Solution of bearings heavy machining by CBN Inserts

www.halnn-group.com

Halnn Tools - Engineering Project Department

Wind power bearing processing characteristics

• Common materials for wind power bearings are 50Mn and 42CrMo. The hardness after quenching is above HRC50, and the machining allowance after heat treatment is 2-6mm. The material of the wind power bearing tested this time is 42CrMo4.

• Wind power bearings are difficult to machining after heat-treated. Grinding is often used as the final processing step. However, with the development of the modern Inserts industry, a CBN Inserts material that can be ground on the Turning—CBN has been developed Insert. The last processing step of this processing of wind power bearing processing uses Halnn BN-H200 instead of grinding processing, which not only improves the processing efficiency, but also reduces the processing cost.

• When machining the outer ring of a wind turbine bearing, intermittent cuts are formed due to oil holes in the moon groove of the outer ring raceway, and the machining allowance at the moon groove is higher than the machining allowance of the raceway and the inner hole flange Therefore, the machining performance of the CBN Inserts is more important.

• For wind power bearings, the accuracy tolerance of the raceway radian is 0.08, and the surface roughness of the raceway is Ra0.4.

The Bearings process steps and Inserts usage details

Machining bearing outer ring

Roughing bearing rib

Finishing bearing rib

Use the last bearing finishing Raceway's inserts

Change new inserts

Roughing bearing raceway

Use the last bearing finishing bearing rib's inserts

Roughing bearing moon groove

Finishing bearing raceway

With the same inserts that Roughing raceway

Change new inserts

Finishing bearing moon groove

With the same inserts that Finishing raceway

Machining bearing inner ring

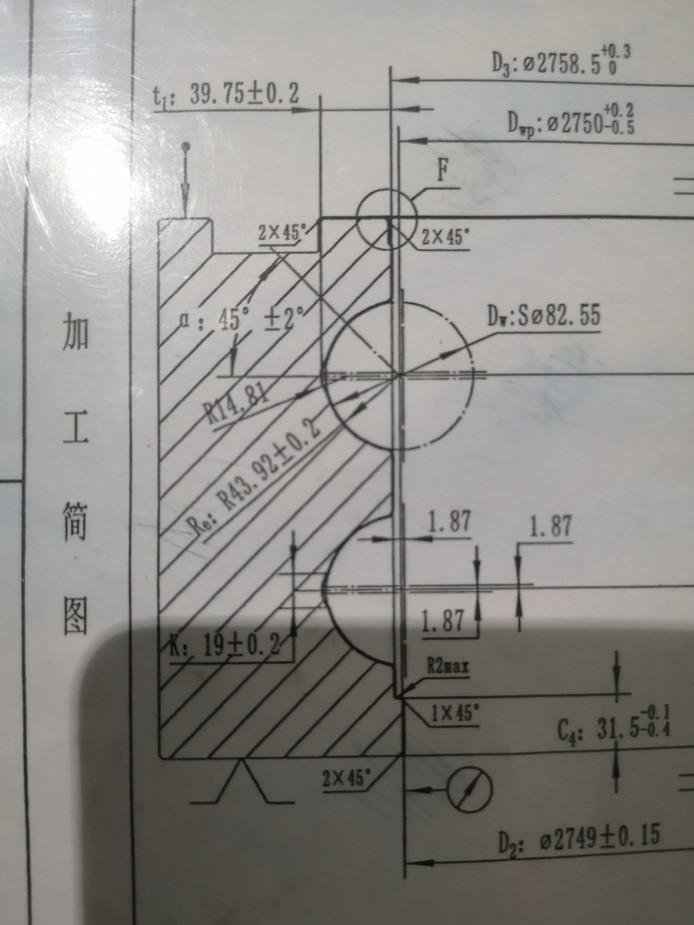

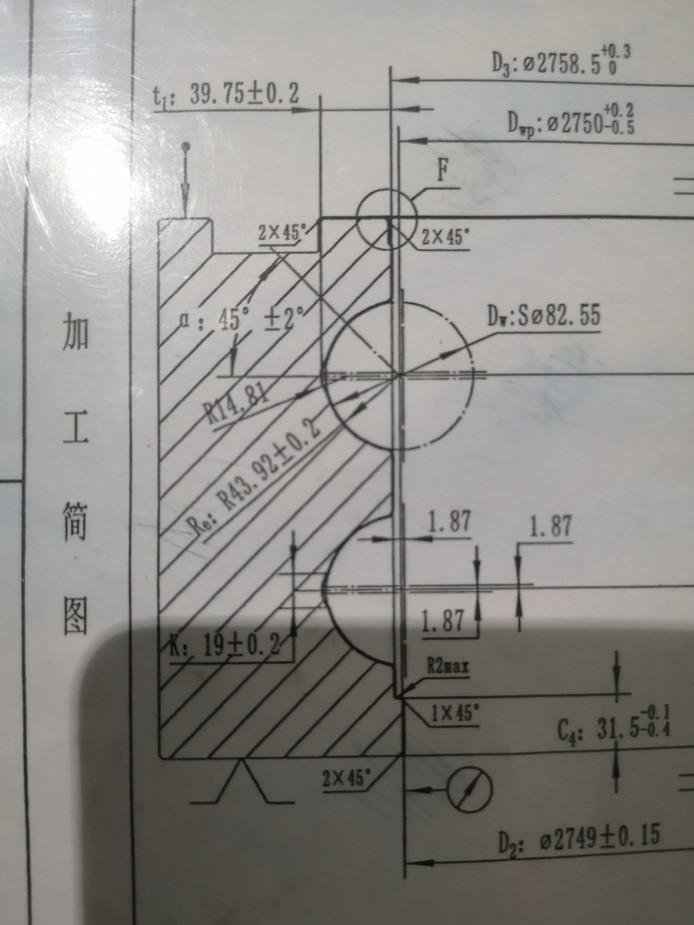

Introduction of working conditions before machining outer ring

The main difficulties that the outer ring is more difficult to process than the inner ring are as follows:

·Several oil holes are evenly distributed in the moon-shaped groove for strong interrupted cutting. In addition, the lunar groove raceway has a large machining allowance, and the blade bears a large cutting force.

·From the perspective of the outer ring as a whole, the upper and lower ribs have stepped holes. Compared with the inner ring, the workpiece has a larger machining allowance and a longer processing circumference, and the cutting force of the blade is relatively increased.

