginning as a single site, the company matured and stretched its presence across Cambridgeshire, Suffolk and Lincolnshire – the acquisition of new HGV workshops, previously MAN Sleaford, its latest strategic acquisition.

This was a significant milestone and boost to Manchetts’ business plan of expanding along the A1 corridor –complementing the purchase of its awardwinning Peterborough site in 2020.

Manchetts business development manager, Lindsay Powell, explained why the installation of a new ATF lane was a vital investment: “As a business, we are always looking to create the perfect partnership with our customers. The ATF lane and rising brake rollers were essential at our Sleaford depot to make sure that we have a one-stop-shop for our customers, new and existing.”

Branch manager, Aaron Woods, concurred – adding that the need for an ATF lane became clear as the demand for brake testing and vehicle inspections increased: “We’ve undergone a lot of changes since opening in February 2024,” he said. “We needed to cater for both our regular MAN customers and growing multi-brand inspection requirements. This included meeting new DVSA standards on meaningful brake testing.”

MAN Sleaford was no stranger to MAHA UK; prior to Manchetts assuming control of the site, there was a 17-year-old MAHA brake tester installed. Bullishly, Aaron revealed the IW7 had “never let us down” and was “bulletproof”. He added: “The backup from MAHA UK has always been brilliant too.” This was echoed by Lindsay: “MAHA’s equipment is proven, high quality and stands the test of time,” she said, “so we didn’t hesitate in proceeding with MAHA with this latest project.”

This project had to be undertaken without disrupting Manchetts’ day-to-day environment, a challenge that required

Communication with MAHA UK and Manchetts was key –once the pit is in, it’s in for good. Precision matters.

“careful coordination, clear zoning and experienced contractors”, according to MAHA UK’s workshop equipment specialist, Louis Tunmore. That is where Premier Pits came in; with 35 years’ experience in designing, manufacturing and installing prefabricated vehicle pits to partners globally, Manchetts was in safe hands.

The installation team and workshop staff worked harmoniously, enabling the smooth installation of a DVSA-spec ATF pit, one that was deeper than normal and with strict entry and exit specifications.

Premier Pits marketing manager, Matt Dilley, explained how this particular part of the process unfolded: “We know that local conditions, especially in Lincolnshire where unstable ground can cause cave-ins, can be problematic, but our team managed the dig and installation without delays.

“Communication with MAHA UK and Manchetts was key – once the pit is in, it’s in for good. Precision matters.”

At the heart of the lane, of course, is the MBT 7250 braker tester with the hydraulic rising roller bed option. As mentioned, unlike traditional systems that use a trailer or loading weights, this technology simulates axle load by lifting it.

Louis dived into the technology: “This generation lifts the axle rather than pulling it down. There’s a restraint system in place to keep the vehicle stable during the test, ensuring the added weight is pushed into the axle rather than lifting the whole truck. This complies with DVSA requirements for a meaningful brake test – 65 per cent of gross axle weight must be replicated.”

The result? Aaron revealed that this method was “quicker and safer than loading the trailer with weights and much easier to operate”. He added: “Our technicians, both seasoned and newly qualified, have adapted quickly and collaboratively to the new equipment.”

Safety, compliance and DVSA collaboration

Safety and regulatory compliance were critical from day one. The DVSA was involved in the planning phase, offering input to avoid issues that could delay final approval. CCTV coverage, pit safety interlocks and minimum spacing regulations were all part of the design and walk-through inspections.

“The DVSA has hard-and-fast rules for ATF lanes,” Louis explained. “It is vital that their operatives are safe. That means no trip hazards, no unnecessary obstructions and no delays. With Premier Pits and MAHA both working closely with DVSA and the Garage Equipment Association (GEA), the lane met the requirements.”

An informal DVSA site visit ahead of the official sign-off gave Manchetts a head start – Lindsay said: “A few minor tweaks were needed, but that’s the benefit of working with experienced suppliers.”

The lane includes, not just the rising roller brake tester, but also axle play detectors, headlight alignment tester and radius plates to support Class 7 vehicles –everything needed for a full ATF lane. All of this equipment was installed within the existing workshop building, meaning no structural extensions.

