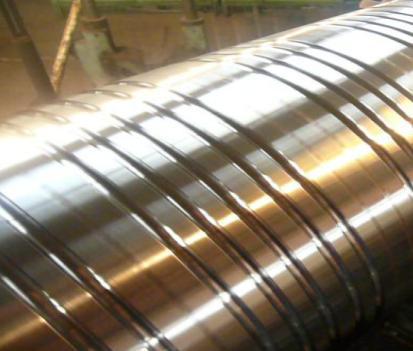

Highhardnesscoldrolls

02

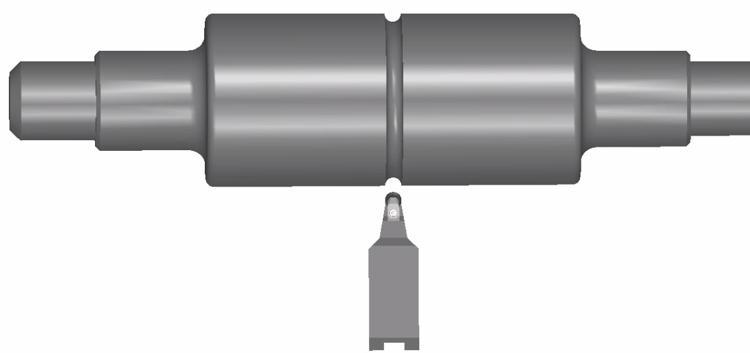

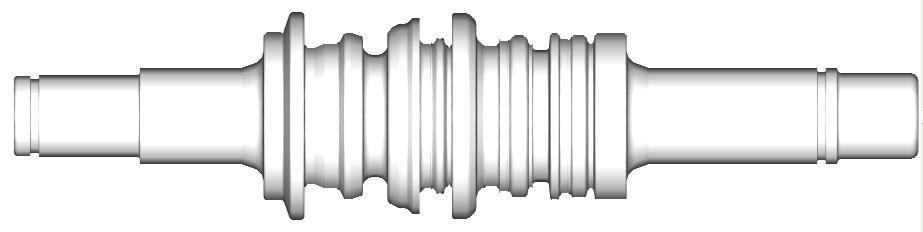

RollsCommonCuttingTypes RoughingCylindrical HoleTurning Milling RollRepairing TurningGroove HeavyTurning

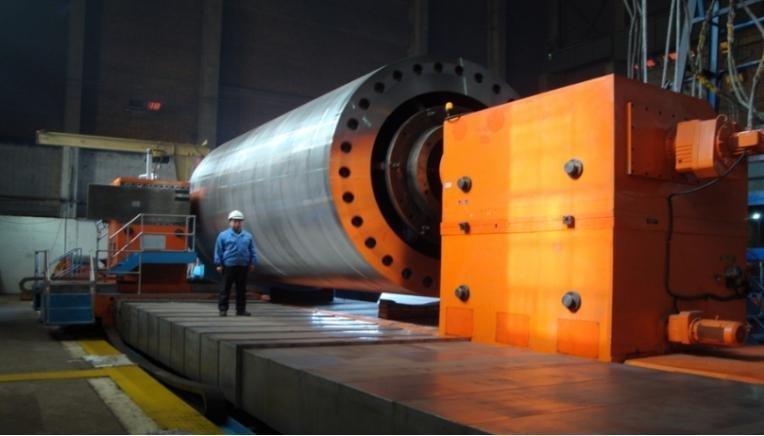

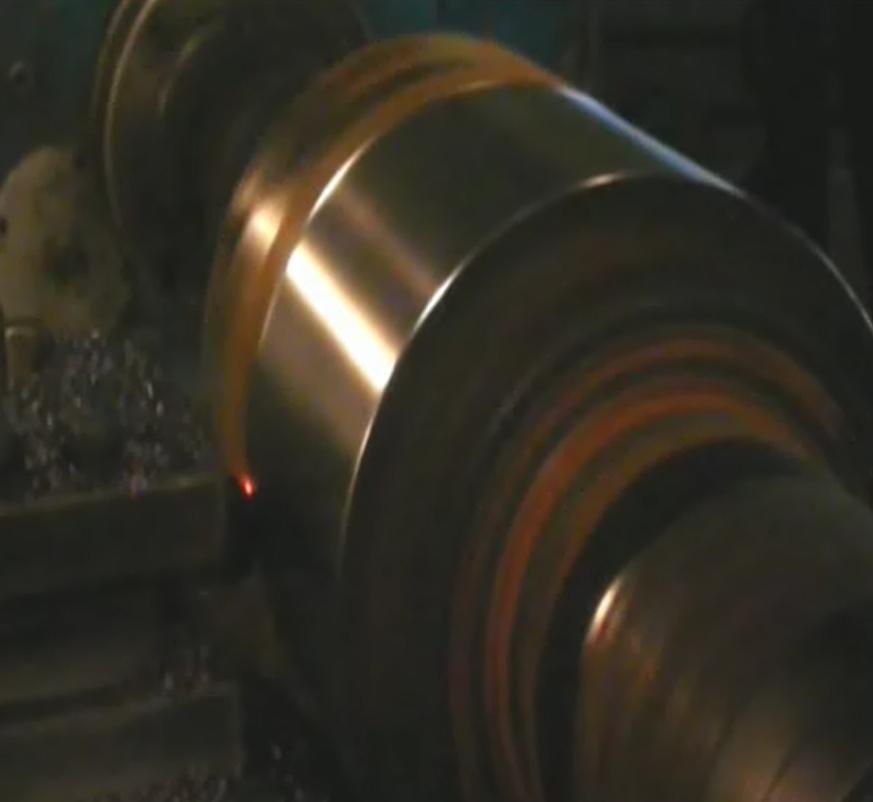

1.Lowhardnessrollsprocessingcharacteristicsandtoolselection Suchasductileironroll,highalloycastironroll,theycommonly usedinhotroll,Supportingroller,middleroller.Comparewith workingrolls,theircharacteristicsarelowhardness. Turningthistyperolls,youcanchoosecarbideinsert. 2.Processingcharacteristicsofhighhardnessrollsandtoolselection Suchasmachiningchilledcastiron(ICDP),Highnickelchromium castironrolls,highboronsteelrolls,HSSRolls,Semi-steelrolls (castingsemi-steelrollsandhighcarbonsemi-steelrolls),Ni-Cr-Mocentrifugalcompositerolls. Becauseofitshighhardness,theserollsblankusuallyhasstomatal,sand,ectdefects.Anditrequireshighon thecuttingtoolsperformance,suchasimpactresistance,heat-resistance,wearresistance,ect.

Rollclassificationandcommonprocessingdifficulties Accordingtothelevelofhardnessclassification

