Grooving tools Micro-precision tools for radial grooving

Indexable inserts for radial grooving

Micro-precision tools for axial grooving

Indexable inserts for axial grooving

Indexable inserts for parting off

Micro-precision tools for turning

Micro-precision tools for internal threading

Indexable inserts for threading

Micro-precision tools for broaching

Tool holders for micro-precision tools

Tool holders for indexable inserts

General

Grooving tools

ALL-ROUNDER Highdegreeofmaterialflexibility

System 222

Didn’t find what you were looking for?

EnterveryspecificrequirementsintoouronlineGühringNavigatorand youwillreceiveprecisetoolrecommendations−cuttingvaluesincluded.

Highdegreeofmaterialflexibility

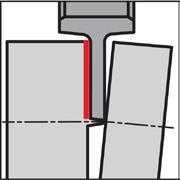

Parting off Boring outThreading | InternalThreading | ExternalBroaching

Dmin. Pmin. from SW

0,7 mm 0,2 mm 1,5 mm

e.g. # 25052 p.65 e.g. # 25158 p.99

e.g. # 25229 p.110

Dmin. Pmin.

SW 5,0 mm 1,0 mm

e.g. # 25834 p. 66 e.g. # 25774 p. 101 e.g. # 25897 p. 110

Dmin. Pmin. from SW 7,0 mm 1,5 mm 8,0 mm e.g. # 27100 p.68 e.g. # 27132 p.98 e.g. # 27146 p.111

tmax. Pmin.

5,0 mm 0,3 mm

e.g. # 25641 p.61 e.g. # 25654 p.106

tmax. 45,0 mm

e.g. # 26601 p. 63

SYSTEM 10 4 | 10 6 | 108

Cuttinginsert

Tooldescription:Example:

System Angle W1°

Dimension a Radius

La (neck) length Dmin.

Version R/L/N

SYSTEM 10 4 | 10 6 | 10 8 | 110

Toolholder

SYSTEM 305

Indexableinsert

Tooldescription:Example:GB110.0010.090.00.22.N.IK

System Shank size

Total length

Cutting edge position

Size

Version R/L/N IC

Tooldescription:Example:

System

Cutting width

Corner radius

Rake angle

Insert width

Version R/L/N

Indexableinsert

Tooldescription:Example:GZ222.0300.020.PM.01.N/R/L.08

System

Cutting width

Corner radius

Rake angle

Range of application

Version R/L/N for R/L: Ang le

SYSTEM 305 | 222 Toolholder

Tooldescription:Example:

System

SYSTEM 222 Partingoffblade

Tooldescription:Example:

Internal radial grooving Internal threading Grooving tools

Round

Round

Round shank holders,

Round

Polygon shank holders,

Polygon shank holders, according to

26623, offset 90°

Polygon shank holders, according to ISO 26623, offset 90°

HSK-T holders, according to ISO 12164-3, straight 0°

Square shank holders 90° offset and stepped, without IC

Cutting inserts for internal grooving, flat bottom slots groovingdepth0.2-1.0mm fortoolholderstypeGB104/GH104

PMKNSH GE104 Cuttingdatapage185

PMKNSH GE104 Cuttingdatapage185

Right-handdesignasshown.Left-handdesignismirrorimage.

25126 R

25130

1.000.301.950.850.030.204.0025.004.004.001GE104.0030.000.04.10.R 1.000.301.950.850.030.207.0025.004.004.002GE104.0030.000.07.10.R 1.500.401.951.300.030.404.0025.004.004.003GE104.0040.000.04.15.R 1.500.401.951.300.030.407.0025.004.004.004GE104.0040.000.07.15.R 1.500.401.951.300.030.4012.0030.004.004.005GE104.0040.000.12.15.R 2.000.501.951.800.030.504.0025.004.004.006GE104.0050.000.04.20.R 2.000.501.951.800.030.507.0025.004.004.007GE104.0050.000.07.20.R 2.000.501.951.800.030.5012.0030.004.004.008GE104.0050.000.12.20.R 2.000.501.951.800.030.5017.0035.004.004.009GE104.0050.000.17.20.R 3.000.701.952.700.030.707.0025.004.004.010GE104.0070.000.07.30.R 3.000.701.952.700.030.7012.0030.004.004.011GE104.0070.000.12.30.R 3.000.701.952.700.030.7017.0035.004.004.012GE104.0070.000.17.30.R 3.000.701.952.700.030.7022.0040.004.004.013GE104.0070.000.22.30.R 4.000.791.703.700.031.0012.0030.004.004.014GE104.0079.000.12.40.R 4.000.791.703.700.031.0017.0035.004.004.015GE104.0079.000.17.40.R 4.000.791.703.700.031.0022.0040.004.004.016GE104.0079.000.22.40.R 4.000.791.703.700.031.0027.0045.004.004.017GE104.0079.000.27.40.R 4.000.791.703.700.031.0032.0050.004.004.018GE104.0079.000.32.40.R 4.001.001.703.700.051.0012.0030.004.004.019GE104.0100.000.12.40.R 4.001.001.703.700.051.0017.0035.004.004.020GE104.0100.000.17.40.R 4.001.001.703.700.051.0022.0040.004.004.021GE104.0100.000.22.40.R 4.001.001.703.700.051.0027.0045.004.004.022GE104.0100.000.27.40.R 4.001.001.703.700.051.0032.0050.004.004.023GE104.0100.000.32.40.R 4.001.501.703.700.051.0012.0030.004.004.024GE104.0150.000.12.40.R 4.001.501.703.700.051.0017.0035.004.004.025GE104.0150.000.17.40.R 4.001.501.703.700.051.0022.0040.004.004.026GE104.0150.000.22.40.R 4.001.501.703.700.051.0027.0045.004.004.027GE104.0150.000.27.40.R 4.001.501.703.700.051.0032.0050.004.004.028GE104.0150.000.32.40.R

25127 L

Ontheleft-handdesign,thedesignationchangesto.L

25131 L Cuttingdatapage1544

Articleno.

Articleno.

Articleno.

Articleno.

Micro-precision tools for radial grooving Cutting inserts for internal grooving, flat bottom slots groovingdepthupto1.2mm fortoolholderstypeGB106/GH106

PMKNSH GE106 Cuttingdatapage185

PMKNSH GE106 Cuttingdatapage185

Right-handdesignasshown.Left-handdesignismirrorimage.

25874 R

25878 R Dmin.bfaEFtmax.LaLgDh6Codeno.Description

5.001.002.954.700.051.2012.0037.006.006.010GE106.0100.000.12.50.R 5.001.002.954.700.051.2017.0042.006.006.020GE106.0100.000.17.50.R 5.001.002.954.700.051.2022.0047.006.006.030GE106.0100.000.22.50.R 5.001.002.954.700.051.2027.0052.006.006.040GE106.0100.000.27.50.R 5.001.002.954.700.051.2032.0057.006.006.050GE106.0100.000.32.50.R 5.001.002.954.700.051.2037.0062.006.006.060GE106.0100.000.37.50.R 5.001.002.954.700.051.2042.0067.006.006.070GE106.0100.000.42.50.R 5.001.502.954.700.051.2012.0037.006.006.110GE106.0150.000.12.50.R 5.001.502.954.700.051.2017.0042.006.006.120GE106.0150.000.17.50.R 5.001.502.954.700.051.2022.0047.006.006.130GE106.0150.000.22.50.R 5.001.502.954.700.051.2027.0052.006.006.140GE106.0150.000.27.50.R 5.001.502.954.700.051.2032.0057.006.006.150GE106.0150.000.32.50.R 5.001.502.954.700.051.2037.0062.006.006.160GE106.0150.000.37.50.R 5.001.502.954.700.051.2042.0067.006.006.170GE106.0150.000.42.50.R 5.002.002.954.700.051.2012.0037.006.006.210GE106.0200.000.12.50.R 5.002.002.954.700.051.2017.0042.006.006.220GE106.0200.000.17.50.R 5.002.002.954.700.051.2022.0047.006.006.230GE106.0200.000.22.50.R 5.002.002.954.700.051.2027.0052.006.006.240GE106.0200.000.27.50.R 5.002.002.954.700.051.2032.0057.006.006.250GE106.0200.000.32.50.R 5.002.002.954.700.051.2037.0062.006.006.260GE106.0200.000.37.50.R 5.002.002.954.700.051.2042.0067.006.006.270GE106.0200.000.42.50.R

25875 L

Ontheleft-handdesign,thedesignationchangesto.L

25879 L Cuttingdatapage1544

Articleno.

Articleno.

Articleno.

Articleno.

Cutting inserts for internal grooving, flat bottom slots groovingdepthupto2mm fortoolholderstypeGB106/GH106

PMKNSH GE106 Cuttingdatapage185

PMKNSH GE106 Cuttingdatapage185

Right-handdesignasshown.Left-handdesignismirrorimage.

25750 R

25754 R Dmin.bfaEFtmax.LaLgDh6Codeno.Description

6.001.002.705.700.052.0012.0037.006.006.001GE106.0100.000.12.60.R 6.001.002.705.700.052.0017.0042.006.006.002GE106.0100.000.17.60.R 6.001.002.705.700.052.0022.0047.006.006.003GE106.0100.000.22.60.R 6.001.002.705.700.052.0027.0052.006.006.004GE106.0100.000.27.60.R 6.001.002.705.700.052.0032.0057.006.006.005GE106.0100.000.32.60.R 6.001.002.705.700.052.0037.0062.006.006.006GE106.0100.000.37.60.R 6.001.002.705.700.052.0042.0067.006.006.007GE106.0100.000.42.60.R 6.001.502.705.700.052.0012.0037.006.006.008GE106.0150.000.12.60.R 6.001.502.705.700.052.0017.0042.006.006.009GE106.0150.000.17.60.R 6.001.502.705.700.052.0022.0047.006.006.010GE106.0150.000.22.60.R 6.001.502.705.700.052.0027.0052.006.006.011GE106.0150.000.27.60.R 6.001.502.705.700.052.0032.0057.006.006.012GE106.0150.000.32.60.R 6.001.502.705.700.052.0037.0062.006.006.013GE106.0150.000.37.60.R 6.001.502.705.700.052.0042.0067.006.006.014GE106.0150.000.42.60.R 6.002.002.705.700.052.0012.0037.006.006.015GE106.0200.000.12.60.R 6.002.002.705.700.052.0017.0042.006.006.016GE106.0200.000.17.60.R 6.002.002.705.700.052.0022.0047.006.006.017GE106.0200.000.22.60.R 6.002.002.705.700.052.0027.0052.006.006.018GE106.0200.000.27.60.R 6.002.002.705.700.052.0032.0057.006.006.019GE106.0200.000.32.60.R 6.002.002.705.700.052.0037.0062.006.006.020GE106.0200.000.37.60.R 6.002.002.705.700.052.0042.0067.006.006.021GE106.0200.000.42.60.R

25751 L

Ontheleft-handdesign,thedesignationchangesto.L

25755 L Cuttingdatapage1544

Articleno.

Articleno.

Articleno.

Articleno.

Micro-precision tools for radial grooving Cutting inserts for internal grooving, flat bottom slots groovingdepthupto2.5mm fortoolholderstypeGB108/GH108

PMKNSH GE108 Cuttingdatapage185

PMKNSH GE108 Cuttingdatapage185

Right-handdesignasshown.Left-handdesignismirrorimage.

7.001.503.956.700.052.5017.0042.008.008.010GE108.0150.000.17.70.R 7.001.503.956.700.052.5027.0052.008.008.020GE108.0150.000.27.70.R 7.001.503.956.700.052.5037.0062.008.008.030GE108.0150.000.37.70.R 7.001.503.956.700.052.5042.0067.008.008.040GE108.0150.000.42.70.R 7.001.503.956.700.052.5047.0072.008.008.050GE108.0150.000.47.70.R 7.002.003.956.700.052.5017.0042.008.008.110GE108.0200.000.17.70.R 7.002.003.956.700.052.5027.0052.008.008.120GE108.0200.000.27.70.R 7.002.003.956.700.052.5037.0062.008.008.130GE108.0200.000.37.70.R 7.002.003.956.700.052.5042.0067.008.008.140GE108.0200.000.42.70.R 7.002.003.956.700.052.5047.0072.008.008.150GE108.0200.000.47.70.R 7.002.503.956.700.052.5017.0042.008.008.210GE108.0250.000.17.70.R 7.002.503.956.700.052.5027.0052.008.008.220GE108.0250.000.27.70.R 7.002.503.956.700.052.5037.0062.008.008.230GE108.0250.000.37.70.R 7.002.503.956.700.052.5042.0067.008.008.240GE108.0250.000.42.70.R 7.002.503.956.700.052.5047.0072.008.008.250GE108.0250.000.47.70.R 7.003.003.956.700.052.5017.0042.008.008.310GE108.0300.000.17.70.R 7.003.003.956.700.052.5027.0052.008.008.320GE108.0300.000.27.70.R 7.003.003.956.700.052.5037.0062.008.008.330GE108.0300.000.37.70.R 7.003.003.956.700.052.5042.0067.008.008.340GE108.0300.000.42.70.R 7.003.003.956.700.052.5047.0072.008.008.350GE108.0300.000.47.70.R

Ontheleft-handdesign,thedesignationchangesto.L

L Cuttingdatapage1544

Articleno. 27125

Articleno. 27127

Articleno. 27124

Articleno.