“The finished pit is bright, safe and functional,” said Matt. “It’s a textbook installation!”

Staffing has also been a priority at the Sleaford site, ensuring the right balance between experienced professionals and new talent: “We have 14 technicians and 5 support staff,” said Aaron. “We also have apprentices and recently qualified staff who bring energy and a willingness to learn. It’s a great blend when introducing new technology, like the rising roller brake tester.”

With DVSA final sign-off imminent, Manchetts is already looking ahead: “We’ve had the DVSA here for the last checks, and we’re hopeful that we can announce our ATF lane opening very soon,” Lindsay said optimistically. “Having this facility in place will mean quicker turnaround times for customers and full control over compliance.”

For Louis, the Sleaford project is a blueprint for how to do the job right: “Any partner we work with has to know garage equipment inside out. We don’t just use local builders; we use professionals, like Premier Pits, because our reputation and our clients’ compliance depend on it.”

Ultimately, this is a case study – a great example – in what happens when experience, professionalism and teamwork come together.

Relatively new to the world of commercial vehicles, CVW hears about what ISN Garage Assist is bringing to the world of workshop equipment.

ISN; three letters that are not well known in the world of Commercial Vehicle maintenance right now but it’s a business that has plenty to offer the sector. ISN GarageAssist, formally Hofmann Megaplan UK, has a strong reputation in the car and van market for high quality, ergonomically designed workshop equipment, incorporating the latest innovations.Recent focus has been on developing a range of equipment and services for commercial vehicle workshops, with the launch of a new, specialist commercial vehicle division.

Commercial vehicle range

Headed up by Steve Barnfield, who has a proven track record in this sector, the equipment range now available consists of mobile column lifts, 2 and 4 post lifts, floor and surface-mounted roller brake testers, shaker plates (joint play detectors), emissions equipment, a headlamp tester, a brake disc lathe, and a comprehensive lineup of tyre and alignment equipment. With an in-house workshop planning facility and nationwide team of experienced equipment installation and maintenance engineers, ISN Garage Assist is now extremely well-placed to service the evergrowing CV market.

When we first started discussions, it was important that we focused on engineering quality, functionality and whole-life costs.

The thinking behind it

Supplied under the company’s own premium Luxus brand, alongside Balco and Hofmann Megaplan, the products carry industry-leading warranties and are fully installed and maintained by factory-trained technicians.

Steve is keen to highlight the thinking that has gone into the product range; “We didn’t want this to be just another ‘me too’. When we first started discussions, it was important that we focused on engineering quality, functionality and wholelife costs. For example, all our Luxus commercial vehicle column lifts benefit from a three year parts and labour warranty.”

“Our Luxus heavy duty CV roller brake testers and shaker plates are designed and manufactured in Germany, by AHS Prüftechnik, a specialist manufacturer of testing equipment for over 60 years. Still family-run, it’s now a global business with a product range that includes numerous products, from brake test benches to special test equipment for low loaders and excavators.”

He continued, “Our Luxus brake testers carry full DVSA and GEA approval for testing of HGVs, PSVs, Trailers, Class 4, 5 and 7, ATF testing, ATL testing and they are connected equipment approved. They’re designed to meet the highest operational demands; for example, they feature two specially designed and reinforced high performance, heavy duty 15kW flat gear motors, double chains and special bearings to ensure they easily manage the highest demands. Once again they benefit from a three year warranty, covering the rollers, chains, motors and gearboxes, sensors and electronic boards! Not every supplier can claim that.”

Repairify’s director Martin Brown discusses emerging trends in ADAS for commercial vehicles.

The world of Advanced Driver Assistance Systems is undergoing a rapid transformation, and it is being driven by cutting-edge technologies that are reshaping how commercial vehicles perceive and respond to their surroundings. In response to this everchanging technology, I thought it would be a good idea to discuss the ADAS technology trends I am seeing in the sector.

