In recent years the use of gas engines in data centers has started to gain traction due to the difficulty to secure grid power for the increasing energy needs of data centers.

At AB , a global, leading supplier of modular CHP plants we are offering CHP solutions specifically designed for data center applications.

If you require 24/7 natural gas fueled operation as the primary power source for your data center, our modular CHP systems are the ideal energy solution.

Our purpose designed energy plants can run either in parallel as well as independent from the grid while delivering power, and cooling at the highest efficiencies and lowest cost to your data center.

The ever-increasing power demand is causing many electric utilities to struggle with the supply of power required by a data center. Rather than delay a project, or invest in expensive grid upgrades, it will be more cost effective to invest in a modular power plant that can run independently as well as in parallel with the grid.

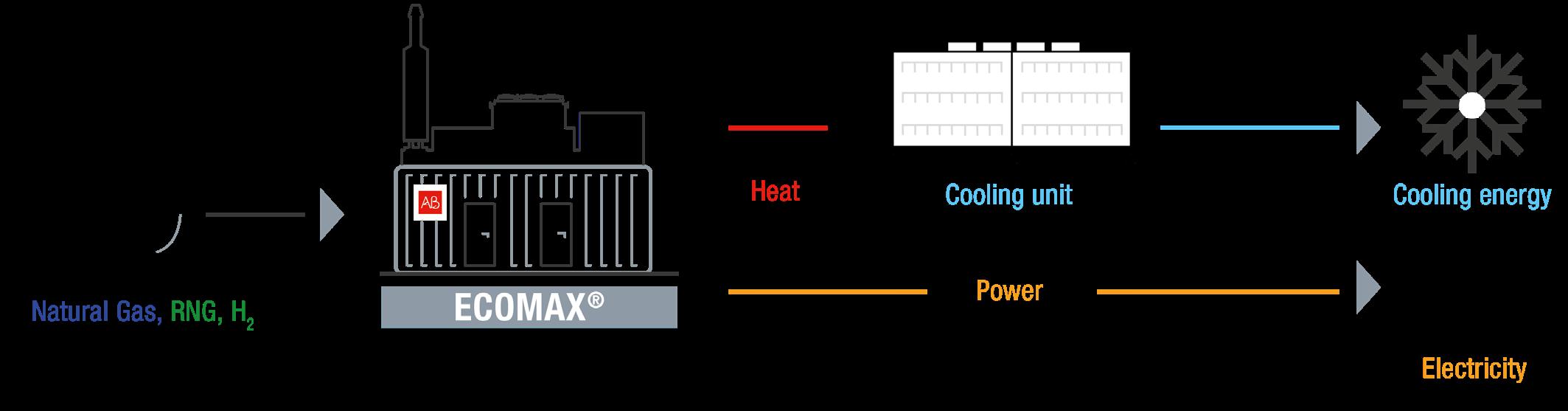

As much as 40% of the energy consumed in a data center is used for cooling the computing servers. The need for a tremendous amount of electricity results in very high energy costs. These facilities require the highest levels of reliability to ensure continuous operation.

That’s why ECOMAX ® is the perfect solution for data centers. Trigeneration is an extension of the Combined Heat and Power (CHP) concept: CHP allows the simultaneous production of electricity and heat; trigeneration takes this a step further by providing cooling via an absorption chiller, using waste heat from the generator as its energy source.

ECOMAX ® Natural Gas solution is the technological and market leader for modern modular on-site power generation, cogeneration and trigeneration plants that achieve maximum performance and reliability.

ECOMAX ® CHP and on-site power plants, using Jenbacher generating sets, are purpose designed for data center applications optimized for rapid installation and start up.