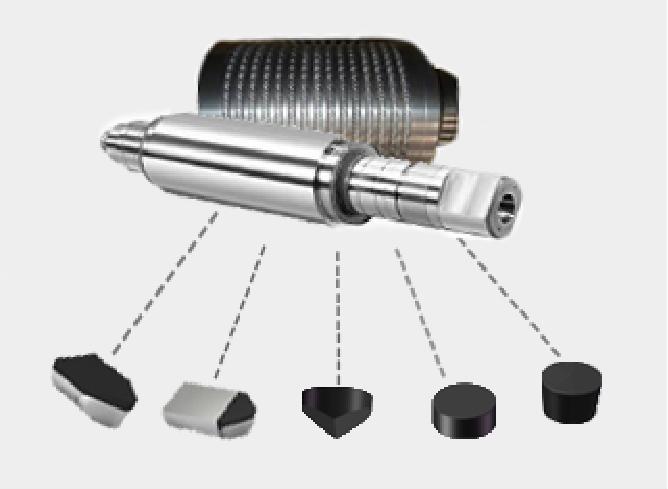

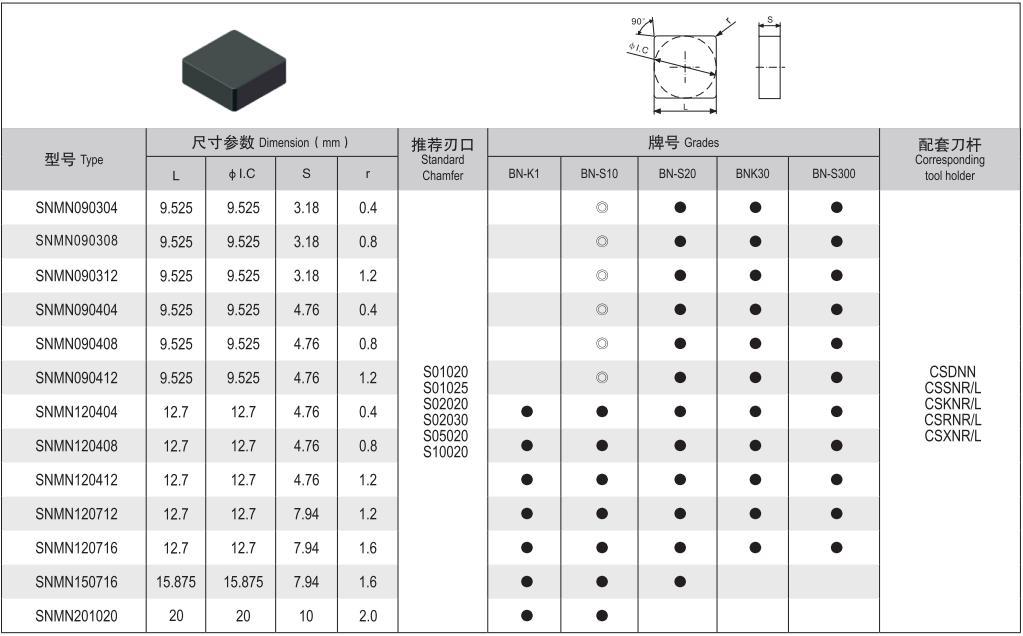

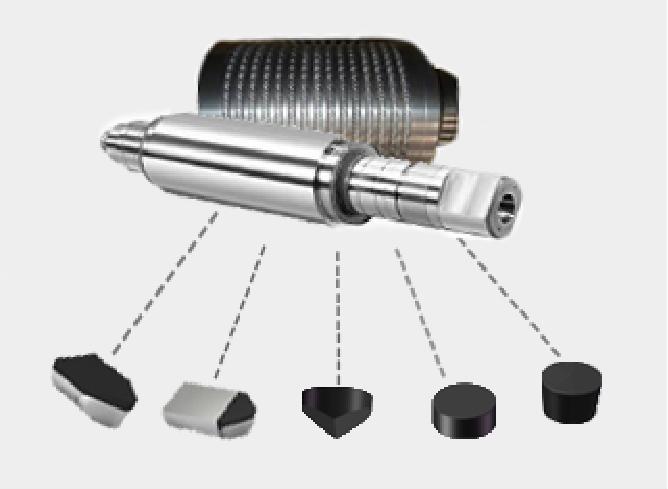

HalnnCBNGradeForMachiningRolls ThepredecessorofHalnnSuperhardMaterialCo.,LtdisHenanSuperhardMaterialInstitutewhichis theearliesttomakeresearchonprocessingthebrittleandhardmaterialswithcubicboronnitride toolsandHigh-GradeDiamondTools.AsthepioneerofIndustrytoolsinChina,Halnnadheretothe initialbusinessphilosophyof"Notseekinglargeandcomplete,onlyinsisthigh-precisionand professional".Withmorethan10yearsexperience,Halnnhasresearchedonebyonenewmaterials grade,newtechnologyandbecomethemostfamouscuttingtoolsbrandinsuperhardcuttingtools industry.Specificabovecastingdefectsandotherproblems,Halnnreserachedsomecbngradesfor machiningthesehighhardnessrolls InsertGrade BN-K1 BN-S10 BN-S20 BN-S200 BN-S300

Howtoconfirmthetoolsolutions ComponentInformation Rolls Materials CuttingType □Roughing□Semi-finishing □Finishing Rolls Hardness CuttingCondition □Continuous□Semi-interrupt □HeavyInterrupt PreviousCuttingToolsInformation Insert Brand InsertModel Insert Materials ToolHolderModel Failure Mode Howcanyougetthetoolsolutionsformachiningrollsfromus? Pleaseoffertheinformationdetailsasthefollowingtablet:

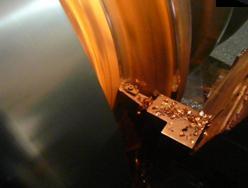

RoughmachiningHighNi-CrAlloyCastIronRolls Material:HighNi-CrCastIron,Hardness HSD80 SelectedInsert:BN-K1 CuttingCondition:ap=9mm, Fr=0.5mm/r,Vc=25m/min SelectedInsert Efficiency HalnnBN-K1Improved3times CarbideInsert /

BN-K1:NormalWear,itcanuse allcuttingedges. BN OtherCBN:Insertfragmented,it leadtoseriousloss. FailureModeComparision BN-K1 OtherCBN

Semi-finishingchilledcastironrolls Material:Chilledcastironrolls,HardnessHSD67 SelectedInsert:BN-K1 CuttingCondition:ap=2mm, Fr=0.5mm/r,Vc=66m/min SelectedInsertEfficiencyLifetime HalnnBN-K1Improved2times3times CarbideInsert / / BN-K1 BN-K1

Finishturningforgedsteelcoldrolls Material:Forgedsteelcoldrolls,Hardness HRC60 SelectedInsert:BN-20 InsertmaterialEfficiency HalnnBN-S20Improved5 times CarbideInsert / BNS20

TurningthehighboronsteelrollsGroove Material:HighBoronSteel, HardnessHSD68 SelectedInsert:HLCBN InsertmaterialMachining Effect HalnnHLCBN24holes/insert