BN-H200

Inner ring processing case

Parts : Rough finishing of inner ring ribs

Diameter : 2750mm

Material : 42CrMo4

Hardness : HRC58-63

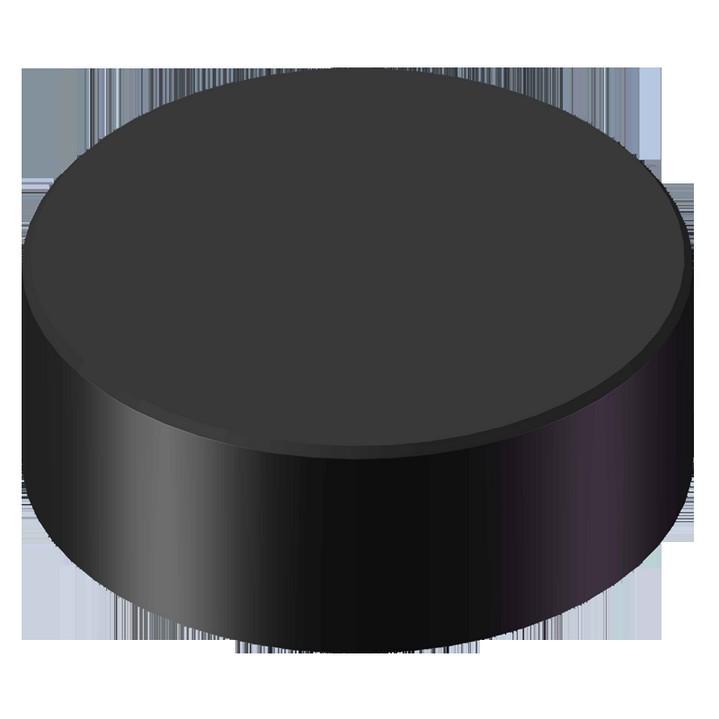

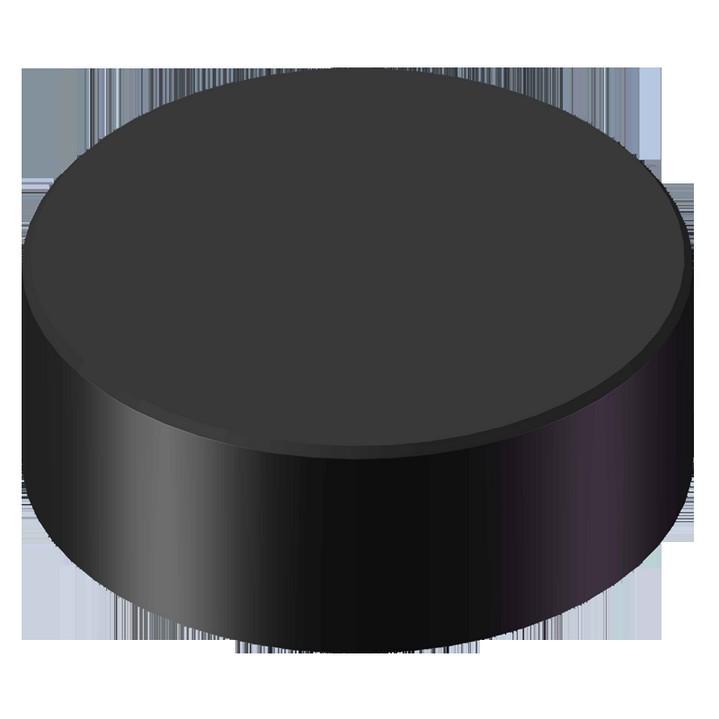

Type : BN-H200 RNMN090300

Machining parameter : Vc=190m/min Fr=0.32mm/r

ap=0.6-0.7mm

The processing conditions of the raceway such as ribs

The cutting edge life of the Hualing tool tested and processed all meet the tool life standard. During the tool processing, the cutting is stable, the sound is normal, and the performance is stable. And the surface accuracy of the processed raceway can reach Ra0.4.

RNMN09030

Outer ring processing case

• Parts : Rough finishing of outer ring ribs

• Diameter : 2750mm

• Material : 42CrMo4

• Hardness : HRC58-63

• Type : BN-H200 RNMN090300

• Machining parameter : Vc=190m/min Fr=0.32mm/r

ap=1-1.5mm S=25r/min

The processing parameters are adjusted slightly according to the degree of wear of the blade.

For the machining of the outer ring, the machining allowance is larger than the machining allowance of the inner ring, and the maximum machining allowance can reach 3mm. The machining difficulty is greater than that of the inner ring, and there are several oil holes in the lunar groove of the raceway. For strong interrupted cutting, one cutting edge of the Valin blade can complete the entire roughing process. The performance is seen from the form of tool failure. Better than the original brand cbn tool.

BN-H200

RNGN PCBN Inserts

Select Inserts

Inserts

BN-H50 PCBN Inserts Can make coated.

