SKETCH ANY THREE PRODUCTS

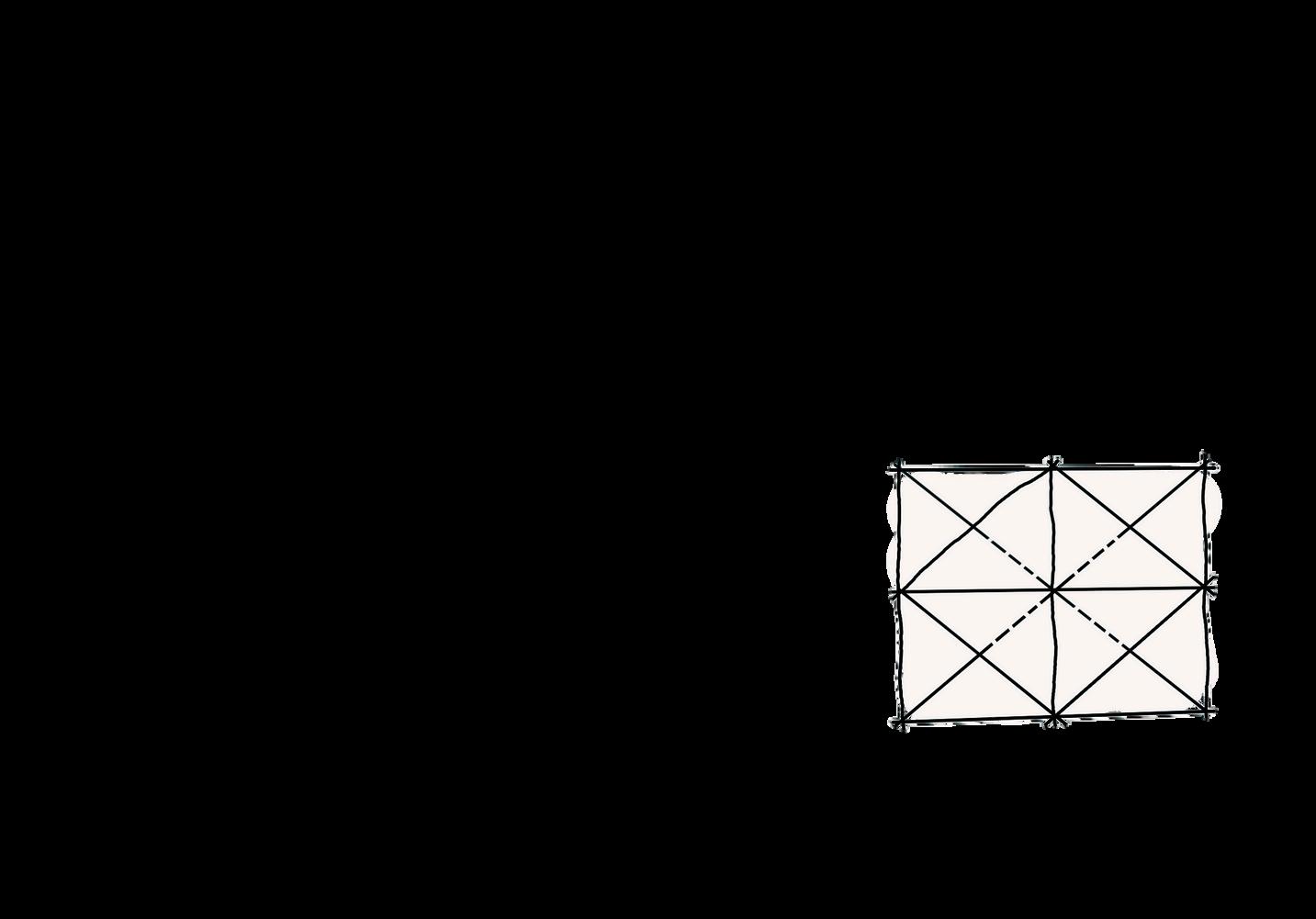

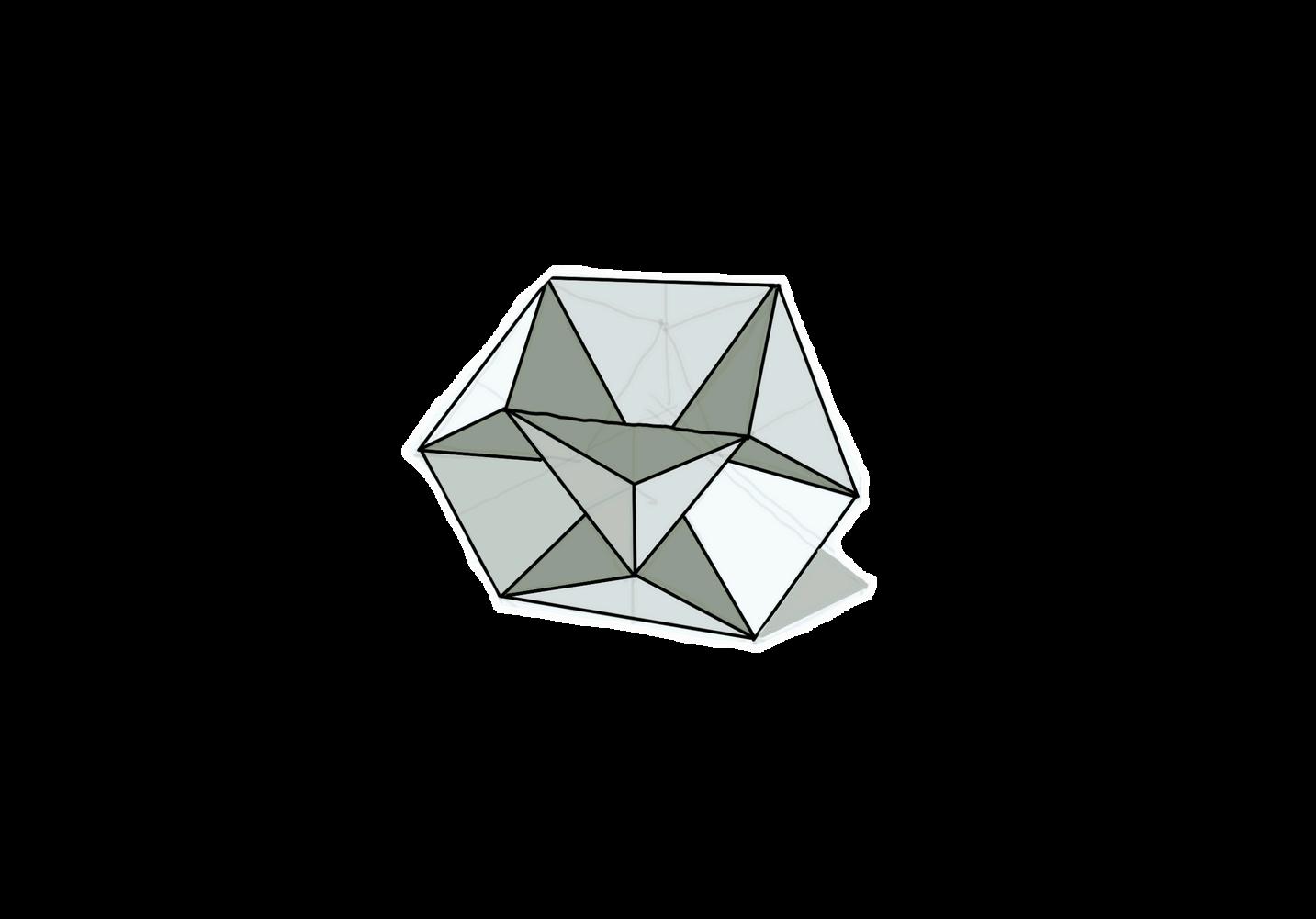

) DETAIL OF JOINERY FOR ANY ONE PRODUCT GEOMETRIC MODEL WITH ELEVATIONS

The sketch represents a classic hat, possibly a fedora or bowler style, featuring a structured crown and a curved brim. It is likely made from felt, wool, straw, or synthetic fabric, depending on its intended use. The hat's construction involves blocking and shaping the material over a mold, ensuring a structured form. The brim is reinforced to maintain its shape, possibly with a wire or stiff fabric lining. A decorative band wraps around the base of the crown, stitched or glued for secure attachment. The inner lining is often added for comfort and durability, using soft fabric or sweat-absorbent materials. The joinery includes stitching, pressing, and adhesive bonding, ensuring durability while maintaining a stylish appearance.