Cutting inserts for internal grooving, flat bottom slots groovingdepthupto3mm fortoolholderstypeGB108/GH108

PMKNSH GE108 Cuttingdatapage185

PMKNSH GE108 Cuttingdatapage185

Right-handdesignasshown.Left-handdesignismirrorimage.

8.001.503.707.700.053.0017.0042.008.008.010GE108.0150.000.17.80.R 8.001.503.707.700.053.0027.0052.008.008.020GE108.0150.000.27.80.R 8.001.503.707.700.053.0037.0062.008.008.030GE108.0150.000.37.80.R 8.001.503.707.700.053.0042.0067.008.008.040GE108.0150.000.42.80.R 8.001.503.707.700.053.0047.0072.008.008.050GE108.0150.000.47.80.R 8.002.003.707.700.053.0017.0042.008.008.110GE108.0200.000.17.80.R 8.002.003.707.700.053.0027.0052.008.008.120GE108.0200.000.27.80.R 8.002.003.707.700.053.0037.0062.008.008.130GE108.0200.000.37.80.R 8.002.003.707.700.053.0042.0067.008.008.140GE108.0200.000.42.80.R 8.002.003.707.700.053.0047.0072.008.008.150GE108.0200.000.47.80.R 8.002.503.707.700.053.0017.0042.008.008.210GE108.0250.000.17.80.R 8.002.503.707.700.053.0027.0052.008.008.220GE108.0250.000.27.80.R 8.002.503.707.700.053.0037.0062.008.008.230GE108.0250.000.37.80.R 8.002.503.707.700.053.0042.0067.008.008.240GE108.0250.000.42.80.R 8.002.503.707.700.053.0047.0072.008.008.250GE108.0250.000.47.80.R 8.003.003.707.700.053.0017.0042.008.008.310GE108.0300.000.17.80.R 8.003.003.707.700.053.0027.0052.008.008.320GE108.0300.000.27.80.R 8.003.003.707.700.053.0037.0062.008.008.330GE108.0300.000.37.80.R 8.003.003.707.700.053.0042.0067.008.008.340GE108.0300.000.42.80.R 8.003.003.707.700.053.0047.0072.008.008.350GE108.0300.000.47.80.R

Ontheleft-handdesign,thedesignationchangesto.L

27227 L Cuttingdatapage1544

Articleno. 27226

Articleno.

Articleno. 27224

Articleno.

Micro-precision tools for radial grooving Cutting inserts for internal grooving, full radius slots

grooving depth 0.7-1.0 mm • full radius R0.4-R0.58 mm

fortoolholderstypeGB104/GH104

PMKNSH GE104 Cuttingdatapage185

PMKNSH GE104 Cuttingdatapage185

Right-handdesignasshown.Left-handdesignismirrorimage.

25134 R

25138 R Dmin.bRfatmax.LaLgDh6Codeno.Description mmmmmmmmmmmmmmmmmm

3.000.800.401.952.700.707.0025.004.004.001GE104.0080.040.07.30.R 3.000.800.401.952.700.7012.0030.004.004.002GE104.0080.040.12.30.R 3.000.800.401.952.700.7017.0035.004.004.003GE104.0080.040.17.30.R 3.000.800.401.952.700.7022.0040.004.004.004GE104.0080.040.22.30.R 4.001.000.501.703.701.0012.0030.004.004.005GE104.0100.050.12.40.R 4.001.000.501.703.701.0017.0035.004.004.006GE104.0100.050.17.40.R 4.001.000.501.703.701.0022.0040.004.004.007GE104.0100.050.22.40.R 4.001.000.501.703.701.0027.0045.004.004.008GE104.0100.050.27.40.R 4.001.000.501.703.701.0032.0050.004.004.009GE104.0100.050.32.40.R 4.001.170.581.703.701.0012.0030.004.004.010GE104.0117.058.12.40.R 4.001.170.581.703.701.0017.0035.004.004.011GE104.0117.058.17.40.R 4.001.170.581.703.701.0022.0040.004.004.012GE104.0117.058.22.40.R 4.001.170.581.703.701.0027.0045.004.004.013GE104.0117.058.27.40.R 4.001.170.581.703.701.0032.0050.004.004.014GE104.0117.058.32.40.R

25135 L

Ontheleft-handdesign,thedesignationchangesto.L

25139 L Cuttingdatapage1544

Articleno.

Articleno.

Articleno.

Articleno.

Cutting inserts for internal grooving, full radius slots grooving depth up to 1.2 mm • full radius R0.5-R1.0 mm

fortoolholderstypeGB106/GH106

PMKNSH GE106 Cuttingdatapage185

PMKNSH GE106 Cuttingdatapage185

Right-handdesignasshown.Left-handdesignismirrorimage.

25882 R

25886 R Dmin.bRfatmax.LaLgDh6Codeno.Description

5.001.000.502.954.701.2012.0037.006.006.010GE106.0100.050.12.50.R 5.001.000.502.954.701.2017.0042.006.006.020GE106.0100.050.17.50.R 5.001.000.502.954.701.2022.0047.006.006.030GE106.0100.050.22.50.R 5.001.000.502.954.701.2027.0052.006.006.040GE106.0100.050.27.50.R 5.001.000.502.954.701.2032.0057.006.006.050GE106.0100.050.32.50.R 5.001.000.502.954.701.2037.0062.006.006.060GE106.0100.050.37.50.R 5.001.000.502.954.701.2042.0067.006.006.070GE106.0100.050.42.50.R 5.001.500.752.954.701.2012.0037.006.006.110GE106.0150.075.12.50.R 5.001.500.752.954.701.2017.0042.006.006.120GE106.0150.075.17.50.R 5.001.500.752.954.701.2022.0047.006.006.130GE106.0150.075.22.50.R 5.001.500.752.954.701.2027.0052.006.006.140GE106.0150.075.27.50.R 5.001.500.752.954.701.2032.0057.006.006.150GE106.0150.075.32.50.R 5.001.500.752.954.701.2037.0062.006.006.160GE106.0150.075.37.50.R 5.001.500.752.954.701.2042.0067.006.006.170GE106.0150.075.42.50.R 5.002.001.002.954.701.2012.0037.006.006.210GE106.0200.100.12.50.R 5.002.001.002.954.701.2017.0042.006.006.220GE106.0200.100.17.50.R 5.002.001.002.954.701.2022.0047.006.006.230GE106.0200.100.22.50.R 5.002.001.002.954.701.2027.0052.006.006.240GE106.0200.100.27.50.R 5.002.001.002.954.701.2032.0057.006.006.250GE106.0200.100.32.50.R 5.002.001.002.954.701.2037.0062.006.006.260GE106.0200.100.37.50.R 5.002.001.002.954.701.2042.0067.006.006.270GE106.0200.100.42.50.R

25883 L

Ontheleft-handdesign,thedesignationchangesto.L

25887 L Cuttingdatapage1544

Articleno.

Articleno.

Articleno.

Articleno.

Cutting inserts for internal grooving, full radius slots

grooving depth up to 2 mm • full radius R0.5-R1.0 mm

fortoolholderstypeGB106/GH106

PMKNSH

PMKNSH

GE106

Cuttingdatapage185

GE106 Cuttingdatapage185

Right-handdesignasshown.Left-handdesignismirrorimage.

25758 R

25762 R

6.001.000.502.705.702.0012.0037.006.006.001GE106.0100.050.12.60.R 6.001.000.502.705.702.0017.0042.006.006.002GE106.0100.050.17.60.R 6.001.000.502.705.702.0022.0047.006.006.003GE106.0100.050.22.60.R 6.001.000.502.705.702.0027.0052.006.006.004GE106.0100.050.27.60.R 6.001.000.502.705.702.0032.0057.006.006.005GE106.0100.050.32.60.R 6.001.000.502.705.702.0037.0062.006.006.006GE106.0100.050.37.60.R 6.001.000.502.705.702.0042.0067.006.006.007GE106.0100.050.42.60.R 6.001.500.752.705.702.0012.0037.006.006.008GE106.0150.075.12.60.R 6.001.500.752.705.702.0017.0042.006.006.009GE106.0150.075.17.60.R 6.001.500.752.705.702.0022.0047.006.006.010GE106.0150.075.22.60.R 6.001.500.752.705.702.0027.0052.006.006.011GE106.0150.075.27.60.R 6.001.500.752.705.702.0032.0057.006.006.012GE106.0150.075.32.60.R 6.001.500.752.705.702.0037.0062.006.006.013GE106.0150.075.37.60.R 6.001.500.752.705.702.0042.0067.006.006.014GE106.0150.075.42.60.R 6.002.001.002.705.702.0012.0037.006.006.015GE106.0200.100.12.60.R 6.002.001.002.705.702.0017.0042.006.006.016GE106.0200.100.17.60.R 6.002.001.002.705.702.0022.0047.006.006.017GE106.0200.100.22.60.R 6.002.001.002.705.702.0027.0052.006.006.018GE106.0200.100.27.60.R 6.002.001.002.705.702.0032.0057.006.006.019GE106.0200.100.32.60.R 6.002.001.002.705.702.0037.0062.006.006.020GE106.0200.100.37.60.R 6.002.001.002.705.702.0042.0067.006.006.021GE106.0200.100.42.60.R

25759 L

Ontheleft-handdesign,thedesignationchangesto.L

25763 L Cuttingdatapage1544

Articleno.

Articleno.

Articleno.

Articleno.

Cutting inserts for internal grooving, full radius slots

grooving depth up to 2.5 mm • full radius R0.75-R1.5 mm

fortoolholderstypeGB108/GH108

PMKNSH GE108 Cuttingdatapage185

PMKNSH GE108 Cuttingdatapage185

Right-handdesignasshown.Left-handdesignismirrorimage.

7.001.500.753.956.702.5017.0042.008.008.010GE108.0150.075.17.70.R 7.001.500.753.956.702.5027.0052.008.008.020GE108.0150.075.27.70.R 7.001.500.753.956.702.5037.0062.008.008.030GE108.0150.075.37.70.R 7.001.500.753.956.702.5042.0067.008.008.040GE108.0150.075.42.70.R 7.001.500.753.956.702.5047.0072.008.008.050GE108.0150.075.47.70.R 7.002.001.003.956.702.5017.0042.008.008.110GE108.0200.100.17.70.R 7.002.001.003.956.702.5027.0052.008.008.120GE108.0200.100.27.70.R 7.002.001.003.956.702.5037.0062.008.008.130GE108.0200.100.37.70.R 7.002.001.003.956.702.5042.0067.008.008.140GE108.0200.100.42.70.R 7.002.001.003.956.702.5047.0072.008.008.150GE108.0200.100.47.70.R 7.002.501.253.956.702.5017.0042.008.008.210GE108.0250.125.17.70.R 7.002.501.253.956.702.5027.0052.008.008.220GE108.0250.125.27.70.R 7.002.501.253.956.702.5037.0062.008.008.230GE108.0250.125.37.70.R 7.002.501.253.956.702.5042.0067.008.008.240GE108.0250.125.42.70.R 7.002.501.253.956.702.5047.0072.008.008.250GE108.0250.125.47.70.R 7.003.001.503.956.702.5017.0042.008.008.310GE108.0300.150.17.70.R 7.003.001.503.956.702.5027.0052.008.008.320GE108.0300.150.27.70.R 7.003.001.503.956.702.5037.0062.008.008.330GE108.0300.150.37.70.R 7.003.001.503.956.702.5042.0067.008.008.340GE108.0300.150.42.70.R 7.003.001.503.956.702.5047.0072.008.008.350GE108.0300.150.47.70.R

Ontheleft-handdesign,thedesignationchangesto.L

L Cuttingdatapage1544

Articleno. 27129

Articleno. 27131

Articleno. 27128

Articleno.

Micro-precision tools for radial grooving Cutting inserts for internal grooving, full radius slots

grooving depth up to 3 mm • full radius R0.75-R1.5 mm

fortoolholderstypeGB108/GH108

PMKNSH GE108 Cuttingdatapage185

PMKNSH GE108 Cuttingdatapage185

Right-handdesignasshown.Left-handdesignismirrorimage.