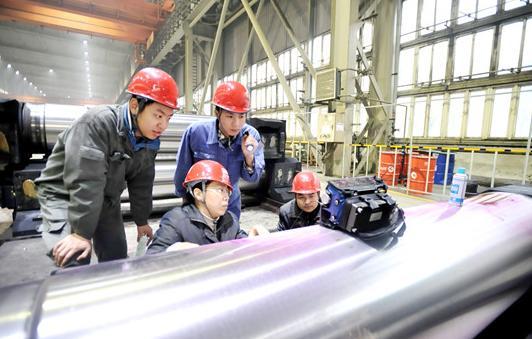

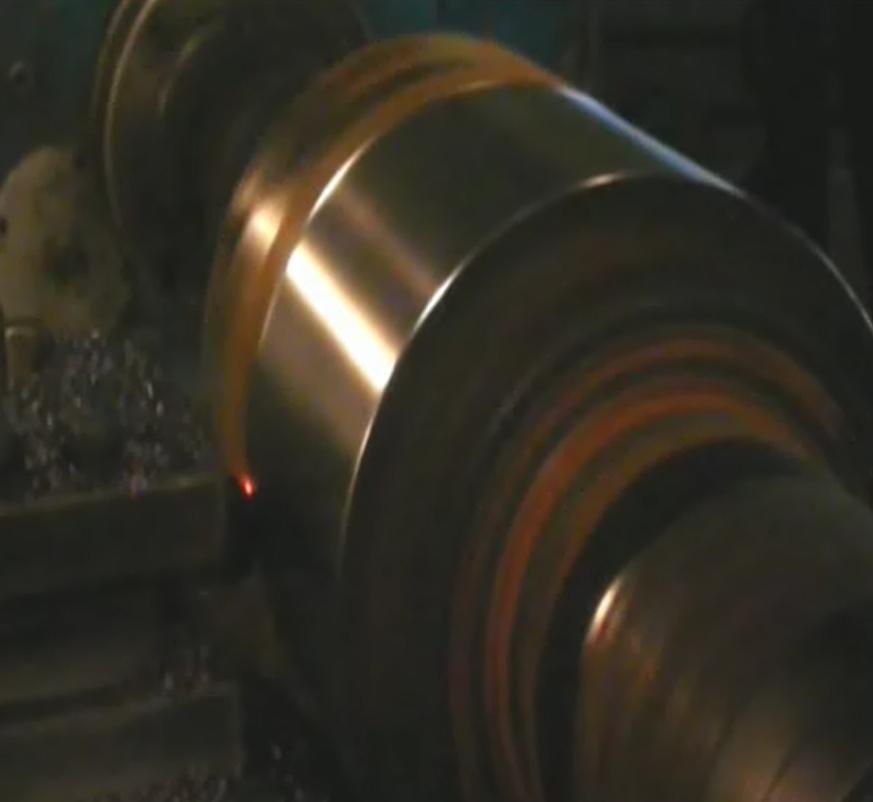

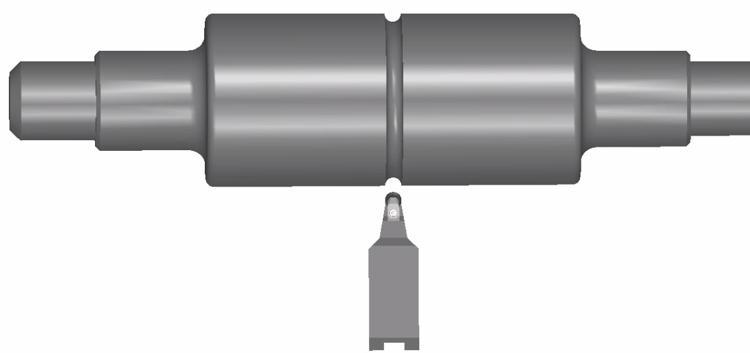

Intheuseofmetallurgicalrolls,whetheritiswirebarrolls,profilerolls,narrowstriprolls,striprolls, etc.,therewillbedefectssuchaswear,deformationandcrackingoftheworkingsurface.Thereareevendefects suchaspeelingoffthebody,fallingoff,andchipping.Therefore, hasbecomeaprojectonthe rollinglineinsteelcompanies. Withtheadvancementofsteelrolling,thewearresistanceoftherollsisbecominghigherandhigher, whichmakesitdifficulttoprocessandrepairtherolls.Inparticular,casthigh-speedsteel(HSS)rollsarea highlywear-resistantrolldevelopedinrecentyearsbecauseofitshighhardness,highwearresistance,good thermalhardnessandgoodtoughness.Therefore,moreandmorepeoplepayattentiontoit.However,therepair afteritsusehasalwaysbeenaproblem. Thedifficultyofcuttingalsorestrictstheapplicationanddevelopmentofhigh-speedsteelrolls.People havebeenpursuingandsearchingforatoolthatismoresuitableforhigh-speedsteelrollcutting. EarlyTimes,themanufacturerusecarbidetoolsandceramictools,whichcannotmeettheneedsofroll repairprocessingduetotheperformanceoftherolls,processingefficiency,processingaccuracy,etc.,.HALNN combinestheexperienceofalargenumberofsteelmillrepairrolls,andselectstheappropriateCBNgradefor differentrollrepairconditionstohelprollmillsandsteelmillsfactorysolveaseriesofsimilarproblems.The followingaresomeoftheexamplesoftherepairrollindustry. RepairingRolls

TurningtherepairingThreadedsteelroll BNS20BNS10 Material:HighSpeedSteelrolls,HardnessHRC60 SelectedInsert:BN-S20/BN-K1 MachiningCondition: Vc=25m/min,ap=0.5mm,f=0.5mm/r Insertmaterial Efficiency HalnnBN-S20 5times CarbideInsert / Note:Whenreparingthegrooves,belongtoheavyinterruptturningcondition,whichwillrequire theinsertshightoughness,FirstChooseBN-K1,SecondBN-S20

TurningRepairedHSSRolls TurningrepairedHSSRolls Material:HighSpeedSteelrolls,HardnessHRC63 SelectedInsert:BN-S300(Therollsneedhave goodsurface) MachiningCondition:Vc=26m/min,ap=2mm, f=0.5mm/r

§1SurfaceQuality TungstenCarbideInsertsMachining HalnnCBNInsertsMachining

SurfacequalityComparison

Materials:CastingHighSpeedSteel Hardness:HRC64 InsertMaterials:BN-S300Vc=40m/min, ap=0.5mm,f=0.5mm/r TurningRepairedCastingHSSRolls TurningRepairedCastingHSSRolls Note:Asourexperience,Iftherepqiredrollssurfacequalityisgood,wecanchooseBN-S300,Ifit hassomecracks,drops,wecanchooseBN-S20,ifthesurfacequalityisterriblebad,wecan chooseBN-K1.

03

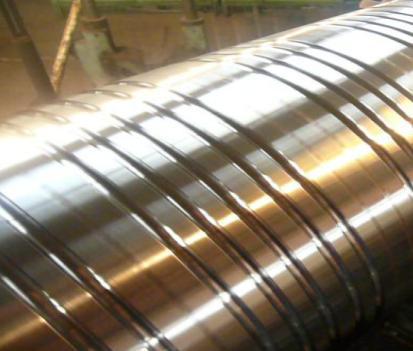

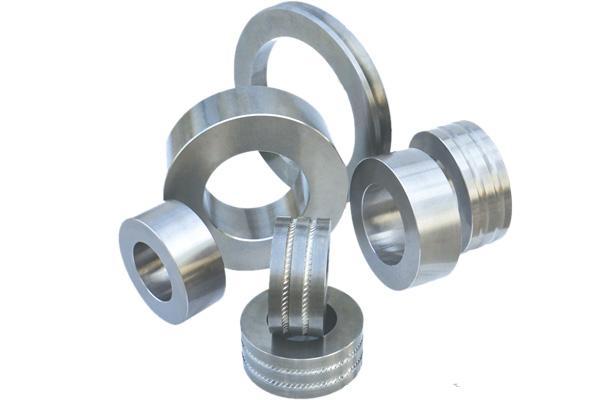

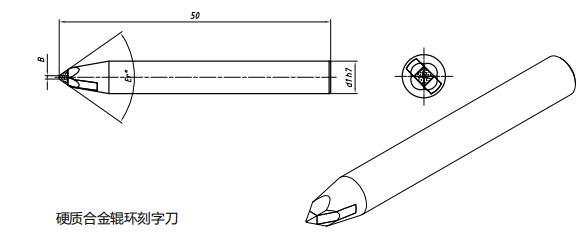

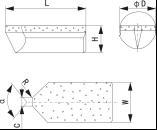

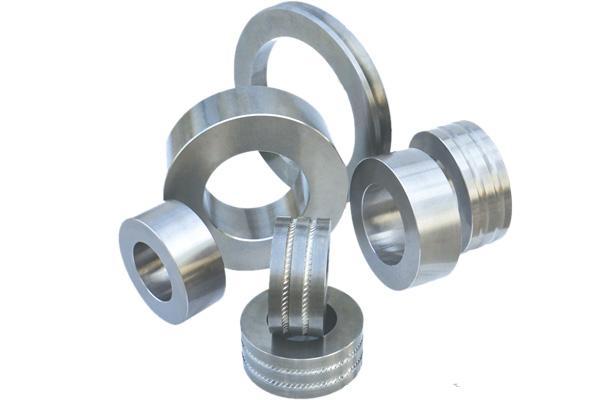

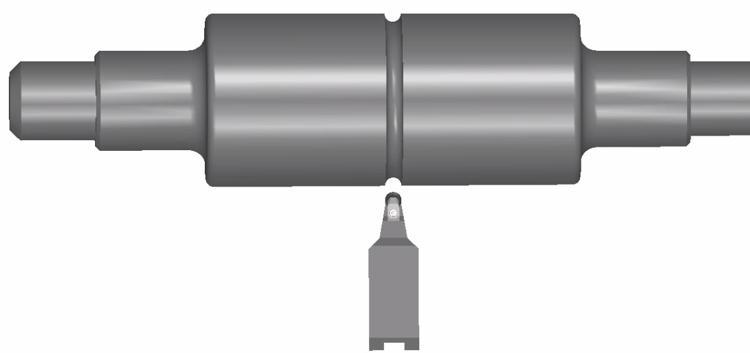

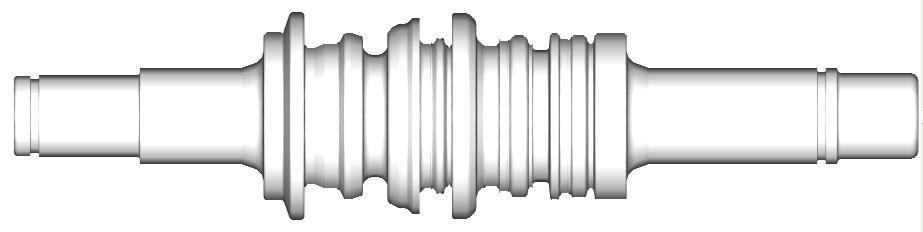

TungstenCarbideringisalsocalledtungstencarbide(WC)alloyrollring.Its hardnesscanreachHRA78~95atroomtemperature. Thecoldworkingmethodsofcementedcarbiderollsaremainlyand crescent(etchingribs),. Thetoolsusedforcarbideprocessingrollare .Normally,PCBN isgenerallyusedforroughturningcarbiderollswhichhardness≤HRA88.PCDTools aremostlyusedforfinishturningcylinder,chamferingandengraving. TurningTungstenCarbideRings

