DifficultiesinturningRolls

andselectionofCBNtools、Rollsringnotchingtools

Therollsingmilliswidelyusedinthemetallurgicalindustry,andtherollsasthe mainworkingpartdeterminestheefficiencyandqualityoftherollsingmill,sothe selectionofcubicboronnitridetool(CBNtool)isveryimportantwhenturningthe rolls.Today,combinedwiththepracticalapplicationcase,wewilltalkaboutthe difficultiesofturningtherolls,aswellastheselectionofcubicboronnitridetool (CBNtool)andRollsringnotchinginserts

Atpresent,thecommonrollsare:HighNi-CrAlloyrolls,Chilledcastironrolls, forgedsteelcoldrolls,HighBoronSteelrolls,Profiledrolls,Threadedsteelrolls,wire rodHSSrolls,CastingHSSRollsandsoon.themainprocessingformsare: cylindricalwastelandturning,passturning,heavycutting,crescentgrooveprocessing, flatheadmilling,rollrepairandotherprocessingforms

ProblemsfacedbyturningRoller:

1、Heavyquality,heavyloadcuttingisdifficultTherollsrequiringturningare generallyoflargesizeandheavyqualitycomparedwithordinarycutting,theyhave thecharacteristicsoflargecuttingdepth,relativelylowcuttingspeedandrelatively slowfeedspeed.therefore,itsmachiningprocessisverydifferentfromtheordinary mechanicalcuttingprocess,whichliesinthedecreaseoftherigidityandstabilityof

图1RollsCommonCuttingTypesthemachinetoolSelectionofcuttingtools,installationofcuttingtools,selectionof cuttingparametersandclampingofworkpieces,etc.Amongthem,highhardness heavypartsarethemostdifficulttoprocess.

2、Largesizeandlongprocessingtime.Mostoftherollsthatneedturningare largerinsizeandtakealongtimetoprocess,sothetooliseasytowearoutbeforeit comestotheend,whichleadstoreworkandfrequenttoolchange,whichaffectsthe machiningefficiency

3、Afteraddingmaterial,thehardnessishigh,andthecuttingdifficultyis increased.Inordertoimprovethehardness,wearresistanceandthermalstrengthof therollandpreventtherollfromcracking,elementssuchasmolybdenum,manganese andchromiumwillbeaddedintherollproductionprocesstoformanalloylayeron therollsurfacetoprolongtheservicelifeoftherollthisalsoincreasesthecutting difficultyoftherolltoacertainextent

Defectsaredifficulttoavoidandtheprocessingconditionsarecomplex.Someof therollsthatneedturninghavedefectssuchassandentrapment,airholes,hardspots andsoon,andthemachiningconditionsarecomplex,whichleadstothephenomenon oftoolcollapseorevenknifestabbing

Atpresent,thecommontoolsinthemarketarecementedcarbidetools,ceramic toolsandcubicboronnitridetools(CBNtools).However,withtheimprovementof rollhardness,wearresistance,machiningefficiencyandmachiningprecision, traditionaltoolscannolongermeetthemachiningneedsofrollers.Althoughrookie cubicboronnitridetoolscanmeettheneedsofmachiningrolls,theyaredifferentdue todifferentproductionenterprisesandproductionprocessesTheperformanceof cubicboronnitridetools(CBNtools)isalsoslightlydifferent.Today,theauthorwill talkaboutthegradesandchoicesofcubicboronnitridetools(CBNtools)commonly usedinturningrollsaccordingtotheirownexperienceandrelatedcases.

、RoughmachiningHighNi-CrAlloyCastIronRolls

ForhighNi-Cralloycastironrollswithlargecuttingmargin,highhardnessand serioussandcoating,BN-K1cubicboronnitrideCBNtoolcanbeselected.The

relevantcaseparametersareasfollows:

Material:HighNi-CrCastIron, Hardness:HSD80

SelectedInsert:BN-K1

CuttingCondition:ap=9mm,Fr=05mm/r,Vc=25m/min

二、Finishturningforgedsteelcoldrolls

IfthecoldrollsofforgedsteelismachinedbyFinishturning,thecubicboron nitrideCBNtoolsofBN-S20gradecanbeselected.Comparedwiththealloytool,the efficiencycanbeincreasedby5xTherelevantcaseparametersareasfollows:

Material:Forgedsteelcoldrolls

Hardness:HRC60

SelectedInsert:BN-20

Semi-finishingchilledcastironrolls

Ifitisasemi-finishinginfinitelychilledcastironrolls,youcanalsochoose BN-K1cubicboronnitrideCBNtools,whichcanincreasetheefficiencyby2x comparedwithalloytoolsTherelevantcaseparametersareasfollows:

四、notchinginsertsformachiningcrescentgrooveofProfiledrolls

IftheProfiledrollsmillingcrescentgroove,accordingtotheactualneedsofthe enterprisecanchoosethecorrespondingPCDrotarymillingtools,whetheritisthe repairrollorthenewroll,PCDrotarymillingtoolscanbeused.