,

BN-S200

RNMN 、 RCM X-Y 、 RCMNV Solid CBN

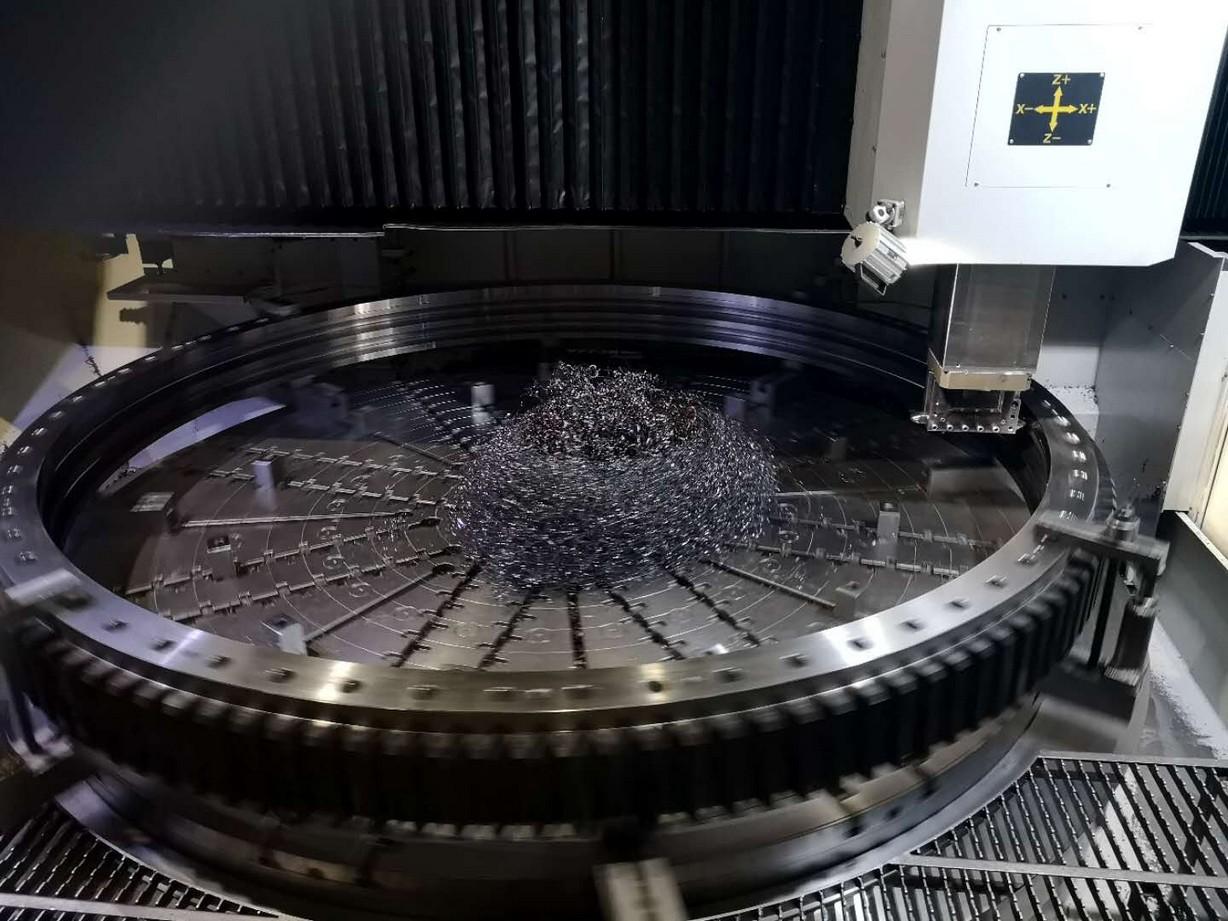

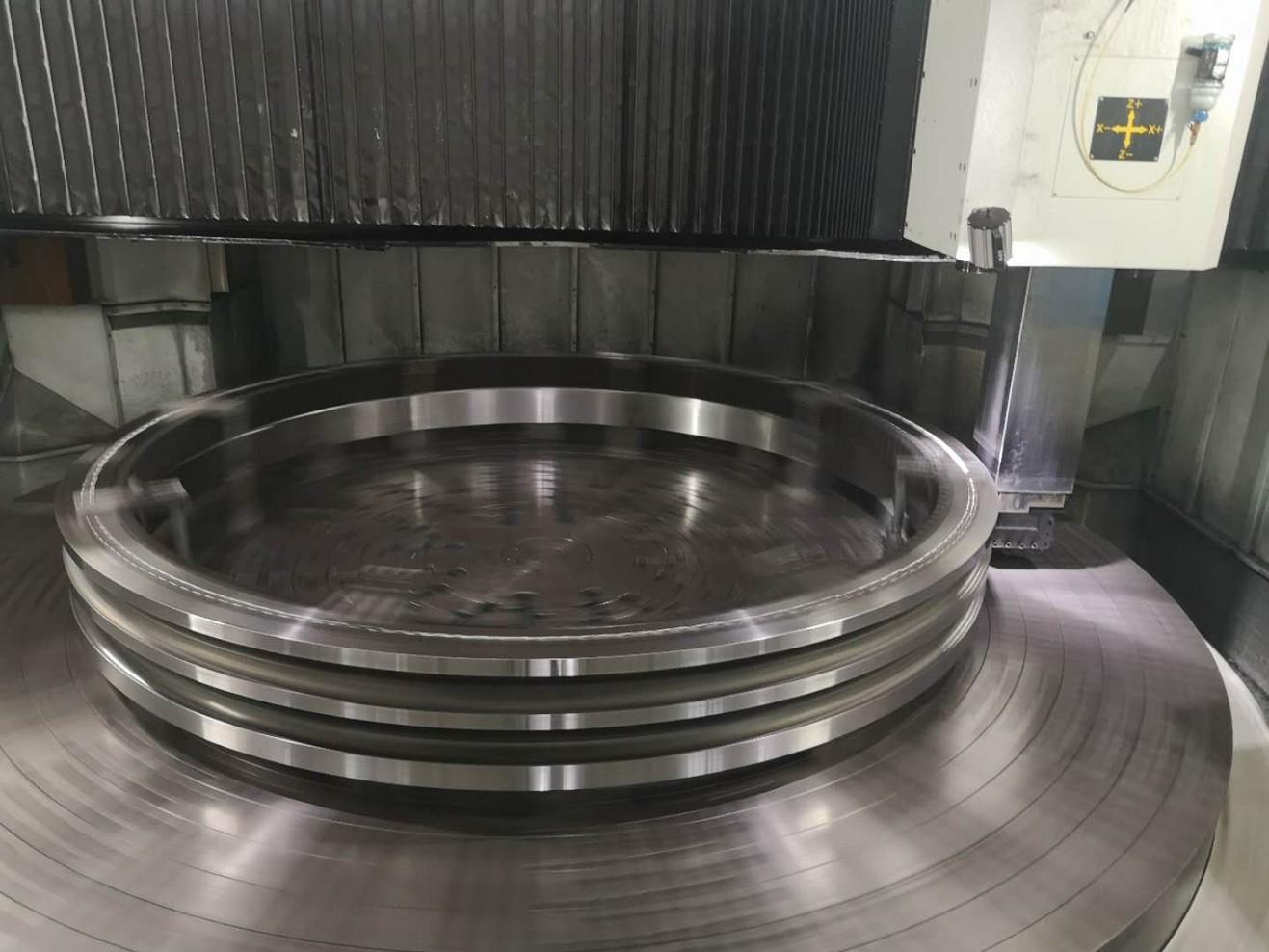

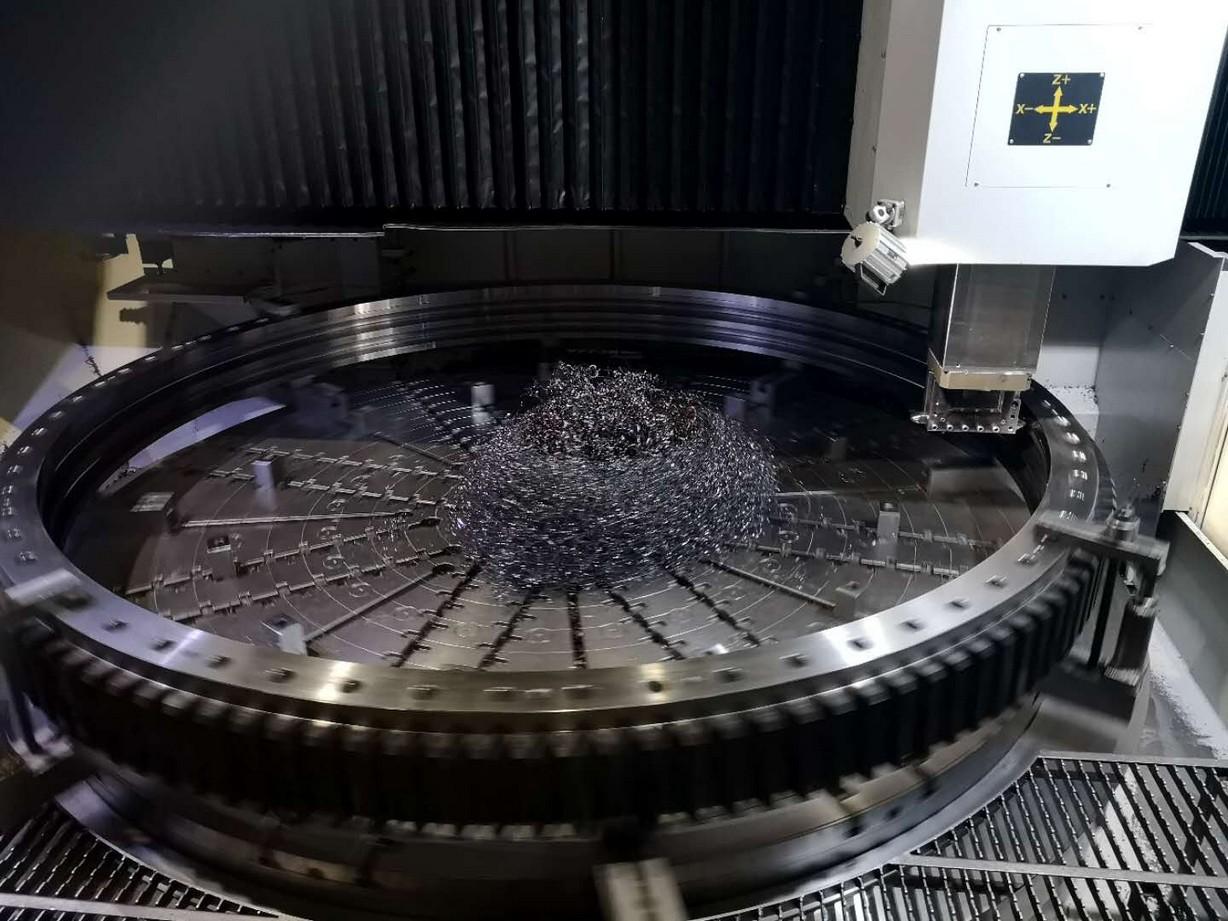

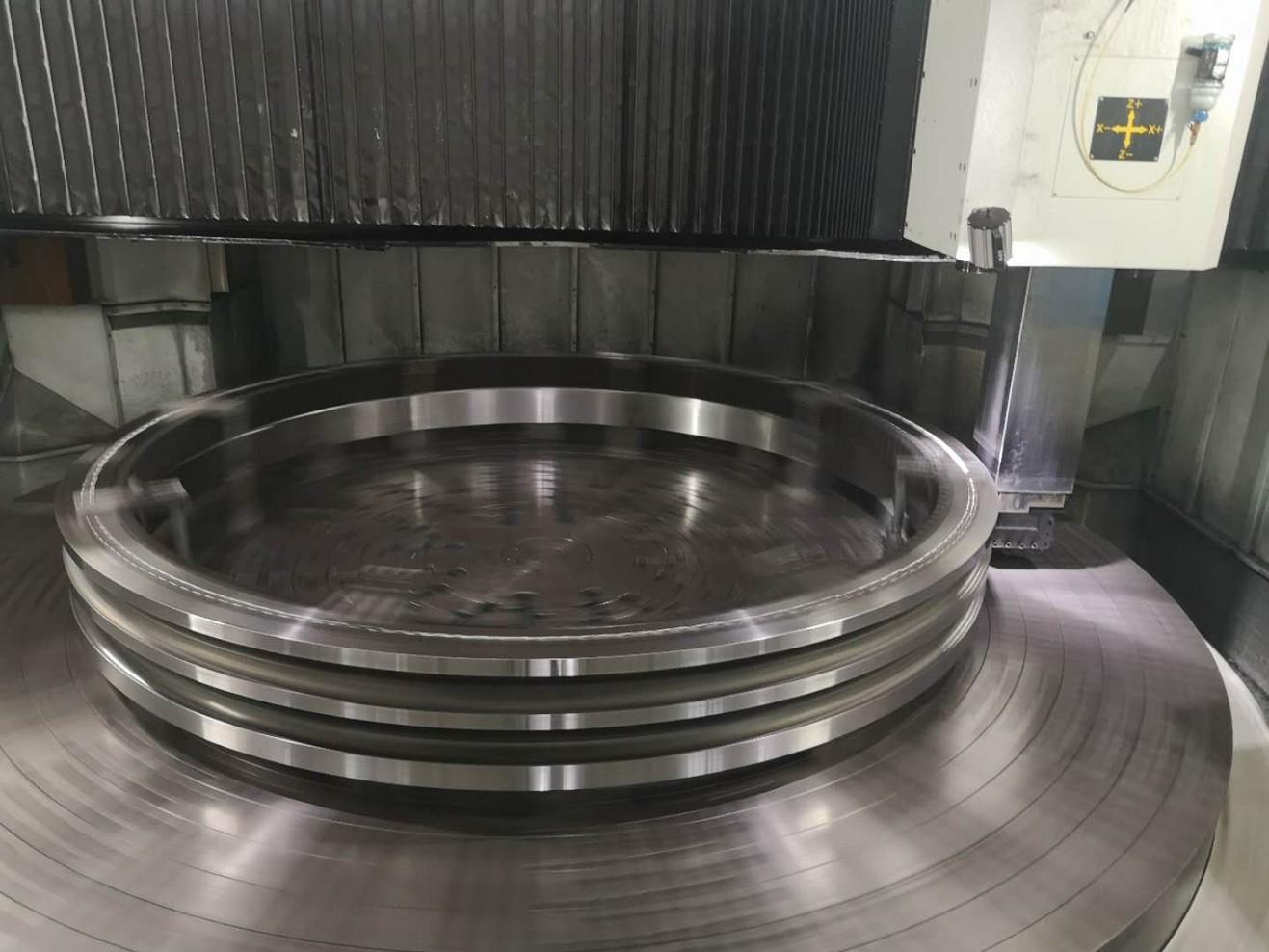

Wind power bearing machining workshop

On-site trial installation pictures

About Halnn

Halnn Superhard, as the pioneer of superhard cutting tools in

China, make national Superhard Materials Key Laboratory and Henan University of Science and technology as technical support, have our own research center, focus on cbn cutting tools and high grade diamond tools for machining brittle and hard materials, have obvious advantages on most industries, such as turning instead of grinding, high hardness materials machining, heavy turning, high speed machining, ect. At the same time, we have launched a series of new cbn/pcd cutting tools and other material tools in 3C, aerospace and Nuclear energy military field, depending on the research center of Henan Superhard Materials Institute. Our customers have covered many countries and areas, including China Mainland, German, Italy, USA, Korea and other areas.

TNANKS

Halnn Tools