BN-S300belongtosolidcbn, onlyrecommendtoturning tungstencarbideringswhich hardnsiswithinHRC88, othersadvise Materials:TungstenCarbidweRings; Hardness:HRA88 InsertsMaterials:BN-S300 CuttingParameters: Vc=15m/min,ap=1mm,f=0.3mm/r CBNInsertsTurningTCRings CBNTurningTungstenCarbideRings

PCDInsertsTurningTCRings Materials:WC(TungstenCarbideRings); Hardness:HRA88InsertMaterisl: ; (ForsomelargescaleTCrings,hardturning willperformmuchbetterthangrinding. PCDTurningTungstenCarbideRings

PCDNotchingToolsMillingTCRings

MillingTCRingsGrooves

3TypesCommonRolls

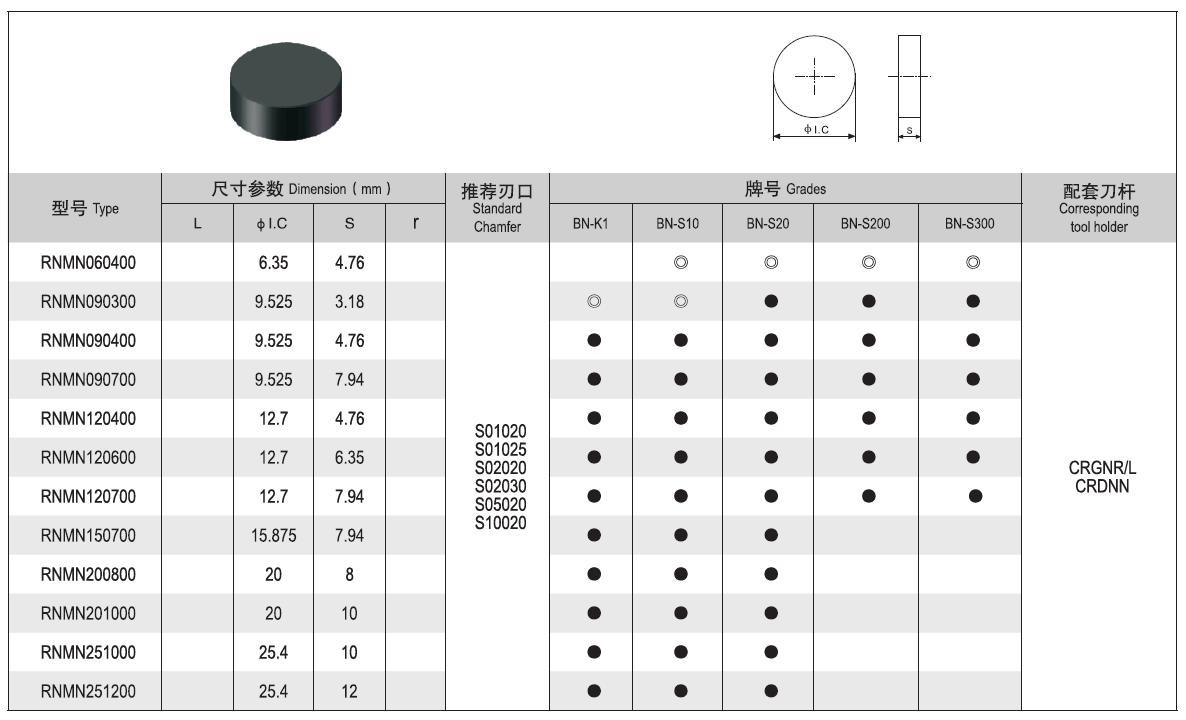

1.CBNInsertsandToolsHolderforrollswhichproducingplatesteel

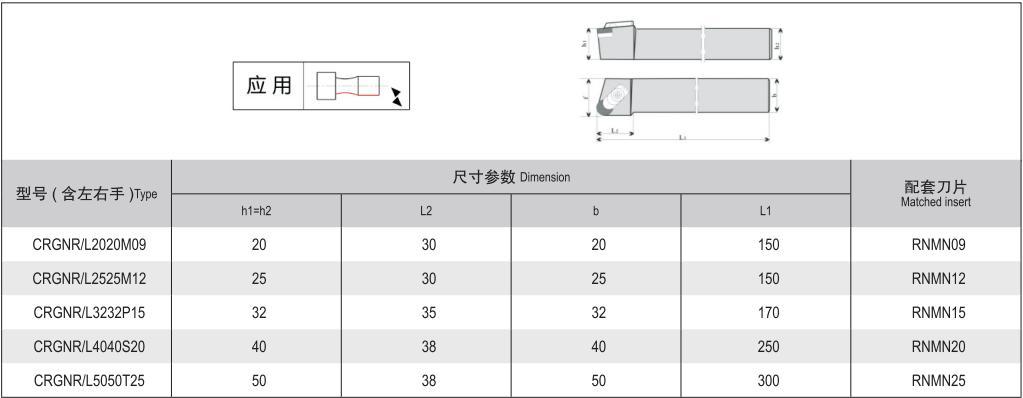

