Welcome to METALMAG by Weldclass

We're excited to bring you the very first edition of MetalMag – Weldclass’ brand new quarterly magazine created especially for the people who keep the sparks flying and the metal moving.

Whether you’re in the workshop, on-site, or behind the scenes, this is your go-to spot for all things Weldclass.

In every issue, you'll find exclusive deals, a first look at new products, handy tips and tricks, and real-world stories from Weldclass users just like you. It’s our way of keeping you in the loop, sharing useful insights, and celebrating the incredible work being done by the welding and metalworking community across Australia and beyond.

Thanks for being part of the Weldclass family – we hope you enjoy MetalMag as much as we’ve enjoyed putting it together.

Let’s get stuck in!

WELDING FUME EXPOSURE

What You Need to Know About the New Legal Limits

Welding fume is more than just smoke — it’s a complex mixture of hazardous particles and gases that can lead to serious long-term health effects. With Australia’s new legal exposure limits now in place, it’s critical that welders and employers alike understand the risks and the requirements to stay safe and compliant.

Welding fumes are produced when metals are heated and vaporised, forming airborne particles. Depending on the materials used, these fumes can contain substances like iron, manganese, zinc, aluminium, and — in the case of stainless steel — hazardous compounds like hexavalent chromium and nickel. These particles, especially in processes like MIG, stick, and flux-core welding, pose real respiratory dangers over time.

As of January 18, 2024, Safe Work Australia has officially reduced the 8-hour time-weighted average (TWA) exposure limit for welding fumes from 5.0 mg/m³ to 1.0 mg/m³. This significant change reflects growing global concern about welding fume toxicity and aligns Australia with international best practice.

Employers and PCBU’s must now take stronger steps to manage fume exposure. First, engineering controls such as local exhaust ventilation or fume-extracting torches should be the frontline defence. In many cases, this means retrofitting work areas or upgrading extraction systems.

Where ventilation alone isn’t enough, welders must use appropriate respiratory protection. Basic dust masks are no longer sufficient — powered air purifying respirators (PAPR) with P2 or P3 filters are now considered best practice, particularly in confined spaces or high-fume applications.

Regular air monitoring is also required to ensure exposure remains within legal limits. In some cases, particularly where high-risk fumes like hexavalent chromium are present, ongoing health surveillance may be needed under WHS regulations.

'Fume Extraction is Now a Necessity, Not an Optional Extra'

PPE must be chosen carefully based on the task and the materials being welded. Welders also have a responsibility to stay informed and trained in how to use these controls effectively.

Welding is a proud, skilled trade — and it should also be a safe one. With the right controls in place, we can adapt to these changes and protect the health of every welder for the long haul.

For more information, visit weldclass.com.au/fumecontrol

ALLCLEAR® MOBILE FUME EXTRACTORS

Do They Really Work?

If you spend your days under the hood, you already know welding fumes aren’t just a bit of smoke - they’re full of nasty stuff like metal particles and chemicals that can mess with your lungs over time. That’s where mobile fume extractors come in, and the ALLCLEAR® range from Weldclass is built to handle the job without making life harder on the workshop floor.

What Do These Machines Actually Do?

ALLCLEAR® mobile extractors are designed to suck up fumes right where you’re welding, clean the air, and pump it back out so you’re not breathing it all in. You just wheel the unit close to where you’re working, swing the extraction arm into place, and get on with it. No mucking around with permanent ducting or setups. Easy to move. Easy to use.

MA100: Compact & Cost-Saving

The ALLCLEAR® MA100 is the small but tough option. It runs on a regular power point (240V), and the filter inside can be cleaned instead of replaced all the time, so it saves you cash long term. There's even a built-in deflector to help stop sparks from reaching the filter, reducing fire risk. Perfect if you’re doing lighter or on-andoff welding jobs in different spots around the workshop. If you’re running bigger weld jobs or multi-booth setups, check out the MA350 range.

MA350 Series: For Bigger, Busier Workshops

MA300 AUTO: More Muscle, Less Maintenance

Need something a bit beefier?

The MA300 AUTO does everything the MA100 does, but adds an auto-cleaning filter system. That means less time spent opening it up and cleaning by hand. Plus, it’s got warning lights to tell you when the filter’s full, and a dust bin to catch the crap it pulls from the air. Still runs on single-phase power, still mobile, just more grunt.

These run on 3-phase power and come with two 3-metre extraction arms, so you can cover more area or run two welding stations off the same unit.

Bottom Line

MA350 STD has a cleanable filter, dust bin, and access door so you can empty it without getting a face full of fume dust.

MA350 AUTO takes it up another notch with an automatic filter cleaning system, just like the MA300 AUTO but made for heavyduty, all-day work.

The ALLCLEAR® extractors are made to work as hard as you do. They’re tough, easy to move, and built to help you breathe easier—literally. Whether you're doing small jobs or full-time production welding, there's an option that’ll fit your setup and keep the workshop safer.

BREATHE EASY, WELD SMART...