The first trend is the move from passive systems to active. Traditionally, in the CV sector, the ADAS systems on vehicles have relied heavily on passive systems such as proximity sensors. These sensors have been designed and developed to detect the presence of objects near the vehicle, but they provide very limited insight as to what the object is and the way it is moving. This is leading to passive systems being phased out and replaced with active sensor technology. These systems are especially useful in cities because they can actively identify and track both stationary and moving objects in real-time. An example of this is that the active system can distinguish between a

stationary object such as a bollard, or a cyclist crossing the road, which allows the vehicle to react appropriately, whether that is by alerting the driver or initiating emergency braking. This improved situational awareness significantly reduces the risk of collisions in urban environments.

The second trend we are seeing is the use of AI cameras. These cameras use the AI to continuously learn and adapt to the routes taken by the vehicle and the sites being visited. The system’s continuous learning helps it build an understanding of the environment, which means that it can better anticipate potential hazards as well as changes to traffic patterns and road signs, to name a few.

“These systems are especially useful in cities because they can actively identify and track both stationary and moving objects in real-time.”

The AI cameras are an asset to drivers, but they also work in tandem with the radar systems mounted on the front and side of the vehicles. The data that comes from both these systems helps create a detailed map of the vehicle’s surrounding to help provide the driver with an early warning system for potential dangers that could range from a car driving into the vehicle’s blind spot or a worker stepping out onto the road to get from one side of the depot to the other.

The final trend is driver facing cameras, which you might have seen on the Ford Mustang Mach-E. This system is a crucial safety feature in both cars and commercial vehicles as it monitors the driver’s alertness and attention in real time.

By using advanced computer vision, the system can detect signs of fatigue such as drooping eyelids or frequent yawning. In addition, if the driver takes their eyes off the road for too long, due to a distraction or drowsiness, the system issues an audible or haptic alert to prompt them to refocus. This proactive approach significantly helps enhance overall road safety.

ADAS technology is in a constant state of evolution, and it is important that technicians stay up to date with the relevant technology by doing their own research or undergoing the necessary training to ensure they have the requisite knowledge and skills to understand how the systems work and the benefits they deliver.

For all the latest industry news, business advice and technical guides from the trade magazine for CV servicing and repair professionals

Everything you need to know about battery testing with an oscilloscope from Pico Technology’s Ben Martins, automotive application specialist.

The humble battery. It’s in everything. With different chemistries, it’s powering everything from your toothbrush to 700T mining machines and everything in between. Ignoring all the fancy lithium batteries, the humble flooded battery is still found at the heart of many vehicles and machines.

As the demand for technology in modern vehicles increases, so does the demand on the low-voltage system. With increases in the number of ECUs, cameras, infotainment systems, OTA updates and more, it’s no wonder that the battery gets a hard time.

Over the years, many different types of battery testing techniques have emerged. Ultimately, however, to test batteries properly, you end up having to destroy them. Not ideal, especially if there was nothing wrong with it to start with, and the customer was in for a winter check!

When it comes to testing batteries on a 24 V system, the traditional testers might only let you test one battery at a time, which takes more time and introduces variability, or combine both batteries for an overall test. With this situation comes the question: Which battery is at fault?

We do know that batteries give up their status most when they are put under load. I remember testing batteries with the old drop testers where, if the bendy bit of metal glowed a nice orange colour it meant the battery was good. Fortunately, technology and common sense prevailed; it’s not like hydrogen and sparks are a bad thing, right?

Modern testers use complex algorithms,

pre-existing data comparisons and clever frequency testing to determine a battery's state of health and charge. In my experience, I’ve seen batteries I know to be bad would sometimes still pass this test, and only when loading the battery would you see it fail. Existing testers, such as carbon pile testers, give much better results off the car, but we could make use of the best test bench we have, the engine itself.

By using the effects that cranking has on a battery, we can start to build a picture of a battery's health. So, how does an oscilloscope help? Well, the benefit of, say, a

“By observing how both battery voltage levels react to cranking, we can get an idea of the battery's health”

4-channel scope like a PicoScope is that we can now measure both batteries at the same time. In a simple test, you can measure across each individual battery voltage and the overall current that is being drawn from both batteries. Caution – do not try this test if using a common ground scope, especially if you suspect a fault.

By observing how both battery voltage levels react to cranking, we can get an idea of the battery's health. In an ideal world, both batteries should be the same. Using the settings file from the guided test, we can make some measurements.