8.001.500.753.707.703.0017.0042.008.008.010GE108.0150.075.17.80.R 8.001.500.753.707.703.0027.0052.008.008.020GE108.0150.075.27.80.R 8.001.500.753.707.703.0037.0062.008.008.030GE108.0150.075.37.80.R 8.001.500.753.707.703.0042.0067.008.008.040GE108.0150.075.42.80.R 8.001.500.753.707.703.0047.0072.008.008.050GE108.0150.075.47.80.R 8.002.001.003.707.703.0017.0042.008.008.110GE108.0200.100.17.80.R 8.002.001.003.707.703.0027.0052.008.008.120GE108.0200.100.27.80.R 8.002.001.003.707.703.0037.0062.008.008.130GE108.0200.100.37.80.R 8.002.001.003.707.703.0042.0067.008.008.140GE108.0200.100.42.80.R 8.002.001.003.707.703.0047.0072.008.008.150GE108.0200.100.47.80.R 8.002.501.253.707.703.0017.0042.008.008.210GE108.0250.125.17.80.R 8.002.501.253.707.703.0027.0052.008.008.220GE108.0250.125.27.80.R 8.002.501.253.707.703.0037.0062.008.008.230GE108.0250.125.37.80.R 8.002.501.253.707.703.0042.0067.008.008.240GE108.0250.125.42.80.R 8.002.501.253.707.703.0047.0072.008.008.250GE108.0250.125.47.80.R 8.003.001.503.707.703.0017.0042.008.008.310GE108.0300.150.17.80.R 8.003.001.503.707.703.0027.0052.008.008.320GE108.0300.150.27.80.R 8.003.001.503.707.703.0037.0062.008.008.330GE108.0300.150.37.80.R 8.003.001.503.707.703.0042.0067.008.008.340GE108.0300.150.42.80.R 8.003.001.503.707.703.0047.0072.008.008.350GE108.0300.150.47.80.R

Ontheleft-handdesign,thedesignationchangesto.L

R

L

L Cuttingdatapage1544

Articleno. 27229

Articleno. 27231

Articleno. 27228

Articleno. 27230

Cutting inserts for internal pre-grooving and chamfering

45°chamfer fortoolholderstypeGB104/GH104

PMKNSH GV104 Cuttingdatapage185

PMKNSH GV104 Cuttingdatapage185

Right-handdesignasshown.Left-handdesignismirrorimage.

25142 R

25146 R

2.000.701.950.201.800.504.0025.004.004.001GV104.0807.045.04.20.R 2.000.701.950.201.800.507.0025.004.004.002GV104.0807.045.07.20.R 2.000.701.950.201.800.5012.0030.004.004.003GV104.0807.045.12.20.R 2.000.701.950.201.800.5017.0035.004.004.004GV104.0807.045.17.20.R 3.000.701.950.202.700.707.0025.004.004.005GV104.0807.045.07.30.R 3.000.701.950.202.700.7012.0030.004.004.006GV104.0807.045.12.30.R 3.000.701.950.202.700.7017.0035.004.004.007GV104.0807.045.17.30.R 3.000.701.950.202.700.7022.0040.004.004.008GV104.0807.045.22.30.R 4.001.001.700.203.701.0012.0030.004.004.009GV104.0810.045.12.40.R 4.001.001.700.203.701.0017.0035.004.004.010GV104.0810.045.17.40.R 4.001.001.700.203.701.0022.0040.004.004.011GV104.0810.045.22.40.R 4.001.001.700.203.701.0027.0045.004.004.012GV104.0810.045.27.40.R 4.001.001.700.203.701.0032.0050.004.004.013GV104.0810.045.32.40.R

Ontheleft-handdesign,thedesignationchangesto.L

L

25147 L Cuttingdatapage1544

Articleno. 25143

Articleno.

Articleno.

Articleno.

Cutting inserts for internal pre-grooving and chamfering 45°chamfer fortoolholderstypeGB106/GH106

PMKNSH GV106 Cuttingdatapage185

PMKNSH GV106 Cuttingdatapage185

Right-handdesignasshown.Left-handdesignismirrorimage.

Ontheleft-handdesign,thedesignationchangesto.L

26903 L

26905 L Cuttingdatapage1544

Articleno.

Indexable inserts for radial

Indexable inserts for radial grooving external and internal snapringgroovestoDIN471/472,NW=0.5-5.15mm indexable inserts applicable in right and left holders • geometry .BA ground • pay attention to assignment holder/insert seat size 04/06 • for tool holders type GH305/GB305, size 04/06

PMKNSH

PMKNSH

GE305 F Cuttingdatapage185-187

GE305 E Cuttingdatapage185-187

PMKNSH GE305 Cuttingdatapage185-187

0.500.551.504.200412.001GE305.0050.000.BA.04.N 0.600.651.504.200412.002GE305.0060.000.BA.04.N 0.700.751.504.200412.003GE305.0070.000.BA.04.N 0.800.851.504.200412.004GE305.0080.000.BA.04.N 0.900.951.504.200412.005GE305.0090.000.BA.04.N 1.001.050.053.004.200412.006GE305.0100.000.BA.04.N 1.101.220.053.004.200412.007GE305.0110.000.BA.04.N 1.301.420.053.004.200412.008GE305.0130.000.BA.04.N 1.601.720.054.004.200412.009GE305.0160.000.BA.04.N 1.851.970.154.004.200412.010GE305.0185.015.BA.04.N 2.152.270.155.004.200412.011GE305.0215.015.BA.04.N 2.652.770.155.004.200412.012GE305.0265.015.BA.04.N 3.153.270.155.004.200412.013GE305.0315.015.BA.04.N 4.154.270.155.006.200612.014GE305.0415.015.BA.06.N 5.155.270.155.006.200612.015GE305.0515.015.BA.06.N

Articleno. 25601

Articleno. 25602

Articleno. 25603

Indexable inserts for radial grooving Indexable inserts for radial grooving and external and internal copying groovingdepthupto5mm

indexable inserts applicable in right and left holders • geometry .BA ground • for tool holders type GH305/GB305, size 04

PMKNSH

PMKNSH

GE305 F Cuttingdatapage187-188

GE305 E Cuttingdatapage187-188

PMKNSH GE305 Cuttingdatapage187-188

N b±0,02Rtmax.sSizeCodeno.Description mmmmmmmm

1.000.103.004.200412.001GE305.0100.010.BA.04.N 1.500.203.004.200412.002GE305.0150.020.BA.04.N 2.000.154.004.200412.009GE305.0200.015.BA.04.N 2.000.204.004.200412.003GE305.0200.020.BA.04.N 2.500.205.004.200412.010GE305.0250.020.BA.04.N 2.500.305.004.200412.004GE305.0250.030.BA.04.N 3.000.155.004.200412.011GE305.0300.015.BA.04.N 3.000.205.004.200412.012GE305.0300.020.BA.04.N 3.000.305.004.200412.005GE305.0300.030.BA.04.N 3.500.305.004.200412.006GE305.0350.030.BA.04.N 4.000.205.004.200412.007GE305.0400.020.BA.04.N 4.000.405.004.200412.008GE305.0400.040.BA.04.N

Articleno. 25605 F N

Articleno. 25606 E N

Articleno. 25607

Indexable inserts for radial grooving and external and internal copying groovingdepthupto5mm indexable inserts applicable in right and left holders • geometry .AA ground • for tool holders type GH305/GB305, size 04

PMKNSH GE305 F Cuttingdatapage189-190

PMKNSH GE305 E Cuttingdatapage189-190

PMKNSH GE305 Cuttingdatapage189-190

b±0,02Rtmax.sSizeCodeno.Description mmmmmmmm

0.500.251.504.200412.001GE305.0050.025.AA.04.N 1.000.503.004.200412.002GE305.0100.050.AA.04.N 1.100.553.004.200412.003GE305.0110.055.AA.04.N 1.200.603.004.200412.004GE305.0120.060.AA.04.N 1.400.703.004.200412.005GE305.0140.070.AA.04.N 1.500.753.004.200412.006GE305.0150.075.AA.04.N 1.600.804.004.200412.007GE305.0160.080.AA.04.N 1.800.904.004.200412.008GE305.0180.090.AA.04.N 2.001.004.004.200412.009GE305.0200.100.AA.04.N 2.201.105.004.200412.010GE305.0220.110.AA.04.N 2.501.255.004.200412.011GE305.0250.125.AA.04.N 2.801.405.004.200412.012GE305.0280.140.AA.04.N 3.001.505.004.200412.013GE305.0300.150.AA.04.N 3.601.805.004.200412.014GE305.0360.180.AA.04.N 4.002.005.004.200412.015GE305.0400.200.AA.04.N

Articleno. 25613

Articleno. 25614

Articleno. 25615

Micro-precision tools for axial grooving Cutting inserts for axial grooving, flat bottom slots groovingdepthupto5mm fortoolholderstypeGB104/GH104

PMKNSH GA104

PMKNSH GA104

Cuttingdatapage191

Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage.

25190 R

25194 R

Dmin.bRftmax.LaLgDh6Codeno.Description

4.001.000.051.602.0012.0030.004.004.001GA104.0100.005.12.40.R 4.001.000.051.602.0017.0035.004.004.002GA104.0100.005.17.40.R 4.001.500.051.603.0012.0030.004.004.003GA104.0150.005.12.40.R 4.001.500.051.603.0017.0035.004.004.004GA104.0150.005.17.40.R 5.002.000.051.605.0012.0030.004.004.005GA104.0200.005.12.50.R 5.002.000.051.605.0017.0035.004.004.006GA104.0200.005.17.50.R

Ontheleft-handdesign,thedesignationchangesto.L Articleno. 25191 L

25195 L Cuttingdatapage1550

Cutting inserts for axial grooving, flat bottom slots groovingdepthupto8mm fortoolholderstypeGB106/GH106

GA106 Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage. Articleno. 25782 R Articleno. 25786 R

Dmin.bRftmax.LaLgDh6Codeno.Description mmmmmmmmmmmmmmmm

6.001.500.102.605.0017.0042.006.006.001GA106.0150.010.17.60.R 6.001.500.102.605.0022.0047.006.006.002GA106.0150.010.22.60.R 6.002.000.152.608.0017.0042.006.006.003GA106.0200.015.17.60.R 6.002.000.152.608.0022.0047.006.006.004GA106.0200.015.22.60.R

Ontheleft-handdesign,thedesignationchangesto.L

Articleno. 25783 L Articleno. 25787 L Cuttingdatapage1550

Articleno.

Cutting inserts for axial grooving, flat bottom slots groovingdepthupto8mm fortoolholderstypeGB108/GH108

GA108 Cuttingdatapage191

PMKNSH GA108 Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage.

Ontheleft-handdesign,thedesignationchangesto.L

27233 L

27235 L Cuttingdatapage1550

Articleno.

Axial

Micro-precision tools for axial grooving Cutting inserts for axial grooving bores, full radius slots groovingdepthupto5mm fortoolholderstypeGB104/GH104

PMKNSH GA104

PMKNSH GA104

Cuttingdatapage191

Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage.

25198 R Articleno. 25202 R

Dmin.bRftmax.LaLgDh6Codeno.Description

6.001.000.501.602.0012.0030.004.004.001GA104.0100.050.12.60.R 6.001.000.501.602.0017.0035.004.004.002GA104.0100.050.17.60.R 6.001.500.751.603.0012.0030.004.004.003GA104.0150.075.12.60.R 6.001.500.751.603.0017.0035.004.004.004GA104.0150.075.17.60.R 6.002.001.001.605.0012.0030.004.004.005GA104.0200.100.12.60.R 6.002.001.001.605.0017.0035.004.004.006GA104.0200.100.17.60.R

Ontheleft-handdesign,thedesignationchangesto.L Articleno. 25199 L

25203 L Cuttingdatapage1550

Cutting inserts for axial grooving bores, full radius slots groovingdepthupto8mm fortoolholderstypeGB106/GH106

GA106

Right-handdesignasshown.Left-handdesignismirrorimage.

25790 R Articleno. 25794 R

Dmin.bRftmax.LaLgDh6Codeno.Description

6.001.500.752.605.0017.0042.006.006.001GA106.0150.075.17.60.R 6.001.500.752.605.0022.0047.006.006.002GA106.0150.075.22.60.R 6.002.001.002.608.0017.0042.006.006.003GA106.0200.100.17.60.R 6.002.001.002.608.0022.0047.006.006.004GA106.0200.100.22.60.R

Ontheleft-handdesign,thedesignationchangesto.L

Articleno. 25791 L Articleno. 25795 L Cuttingdatapage1550

Articleno.

Cutting inserts for axial grooving bores, full radius slots grooving depth up to 8 mm • full radius R1.25-R1.5 mm fortoolholderstypeGB108/GH108

PMKNSH GA108 Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage.

