Direct thermal labels vs. thermal transfer labels USEFUL INFORMATION Do you sometimes wonder what the difference between direct thermal and thermal transfer is? And which of the two suits your activities best? Each type of label has its advantages and disadvantages and below we explain the difference so that you will be able to use the most beneficial labels.

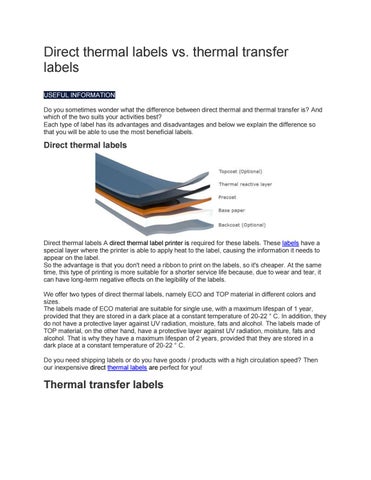

Direct thermal labels

Direct thermal labels A direct thermal label printer is required for these labels. These labels have a special layer where the printer is able to apply heat to the label, causing the information it needs to appear on the label. So the advantage is that you don't need a ribbon to print on the labels, so it's cheaper. At the same time, this type of printing is more suitable for a shorter service life because, due to wear and tear, it can have long-term negative effects on the legibility of the labels. We offer two types of direct thermal labels, namely ECO and TOP material in different colors and sizes. The labels made of ECO material are suitable for single use, with a maximum lifespan of 1 year, provided that they are stored in a dark place at a constant temperature of 20-22 ° C. In addition, they do not have a protective layer against UV radiation, moisture, fats and alcohol. The labels made of TOP material, on the other hand, have a protective layer against UV radiation, moisture, fats and alcohol. That is why they have a maximum lifespan of 2 years, provided that they are stored in a dark place at a constant temperature of 20-22 ° C. Do you need shipping labels or do you have goods / products with a high circulation speed? Then our inexpensive direct thermal labels are perfect for you!

Thermal transfer labels