By utilising the time rulers, the mean of the signal between the time rulers can be displayed. On the OCV (open circuit voltage), we see that battery two (red) is slightly higher, indicating that the state of charge is higher than battery one (blue).

Using the zoom tools, we can highlight the point where cranking starts and the batteries are put under the most load. Both batteries drop to pretty much the same, indicating they are contributing equally to the power demand from the starter motor and therefore cranking the engine.

Once the engine has started, the batteries begin to recover, and then, as charging starts, we can see how each battery reacts. In this instance, battery one (blue) seems to be recovering quicker than battery blue. This absorption rate could be

“By using the fourth channel, we can include some math channels to show us even more detail, including the voltage drop.”

an indicator of poor health. In this example, they are still fairly close, so I would be happy that all is OK here and there are no reported issues with starting.

Using a 4-channel scope, though, we still have a channel free. By using the fourth channel, we can include some math channels to show us even more detail, including the voltage drop across the link lead. This test can be performed with common-ground scopes.

In PicoScope 7 automotive software, the guided tests set everything up for you. Let's talk through the setup. Using the image, the blue channel is connected to the positive of battery one and the negative of battery twp, so it provides the total voltage for both batteries.

The red channel is connected to the negative terminal of battery one and the ground of battery two, giving the voltage of battery two before the link lead. The green channel is measuring from battery two positive to the negative terminal of battery two, therefore measuring the total voltage of battery two.

Using subtraction, we can calculate the voltage of battery one and the voltage drop across the link lead. For battery one, if we subtract the red channel from the blue channel, we will have the difference between them, and therefore the voltage of battery one. If we then subtract the red voltage from the green channel, we will have the difference between the negative of battery one and the positive of battery two, giving us the voltage drop.

By using the extra channel, you can now see information that you wouldn’t have if using the traditional battery testers. The best part is that it takes around the same amount of time to carry out, and you don’t have to disconnect anything.

With the Bosch ESI[tronic] software update in August 2024, the Knorr-Bremse Diagnostics Add-On is now available to commercial vehicle workshops for the diagnosis, maintenance and repair of Knorr-Bremse systems. The new license package complements the ESI[tronic] packages for commercial vehicles (trucks), agricultural vehicles (OHW 1), construction vehicles and engines (OHW 2) as well as material handling (OHW 3).

Modular Bosch ESI[tronic] ESI[tronic] packages can be licensed and combined as required. They can be used with the Bosch KTS series. A license for the ESI[tronic] package truck is prerequisite for the Knorr-Bremse diagnostics add-on.

Advantages at a glance

● Access to new Knorr-Bremse systems including iTEBS X trailer braking systems.

● Combination of functionality from NEO andE CUtalk for diagnosis of commercial vehicle and trailer systems.

● Interaction with the new online configuration tool (OCT) for advanced

All vehicle-specific programs for repairs are combined in the Knorr-Bremse diagnostics add-on – and are constantly updated.

Bosch ESI[tronic] integrates all the solutions required for diagnostics, that previously used NEO and ECUtalk, in one software package. The new functions can be accessed via the easy-to-understand and easy-to-use interface of Bosch ESI[tronic].

trailer diagnostics will enable parameter adjustments (for iTEBS X units) and the replacement of control units in accordance with the latest cybersecurity and SUMS regulations.

● The Knorr-Bremse diagnostics add-on provides access to original and specific Knorr-Bremse diagnostic functions and technical documents.

Add-on

The adapter cable is required when replacing the control unit in the KnorrBremse EBS 5 systems.

Order number: 1 684 465 934

Advantages of subscription and comprehensive system coverage

Coordinated updates of Knorr-Bremse diagnostics add-on and ESI[tronic] software:

● Covering new Knorr-Bremse systems.

● New diagnostics functions.

● Necessary updates for cybersecurity.

● New content, such as additional troubleshooting guides.

Exclusive support for Knorr-Bremse systems basd on original specifications:

● Exclusive access to new Knorr-Bremse systems such as as iTEBS X.

● Future interaction with new cloud-based configeration for advanced trailer diagnostics.