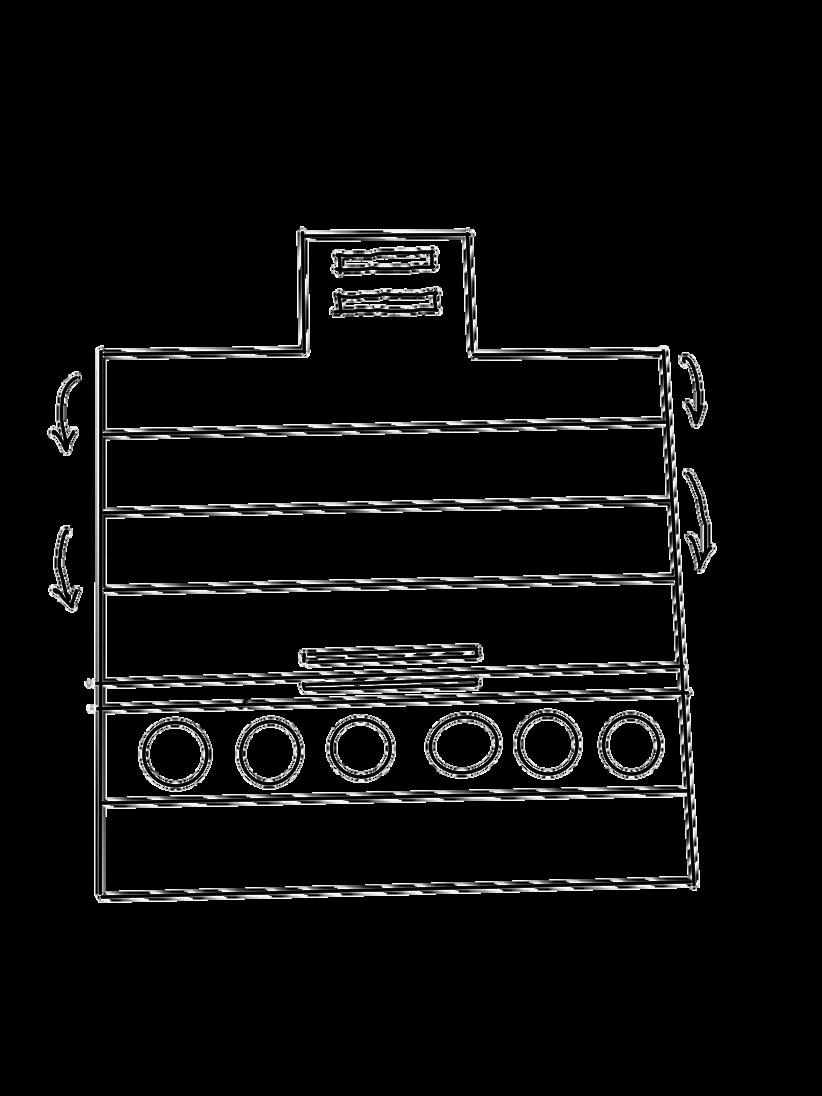

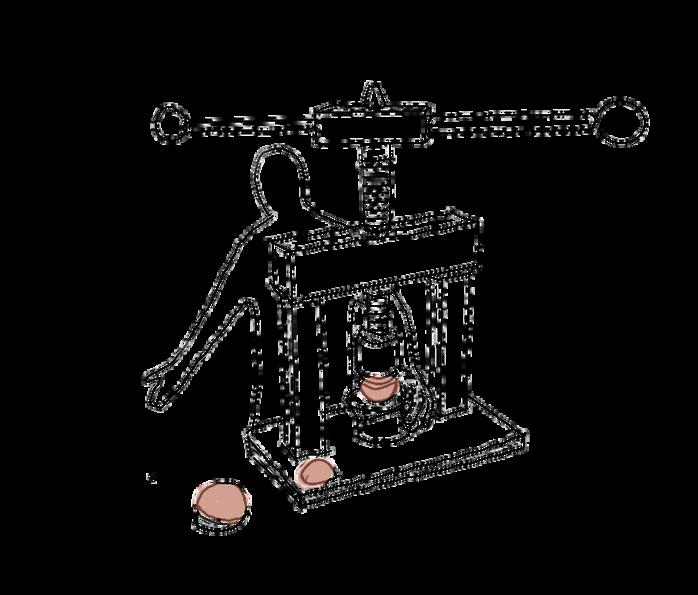

The sketch represents a rotating turntable or pedestal, likely used for pottery, cake decoration, or display purposes. The structure consists of a flat circular top platform and a wider conical base for stability. It is likely made from metal, wood, or ceramic, depending on its intended use. The top disc may be welded, screwed, or riveted to the base, ensuring a secure attachment. If designed to rotate, it could incorporate a ball-bearing mechanism or central pivot for smooth movement. The edges of the top appear reinforced, possibly with metal rims or extra layering for added durability. The base may have a textured or ribbed surface to improve grip and stability.