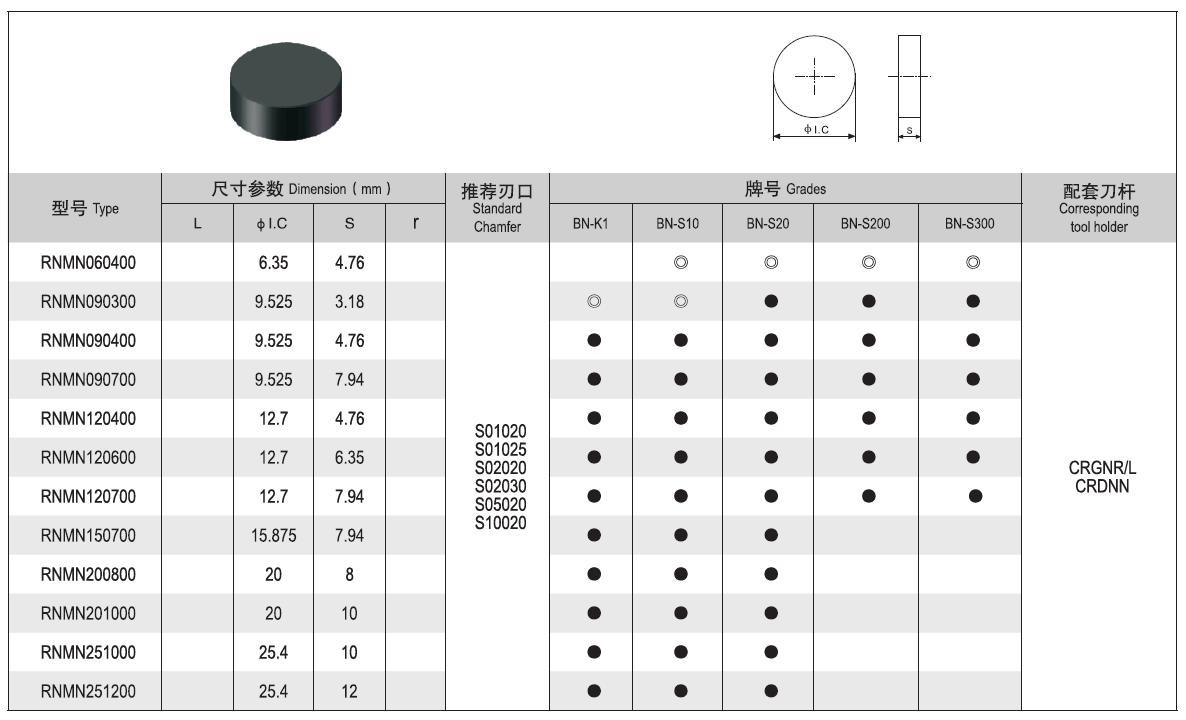

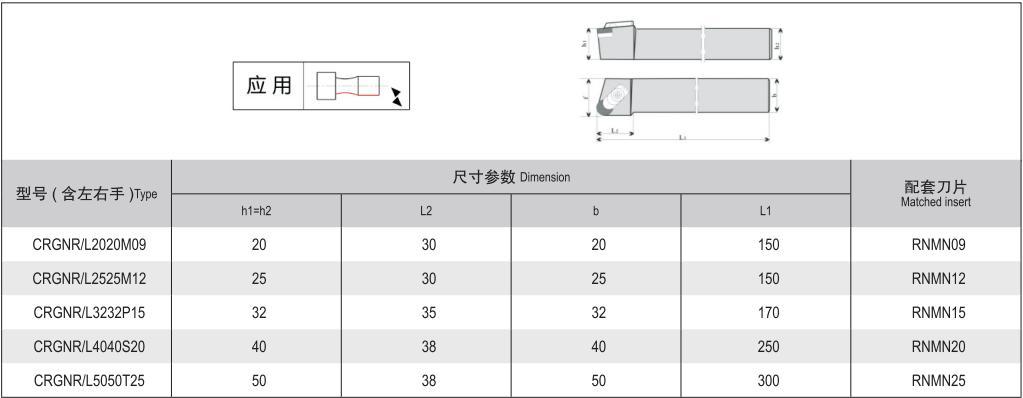

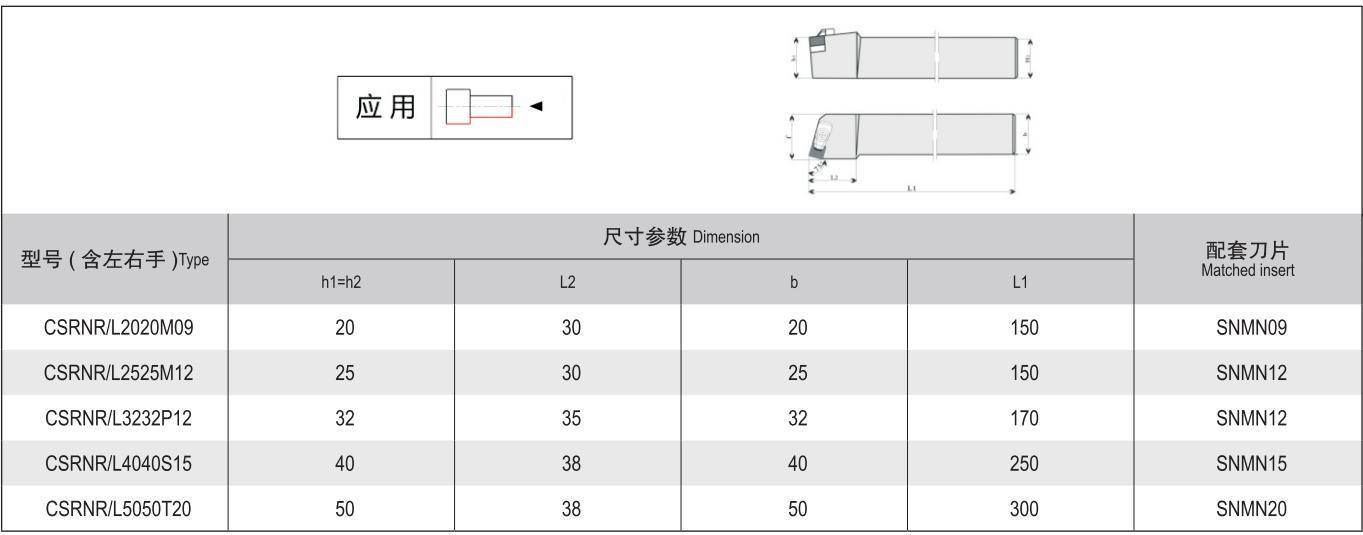

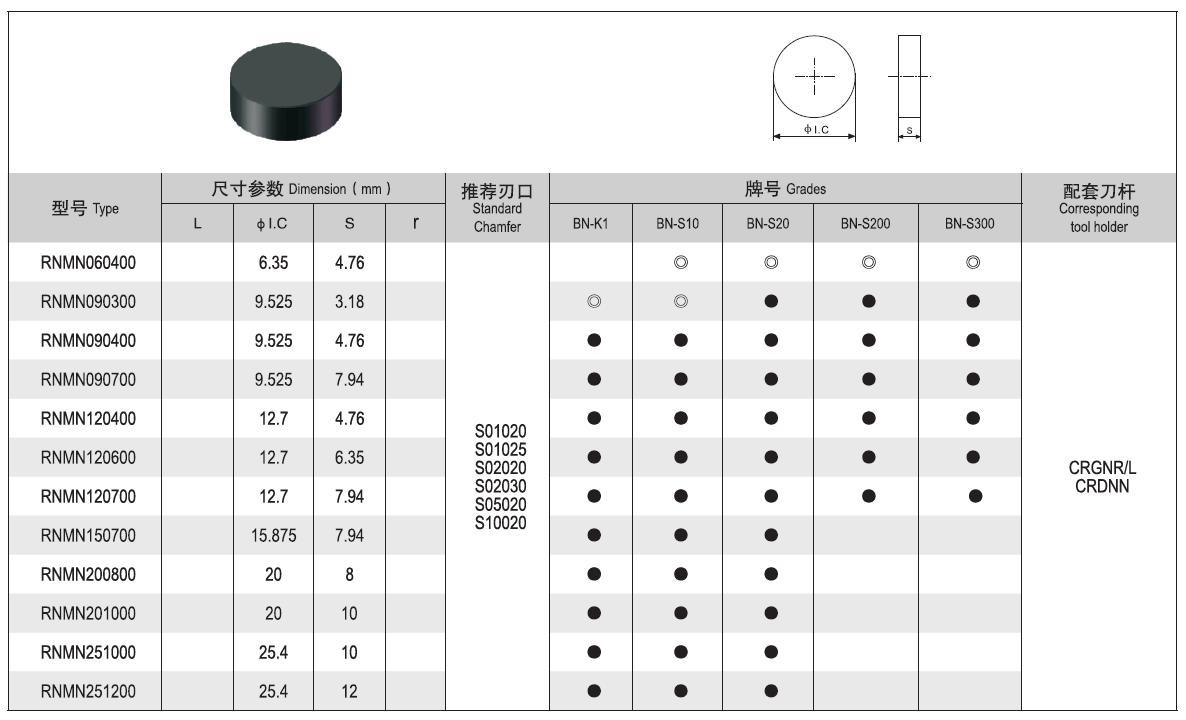

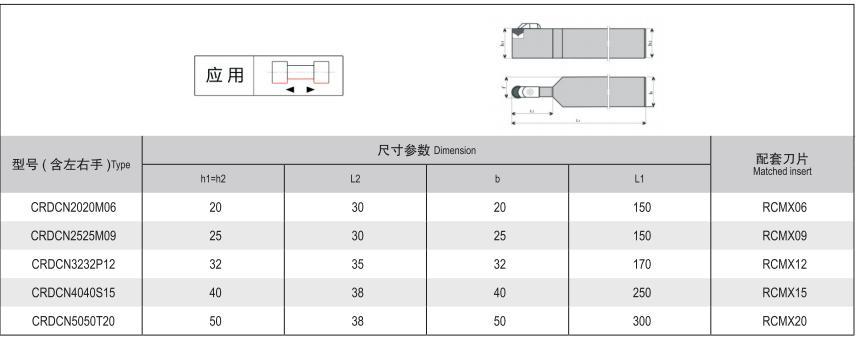

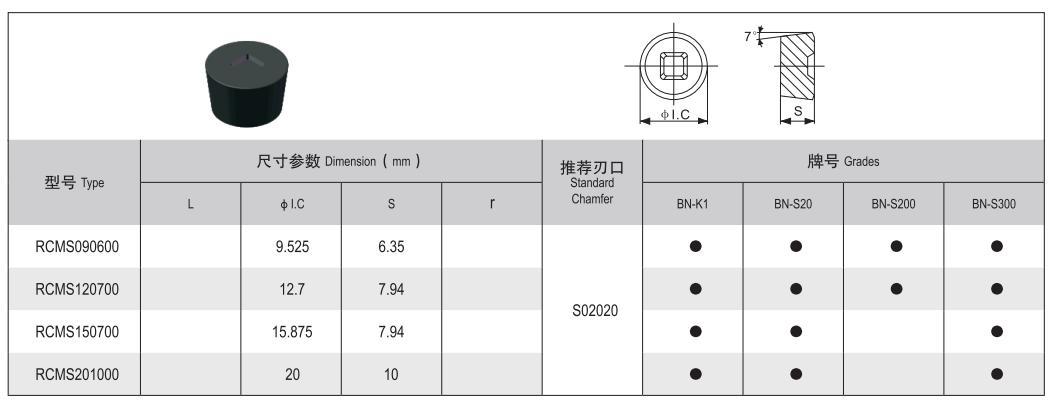

CommonModelRNMN,CorrespondingToolHolderCRGNR/L

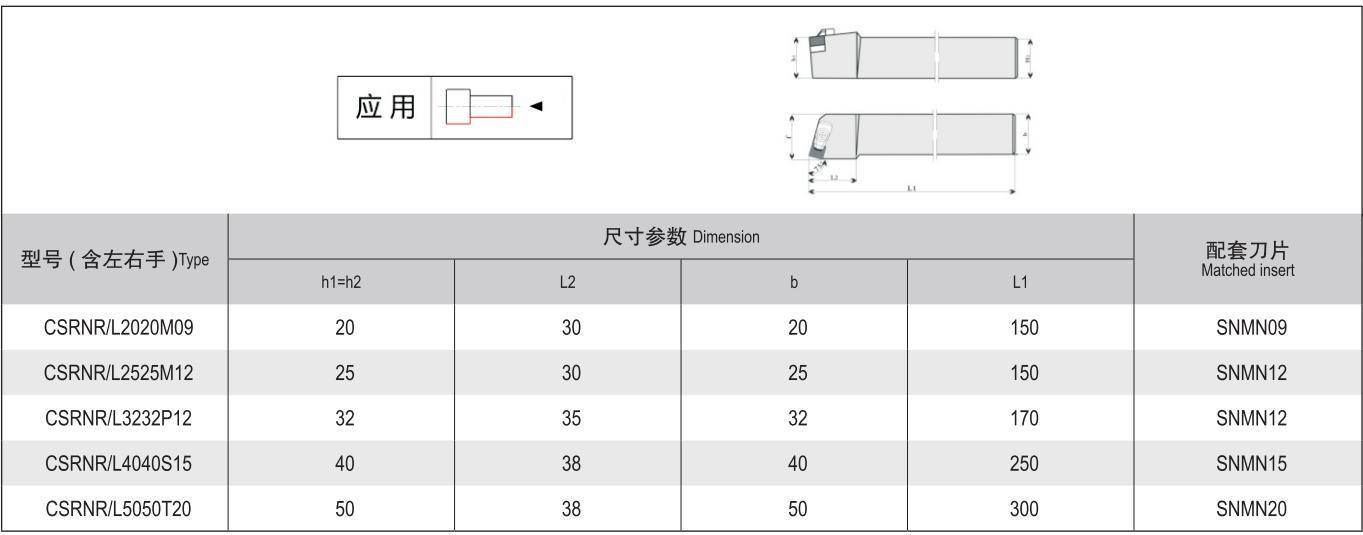

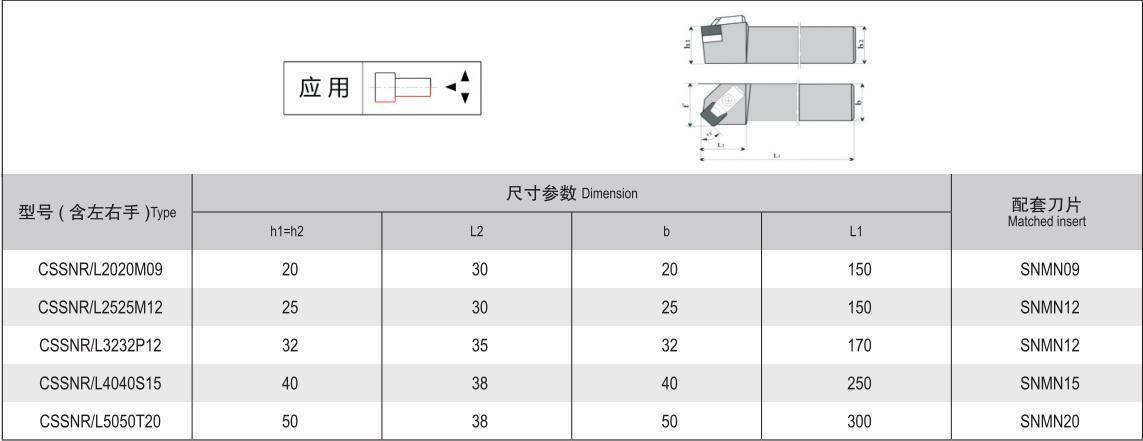

2.CBNInsertsandToolsHolderforrollswhichproducingwireballsteel

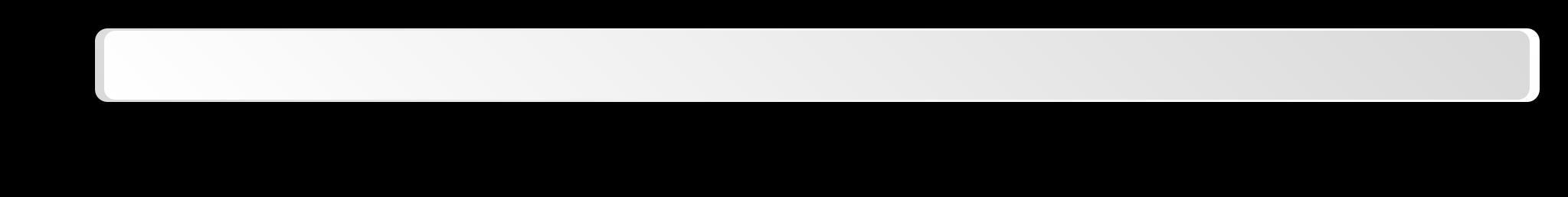

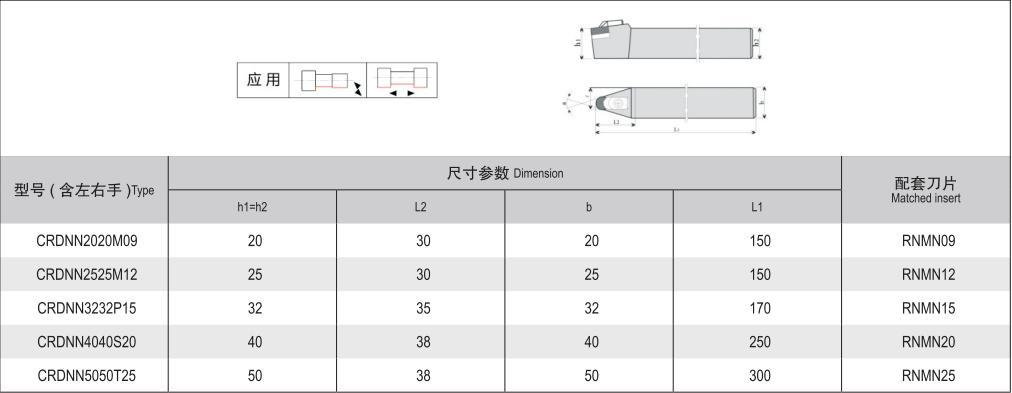

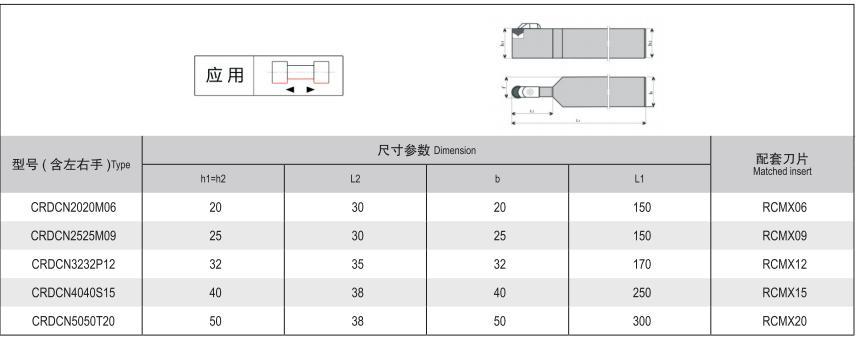

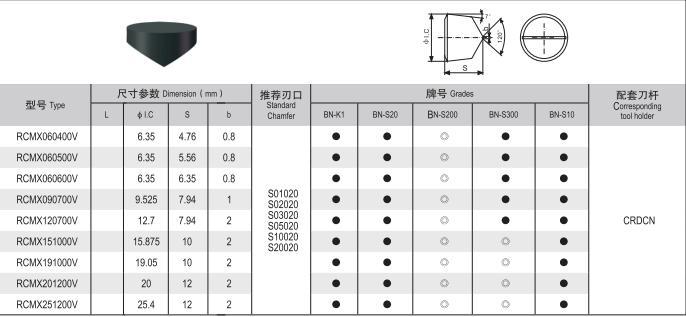

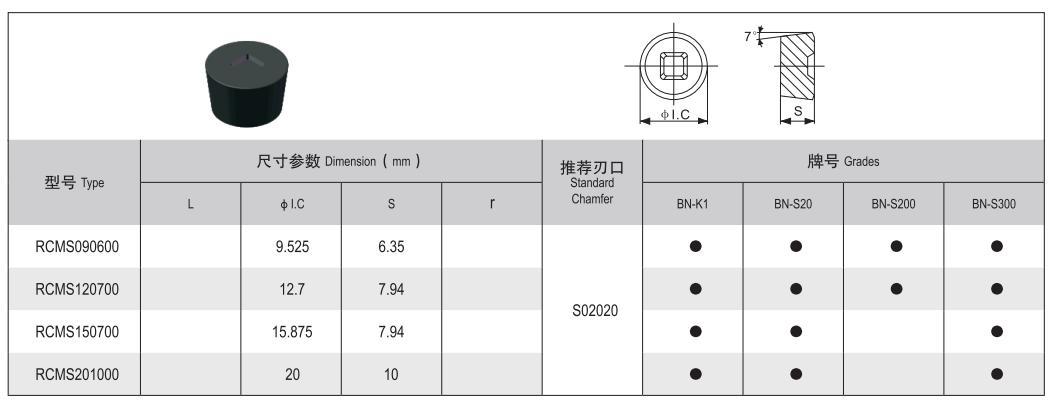