● Programming EAC1+ and EAX 2.5 air dryer control units on Volvo and Renault.

New industry maintenance benchmark is a “beacon of confidence” says Logistics UK.

Designed to raise standards and drive confidence across the unregulated commercial vehicle maintenance sector, government and industry has launched the Maintenance Provision Rating Scheme (MPRS).

Announced on the 29th April 2025, MPRS is a new single rating system introduced to bring consistency to performance ratings and generate more transparency for vehicle operators and workshop facilities.

The industry-led scheme, steered by IRTE, is the result of a significant collaboration across the commercial vehicle sector and was developed in conjunction with Logistics UK, DfT, Traffic Commissioners, DVSA, SMMT, RHA, CPT, BVRLA and NFDA. Daimler Truck UK and DAF also took part in the MPRS pilot.

MPRS reflects the sector’s desire to continually improve commercial vehicle compliance and differentiates workshops and maintenance providers, based on the

competency of their people and the quality of their facilities. A “Qualified” rating indicates that a workshop has the tools, equipment and staff competencies to meet minimum industry compliance standards, while the highest “Platinum” level, will be awarded to operators at the leading edge of maintenance technology ensuring full readiness for future vehicle trends, including electric, hybrid, and hydrogen-powered systems.

Phil Lloyd, head of engineering policy at Logistics UK said, “Workshops are currently entirely unregulated, but MPRS can be a beacon of confidence for operators working with external workshops and maintenance facilities. It provides a trusted way for maintenance providers to demonstrate their competencies to reassure operators, who will know that their vehicles are being maintained by workshops and facilities that are serious about quality, compliance and safety.”

Workshops will apply for their rating through the MPRS portal, managed by IRTE on behalf of the industry. MPRS assessment is based on a comprehensive audit of facilities and staff knowledge. The “Qualified” and “Bronze” levels are based on independent assessment of selfdeclarations, “Silver”, “Gold” and “Platinum” will be audited by approved auditors.

To access the portal, simply scan the QR code.

Commenting after the launch, IRTE executive director, Emma Thompson said, “MPRS puts the spotlight on improving current standards across workshops and maintenance facilities across the nation, highlighting non-compliant and unsafe practices that compromise safety and standards within the commercial industry.”

S&G Transport operates a fleet of trucks and trailers from Hitchcock, north-east of Exeter on the M5 corridor. The trailer fleet includes flatbeds, curtainsiders and chiller units. A significant amount of the company’s business is transporting loads to London, with a focus on refrigerated goods.

S&G, which holds FORS Silver accreditation, needed additional equipment for its fleet to ensure that all London-bound vehicles met the new progressive safe system (PSS) regulations for the capital. The company invested in camera solutions from Durite, a UK provider of vehicle camera systems and an expert on DVS.

“We’d bought beacon lights for our workshop van from Durite in the past and found them very easy to deal with,” said Stefan Maunder, director of S&G. “We already had cameras on the trucks from a different supplier, so we were simply looking for an upgrade kit to make us compliant with the new regulations and help us maintain our FORS Silver accreditation. Durite were able to quickly identify a solution for us that was very competitive on price.”

From October 2024, all HGVs over 12t operating in Greater London had to be PSS compliant. The new standard aims to build on the existing direct vision capabilities and provides truck drivers with indirect vision, meaning it eliminates the remaining nearside blind spot.

“The drivers absolutely love them, which was a nice surprise as drivers are usually the first to complain when we add new technology to their vehicles,” added Stefan. “They tell me that the Durite cameras make manoeuvring much easier, particularly blindside reversing in and around sites.”

S&G has also added a dash of colour to the cameras. “We take great pride in the appearance of our fleet,” said Stefan. “We’ve had the cameras painted to match our livery and they look fantastic to be fair.”

Durite’s vehicle camera systems are said to enhance fleet safety and compliance control. Reduced risk of collisions can also mean lower insurance and repair costs, plus improved vehicle uptime. Durite’s DVS kits are designed to be plug n play,

S&B Transport has quickly been able to adapt to new regulations thanks to Durite –and its drivers love the new system. CVW finds out more.

enabling fleet operators to fit the technology themselves.