Introducing the PROMAX 680R and 850R PAPR Helmets from Weldclass

Weldclass is proud to introduce its latest advancements in welding safety: the PROMAX 680R and PROMAX 850R Powered Air Purifying Respirator (PAPR) welding helmets.

Designed to meet the demands of today’s welding professionals, both models offer cutting-edge protection, crystal-clear optics, and all-day comfort — tailored to suit different working styles and preferences.

PROMAX 680R

Efficient and Accessible

The PROMAX 680R is an ideal choice for welders who want highquality respiratory protection in a clean, lightweight package.

With a fixed-front design and a generous 95cm² viewing area, this helmet offers clarity and coverage without the bulk. An external grind mode switch allows for quick transitions between weld and grind settings, making it a go-to for allround welding work.

At a recommended price of $899 inc GST, the 680R delivers outstanding value with the advanced features and reliability Weldclass is known for.

PROMAX 850R

Premium Performance, Maximum Protection

At the top of the range, the PROMAX 850R is engineered for professionals who want the best in both safety and flexibility. It features a flip-up welding lens that reveals a full-face, clear grinding visor — perfect for fabricators or anyone who frequently moves between processes.

The PROMAX 850R is priced at $1,149 inc GST.

Built on Shared Technology

Both helmets are powered by the PROMAX R50 PAPR unit, delivering a consistent, clean airflow that ensures safe, breathable air throughout the day. Weldclass’ V1-rated lens technology provides ultra-crisp optics, minimal distortion, and natural colour definition — helping users see more accurately, weld with more control, and reduce eye strain.

The 680R and 850R are fully compliant with AS/NZS 1716, 1337.1, and 1338.1 standards and are backed by an industry-leading 7-year lens warranty — a true mark of durability and long-term performance.

In addition to its broader field of view, the 850R also incorporates a fully sealed face and head system. This advanced sealing design further reduces the risk of exposure to welding fume by keeping contaminated air out, even during movement or long shifts in high-fume environments. It's an added layer of protection for welders who take safety seriously.

Learn more at www.weldclass.com.au or speak to your local Weldclass distributor.

Advanced digital controls + illuminated LCD screen

External Controls

Super-size view equivalent to 97.5 x 97.5mm with V1 (1/1/1/1) rated optics Auto or manual

sensitivity & delay control

Adjust settings & switch to grind mode without lifting helmet.