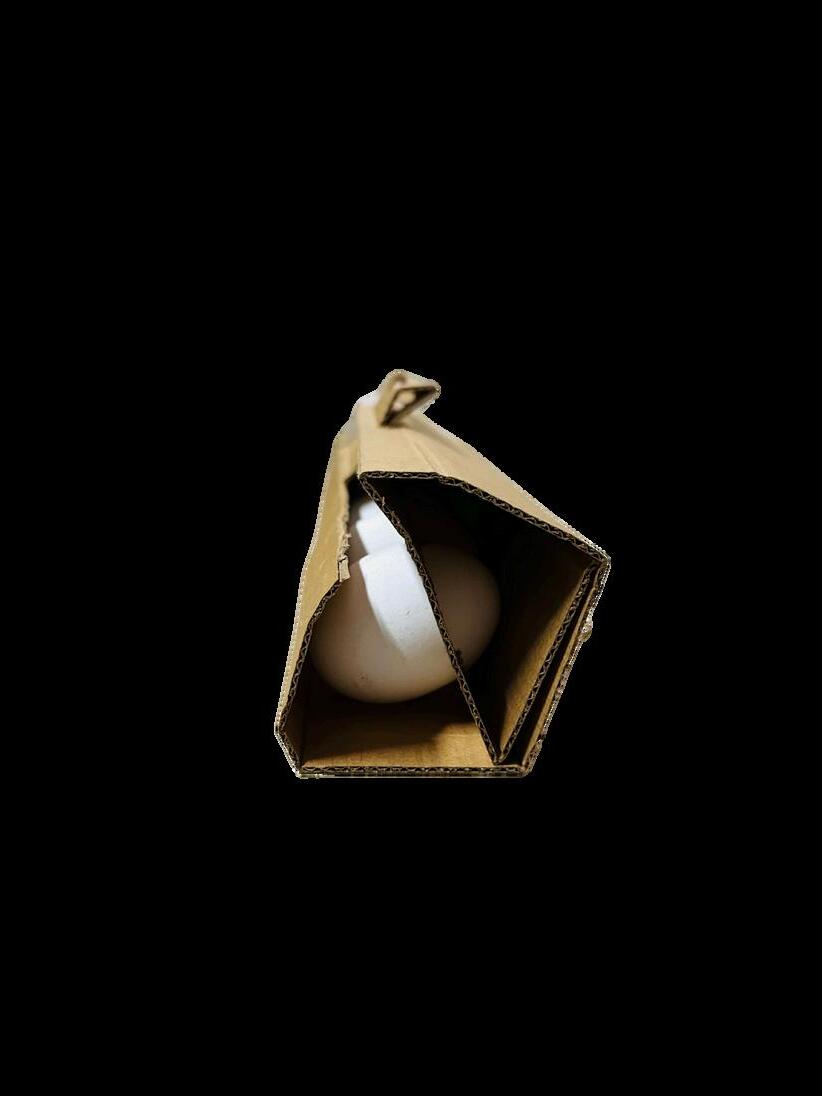

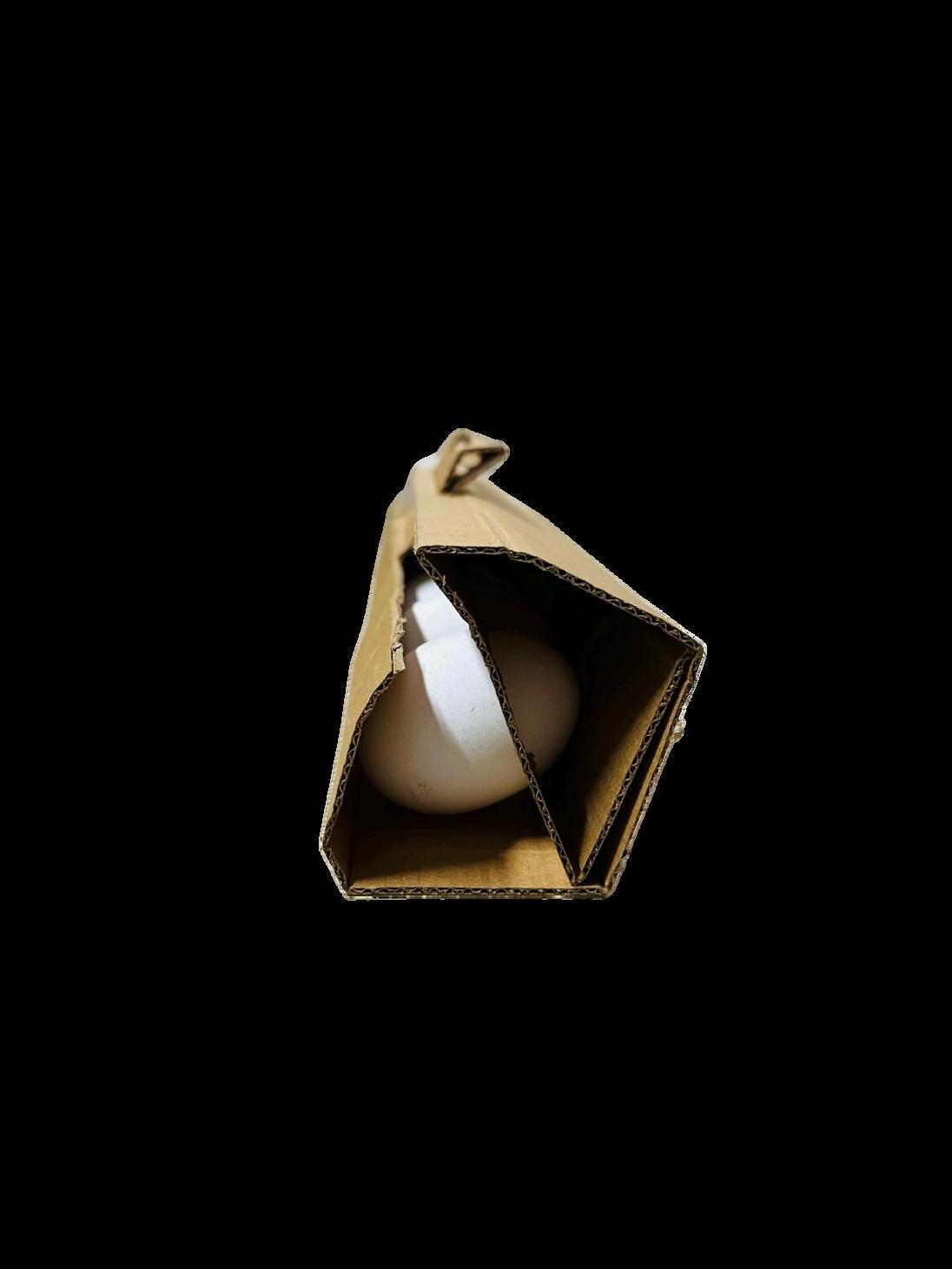

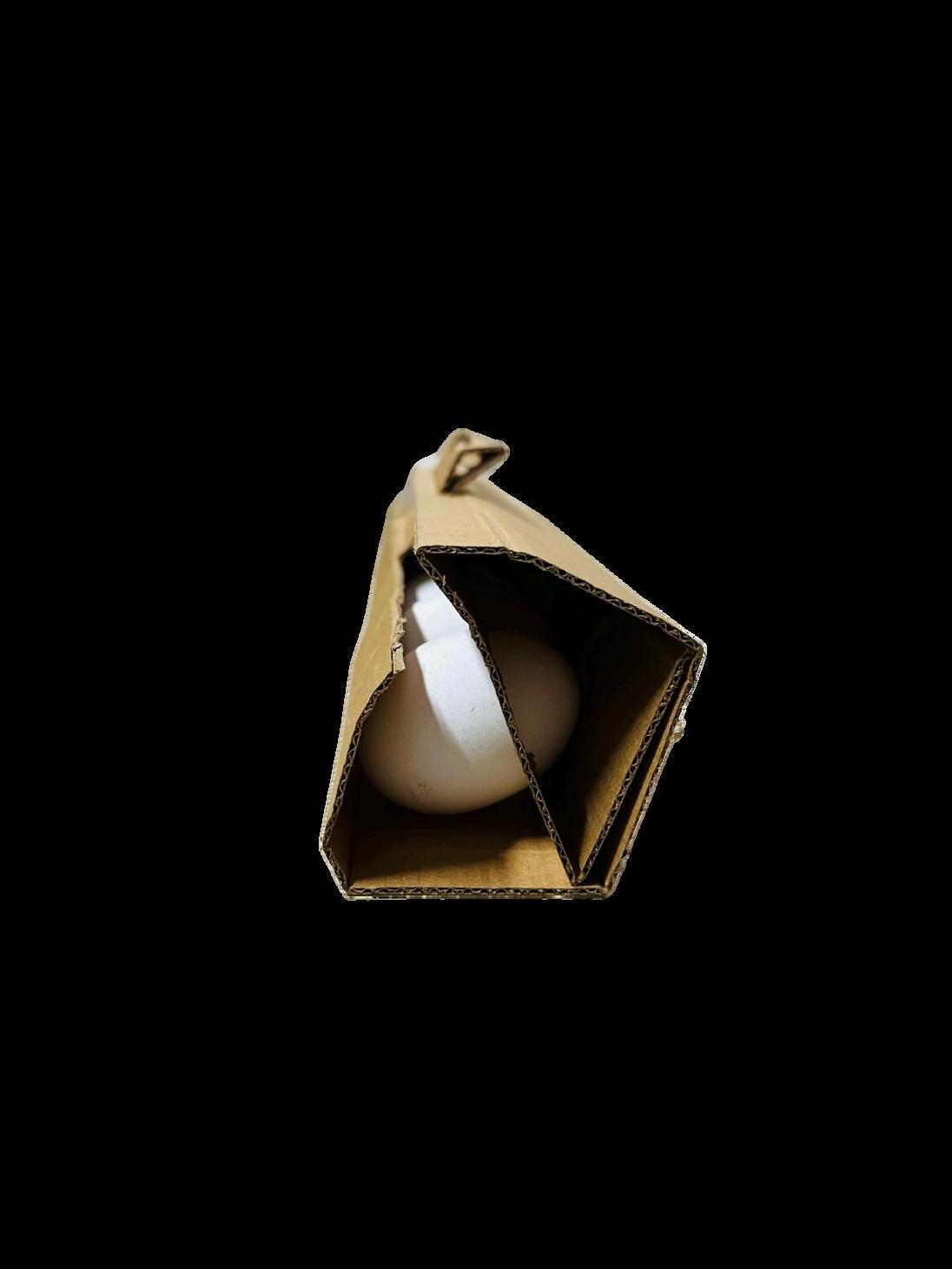

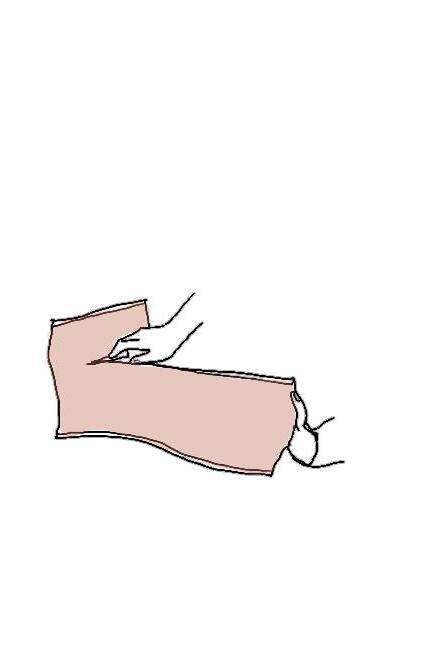

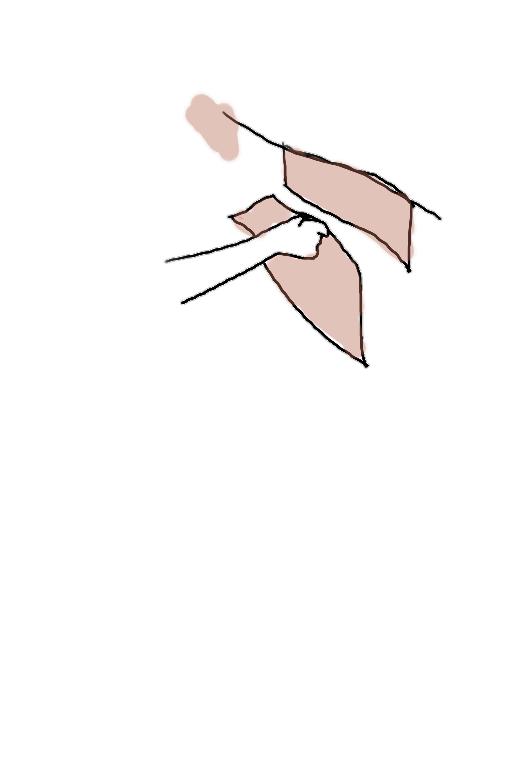

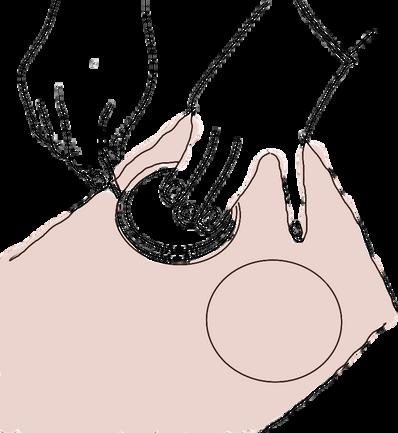

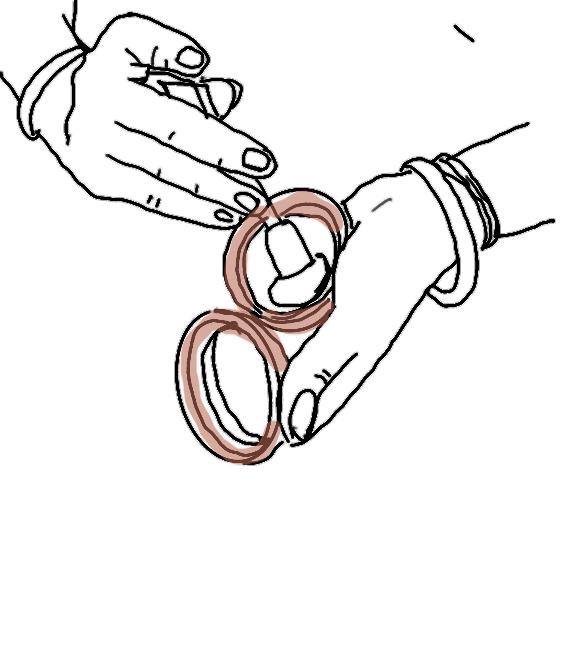

The bag is designed using a single folded leather piece with minimal seams, ensuring durability. The edges are joined using reinforced stitching techniques like saddle stitching or lockstitch. Handles are attached with rivets or stitched flaps for added strength. The closure system appears to use a snap button or loop mechanism. The diagrams suggest detailed sewing techniques for secure joinery. Finishing touches, including edge burnishing, polishing, and waxing, enhance durability and aesthetics, making the bag both functional and stylish.