Ontheleft-handdesign,thedesignationchangesto.L

27237 L Articleno. 27239 L Cuttingdatapage1550

Articleno.

Axial

Micro-precision tools for axial grooving Cutting inserts for axial grooving studs, flat bottom slots groovingdepthupto5mm fortoolholderstypeGB104/GH104

PMKNSH GA104 Cuttingdatapage191

PMKNSH GA104 Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage.

25206 R Articleno. 25210 R

Dmin.bRftmax.LaLgDh6Codeno.Description

4.001.000.051.602.0012.0030.004.004.001GA104.Z100.005.12.40.R 4.001.000.051.602.0017.0035.004.004.002GA104.Z100.005.17.40.R 4.001.500.051.603.0012.0030.004.004.003GA104.Z150.005.12.40.R 4.001.500.051.603.0017.0035.004.004.004GA104.Z150.005.17.40.R 5.002.000.051.605.0012.0030.004.004.005GA104.Z200.005.12.50.R 5.002.000.051.605.0017.0035.004.004.006GA104.Z200.005.17.50.R

Ontheleft-handdesign,thedesignationchangesto.L Articleno. 25207 L

25211 L Cuttingdatapage1550

Cutting inserts for axial grooving studs, flat bottom slots groovingdepthupto8mm fortoolholderstypeGB106/GH106

Right-handdesignasshown.Left-handdesignismirrorimage. Articleno. 25798 R Articleno. 25802 R

Dmin.bRftmax.LaLgDh6Codeno.Description mmmmmmmmmmmmmmmm

6.001.500.102.605.0017.0042.006.006.001GA106.Z150.010.17.60.R 6.001.500.102.605.0022.0047.006.006.002GA106.Z150.010.22.60.R 6.002.000.152.608.0017.0042.006.006.003GA106.Z200.015.17.60.R 6.002.000.152.608.0022.0047.006.006.004GA106.Z200.015.22.60.R

Ontheleft-handdesign,thedesignationchangesto.L

Articleno. 25799 L Articleno. 25803 L Cuttingdatapage1550

Articleno.

Cutting inserts for axial grooving studs, flat bottom slots groovingdepthupto8mm fortoolholderstypeGB108/GH108

GA108 Cuttingdatapage191

PMKNSH GA108 Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage.

Ontheleft-handdesign,thedesignationchangesto.L

27241 L Articleno. 27243 L Cuttingdatapage1550

Articleno.

Axial grooving

Micro-precision tools for axial grooving Cutting inserts for axial grooving studs, full radius slots grooving depth up to 5 mm • full radius R0.5-R1.0 mm fortoolholderstypeGB104/GH104

PMKNSH GA104 Cuttingdatapage191

PMKNSH GA104 Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage.

Articleno. 25214 R Articleno. 25218 R

Dmin.bRftmax.LaLgDh6Codeno.Description

6.001.000.501.602.0012.0030.004.004.001GA104.Z100.050.12.60.R 6.001.000.501.602.0017.0035.004.004.002GA104.Z100.050.17.60.R 6.001.500.751.603.0012.0030.004.004.003GA104.Z150.075.12.60.R 6.001.500.751.603.0017.0035.004.004.004GA104.Z150.075.17.60.R 6.002.001.001.605.0012.0030.004.004.005GA104.Z200.100.12.60.R 6.002.001.001.605.0017.0035.004.004.006GA104.Z200.100.17.60.R

25215 L

Ontheleft-handdesign,thedesignationchangesto.L

Cutting inserts for axial grooving studs, full radius slots grooving depth up to 8 mm • full radius R0.75-R1.0 mm fortoolholderstypeGB106/GH106

GA106

Cuttingdatapage191

Articleno. 25219 L Cuttingdatapage1550

GA106

Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage.

25806

25810

Dmin.bRftmax.LaLgDh6Codeno.Description mmmmmmmmmmmmmmmm

6.001.500.752.605.0017.0042.006.006.001GA106.Z150.075.17.60.R 6.001.500.752.605.0022.0047.006.006.002GA106.Z150.075.22.60.R 6.002.001.002.608.0017.0042.006.006.003GA106.Z200.100.17.60.R 6.002.001.002.608.0022.0047.006.006.004GA106.Z200.100.22.60.R

Ontheleft-handdesign,thedesignationchangesto.L Articleno. 25807

25811

Cuttingdatapage1550

Articleno.

Cutting inserts for axial grooving studs, full radius slots grooving depth up to 8 mm • full radius R1.25-R1.5 mm fortoolholderstypeGB108/GH108

PMKNSH GA108 Cuttingdatapage191

PMKNSH GA108 Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage.

Ontheleft-handdesign,thedesignationchangesto.L

27245 L Articleno. 27247 L Cuttingdatapage1550

Articleno.

Axial

Micro-precision tools for axial grooving Cutting inserts for axial chamfering bores 45°/60°/75°chamferangle fortoolholderstypeGB104/GH104

PMKNSH GA104 Cuttingdatapage191

PMKNSH GA104 Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage.

25222 R

25226 R Dmin.RW1ftmax.LaLgDh6Codeno.Description

Ontheleft-handdesign,thedesignationchangesto.L

25223 L Articleno. 25227 L Cuttingdatapage1550

Articleno.

Indexable inserts for axial grooving, flat bottom slots groovingdepthupto3mm rightindex.insertsinright,leftindex.insertsinlefttoolholders • geometry .BA ground • for tool holders type GH305, size 04

PMKNSH GA305 F Cuttingdatapage191

PMKNSH GA305 E Cuttingdatapage191

PMKNSH GA305 Cuttingdatapage191

Indexable inserts for axial grooving

25628

25630 R

Right-handdesignasshown.Left-handdesignismirrorimage. Articleno. 25626 F R

Ontheleft-handdesign,thedesignationchangesto.L Articleno. 25627 F L Articleno. 25629 E

Articleno. 25631 L Cuttingdatapage1550

Axial

Indexable inserts for axial grooving, full radius slots groovingdepthupto3mm rightindex.insertsinright,leftindex.insertsinlefttoolholders • geometry .AA ground • for tool holders type GH305, size 04

PMKNSH GA305 F Cuttingdatapage191

PMKNSH GA305 E Cuttingdatapage191

PMKNSH GA305 Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage. Articleno. 25634 F R Articleno. 25636 E R Articleno. 25638 R

Ontheleft-handdesign,thedesignationchangesto.L

Articleno. 25635 F L

Articleno. 25637 E L

Articleno. 25639 L Cuttingdatapage1550

Indexable inserts for axial grooving

Indexable inserts for grooving axial external recesses groovingdepthupto2mm rightindex.insertsinright,leftindex.insertsinlefttoolholders • geometry .AA ground • for axial external recesses according to ISO 9974-2 • for tool holders type GH305, 45° offset

PMKNSH GA305 F Cuttingdatapage191

PMKNSH GA305 E Cuttingdatapage191

PMKNSH GA305 Cuttingdatapage191

Right-handdesignasshown.Left-handdesignismirrorimage. Articleno. 25618 F

25620

25622

Ontheleft-handdesign,thedesignationchangesto.L Articleno. 25619 F

25621 E

25623 L Cuttingdatapage1550

Axial grooving

Indexable Indexable inserts for parting off groovingdepthupto5mm

indexable inserts applicable in right and left holders • geometry .AA ground • for tool holders type GH305, size 04

PMKNSH GZ305 F Cuttingdatapage193

PMKNSH GZ305 E Cuttingdatapage193

PMKNSH GZ305 Cuttingdatapage193

25641 F N

25642 E N

25643 N b±0,02Rtmax.sSizeCodeno.Description

1.000.105.004.200412.001GZ305.0100.000.AA.04.N 1.500.105.004.200412.002GZ305.0150.000.AA.04.N

Articleno.

Articleno.

Articleno.

Indexable inserts for parting off groovingdepthupto5mm

indexable inserts applicable in right and left holders • geometry .AA ground • for tool holders type GH305, size 04

PMKNSH GZ305 F Cuttingdatapage193

PMKNSH GZ305 E Cuttingdatapage193

PMKNSH GZ305 Cuttingdatapage193

Right-handdesignasshown.Left-handdesignismirrorimage.

Articleno. 25646 F R

Articleno. 25648 E R

Articleno. 25650 R b±0,02RW2tmax.sSizeCodeno.Description

Ontheleft-handdesign,thedesignationchangesto.L

Articleno. 25647 F L

Articleno. 25649 E L

Articleno. 25651 L Cuttingdatapage1552

Indexable inserts for parting off

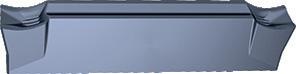

Indexable inserts for parting off with chip former • geometry .PP sintered • for tool holders type GH222/GS222

PMKNSH GZ222 F Cuttingdatapage193

26601 F N

bLRtmax.Codeno.Description mmmmmmmm

2.0022.000.2021.0022.020GZ222.0200.020.PP.02.N 3.0022.000.2021.0022.030GZ222.0300.020.PP.02.N

Indexable inserts for parting off with chip former • geometry .PM sintered • for tool holders type GH222/GS222

PMKNSH GZ222 F Cuttingdatapage193

Right-handdesignasshown.Left-handdesignismirrorimage.

26602 F R

bLRW2tmax.Codeno.Description mmmmmm°mm 3.0022.3500.20821.0022.030GZ222.0300.020.PM.01.R.08

Ontheleft-handdesign,thedesignationchangesto.LArticleno. 26603 F L Cuttingdatapage1552

Articleno.

Articleno.

Indexable inserts for parting off with chip former • geometry .PP sintered • for tool holders type GH222/GS222

GZ122 F Cuttingdatapage193

Indexable inserts for parting off with chip former • geometry .MP sintered • for tool holders type GH222/GS222

Micro-precision tools for turning Cutting inserts for boring out and profiling radialfree23° fortoolholderstypeGB104/GH104

PMKNSH GT104

Cuttingdatapage194

PMKNSH GT104

Cuttingdatapage194

Right-handdesignasshown.Left-handdesignismirrorimage.

25056 R Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

0.700.052381.950.600.053.0025.004.004.001GT104.2306.005.03.07.R 1.000.052381.950.900.104.0025.004.004.002GT104.2309.005.04.10.R 1.000.052381.950.900.107.0025.004.004.003GT104.2309.005.07.10.R 1.500.052381.951.400.154.0025.004.004.004GT104.2314.005.04.15.R 1.500.052381.951.400.157.0025.004.004.005GT104.2314.005.07.15.R 1.500.052381.951.400.1512.0030.004.004.006GT104.2314.005.12.15.R 1.500.102381.951.400.154.0025.004.004.007GT104.2314.010.04.15.R 1.500.102381.951.400.157.0025.004.004.008GT104.2314.010.07.15.R 1.500.102381.951.400.1512.0030.004.004.009GT104.2314.010.12.15.R 2.000.052381.951.900.154.0025.004.004.010GT104.2319.005.04.20.R 2.000.052381.951.900.157.0025.004.004.011GT104.2319.005.07.20.R 2.000.052381.951.900.1512.0030.004.004.012GT104.2319.005.12.20.R 2.000.052381.951.900.1517.0035.004.004.013GT104.2319.005.17.20.R 2.000.102381.951.900.154.0025.004.004.014GT104.2319.010.04.20.R 2.000.102381.951.900.157.0025.004.004.015GT104.2319.010.07.20.R 2.000.102381.951.900.1512.0030.004.004.016GT104.2319.010.12.20.R 2.000.102381.951.900.1517.0035.004.004.017GT104.2319.010.17.20.R 2.000.152381.951.900.154.0025.004.004.018GT104.2319.015.04.20.R 2.000.152381.951.900.157.0025.004.004.019GT104.2319.015.07.20.R 2.000.152381.951.900.1512.0030.004.004.020GT104.2319.015.12.20.R 2.000.152381.951.900.1517.0035.004.004.021GT104.2319.015.17.20.R 3.000.052381.952.600.207.0025.004.004.022GT104.2326.005.07.30.R 3.000.052381.952.600.2012.0030.004.004.023GT104.2326.005.12.30.R 3.000.052381.952.600.2017.0035.004.004.024GT104.2326.005.17.30.R 3.000.052381.952.600.2022.0040.004.004.025GT104.2326.005.22.30.R 3.000.102381.952.600.207.0025.004.004.026GT104.2326.010.07.30.R 3.000.102381.952.600.2012.0030.004.004.027GT104.2326.010.12.30.R 3.000.102381.952.600.2017.0035.004.004.028GT104.2326.010.17.30.R 3.000.102381.952.600.2022.0040.004.004.029GT104.2326.010.22.30.R 3.000.202381.952.600.207.0025.004.004.030GT104.2326.020.07.30.R 3.000.202381.952.600.2012.0030.004.004.031GT104.2326.020.12.30.R 3.000.202381.952.600.2017.0035.004.004.032GT104.2326.020.17.30.R 3.000.202381.952.600.2022.0040.004.004.033GT104.2326.020.22.30.R 4.000.052381.703.700.3012.0030.004.004.034GT104.2337.005.12.40.R 4.000.052381.703.700.3017.0035.004.004.035GT104.2337.005.17.40.R 4.000.052381.703.700.3022.0040.004.004.036GT104.2337.005.22.40.R 4.000.052381.703.700.3027.0045.004.004.037GT104.2337.005.27.40.R 4.000.052381.703.700.3032.0050.004.004.038GT104.2337.005.32.40.R 4.000.152381.703.700.3012.0030.004.004.039GT104.2337.015.12.40.R 4.000.152381.703.700.3017.0035.004.004.040GT104.2337.015.17.40.R 4.000.152381.703.700.3022.0040.004.004.041GT104.2337.015.22.40.R 4.000.152381.703.700.3027.0045.004.004.042GT104.2337.015.27.40.R 4.000.152381.703.700.3032.0050.004.004.043GT104.2337.015.32.40.R 4.000.252381.703.700.3012.0030.004.004.044GT104.2337.025.12.40.R 4.000.252381.703.700.3017.0035.004.004.045GT104.2337.025.17.40.R 4.000.252381.703.700.3022.0040.004.004.046GT104.2337.025.22.40.R 4.000.252381.703.700.3027.0045.004.004.047GT104.2337.025.27.40.R 4.000.252381.703.700.3032.0050.004.004.048GT104.2337.025.32.40.R 4.000.102381.703.700.3012.0030.004.004.049GT104.2337.010.12.40.R 4.000.102381.703.700.3017.0035.004.004.050GT104.2337.010.17.40.R 4.000.102381.703.700.3022.0040.004.004.051GT104.2337.010.22.40.R 4.000.202381.703.700.3012.0030.004.004.052GT104.2337.020.12.40.R 4.000.202381.703.700.3017.0035.004.004.053GT104.2337.020.17.40.R 4.000.202381.703.700.3022.0040.004.004.054GT104.2337.020.22.40.R