Bonus 2nd battery

Flip-up lens, wide view grinding visor, side view windows

Advanced digital controls + illuminated LCD screen

Super-size view equivalent to 97.5 x 97.5mm with V1 (1/1/1/1) rated optics

Auto or manual shade, sensitivity & delay control

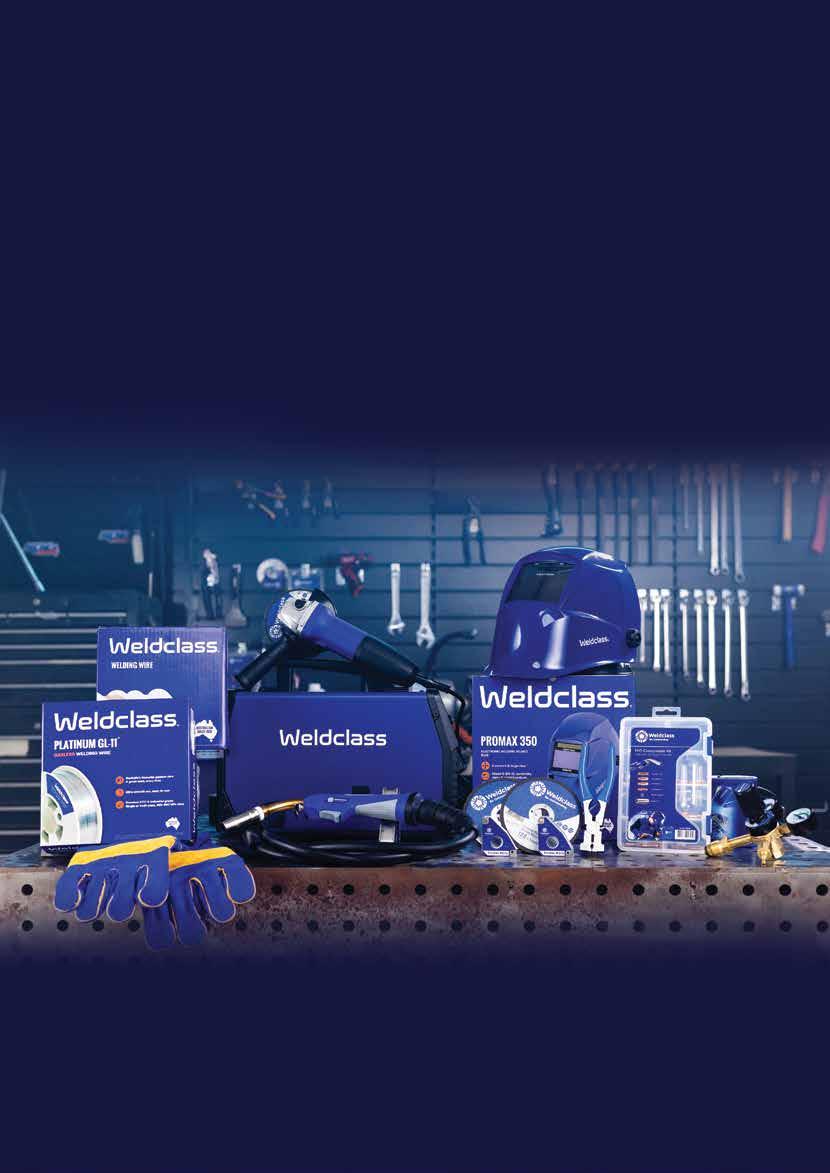

EOFY KITS 2025 WELD SMARTER. SAVE MORE WELDING & PLASMA MACHINES

• 132MST Machine with MIG torch

• Earth Lead

• Stick Lead

• Spool of Gasless 0.9mm x 0.45kg wire

• Wire Brush with slag remover

• Welding Gloves

• Spare MIG tips

• Force 160MST MK2 MIG / Stick / TIG Welder

• Promax 350 Blue Helmet

• Promax WG16 Blue Gloves

• Platinum GL-11 Gasless Wire 4.5kg 0.9mm

• MIG Parts Kit BZL 15 with Storage Box

• Force 180MST MIG / Stick / TIG Welder

• Promax 350 Blue Helmet

• Promax WG16 Blue Gloves

• Platinum GL-11 Gasless Wire 4.5kg 0.9mm

• Platinum XT6 MIG Steel Wire 5kg 0.9mm

• MIG Parts Kit BZL 25 with Storage Box

• Promax G1250 125mm Angle Grinder

• Promax Inox Thin Cutting Discs

• Promax MG12 Mini Magnets 2-pk

• Weldclass MIG

• Force 200MST MIG / Stick / TIG Welder

• Promax 650 Matte Black Helmet

• MIG Parts Kit BZL 25 with Storage Box

• Promax WG16 Blue Gloves

• Promax Leather Blanket with Eyelets 1.8m x 1.8m

• Promax MG22 On/Off Magnet

• Weldclass MIG Pliers

• Force 201T AC/DC TIG Welder

• Promax 650 Matte Black Helmet

• Platinum TG-21 TIG Gloves

• TIG Parts Kit with Storage Box #17/18/26 Standard

• Platinum PX Glass Cup TIG Parts Kit #17/18/26 Standard

• Foot Controller FC1 with 2.5m cable (12-pin plug)

• Platinum TK17 Super-Flex 4m TIG Torch

• 17F 8m Torch with Remote Controls

• Force 45P Plasma Cutter

• Promax WG16 Blue Gloves

• XTP40/60 Plasma Parts Kit with Storage Box

• Safety Specs - Shade (For Oxy / Plasma)

• 8m Torch

WELDING BLANKETS

• Heavy duty split cowhide leather

• Sewn with Heat-Resistant Kevlar thread, for resistance to seam failure

• With eyelets

• ‘General purpose’ high-temperature welding blanket

• Withstands up to 550°c long duration and 700°C short duration exposure welding, etc

• ‘Heavy duty’ hightemperature silica glass fabric

• Max recommended working temperature / exposure: 1100°C

• High-tech coating resists up to 1600°C

• Completely non-irritant

• Easy to cut to any length/ shape

8-WBSG11/0918 1.0 x 1.8m

8-WBSG11/1820 1.8 x 2.0m w/ eyelets $265.00 8-WBSG11/3030 2.0 x 3.0m

• Dual length - Suits

1.8x1.8m AND 1.8x2.0m curtains

• Coated steel frame

• Spring-pin joints for fast assembly

• Includes castor wheels

• Multiple frames can be joined together using connector pieces included

• Free Zip-Ties and Curtain Rings supplied with each curtain - Ready to install, no need to

• Fire retardant

• Tested & Conforms to EN ISO 25980

• Metal eyelets for superior strength

• Heavy-duty coated RHS frame with welded corner brackets

• Includes lockable castor wheels

• Two or more frames can be Joined together (bolts and nuts/washers included), to create longer screens (4m, 6m, 8m, etc)

WELDING JACKETS

• Premium Blue cowhide leather; Does not shed fibres like standard grey/ chrome leather

• 7-Year Warranty* • Lighter & cooler than full leather, with leather sleeves for heavy duty protection where it is most needed

• Close fitting wrap around design

• Full UV protection against sun glare

• AS1337.1 High-Impact Rated

• Robust, yet light weight

• Reduces "Hot Hand" - Aluminised / Reflective Kevlar back reflects heat away from welding glove

• Crafted for excellent fit: Try a pair to experience the difference!

• Top Quality: Premium cowhide leather,reinforced, Sewn with heatresistant Kevlar thread

• Xtended Cuff: Provides full arm protection - total glove length 680mm

• Enjoy a generous viewing area equivalent to 72.8 x 72.8mm, with Ultra-Clear Vision

• Dual Shade Range 5-8 / 9-13 plus grind mode to cover a wide range of welding processes

Suits 1mm to 4mm TIG Tungstens

Use with Rotary Power Tool Common 3/4” mounting thread

3