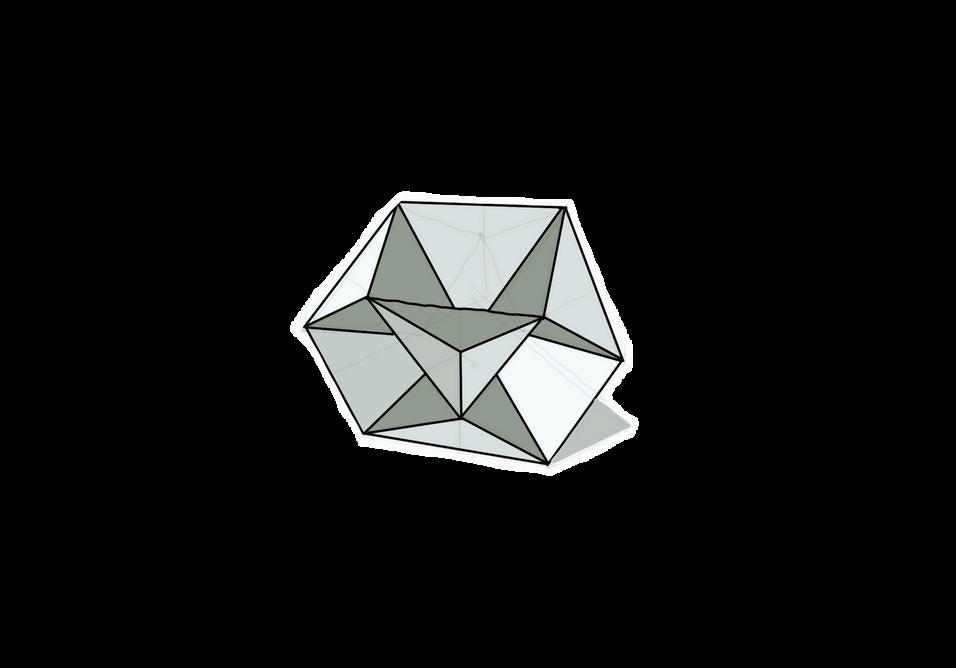

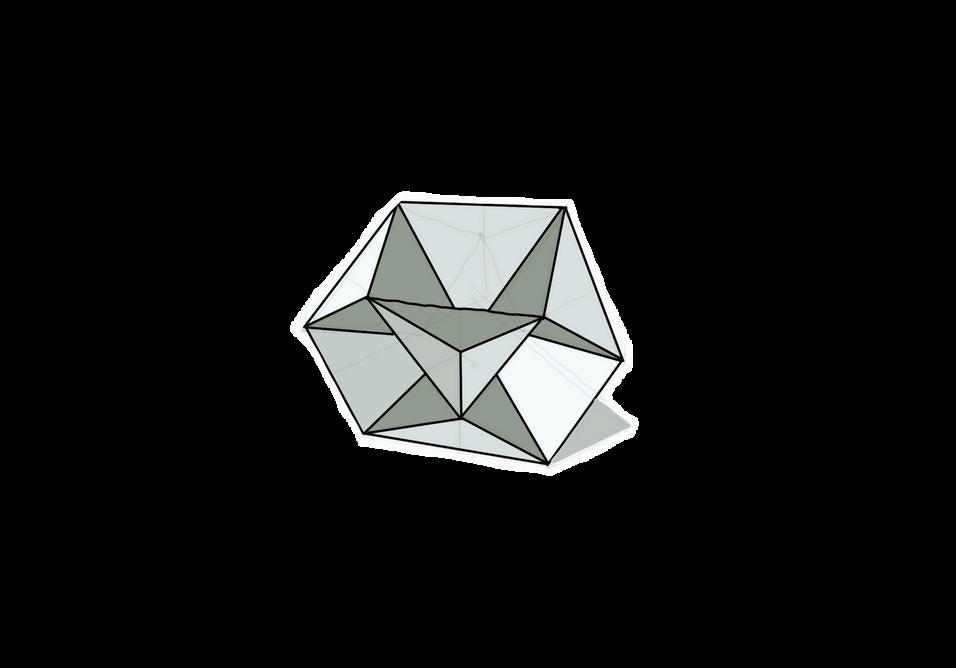

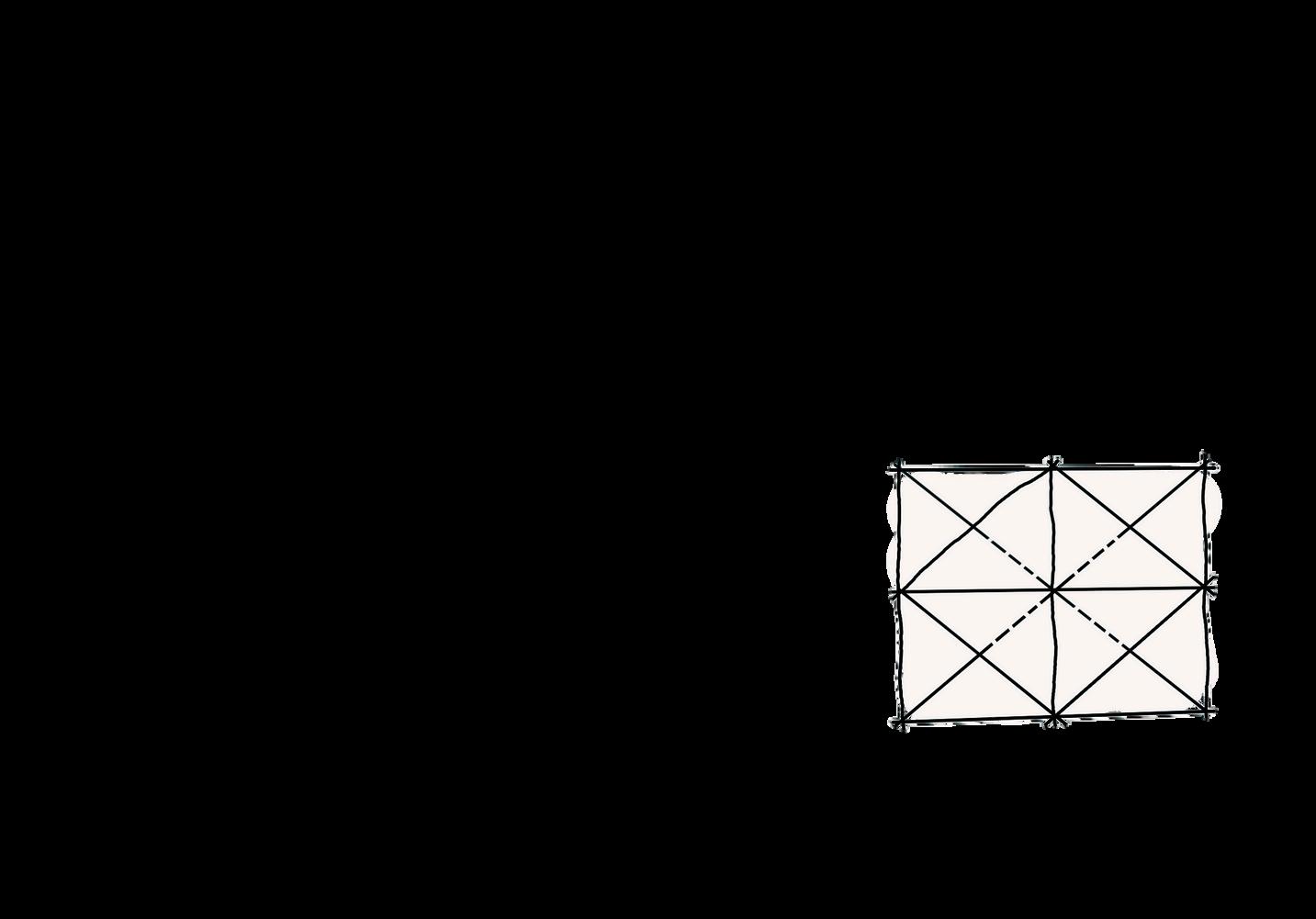

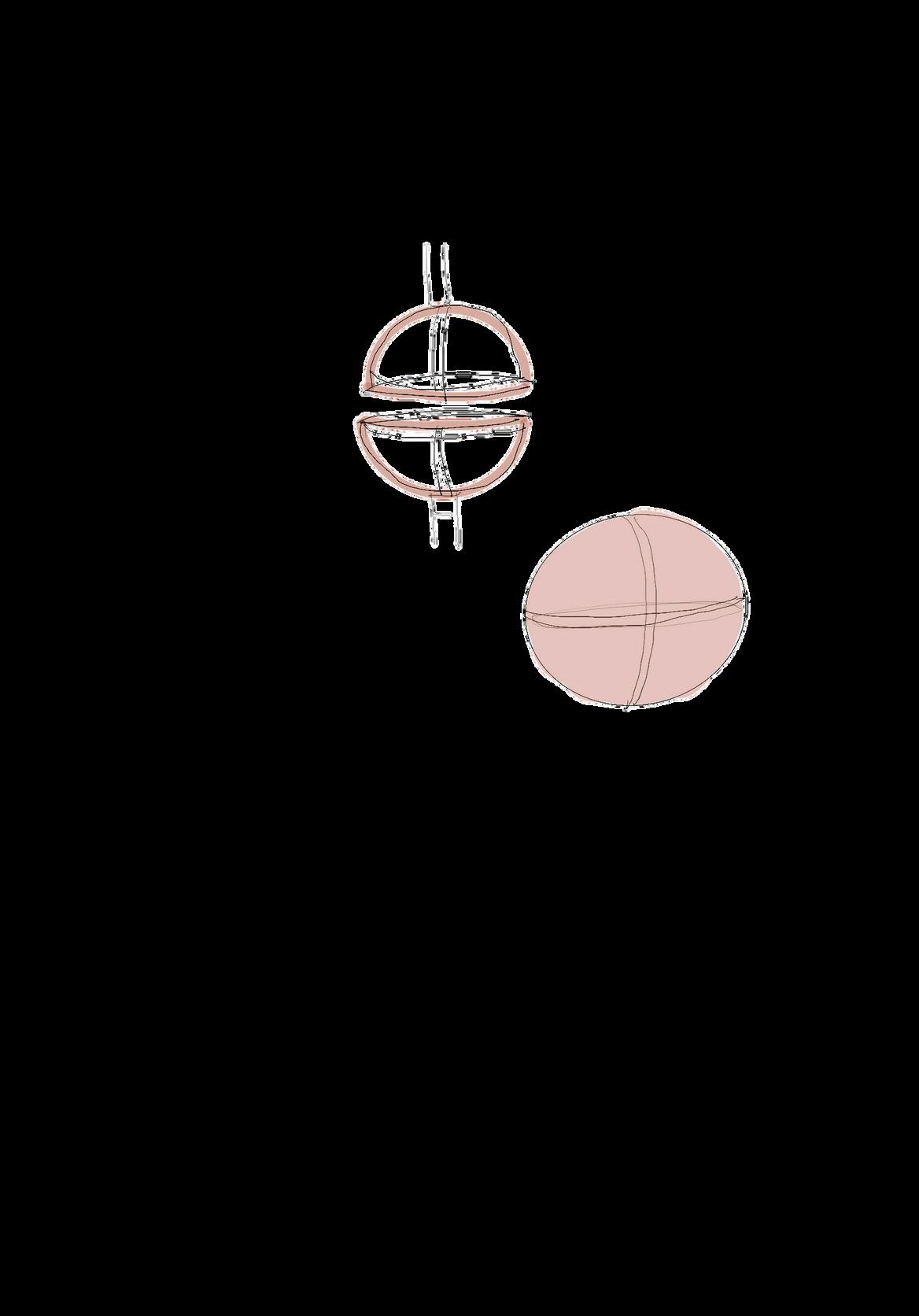

The model is made from hexagons but appears as a square from all six elevations. It consists of four outer edges, with two perpendicular lines and two diagonal lines intersecting at the center. The intersection creates a recessed depression on each face, adding depth and symmetry. This geometric design maintains a uniform, balanced appearance across all views, combining intricate structure with a clean, square-like visual effect.

- High-quality alum-tanned leather (usually cowhide) is selected for durability and shine.

- The leather is cut into large rectangular pieces using precision cutting tools to ensure uniform thickness and grain quality.

The cut leather pieces undergo a thorough eaning process to remove any impurities, atural oils, and loose fibers. The cleaning helps the leather absorb the ye evenly in the next step.