Ontheleft-handdesign,thedesignationchangesto.L

25057 L Cuttingdatapage1553

Articleno. 25053

Articleno.

Articleno. 25052

Articleno.

Cutting inserts for boring out and profiling radialfree23° fortoolholderstypeGB106/GH106

PMKNSH GT106 Cuttingdatapage195

Right-handdesignasshown.Left-handdesignismirrorimage.

Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

5.000.052382.954.700.3012.0037.006.006.010GT106.2347.005.12.50.R 5.000.052382.954.700.3017.0042.006.006.020GT106.2347.005.17.50.R 5.000.052382.954.700.3022.0047.006.006.030GT106.2347.005.22.50.R 5.000.052382.954.700.3027.0052.006.006.040GT106.2347.005.27.50.R 5.000.052382.954.700.3032.0057.006.006.050GT106.2347.005.32.50.R 5.000.052382.954.700.3037.0062.006.006.060GT106.2347.005.37.50.R 5.000.052382.954.700.3042.0067.006.006.070GT106.2347.005.42.50.R 5.000.102382.954.700.3012.0037.006.006.110GT106.2347.010.12.50.R 5.000.102382.954.700.3017.0042.006.006.120GT106.2347.010.17.50.R 5.000.102382.954.700.3022.0047.006.006.130GT106.2347.010.22.50.R 5.000.102382.954.700.3027.0052.006.006.140GT106.2347.010.27.50.R 5.000.102382.954.700.3032.0057.006.006.150GT106.2347.010.32.50.R 5.000.102382.954.700.3037.0062.006.006.160GT106.2347.010.37.50.R 5.000.102382.954.700.3042.0067.006.006.170GT106.2347.010.42.50.R 5.000.152382.954.700.3012.0037.006.006.210GT106.2347.015.12.50.R 5.000.152382.954.700.3017.0042.006.006.220GT106.2347.015.17.50.R 5.000.152382.954.700.3022.0047.006.006.230GT106.2347.015.22.50.R 5.000.152382.954.700.3027.0052.006.006.240GT106.2347.015.27.50.R 5.000.152382.954.700.3032.0057.006.006.250GT106.2347.015.32.50.R 5.000.152382.954.700.3037.0062.006.006.260GT106.2347.015.37.50.R 5.000.152382.954.700.3042.0067.006.006.270GT106.2347.015.42.50.R 5.000.202382.954.700.3012.0037.006.006.310GT106.2347.020.12.50.R 5.000.202382.954.700.3017.0042.006.006.320GT106.2347.020.17.50.R 5.000.202382.954.700.3022.0047.006.006.330GT106.2347.020.22.50.R 5.000.202382.954.700.3027.0052.006.006.340GT106.2347.020.27.50.R 5.000.202382.954.700.3032.0057.006.006.350GT106.2347.020.32.50.R 5.000.202382.954.700.3037.0062.006.006.360GT106.2347.020.37.50.R 5.000.202382.954.700.3042.0067.006.006.370GT106.2347.020.42.50.R 5.000.302382.954.700.3012.0037.006.006.410GT106.2347.030.12.50.R 5.000.302382.954.700.3017.0042.006.006.420GT106.2347.030.17.50.R 5.000.302382.954.700.3022.0047.006.006.430GT106.2347.030.22.50.R 5.000.302382.954.700.3027.0052.006.006.440GT106.2347.030.27.50.R

5.000.302382.954.700.3032.0057.006.006.450GT106.2347.030.32.50.R 5.000.302382.954.700.3037.0062.006.006.460GT106.2347.030.37.50.R 5.000.302382.954.700.3042.0067.006.006.470GT106.2347.030.42.50.R

Ontheleft-handdesign,thedesignationchangesto.L

Cuttingdatapage1553

Articleno. 25835

Articleno. 25839

Articleno. 25834

Micro-precision tools for turning Cutting inserts for boring out and profiling radialfree23° fortoolholderstypeGB106/GH106

PMKNSH GT106 Cuttingdatapage195

PMKNSH GT106 Cuttingdatapage195

Right-handdesignasshown.Left-handdesignismirrorimage.

Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

6.000.052382.705.700.3012.0037.006.006.019GT106.2357.005.12.60.R 6.000.052382.705.700.3017.0042.006.006.020GT106.2357.005.17.60.R 6.000.052382.705.700.3022.0047.006.006.021GT106.2357.005.22.60.R 6.000.052382.705.700.3027.0052.006.006.022GT106.2357.005.27.60.R 6.000.052382.705.700.3032.0057.006.006.023GT106.2357.005.32.60.R 6.000.052382.705.700.3037.0062.006.006.024GT106.2357.005.37.60.R 6.000.052382.705.700.3042.0067.006.006.025GT106.2357.005.42.60.R 6.000.052382.705.700.3047.0072.006.006.026GT106.2357.005.47.60.R 6.000.052382.705.700.3052.0077.006.006.027GT106.2357.005.52.60.R 6.000.102382.705.700.3012.0037.006.006.028GT106.2357.010.12.60.R 6.000.102382.705.700.3017.0042.006.006.029GT106.2357.010.17.60.R 6.000.102382.705.700.3022.0047.006.006.030GT106.2357.010.22.60.R 6.000.102382.705.700.3027.0052.006.006.031GT106.2357.010.27.60.R 6.000.102382.705.700.3032.0057.006.006.032GT106.2357.010.32.60.R 6.000.102382.705.700.3037.0062.006.006.033GT106.2357.010.37.60.R 6.000.102382.705.700.3042.0067.006.006.034GT106.2357.010.42.60.R 6.000.102382.705.700.3047.0072.006.006.035GT106.2357.010.47.60.R 6.000.102382.705.700.3052.0077.006.006.036GT106.2357.010.52.60.R 6.000.152382.705.700.3012.0037.006.006.013GT106.2357.015.12.60.R 6.000.152382.705.700.3017.0042.006.006.014GT106.2357.015.17.60.R 6.000.152382.705.700.3022.0047.006.006.015GT106.2357.015.22.60.R 6.000.152382.705.700.3027.0052.006.006.001GT106.2357.015.27.60.R 6.000.152382.705.700.3032.0057.006.006.002GT106.2357.015.32.60.R 6.000.152382.705.700.3037.0062.006.006.003GT106.2357.015.37.60.R 6.000.152382.705.700.3042.0067.006.006.004GT106.2357.015.42.60.R 6.000.152382.705.700.3047.0072.006.006.005GT106.2357.015.47.60.R 6.000.152382.705.700.3052.0077.006.006.006GT106.2357.015.52.60.R 6.000.202382.705.700.3012.0037.006.006.037GT106.2357.020.12.60.R 6.000.202382.705.700.3017.0042.006.006.038GT106.2357.020.17.60.R 6.000.202382.705.700.3022.0047.006.006.039GT106.2357.020.22.60.R 6.000.202382.705.700.3027.0052.006.006.040GT106.2357.020.27.60.R 6.000.202382.705.700.3032.0057.006.006.041GT106.2357.020.32.60.R 6.000.202382.705.700.3037.0062.006.006.042GT106.2357.020.37.60.R 6.000.202382.705.700.3042.0067.006.006.043GT106.2357.020.42.60.R 6.000.202382.705.700.3047.0072.006.006.044GT106.2357.020.47.60.R 6.000.202382.705.700.3052.0077.006.006.045GT106.2357.020.52.60.R 6.000.252382.705.700.3012.0037.006.006.046GT106.2357.025.12.60.R 6.000.252382.705.700.3017.0042.006.006.047GT106.2357.025.17.60.R 6.000.252382.705.700.3022.0047.006.006.048GT106.2357.025.22.60.R 6.000.252382.705.700.3027.0052.006.006.049GT106.2357.025.27.60.R 6.000.252382.705.700.3032.0057.006.006.050GT106.2357.025.32.60.R 6.000.252382.705.700.3037.0062.006.006.051GT106.2357.025.37.60.R 6.000.252382.705.700.3042.0067.006.006.052GT106.2357.025.42.60.R 6.000.252382.705.700.3047.0072.006.006.053GT106.2357.025.47.60.R 6.000.252382.705.700.3052.0077.006.006.054GT106.2357.025.52.60.R 6.000.302382.705.700.3012.0037.006.006.016GT106.2357.030.12.60.R 6.000.302382.705.700.3017.0042.006.006.017GT106.2357.030.17.60.R 6.000.302382.705.700.3022.0047.006.006.018GT106.2357.030.22.60.R 6.000.302382.705.700.3027.0052.006.006.007GT106.2357.030.27.60.R 6.000.302382.705.700.3032.0057.006.006.008GT106.2357.030.32.60.R 6.000.302382.705.700.3037.0062.006.006.009GT106.2357.030.37.60.R 6.000.302382.705.700.3042.0067.006.006.010GT106.2357.030.42.60.R 6.000.302382.705.700.3047.0072.006.006.011GT106.2357.030.47.60.R 6.000.302382.705.700.3052.0077.006.006.012GT106.2357.030.52.60.R

Ontheleft-handdesign,thedesignationchangesto.L

25707 L Cuttingdatapage1553

Articleno. 25703

Articleno.

Articleno.

Cutting inserts for boring out and profiling radialfree23° fortoolholderstypeGB108/GH108

PMKNSH GT108 Cuttingdatapage197

PMKNSH GT108 Cuttingdatapage197

Right-handdesignasshown.Left-handdesignismirrorimage.

Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

7.000.102383.956.700.5017.0042.008.008.120GT108.2367.010.17.70.R 7.000.102383.956.700.5027.0052.008.008.140GT108.2367.010.27.70.R 7.000.102383.956.700.5037.0062.008.008.160GT108.2367.010.37.70.R 7.000.102383.956.700.5042.0067.008.008.170GT108.2367.010.42.70.R 7.000.102383.956.700.5047.0072.008.008.180GT108.2367.010.47.70.R 7.000.102383.956.700.5052.0077.008.008.190GT108.2367.010.52.70.R 7.000.202383.956.700.5017.0042.008.008.320GT108.2367.020.17.70.R 7.000.202383.956.700.5027.0052.008.008.340GT108.2367.020.27.70.R 7.000.202383.956.700.5037.0062.008.008.360GT108.2367.020.37.70.R 7.000.202383.956.700.5042.0067.008.008.370GT108.2367.020.42.70.R 7.000.202383.956.700.5047.0072.008.008.380GT108.2367.020.47.70.R 7.000.202383.956.700.5052.0077.008.008.390GT108.2367.020.52.70.R

Ontheleft-handdesign,thedesignationchangesto.L

27103 L Cuttingdatapage1553

Articleno. 27101

Articleno.

Cutting inserts for boring out and profiling radialfree23° fortoolholderstypeGB108/GH108

PMKNSH GT108 Cuttingdatapage197

PMKNSH GT108 Cuttingdatapage197

Right-handdesignasshown.Left-handdesignismirrorimage.