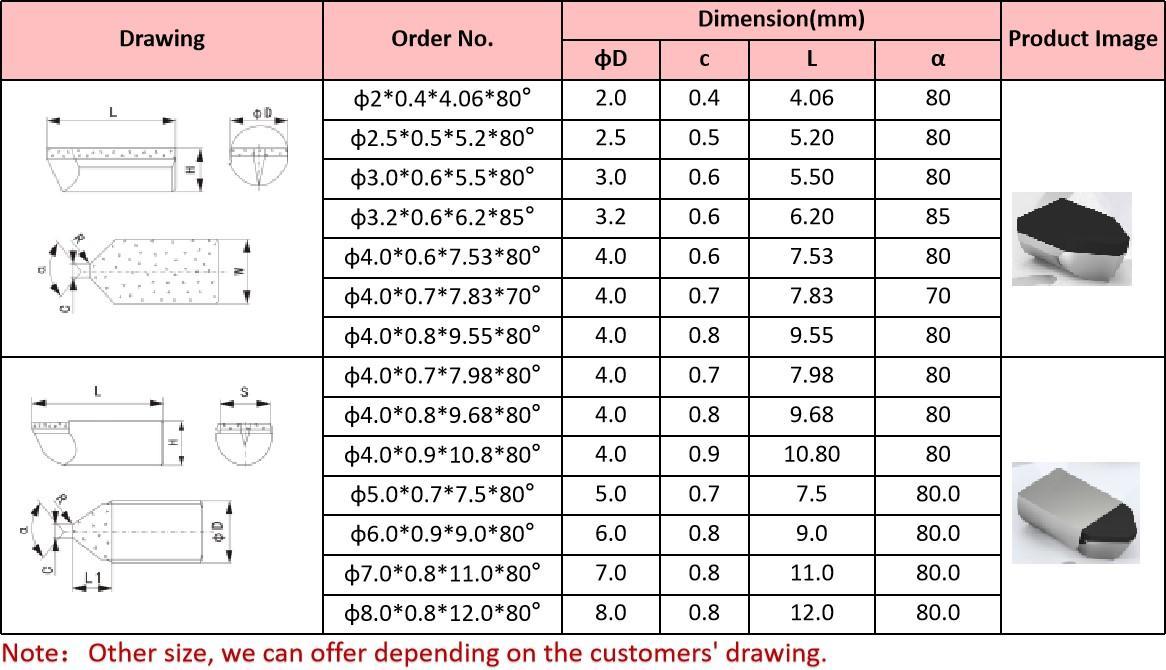

SpecificationofPCDNotchingtools:

Diameter4mmandabovecanchoosebrazingstructurePCDrotarymillingtools (ribtools),diameterlessthan4mmcanchoosefullveneer.

Diameter4mmandabovecanchoosebrazingstructurePCDrotarymillingtools (ribtools),diameterlessthan4mmcanchoosefullveneer.

Amongthem,PCDrollrotarymillingtoolsandCVDRollsnotchingtoolscan alsobenon-standardcustomizedaccordingtotheactualneedsofenterprisesAt present,thecommonCVDRollsnotchingtoolsareasfollows:

Inaddition,BN-K1,BN-S20,BN-S300andothercubicboronnitrideCBNtools arealsousedtoprocesspassgroovesofhighboronsteelrolls,repairingThreaded steelrolls,RepairedHSSRollsandRepairedCastingHSSRolls.

Asforthespecificcubicboronnitridetool(CBNtool)selectionandmachining parameterswhenturningtherolls,theauthorhassortedoutthecorrespondingtable, whichcanbeusedasareference:

Allright,thesearetheauthor'sopinionsonthedifficultiesofturningrolls,the selectionofcubicboronnitridetools(CBNtools)whenturningrolls,andtherelevant cuttingparametersIfyoualsohavedifferentopinionsorviews,welcometoexchange anddiscusstogether