cricket ball colors typically red for test matches and white for limited-overs formats.

- The dye is applied evenly, and multiple coats may be added to achieve a deep, rich color.

- Some manufacturers also add a waterproofing agent at this stage to improve the leather's resistance to moisture.

- The dyed leather is left to dry naturally or in controlled environments to ensure prope absorption of color

- This process can take several hours to days, depending on humidity and drying techniques used.

- Proper drying helps in maintaining the leather’s flexibility and strength.

- Once dried, the leather is cut into perfectly round shapes using die-cutting machines or hand tools.

- Each cricket ball consists of four such leather pieces, which are later shaped and stitched

- The core of a cricket ball is made from layers of tightly wound cork and wool.

- A small cork sphere is at the center, wrapped with multiple layers of tightly compressed wool or string to provide proper weight and bounce

- The core is carefully measured to ensure it meets the weight requirements set by cricket governing bodies (usually between 155.9g - 163g for men's cricket).

8.

- The prepared core is wrapped wit thick, high-quality thread to maintain its spherical shape and provide additional structure.

- This step ensures the ball retains it shape even after repeated impacts during play.

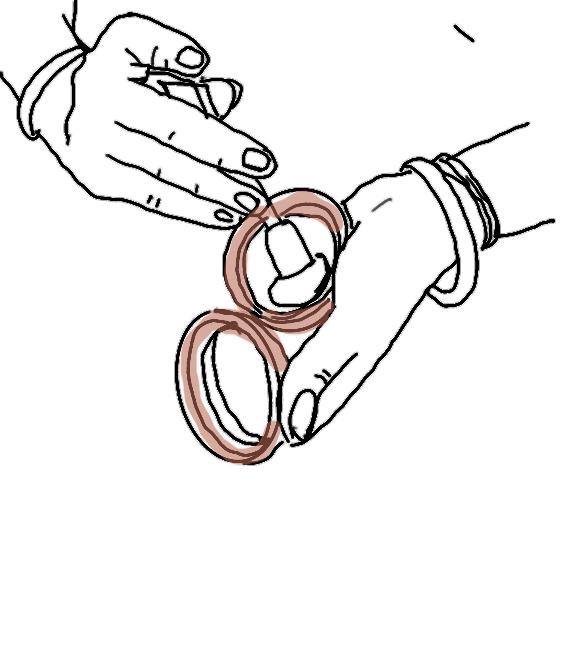

emi-spherical leather halves are und the core, and skilled craftsmen together using high-quality waxed

consists of 6 rows of prominent hich help bowlers grip and swing

ng is done by hand to ensure durability, and proper tension in the

- THE STITCHED BALL IS PRESSED TO ENSURE IT IS PERFECTLY ROUND AND FIRM.

- THE SURFACE IS POLISHED USING WAX AND A BUFFING MACHINE TO GIVE IT A SMOOTH, GLOSSY FINISH.

- BRANDING LOGOS AND CERTIFICATION STAMPS ARE ADDED TO MARK THE BALL’S AUTHENTICITY.