27200 R

27202 R Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

8.000.102383.707.700.6017.0042.008.008.120GT108.2377.010.17.80.R 8.000.102383.707.700.6027.0052.008.008.140GT108.2377.010.27.80.R 8.000.102383.707.700.6037.0062.008.008.160GT108.2377.010.37.80.R 8.000.102383.707.700.6042.0067.008.008.170GT108.2377.010.42.80.R 8.000.102383.707.700.6047.0072.008.008.180GT108.2377.010.47.80.R 8.000.102383.707.700.6052.0077.008.008.190GT108.2377.010.52.80.R 8.000.202383.707.700.6017.0042.008.008.320GT108.2377.020.17.80.R 8.000.202383.707.700.6027.0052.008.008.340GT108.2377.020.27.80.R 8.000.202383.707.700.6037.0062.008.008.360GT108.2377.020.37.80.R 8.000.202383.707.700.6042.0067.008.008.370GT108.2377.020.42.80.R 8.000.202383.707.700.6047.0072.008.008.380GT108.2377.020.47.80.R 8.000.202383.707.700.6052.0077.008.008.390GT108.2377.020.52.80.R

27201 L

Ontheleft-handdesign,thedesignationchangesto.L

27203 L Cuttingdatapage1553

Articleno.

Articleno.

Articleno.

Cutting inserts for boring out and profiling radialfree47° fortoolholderstypeGB104/GH104

PMKNSH GT104

Cuttingdatapage194

PMKNSH GT104

Cuttingdatapage194

Right-handdesignasshown.Left-handdesignismirrorimage.

Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

2.000.054781.951.700.354.0025.004.004.001GT104.4717.005.04.20.R 2.000.054781.951.700.357.0025.004.004.002GT104.4717.005.07.20.R 2.000.054781.951.700.3512.0030.004.004.003GT104.4717.005.12.20.R 2.000.054781.951.700.3517.0035.004.004.004GT104.4717.005.17.20.R 2.000.104781.951.700.354.0025.004.004.005GT104.4717.010.04.20.R 2.000.104781.951.700.357.0025.004.004.006GT104.4717.010.07.20.R 2.000.104781.951.700.3512.0030.004.004.007GT104.4717.010.12.20.R 2.000.104781.951.700.3517.0035.004.004.008GT104.4717.010.17.20.R 2.000.154781.951.700.354.0025.004.004.009GT104.4717.015.04.20.R 2.000.154781.951.700.357.0025.004.004.010GT104.4717.015.07.20.R 2.000.154781.951.700.3512.0030.004.004.011GT104.4717.015.12.20.R 2.000.154781.951.700.3517.0035.004.004.012GT104.4717.015.17.20.R 3.000.054781.952.700.557.0025.004.004.013GT104.4727.005.07.30.R 3.000.054781.952.700.5512.0030.004.004.014GT104.4727.005.12.30.R 3.000.054781.952.700.5517.0035.004.004.015GT104.4727.005.17.30.R 3.000.054781.952.700.5522.0040.004.004.016GT104.4727.005.22.30.R 3.000.104781.952.700.557.0025.004.004.017GT104.4727.010.07.30.R 3.000.104781.952.700.5512.0030.004.004.018GT104.4727.010.12.30.R 3.000.104781.952.700.5517.0035.004.004.019GT104.4727.010.17.30.R 3.000.104781.952.700.5522.0040.004.004.020GT104.4727.010.22.30.R 3.000.254781.952.700.557.0025.004.004.021GT104.4727.025.07.30.R 3.000.254781.952.700.5512.0030.004.004.022GT104.4727.025.12.30.R 3.000.254781.952.700.5517.0035.004.004.023GT104.4727.025.17.30.R 3.000.254781.952.700.5522.0040.004.004.024GT104.4727.025.22.30.R 4.000.054781.703.700.6012.0030.004.004.025GT104.4737.005.12.40.R 4.000.054781.703.700.6017.0035.004.004.026GT104.4737.005.17.40.R 4.000.054781.703.700.6022.0040.004.004.027GT104.4737.005.22.40.R 4.000.054781.703.700.6027.0045.004.004.028GT104.4737.005.27.40.R 4.000.054781.703.700.6032.0050.004.004.029GT104.4737.005.32.40.R 4.000.154781.703.700.6012.0030.004.004.030GT104.4737.015.12.40.R 4.000.154781.703.700.6017.0035.004.004.031GT104.4737.015.17.40.R 4.000.154781.703.700.6022.0040.004.004.032GT104.4737.015.22.40.R 4.000.154781.703.700.6027.0045.004.004.033GT104.4737.015.27.40.R 4.000.154781.703.700.6032.0050.004.004.034GT104.4737.015.32.40.R 4.000.254781.703.700.6012.0030.004.004.035GT104.4737.025.12.40.R 4.000.254781.703.700.6017.0035.004.004.036GT104.4737.025.17.40.R 4.000.254781.703.700.6022.0040.004.004.037GT104.4737.025.22.40.R 4.000.254781.703.700.6027.0045.004.004.038GT104.4737.025.27.40.R 4.000.254781.703.700.6032.0050.004.004.039GT104.4737.025.32.40.R 4.000.104781.703.700.6012.0030.004.004.040GT104.4737.010.12.40.R 4.000.104781.703.700.6017.0035.004.004.041GT104.4737.010.17.40.R 4.000.104781.703.700.6022.0040.004.004.042GT104.4737.010.22.40.R 4.000.204781.703.700.6012.0030.004.004.043GT104.4737.020.12.40.R 4.000.204781.703.700.6017.0035.004.004.044GT104.4737.020.17.40.R 4.000.204781.703.700.6022.0040.004.004.045GT104.4737.020.22.40.R

Ontheleft-handdesign,thedesignationchangesto.L

Articleno.

Articleno.

Micro-precision tools for turning Cutting inserts for boring out and profiling radial free 47° • tmax. 0.6 mm fortoolholderstypeGB106/GH106

PMKNSH GT106 Cuttingdatapage195

PMKNSH GT106 Cuttingdatapage195

Right-handdesignasshown.Left-handdesignismirrorimage.

Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

5.000.054782.954.700.6012.0037.006.006.010GT106.4747.005.12.50.R 5.000.054782.954.700.6017.0042.006.006.020GT106.4747.005.17.50.R 5.000.054782.954.700.6022.0047.006.006.030GT106.4747.005.22.50.R 5.000.054782.954.700.6027.0052.006.006.040GT106.4747.005.27.50.R 5.000.054782.954.700.6032.0057.006.006.050GT106.4747.005.32.50.R 5.000.054782.954.700.6037.0062.006.006.060GT106.4747.005.37.50.R 5.000.054782.954.700.6042.0067.006.006.070GT106.4747.005.42.50.R 5.000.104782.954.700.6012.0037.006.006.110GT106.4747.010.12.50.R 5.000.104782.954.700.6017.0042.006.006.120GT106.4747.010.17.50.R 5.000.104782.954.700.6022.0047.006.006.130GT106.4747.010.22.50.R 5.000.104782.954.700.6027.0052.006.006.140GT106.4747.010.27.50.R 5.000.104782.954.700.6032.0057.006.006.150GT106.4747.010.32.50.R 5.000.104782.954.700.6037.0062.006.006.160GT106.4747.010.37.50.R 5.000.104782.954.700.6042.0067.006.006.170GT106.4747.010.42.50.R 5.000.154782.954.700.6012.0037.006.006.210GT106.4747.015.12.50.R 5.000.154782.954.700.6017.0042.006.006.220GT106.4747.015.17.50.R 5.000.154782.954.700.6022.0047.006.006.230GT106.4747.015.22.50.R 5.000.154782.954.700.6027.0052.006.006.240GT106.4747.015.27.50.R 5.000.154782.954.700.6032.0057.006.006.250GT106.4747.015.32.50.R 5.000.154782.954.700.6037.0062.006.006.260GT106.4747.015.37.50.R 5.000.154782.954.700.6042.0067.006.006.270GT106.4747.015.42.50.R 5.000.204782.954.700.6012.0037.006.006.310GT106.4747.020.12.50.R 5.000.204782.954.700.6017.0042.006.006.320GT106.4747.020.17.50.R 5.000.204782.954.700.6022.0047.006.006.330GT106.4747.020.22.50.R 5.000.204782.954.700.6027.0052.006.006.340GT106.4747.020.27.50.R 5.000.204782.954.700.6032.0057.006.006.350GT106.4747.020.32.50.R 5.000.204782.954.700.6037.0062.006.006.360GT106.4747.020.37.50.R 5.000.204782.954.700.6042.0067.006.006.370GT106.4747.020.42.50.R 5.000.304782.954.700.6012.0037.006.006.410GT106.4747.030.12.50.R 5.000.304782.954.700.6017.0042.006.006.420GT106.4747.030.17.50.R 5.000.304782.954.700.6022.0047.006.006.430GT106.4747.030.22.50.R

5.000.304782.954.700.6027.0052.006.006.440GT106.4747.030.27.50.R

5.000.304782.954.700.6032.0057.006.006.450GT106.4747.030.32.50.R

5.000.304782.954.700.6037.0062.006.006.460GT106.4747.030.37.50.R

5.000.304782.954.700.6042.0067.006.006.470GT106.4747.030.42.50.R

Ontheleft-handdesign,thedesignationchangesto.L

Cuttingdatapage1553

Articleno. 25843

Articleno. 25847

Articleno. 25842

Articleno. 25846

Cutting inserts for boring out and profiling radial free 47° • tmax. 1 mm fortoolholderstypeGB106/GH106

PMKNSH

GT106

Cuttingdatapage195

PMKNSH GT106 Cuttingdatapage195

Right-handdesignasshown.Left-handdesignismirrorimage.

Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

5.000.054782.954.701.0012.0037.006.006.010GT106.4747.005.12.50.R.T1 5.000.054782.954.701.0017.0042.006.006.020GT106.4747.005.17.50.R.T1 5.000.054782.954.701.0022.0047.006.006.030GT106.4747.005.22.50.R.T1 5.000.054782.954.701.0027.0052.006.006.040GT106.4747.005.27.50.R.T1 5.000.054782.954.701.0032.0057.006.006.050GT106.4747.005.32.50.R.T1 5.000.054782.954.701.0037.0062.006.006.060GT106.4747.005.37.50.R.T1 5.000.054782.954.701.0042.0067.006.006.070GT106.4747.005.42.50.R.T1 5.000.104782.954.701.0012.0037.006.006.110GT106.4747.010.12.50.R.T1 5.000.104782.954.701.0017.0042.006.006.120GT106.4747.010.17.50.R.T1 5.000.104782.954.701.0022.0047.006.006.130GT106.4747.010.22.50.R.T1 5.000.104782.954.701.0027.0052.006.006.140GT106.4747.010.27.50.R.T1 5.000.104782.954.701.0032.0057.006.006.150GT106.4747.010.32.50.R.T1 5.000.104782.954.701.0037.0062.006.006.160GT106.4747.010.37.50.R.T1 5.000.104782.954.701.0042.0067.006.006.170GT106.4747.010.42.50.R.T1 5.000.154782.954.701.0012.0037.006.006.210GT106.4747.015.12.50.R.T1 5.000.154782.954.701.0017.0042.006.006.220GT106.4747.015.17.50.R.T1 5.000.154782.954.701.0022.0047.006.006.230GT106.4747.015.22.50.R.T1 5.000.154782.954.701.0027.0052.006.006.240GT106.4747.015.27.50.R.T1 5.000.154782.954.701.0032.0057.006.006.250GT106.4747.015.32.50.R.T1 5.000.154782.954.701.0037.0062.006.006.260GT106.4747.015.37.50.R.T1 5.000.154782.954.701.0042.0067.006.006.270GT106.4747.015.42.50.R.T1 5.000.204782.954.701.0012.0037.006.006.310GT106.4747.020.12.50.R.T1 5.000.204782.954.701.0017.0042.006.006.320GT106.4747.020.17.50.R.T1 5.000.204782.954.701.0022.0047.006.006.330GT106.4747.020.22.50.R.T1 5.000.204782.954.701.0027.0052.006.006.340GT106.4747.020.27.50.R.T1 5.000.204782.954.701.0032.0057.006.006.350GT106.4747.020.32.50.R.T1 5.000.204782.954.701.0037.0062.006.006.360GT106.4747.020.37.50.R.T1 5.000.204782.954.701.0042.0067.006.006.370GT106.4747.020.42.50.R.T1 5.000.304782.954.701.0012.0037.006.006.410GT106.4747.030.12.50.R.T1 5.000.304782.954.701.0017.0042.006.006.420GT106.4747.030.17.50.R.T1 5.000.304782.954.701.0022.0047.006.006.430GT106.4747.030.22.50.R.T1

5.000.304782.954.701.0027.0052.006.006.440GT106.4747.030.27.50.R.T1

5.000.304782.954.701.0032.0057.006.006.450GT106.4747.030.32.50.R.T1

5.000.304782.954.701.0037.0062.006.006.460GT106.4747.030.37.50.R.T1

5.000.304782.954.701.0042.0067.006.006.470GT106.4747.030.42.50.R.T1

Ontheleft-handdesign,thedesignationchangesto.L

25895

Cuttingdatapage1553

Articleno. 25891

Articleno.