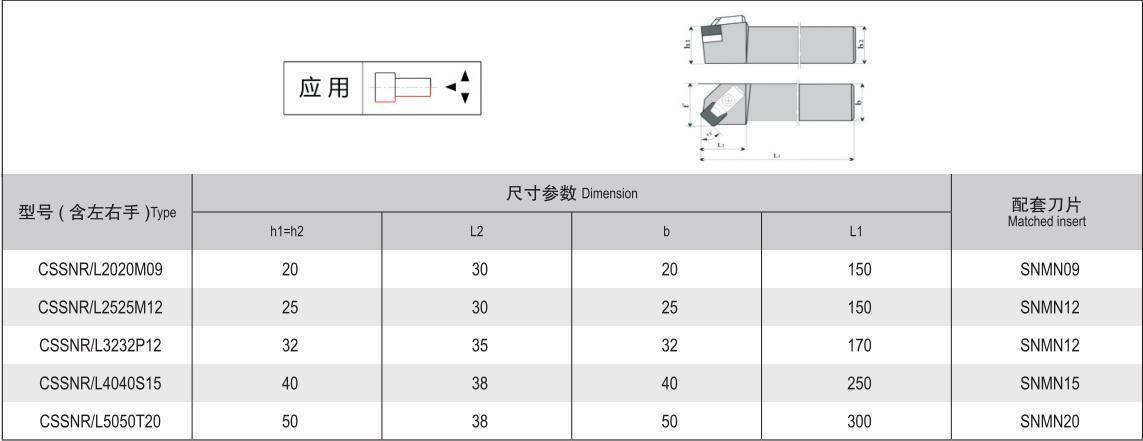

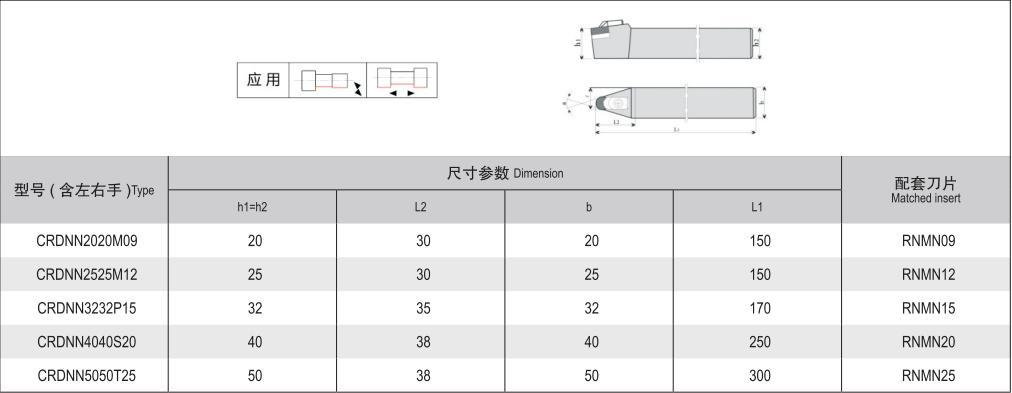

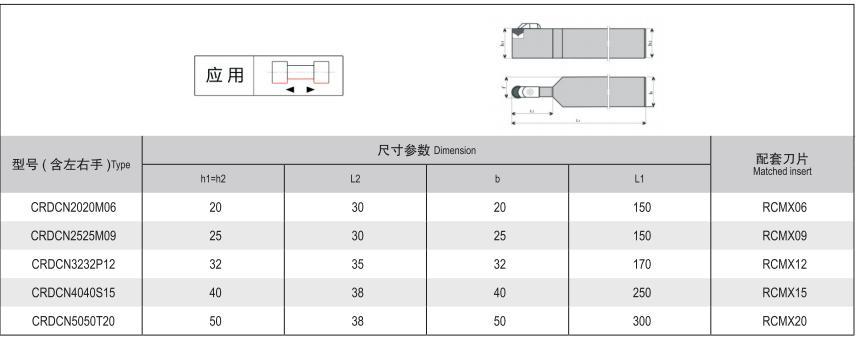

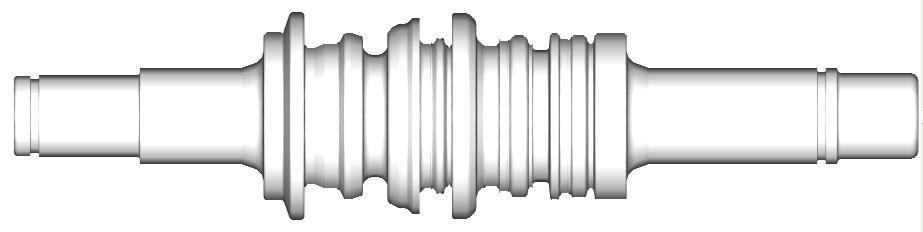

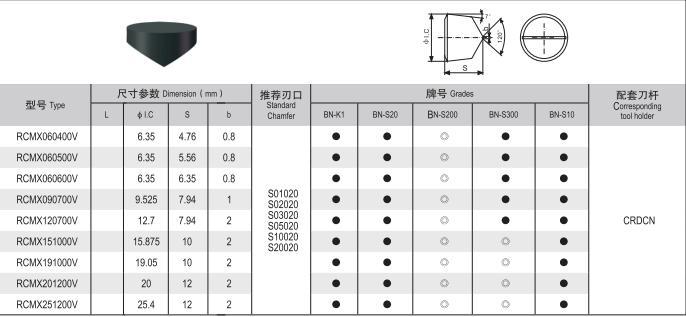

RNMNInserts,CorrespondingToolHolderCRDNN

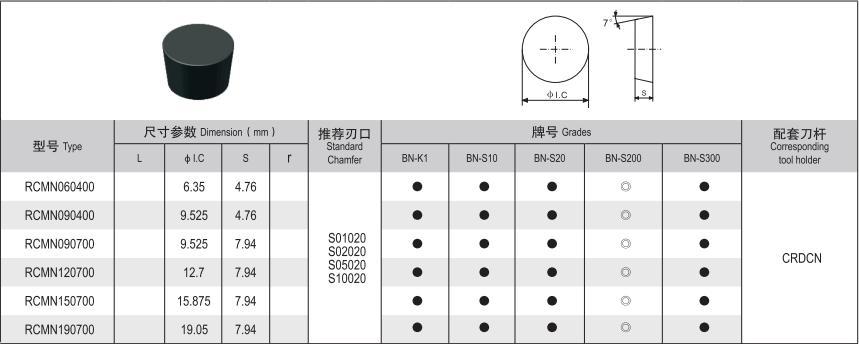

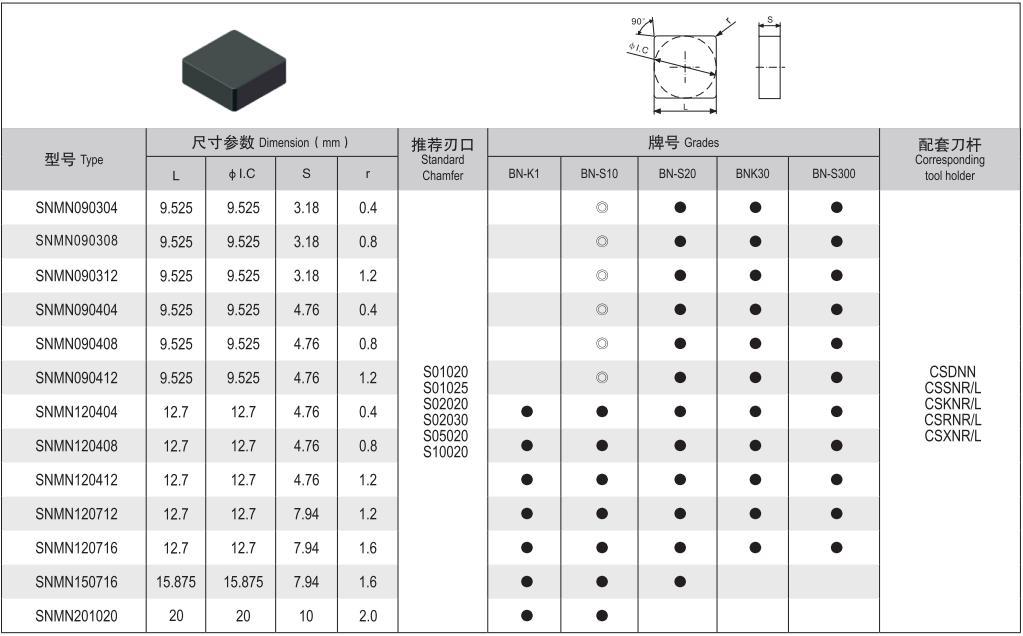

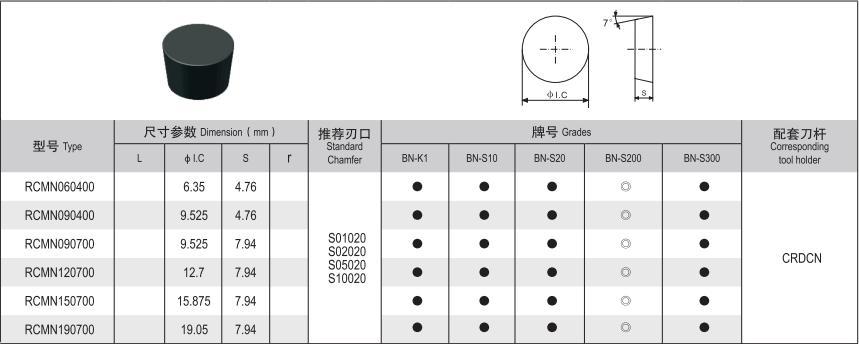

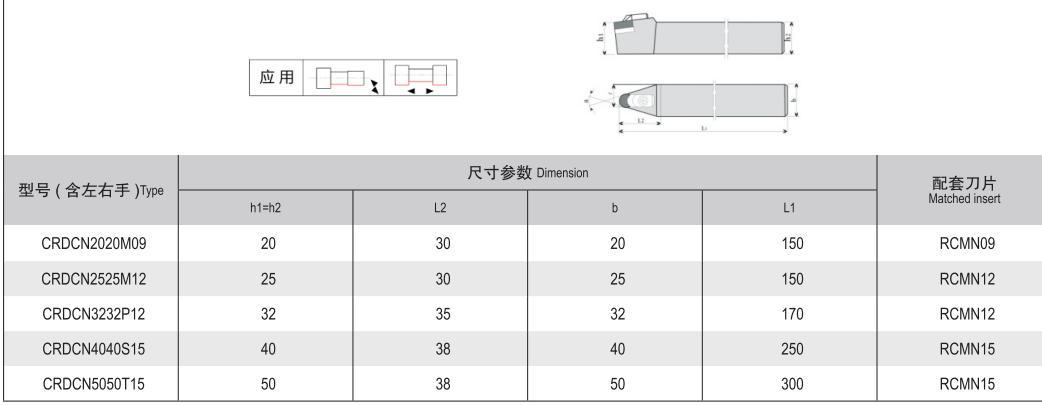

3.CBNInsertsandToolsHolderforrollswhichproducingProfilesteel

05

No.RollsMaterials Wokringlayer hardness Recommendcuttingparameters 1HighChromeNickel CastIron HSD72-82 Roughing Vc=15-30m/min,ap=3-7mm,f=1-2.5mm/r Semi-finishing Vc=20-40m/min,ap=4mm,f=1.5-2.5mm/r 2HighChromeCastIron