Series

AMH = ADP Mobile Home Furnace Revision

Blower Motor

E = 5-speed ECM motor

Cabinet N = Not Included Unit Size

2 = 2 Ton Voltage

3 = 3 Ton

4 = 4 Ton

5 = 5 Ton

Configuration

D = Downflow

Electric Heat Available In:

00 = No heat Size 2-5 Ton

05 = 5.0 kW Size 2-5 Ton

07 = 7.5 kW Size 2-5 Ton

10 = 10 kW Size 2-5 Ton

12 = 12.5 kW Size 3-5 Ton

15 = 15 kW Size 3-5 Ton

20 = 20 kW Size 4-5 Ton

Series MH = Mobile Home

Accessory

= 120 V, 60 Hz, 1 ph., with time delay

= 208/240 V, 60 Hz, 1 ph., with time delay

Line Voltage Connection

= Stripped Wires

= Circuit Breaker

• Standard footprint for installation in manufactured homes.

• Compatible with 2-5 Ton AC or HP systems.

• Factory configured for downflow, field convertible for up-flow.

• Electric heat available factory or field installed for 208/240 V models.

• Multiple coil cabinet and filter grille options available.

• Perfectly matches with ADP manufactured housing coils.

• Meets UL 60335-2-40 product requirements.

• Blower panel with handle and push-to-lock feature for easy access.

• Cabinet and door lined with high quality 5/8" foil faced insulation for quiet operation.

• Cabinet constructed of heavy-gauge, corrosion-resistant galvanized steel.

• Slide-out blower assemblies for easy access to blower motor.

• 120 V or 208/240 V 60 Hz supply voltages available.

• 5-speed high-efficiency ECM motor.

• Terminal board with screw down connections for thermostat wiring.

• Fan time delay built-in (1 second on, 45 seconds off).

• Multiple knockout options for line voltage and thermostat connections.

• Blower door safety switch on all models.

Nominal CFM Range

[1]

Maximum Electric Heat Available (kW)

Transformer Size and Type

Blower Data

5-Speed High Efficiency ECM Motor (120 V)

Blower Data

5-Speed High Efficiency ECM

Motor (240 V)

Approx. Weight lbs (base unit w/o electric heat)

AMHE3D*

AMHE4D*

Notes :