Articleno. 25890

Articleno. 25894

Micro-precision tools for turning Cutting inserts for boring out and profiling radial free 47° • tmax. 0.6 mm fortoolholderstypeGB106/GH106

PMKNSH GT106 Cuttingdatapage195

PMKNSH GT106 Cuttingdatapage195

Right-handdesignasshown.Left-handdesignismirrorimage.

Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

6.000.054782.705.700.6012.0037.006.006.019GT106.4757.005.12.60.R 6.000.054782.705.700.6017.0042.006.006.020GT106.4757.005.17.60.R 6.000.054782.705.700.6022.0047.006.006.021GT106.4757.005.22.60.R 6.000.054782.705.700.6027.0052.006.006.022GT106.4757.005.27.60.R 6.000.054782.705.700.6032.0057.006.006.023GT106.4757.005.32.60.R 6.000.054782.705.700.6037.0062.006.006.024GT106.4757.005.37.60.R 6.000.054782.705.700.6042.0067.006.006.025GT106.4757.005.42.60.R 6.000.054782.705.700.6047.0072.006.006.026GT106.4757.005.47.60.R 6.000.054782.705.700.6052.0077.006.006.027GT106.4757.005.52.60.R 6.000.104782.705.700.6012.0037.006.006.028GT106.4757.010.12.60.R 6.000.104782.705.700.6017.0042.006.006.029GT106.4757.010.17.60.R 6.000.104782.705.700.6022.0047.006.006.030GT106.4757.010.22.60.R 6.000.104782.705.700.6027.0052.006.006.031GT106.4757.010.27.60.R 6.000.104782.705.700.6032.0057.006.006.032GT106.4757.010.32.60.R 6.000.104782.705.700.6037.0062.006.006.033GT106.4757.010.37.60.R 6.000.104782.705.700.6042.0067.006.006.034GT106.4757.010.42.60.R 6.000.104782.705.700.6047.0072.006.006.035GT106.4757.010.47.60.R 6.000.104782.705.700.6052.0077.006.006.036GT106.4757.010.52.60.R 6.000.154782.705.700.6012.0037.006.006.013GT106.4757.015.12.60.R 6.000.154782.705.700.6017.0042.006.006.014GT106.4757.015.17.60.R 6.000.154782.705.700.6022.0047.006.006.015GT106.4757.015.22.60.R 6.000.154782.705.700.6027.0052.006.006.001GT106.4757.015.27.60.R 6.000.154782.705.700.6032.0057.006.006.002GT106.4757.015.32.60.R 6.000.154782.705.700.6037.0062.006.006.003GT106.4757.015.37.60.R 6.000.154782.705.700.6042.0067.006.006.004GT106.4757.015.42.60.R 6.000.154782.705.700.6047.0072.006.006.005GT106.4757.015.47.60.R 6.000.154782.705.700.6052.0077.006.006.006GT106.4757.015.52.60.R 6.000.204782.705.700.6012.0037.006.006.037GT106.4757.020.12.60.R 6.000.204782.705.700.6017.0042.006.006.038GT106.4757.020.17.60.R 6.000.204782.705.700.6022.0047.006.006.039GT106.4757.020.22.60.R 6.000.204782.705.700.6027.0052.006.006.040GT106.4757.020.27.60.R 6.000.204782.705.700.6032.0057.006.006.041GT106.4757.020.32.60.R 6.000.204782.705.700.6037.0062.006.006.042GT106.4757.020.37.60.R 6.000.204782.705.700.6042.0067.006.006.043GT106.4757.020.42.60.R 6.000.204782.705.700.6047.0072.006.006.044GT106.4757.020.47.60.R 6.000.204782.705.700.6052.0077.006.006.045GT106.4757.020.52.60.R 6.000.304782.705.700.6012.0037.006.006.016GT106.4757.030.12.60.R 6.000.304782.705.700.6017.0042.006.006.017GT106.4757.030.17.60.R 6.000.304782.705.700.6022.0047.006.006.018GT106.4757.030.22.60.R 6.000.304782.705.700.6027.0052.006.006.007GT106.4757.030.27.60.R 6.000.304782.705.700.6032.0057.006.006.008GT106.4757.030.32.60.R 6.000.304782.705.700.6037.0062.006.006.009GT106.4757.030.37.60.R

6.000.304782.705.700.6042.0067.006.006.010GT106.4757.030.42.60.R 6.000.304782.705.700.6047.0072.006.006.011GT106.4757.030.47.60.R

6.000.304782.705.700.6052.0077.006.006.012GT106.4757.030.52.60.R

Ontheleft-handdesign,thedesignationchangesto.L

Articleno. 25711

Articleno. 25710

Cutting inserts for boring out and profiling radial free 47° • tmax. 2 mm fortoolholderstypeGB106/GH106

PMKNSH GT106 Cuttingdatapage195

PMKNSH GT106 Cuttingdatapage195

Right-handdesignasshown.Left-handdesignismirrorimage.

25522

Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

6.000.054782.705.702.0012.0037.006.006.010GT106.4757.005.12.60.R.T2 6.000.054782.705.702.0017.0042.006.006.020GT106.4757.005.17.60.R.T2 6.000.054782.705.702.0022.0047.006.006.030GT106.4757.005.22.60.R.T2 6.000.054782.705.702.0027.0052.006.006.040GT106.4757.005.27.60.R.T2 6.000.054782.705.702.0032.0057.006.006.050GT106.4757.005.32.60.R.T2 6.000.054782.705.702.0037.0062.006.006.060GT106.4757.005.37.60.R.T2 6.000.054782.705.702.0042.0067.006.006.070GT106.4757.005.42.60.R.T2 6.000.054782.705.702.0047.0072.006.006.080GT106.4757.005.47.60.R.T2 6.000.054782.705.702.0052.0077.006.006.090GT106.4757.005.52.60.R.T2 6.000.104782.705.702.0012.0037.006.006.110GT106.4757.010.12.60.R.T2 6.000.104782.705.702.0017.0042.006.006.120GT106.4757.010.17.60.R.T2 6.000.104782.705.702.0022.0047.006.006.130GT106.4757.010.22.60.R.T2 6.000.104782.705.702.0027.0052.006.006.140GT106.4757.010.27.60.R.T2 6.000.104782.705.702.0032.0057.006.006.150GT106.4757.010.32.60.R.T2 6.000.104782.705.702.0037.0062.006.006.160GT106.4757.010.37.60.R.T2 6.000.104782.705.702.0042.0067.006.006.170GT106.4757.010.42.60.R.T2 6.000.104782.705.702.0047.0072.006.006.180GT106.4757.010.47.60.R.T2 6.000.104782.705.702.0052.0077.006.006.190GT106.4757.010.52.60.R.T2 6.000.154782.705.702.0012.0037.006.006.210GT106.4757.015.12.60.R.T2 6.000.154782.705.702.0017.0042.006.006.220GT106.4757.015.17.60.R.T2 6.000.154782.705.702.0022.0047.006.006.230GT106.4757.015.22.60.R.T2 6.000.154782.705.702.0027.0052.006.006.240GT106.4757.015.27.60.R.T2 6.000.154782.705.702.0032.0057.006.006.250GT106.4757.015.32.60.R.T2 6.000.154782.705.702.0037.0062.006.006.260GT106.4757.015.37.60.R.T2 6.000.154782.705.702.0042.0067.006.006.270GT106.4757.015.42.60.R.T2 6.000.154782.705.702.0047.0072.006.006.280GT106.4757.015.47.60.R.T2 6.000.154782.705.702.0052.0077.006.006.290GT106.4757.015.52.60.R.T2 6.000.204782.705.702.0012.0037.006.006.310GT106.4757.020.12.60.R.T2 6.000.204782.705.702.0017.0042.006.006.320GT106.4757.020.17.60.R.T2 6.000.204782.705.702.0022.0047.006.006.330GT106.4757.020.22.60.R.T2 6.000.204782.705.702.0027.0052.006.006.340GT106.4757.020.27.60.R.T2 6.000.204782.705.702.0032.0057.006.006.350GT106.4757.020.32.60.R.T2 6.000.204782.705.702.0037.0062.006.006.360GT106.4757.020.37.60.R.T2 6.000.204782.705.702.0042.0067.006.006.370GT106.4757.020.42.60.R.T2 6.000.204782.705.702.0047.0072.006.006.380GT106.4757.020.47.60.R.T2 6.000.204782.705.702.0052.0077.006.006.390GT106.4757.020.52.60.R.T2 6.000.304782.705.702.0012.0037.006.006.410GT106.4757.030.12.60.R.T2

6.000.304782.705.702.0017.0042.006.006.420GT106.4757.030.17.60.R.T2

6.000.304782.705.702.0022.0047.006.006.430GT106.4757.030.22.60.R.T2

6.000.304782.705.702.0027.0052.006.006.440GT106.4757.030.27.60.R.T2

6.000.304782.705.702.0032.0057.006.006.450GT106.4757.030.32.60.R.T2

6.000.304782.705.702.0037.0062.006.006.460GT106.4757.030.37.60.R.T2

6.000.304782.705.702.0042.0067.006.006.470GT106.4757.030.42.60.R.T2

6.000.304782.705.702.0047.0072.006.006.480GT106.4757.030.47.60.R.T2

6.000.304782.705.702.0052.0077.006.006.490GT106.4757.030.52.60.R.T2

Ontheleft-handdesign,thedesignationchangesto.L

25519 L

25523 L Cuttingdatapage1553

Articleno.

Cutting inserts for boring out and profiling radial free 47° • tmax. 0.8 mm fortoolholderstypeGB108/GH108

PMKNSH GT108 Cuttingdatapage197

PMKNSH GT108 Cuttingdatapage197

Right-handdesignasshown.Left-handdesignismirrorimage.

27104

27106 R Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm 7.000.104783.956.700.8017.0042.008.008.120GT108.4767.010.17.70.R 7.000.104783.956.700.8027.0052.008.008.140GT108.4767.010.27.70.R 7.000.104783.956.700.8037.0062.008.008.160GT108.4767.010.37.70.R 7.000.104783.956.700.8042.0067.008.008.170GT108.4767.010.42.70.R 7.000.104783.956.700.8047.0072.008.008.180GT108.4767.010.47.70.R 7.000.204783.956.700.8017.0042.008.008.320GT108.4767.020.17.70.R 7.000.204783.956.700.8027.0052.008.008.340GT108.4767.020.27.70.R 7.000.204783.956.700.8037.0062.008.008.360GT108.4767.020.37.70.R 7.000.204783.956.700.8042.0067.008.008.370GT108.4767.020.42.70.R 7.000.204783.956.700.8047.0072.008.008.380GT108.4767.020.47.70.R

Ontheleft-handdesign,thedesignationchangesto.L

Cuttingdatapage1553

Articleno.

Articleno.

Cutting inserts for boring out and profiling radial free 47° • tmax. 2 mm fortoolholderstypeGB108/GH108

PMKNSH GT108 Cuttingdatapage197

PMKNSH GT108 Cuttingdatapage197

Right-handdesignasshown.Left-handdesignismirrorimage.

27110

Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

7.000.104783.956.702.0017.0042.008.008.120GT108.4767.010.17.70.R.T2 7.000.104783.956.702.0027.0052.008.008.140GT108.4767.010.27.70.R.T2 7.000.104783.956.702.0037.0062.008.008.160GT108.4767.010.37.70.R.T2 7.000.104783.956.702.0042.0067.008.008.170GT108.4767.010.42.70.R.T2 7.000.204783.956.702.0017.0042.008.008.320GT108.4767.020.17.70.R.T2 7.000.204783.956.702.0027.0052.008.008.340GT108.4767.020.27.70.R.T2 7.000.204783.956.702.0037.0062.008.008.360GT108.4767.020.37.70.R.T2 7.000.204783.956.702.0042.0067.008.008.370GT108.4767.020.42.70.R.T2

Ontheleft-handdesign,thedesignationchangesto.L

27111 L Cuttingdatapage1553

Micro-precision tools for turning Cutting inserts for boring out and profiling radial free 47° • tmax. 1 mm fortoolholderstypeGB108/GH108

Right-handdesignasshown.Left-handdesignismirrorimage.