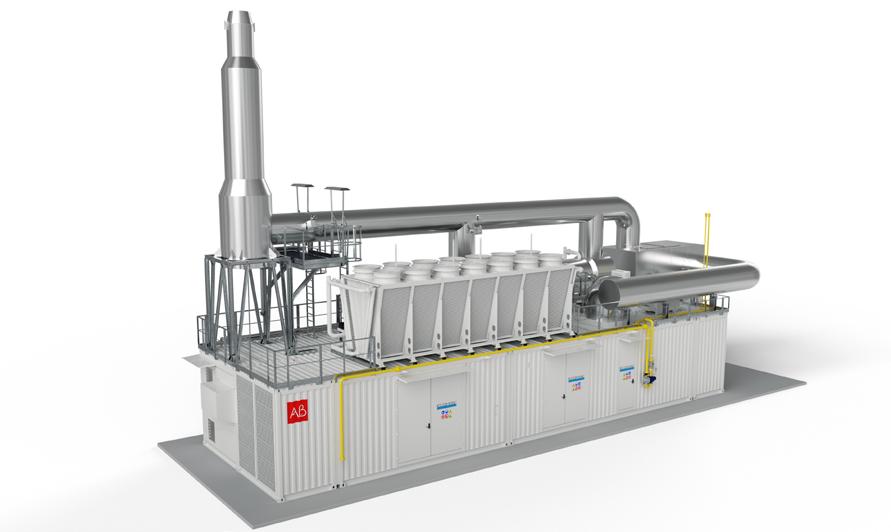

STANDARDIZED, PURPOSE BUILT, MODULAR AND SCALABLE SOLUTION FOR ANY TYPE OF DATA CENTER. AVAILABLE IN INDOOR AND OUTDOOR SOLUTIONS.

OXY CATALYST

EXHAUST GAS SILENCER

DRY COOLER

GAS CONNECTION FLANGE

CHIMNEY

EXHAUST FLANGE TO CAPTURE CO2

UREA TANK

UREA DOSING SYSTEM

CONTROL ROOM

OUTDOOR SOLUTION

Based on a 8,760 energy profile AB will work together with our customers to size and optimize the energy plant.

SCADA SYSTEM

INDOOR SOLUTION AIR OUTLET SILENCER AIR INLET SILENCER

ECOMAX ® MODULAR POWER PLANTS FOR DATA CENTERS

• Modular design optimized over more than 40 years experience with the design, manufacture, construction and operation of best-in-class CHP solutions.

• Maximum power reliability.

• Maximum energy cost savings thanks to a higher overall energy efficiency.

• Compact plug-and-play solution with lower costs , risks, design time, installation and start-up.

• Modular power plant configurations from 10 MW to 50 MW+ specifically designed for data center applications.

• Ultra fast start and fast start capabilities.

• Fast start gas engine option available: a full 3 MW of electric output achieved in less than 45 seconds.

• Fast transient response helps maintain power quality during island operation.

• Highest total efficiency due to conversion of waste heat to chilled water.

• Resilience during prolonged utility outages: in the event of major grid failures, a natural gas power plant can continue to operate without fuel supply concerns.

• Monetization of generation assets: minimize electricity costs or generate revenues from power sales and demand management.

• Significantly lower emissions compared to power only solutions.

• Flexibility of continuous running hours.

• AB developed microgrid and scada system.

• Direct financing through AB , or third party PPA available.

Thanks to our staff of specialized technicians operating around the world, AB guarantees constant support of each plant installed throughout its life cycle.

AB Service advantages:

• Single source of responsibility

• Fully IoT enabled plant

• 24/7 remote monitoring support and online diagnosis

• Availability and supply of original spare parts

• Global service organization capable of complete plant support

• Global network of spare parts warehouses

• Fast turnaround for repairs, updates and overhauls

Since 1981, AB has tackled the challenges posed by energy sustainability, working alongside our customers to improve their competitiveness while saving energy and reducing emissions. From our earliest days, we have focused on innovation to develop world-class technologies and processes dedicated to transforming the world of energy.

Our objective? To ensure our customers benefit from the best energy sustainability solutions available anywhere. How? By dedicating our expertise, production capacity and excellent service capabilities to the problems at hand.

In the cogeneration sector, AB’s leadership team has expanded our company’s reach to encompass biofuels. We have developed advanced purification and liquefaction processes for biomethane, coupled with highly effective emissions treatment.

We take pride in the level of excellence we offer. The AB Group now boasts over 1,200 employees in more than 20 countries throughout Europe, North and South America, and the far East with primary production and engineering centralized in a state-of-the-art industrial complex located in Orzinuovi, Province of Brescia, Italy.

Our customers rely on us to develop the “Better Way” to support them with the skills, technologies and processes, so they perform at their best. Together, we are helping build a better world.

www. gruppoab .com