HSD72-78 Roughing Vc=10-20m/min,ap=3-7mm,f=0.50-1.2mm/r Semi-finishing Vc=15-30m/minap=4mmf=1.5-2.5mm/r 3 CastingHSS HSD82-90 Vc=5-15m/minap=3-8mmf=1-2.5mm/r 4 CastingSemi-steel HSD55-65 Vc=30-60m/minap=4mmf=1.5-2.5mm/r 5HighCartonSemi-Steel HSD65-72 Vc=25-50m/minap=4mmf=1.5-2.5mm/r 6 ChilledCastIron HSD50-70 Vc=25-50m/minap=4mmf=1.5-2.5mm/r 7HighChromeCastSteel HSD68-75 Vc=20-45m/minap=4mmf=1.5-2.5mm/r 8TungstenCarbideRings HRA88 Vc=15-60m/minap=0.2-0.5mmf=0.1-1mm/r 9 Forging9Cr2Mo HSD92-105 Vc=10-25m/minap=1mmf=0.5-1.2mm/r HalnnrecommendCuttingParameters

TypicalCustomsofHalnninrollsindustry pFinalCustomers:WISCO,ANSTELL,HBISSTEELGROUP,VALIN STEEL,BLHI,andBAOSTEELROLL. pCustomersforCarbideRings:XIAMENGOLDENEGRETSPECIALALLOY,ect. pCooperationcompany:QiqiharHeavyCNCequipmentLimited,Qinghaihuading heavy-dutymachinetools,ect.

HalnnSuperhard,asthepioneerofsuperhardcuttingtoolsin China,makenationalSuperhardMaterialsKeyLaboratory andHenanUniversityofScienceandtechnologyastechnical support,haveourownresearchcenter,focuson ,haveobviousadvantagesonmost industries,suchas ect.Atthesametime,wehavelaunchedaseries ofnewcbn/pcdcuttingtoolsandothermaterialtoolsin3C, aerospaceandNuclearenergymilitaryfield,dependingonth researchcenterofHenanSuperhardMaterialsInstitute.Our customershavecoveredmanycountriesandareas,including ChinaMainland,German,Italy,USA,Koreaandotherareas.