Articleno. 27204 R Articleno. 27206 R Dmin.RW1W2fatmax.LaLgDh6Codeno.Description

8.000.104783.707.701.0017.0042.008.008.029GT108.4777.010.17.80.R 8.000.104783.707.701.0027.0052.008.008.031GT108.4777.010.27.80.R 8.000.104783.707.701.0037.0062.008.008.033GT108.4777.010.37.80.R 8.000.104783.707.701.0042.0067.008.008.034GT108.4777.010.42.80.R 8.000.104783.707.701.0047.0072.008.008.035GT108.4777.010.47.80.R 8.000.204783.707.701.0017.0042.008.008.038GT108.4777.020.17.80.R 8.000.204783.707.701.0027.0052.008.008.040GT108.4777.020.27.80.R 8.000.204783.707.701.0037.0062.008.008.042GT108.4777.020.37.80.R 8.000.204783.707.701.0042.0067.008.008.043GT108.4777.020.42.80.R 8.000.204783.707.701.0047.0072.008.008.044GT108.4777.020.47.80.R

Ontheleft-handdesign,thedesignationchangesto.L

Cutting inserts for boring out and profiling radial free 47° • tmax. 2.5 mm fortoolholderstypeGB108/GH108

Articleno. 27205 L Articleno. 27207 L Cuttingdatapage1553

Cuttingdatapage197

Right-handdesignasshown.Left-handdesignismirrorimage.

Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

8.000.104783.707.702.5017.0042.008.008.120GT108.4777.010.17.80.R.T2.5 8.000.104783.707.702.5027.0052.008.008.140GT108.4777.010.27.80.R.T2.5 8.000.104783.707.702.5037.0062.008.008.160GT108.4777.010.37.80.R.T2.5 8.000.104783.707.702.5042.0067.008.008.170GT108.4777.010.42.80.R.T2.5 8.000.204783.707.702.5017.0042.008.008.320GT108.4777.020.17.80.R.T2.5 8.000.204783.707.702.5027.0052.008.008.340GT108.4777.020.27.80.R.T2.5 8.000.204783.707.702.5037.0062.008.008.360GT108.4777.020.37.80.R.T2.5 8.000.204783.707.702.5042.0067.008.008.370GT108.4777.020.42.80.R.T2.5

Ontheleft-handdesign,thedesignationchangesto.L

27211 L Cuttingdatapage1553

Articleno. 27209

Articleno.

Cutting inserts for boring out and profiling radialfree8° fortoolholderstypeGB104/GH104

PMKNSH GT104 Cuttingdatapage194

PMKNSH GT104 Cuttingdatapage194

Right-handdesignasshown.Left-handdesignismirrorimage.

25084 R

25088 R Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

3.000.05881.952.700.157.0025.004.004.001GT104.0827.005.07.30.R 3.000.05881.952.700.1512.0030.004.004.002GT104.0827.005.12.30.R 3.000.05881.952.700.1517.0035.004.004.003GT104.0827.005.17.30.R 3.000.05881.952.700.1522.0040.004.004.004GT104.0827.005.22.30.R 3.000.10881.952.700.157.0025.004.004.005GT104.0827.010.07.30.R 3.000.10881.952.700.1512.0030.004.004.006GT104.0827.010.12.30.R 3.000.10881.952.700.1517.0035.004.004.007GT104.0827.010.17.30.R 3.000.10881.952.700.1522.0040.004.004.008GT104.0827.010.22.30.R 3.000.20881.952.700.157.0025.004.004.009GT104.0827.020.07.30.R 3.000.20881.952.700.1512.0030.004.004.010GT104.0827.020.12.30.R 3.000.20881.952.700.1517.0035.004.004.011GT104.0827.020.17.30.R 3.000.20881.952.700.1522.0040.004.004.012GT104.0827.020.22.30.R 4.000.05881.703.700.1512.0030.004.004.013GT104.0837.005.12.40.R 4.000.05881.703.700.1517.0035.004.004.014GT104.0837.005.17.40.R 4.000.05881.703.700.1522.0040.004.004.015GT104.0837.005.22.40.R 4.000.05881.703.700.1527.0045.004.004.016GT104.0837.005.27.40.R 4.000.05881.703.700.1532.0050.004.004.017GT104.0837.005.32.40.R 4.000.15881.703.700.1512.0030.004.004.018GT104.0837.015.12.40.R 4.000.15881.703.700.1517.0035.004.004.019GT104.0837.015.17.40.R 4.000.15881.703.700.1522.0040.004.004.020GT104.0837.015.22.40.R 4.000.15881.703.700.1527.0045.004.004.021GT104.0837.015.27.40.R 4.000.15881.703.700.1532.0050.004.004.022GT104.0837.015.32.40.R 4.000.25881.703.700.1512.0030.004.004.023GT104.0837.025.12.40.R 4.000.25881.703.700.1517.0035.004.004.024GT104.0837.025.17.40.R 4.000.25881.703.700.1522.0040.004.004.025GT104.0837.025.22.40.R 4.000.25881.703.700.1527.0045.004.004.026GT104.0837.025.27.40.R 4.000.25881.703.700.1532.0050.004.004.027GT104.0837.025.32.40.R 4.000.10881.703.700.1512.0030.004.004.028GT104.0837.010.12.40.R 4.000.10881.703.700.1517.0035.004.004.029GT104.0837.010.17.40.R 4.000.10881.703.700.1522.0040.004.004.030GT104.0837.010.22.40.R

Ontheleft-handdesign,thedesignationchangesto.L

Articleno. 25089 L Cuttingdatapage1553

Articleno. 25085

Articleno.

Articleno.

Micro-precision tools for turning Cutting inserts for boring out and profiling radialfree8° fortoolholderstypeGB106/GH106 22,5

PMKNSH GT106 Cuttingdatapage195

PMKNSH GT106 Cuttingdatapage195

Right-handdesignasshown.Left-handdesignismirrorimage.

25506

Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

5.000.05882.954.700.3012.0037.006.006.010GT106.0847.005.12.50.R 5.000.05882.954.700.3017.0042.006.006.020GT106.0847.005.17.50.R 5.000.05882.954.700.3022.0047.006.006.030GT106.0847.005.22.50.R 5.000.05882.954.700.3027.0052.006.006.040GT106.0847.005.27.50.R 5.000.05882.954.700.3032.0057.006.006.050GT106.0847.005.32.50.R 5.000.05882.954.700.3037.0062.006.006.060GT106.0847.005.37.50.R 5.000.05882.954.700.3042.0067.006.006.070GT106.0847.005.42.50.R 5.000.10882.954.700.3012.0037.006.006.110GT106.0847.010.12.50.R 5.000.10882.954.700.3017.0042.006.006.120GT106.0847.010.17.50.R 5.000.10882.954.700.3022.0047.006.006.130GT106.0847.010.22.50.R 5.000.10882.954.700.3027.0052.006.006.140GT106.0847.010.27.50.R 5.000.10882.954.700.3032.0057.006.006.150GT106.0847.010.32.50.R 5.000.10882.954.700.3037.0062.006.006.160GT106.0847.010.37.50.R 5.000.10882.954.700.3042.0067.006.006.170GT106.0847.010.42.50.R 5.000.15882.954.700.3012.0037.006.006.210GT106.0847.015.12.50.R 5.000.15882.954.700.3017.0042.006.006.220GT106.0847.015.17.50.R 5.000.15882.954.700.3022.0047.006.006.230GT106.0847.015.22.50.R 5.000.15882.954.700.3027.0052.006.006.240GT106.0847.015.27.50.R 5.000.15882.954.700.3032.0057.006.006.250GT106.0847.015.32.50.R 5.000.15882.954.700.3037.0062.006.006.260GT106.0847.015.37.50.R 5.000.15882.954.700.3042.0067.006.006.270GT106.0847.015.42.50.R 5.000.20882.954.700.3012.0037.006.006.310GT106.0847.020.12.50.R 5.000.20882.954.700.3017.0042.006.006.320GT106.0847.020.17.50.R 5.000.20882.954.700.3022.0047.006.006.330GT106.0847.020.22.50.R 5.000.20882.954.700.3027.0052.006.006.340GT106.0847.020.27.50.R 5.000.20882.954.700.3032.0057.006.006.350GT106.0847.020.32.50.R 5.000.20882.954.700.3037.0062.006.006.360GT106.0847.020.37.50.R 5.000.20882.954.700.3042.0067.006.006.370GT106.0847.020.42.50.R 5.000.30882.954.700.3012.0037.006.006.410GT106.0847.030.12.50.R 5.000.30882.954.700.3017.0042.006.006.420GT106.0847.030.17.50.R 5.000.30882.954.700.3022.0047.006.006.430GT106.0847.030.22.50.R 5.000.30882.954.700.3027.0052.006.006.440GT106.0847.030.27.50.R 5.000.30882.954.700.3032.0057.006.006.450GT106.0847.030.32.50.R 5.000.30882.954.700.3037.0062.006.006.460GT106.0847.030.37.50.R 5.000.30882.954.700.3042.0067.006.006.470GT106.0847.030.42.50.R

25503

Ontheleft-handdesign,thedesignationchangesto.L

Cuttingdatapage1553

Articleno.

Cutting inserts for boring out and profiling radialfree8° fortoolholderstypeGB106/GH106

PMKNSH GT106 Cuttingdatapage195

PMKNSH GT106 Cuttingdatapage195

Right-handdesignasshown.Left-handdesignismirrorimage.

Dmin.RW1W2fatmax.LaLgDh6Codeno.Description mmmm°°mmmmmmmmmmmm

6.000.05882.705.700.3012.0037.006.006.010GT106.0857.005.12.60.R 6.000.05882.705.700.3017.0042.006.006.020GT106.0857.005.17.60.R 6.000.05882.705.700.3022.0047.006.006.030GT106.0857.005.22.60.R 6.000.05882.705.700.3027.0052.006.006.040GT106.0857.005.27.60.R 6.000.05882.705.700.3032.0057.006.006.050GT106.0857.005.32.60.R 6.000.05882.705.700.3037.0062.006.006.060GT106.0857.005.37.60.R 6.000.05882.705.700.3042.0067.006.006.070GT106.0857.005.42.60.R 6.000.10882.705.700.3012.0037.006.006.110GT106.0857.010.12.60.R 6.000.10882.705.700.3017.0042.006.006.120GT106.0857.010.17.60.R 6.000.10882.705.700.3022.0047.006.006.130GT106.0857.010.22.60.R 6.000.10882.705.700.3027.0052.006.006.140GT106.0857.010.27.60.R 6.000.10882.705.700.3032.0057.006.006.150GT106.0857.010.32.60.R 6.000.10882.705.700.3037.0062.006.006.160GT106.0857.010.37.60.R 6.000.10882.705.700.3042.0067.006.006.170GT106.0857.010.42.60.R 6.000.15882.705.700.3012.0037.006.006.210GT106.0857.015.12.60.R 6.000.15882.705.700.3017.0042.006.006.220GT106.0857.015.17.60.R 6.000.15882.705.700.3022.0047.006.006.230GT106.0857.015.22.60.R 6.000.15882.705.700.3027.0052.006.006.240GT106.0857.015.27.60.R 6.000.15882.705.700.3032.0057.006.006.250GT106.0857.015.32.60.R 6.000.15882.705.700.3037.0062.006.006.260GT106.0857.015.37.60.R 6.000.15882.705.700.3042.0067.006.006.270GT106.0857.015.42.60.R 6.000.20882.705.700.3012.0037.006.006.310GT106.0857.020.12.60.R 6.000.20882.705.700.3017.0042.006.006.320GT106.0857.020.17.60.R 6.000.20882.705.700.3022.0047.006.006.330GT106.0857.020.22.60.R 6.000.20882.705.700.3027.0052.006.006.340GT106.0857.020.27.60.R 6.000.20882.705.700.3032.0057.006.006.350GT106.0857.020.32.60.R 6.000.20882.705.700.3037.0062.006.006.360GT106.0857.020.37.60.R 6.000.20882.705.700.3042.0067.006.006.370GT106.0857.020.42.60.R 6.000.30882.705.700.3012.0037.006.006.410GT106.0857.030.12.60.R 6.000.30882.705.700.3017.0042.006.006.420GT106.0857.030.17.60.R 6.000.30882.705.700.3022.0047.006.006.430GT106.0857.030.22.60.R 6.000.30882.705.700.3027.0052.006.006.440GT106.0857.030.27.60.R 6.000.30882.705.700.3032.0057.006.006.450GT106.0857.030.32.60.R 6.000.30882.705.700.3037.0062.006.006.460GT106.0857.030.37.60.R 6.000.30882.705.700.3042.0067.006.006.470GT106.0857.030.42.60.R

Ontheleft-handdesign,thedesignationchangesto.L

Cuttingdatapage1553

Articleno. 25511

Articleno. 25510