“Durite’s technical team were brilliant,” said Stefan. “They talked us through every step of the process. I would recommend Durite to other hauliers, one hundred percent.”

Transport for London has warned operators that from May 2025, all HGVs over 12t operating in Greater London will have to be PSS compliant or will be fined, as there won’t be further extension of the Grace period. Vehicles traveling through the capital without a valid safety permit will be identified by the ANPR cameras and fines of up to £550 per day per vehicle will be automatically issued to fleets in breach.

Durite has been supplying vehicle cameras for more than 20 years and has sold more than 100,000 systems to fleets. The company also provides a comprehensive range of vehicle safety products, making it a one-stop shop for fleet operators. In total it offers more than 5,000 parts to customers.

CVW hears more about the work the NTDA has done over the past 14 years to help improve the safety of emergency roadside work.

competent, and now proudly hold a valid professional licence. Among the standout successes, is the Roadside Emergency Action Concerning Technicians (REACT) Licence to work safely at the roadside which continues to lead the charge, with an impressive 11,336 licensed technicians across the UK and ROI.

The NTDA REACT Licence was introduced in 2011, primarily to improve the safety of commercial tyre technicians working at the roadside. This was a direct response to several tragic incidents where technicians were injured or killed while working on vehicles at the side of the road. The licence equips technicians with the knowledge and skills to work safely in these challenging environments. The tyre industry recognised that roadside tyre work is inherently dangerous. As technicians are often called out in all weather conditions, and at any hour, to work near or on the edge of busy roadways.

The REACT initiative is supported by leading tyre manufacturers, distributors, and National Highways, solidifying its importance as the de facto safety standard for the industry.

Close behind, the Licensed Commercial Tyre Technician (LCTT), a more tyre fitting skills focussed programme, boasts a strong community of 3,563 licence holders. But that's not all, as other specialised licenses issued under the NTDA scheme are rapidly gaining ground.

The Licensed Retail Tyre Technician (LRTT), Licensed Mobile Tyre Technician (LMTT), Licensed Electric

Vehicle Tyre Technician (LEVTT), and Responsible Tyre Repair Technician (RTRT) collectively account for an additional 909 licences, marking a surge in independently assessed expertise across diverse areas of tyre technology.

Commenting on the success of the scheme NTDA CEO Stefan Hay said: “This remarkable milestone not only showcases the dedication to quality training by our members and other leading tyre distributors but also highlights the growing recognition of distinct areas of skills specialisation, ensuring that tyre technicians are better equipped than ever to work safely and efficiently across all sub-sectors of the tyre trade. The future of the trade is looking brighter and more skilled than ever!”

The NTDA is the licensing and certification body for Tyre Technician Professional Development Scheme (TTPDS), with an impressive network of approved training providers, carrying out the training and assessment. The current training providers are: Autotech Training, ContiAcademy Training

Centre, Delphi Academy, DM Training Solutions (NI) Ltd, Engage Training Academy Ltd, Michelin Training and Information Centre, PFTP Ltd, Pirelli Performance Centre, Rema Tip Top Automotive (UK) Ltd, RWC Training, Leading Edge and the Irish Tyre Industry Association for the ROI.

In addition, several NTDA tyre distributor members, including ATS Euromaster, Central Tyre, Halfords Commercial Fleet Services, Kwik Fit and TrucTyre, have become approved centres, delivering a significant number of internal training and assessment programmes to enhance the skill sets of their employees.

These leading company commitments to professional development are also helping to strengthen the workforce and elevate industry standards across the board.

Stefan Hay continued: “The TTPDS is

Tyre technicians are better equipped than ever to work safely and efficiently across all sub-sectors of the tyre trade.

continuously evolving to meet the needs of the trade. In early March, a pivotal meeting took place at the Michelin Training and Information Centre, where several key objectives were discussed to further refine and expand the programme, namely:

● Formalising the TTPDS as a central framework, with standardised training, assessment protocols, terminology, and ongoing CPD criteria.

● Developing a new set of criteria for a Licensed Specialist Tyre Technician

(LSTT), specifically tailored to the OTR sector. and