1. All data is given while air handler is operating with a dry coil and air filter installed.

2. Speeds marked *bold with asterisk are the factory speed settings for Cooling.

3. Speeds marked #bold with asterisk are the factory speed settings for Heating.

4. Heating speeds should not be reduced below factory setting.

5. Different speeds can be set for cooling mode; see installation instructions for changing cooling speeds. AMHE5D*

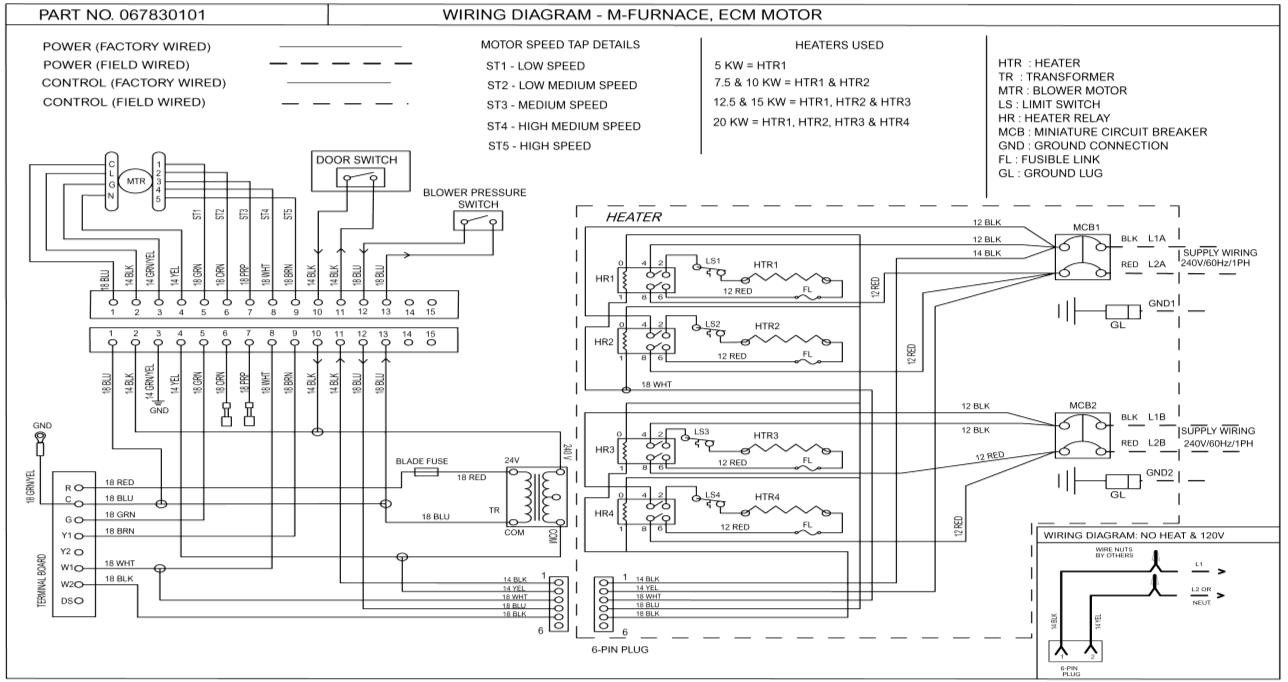

Wiring Diagram

Cooling Application Only

Thermostat Terminals

Condensing unit Terminals mFurnace Terminals

Cooling with Single-Stage Electric Heat Application

Thermostat Terminals

Condensing unit Terminals mFurnace Terminals

Cooling with Two-Stage Electric Heat Application

Thermostat Terminals

unit Terminals

Terminals

Heat Pump with Single-Stage Electric Heat Application

Thermostat Terminals

Condensing unit Terminals mFurnace Terminals

Heat Pump with Two-Stage Electric Heat Application

Thermostat Terminals mFurnace Terminals

Condensing unit Terminals

Heating Application Only

Thermostat Terminals mFurnace Terminals

• High efficiency lanced fin design.

• “No-hassle” 5-year warranty. 10 year Limited Warranty available.

• R-32, R454B, AC & Heat Pump compatible with Refrigerant Detection System

• All coils have durable packaging with bar coded labels on the box.

• Threaded expansion valves available factory installed or as a field installed kit.

• Factory installed Refrigerant Detection Sensor Bracket

• Coils are air pressure tested at 500 psi, leak tested with helium, sealed with rubber plugs, then charged with dry air.

• Downflow drip shields are molded into drain pan.

• Filter-friendly top plate on most models (except 22" & above).

• Down-turned headers are sized out to easily receive line set.

• Factory software for TXV failure testing.

• Includes die-cut foam sheet for sealing, drain ELL, drain hose & clamp.

• Dedicated upflow/downflow.

• Copper refrigerant connections for easy brazing

• Rifled copper tubing.

• Field or factory installed threaded expansion valve.

Refrigerant Detection System (Field Configurable)

Series R = RDS Controller & Sensor (Factory Installed)

M = Manufactured Housing

L = Leak Detection Sensor (Factory Installed) (Uncased)

N = Not Included (Field Installed)

Nominal MBTUH

Slab Number

E30

E31 etc.

Refrigerant Type & Metering Device (Field Configurable)

1 = Piston *

A = R-454B Non-bleed HP-A/C TXV

B = R-32 Non-bleed HP-A/C TXV

C = R-454B Bleed HP-A/C TXV

* R-454B Piston factory installed to match the nominal BTU rating of the coil.